Method for extracting arc sensor welding gun position deviation information

An arc sensor and information extraction technology, applied in the field of arc sensing, can solve the problems of sensor model inaccuracy, sensing accuracy limitation, and low sensing accuracy, and achieve reliable extraction results, strong anti-interference, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

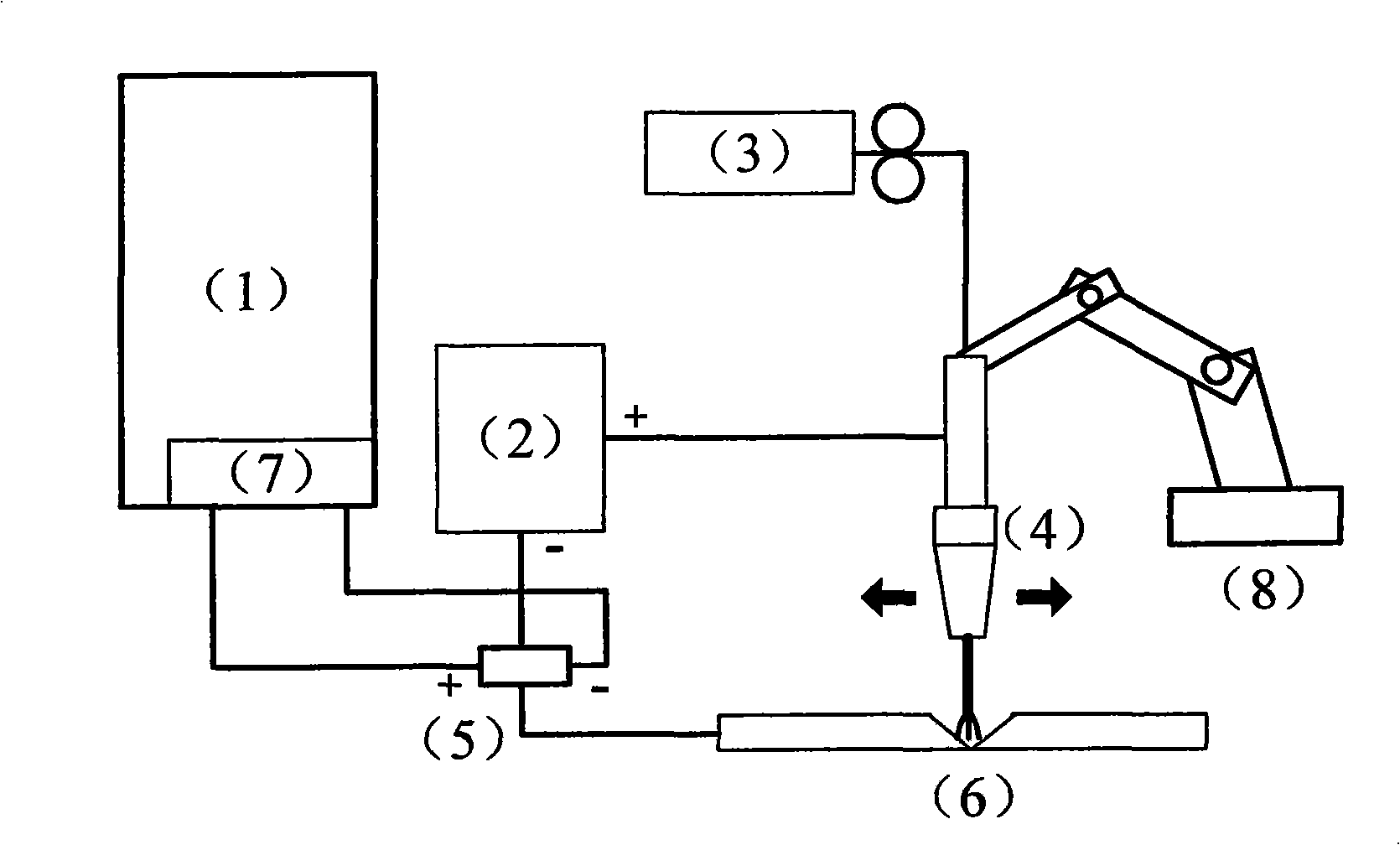

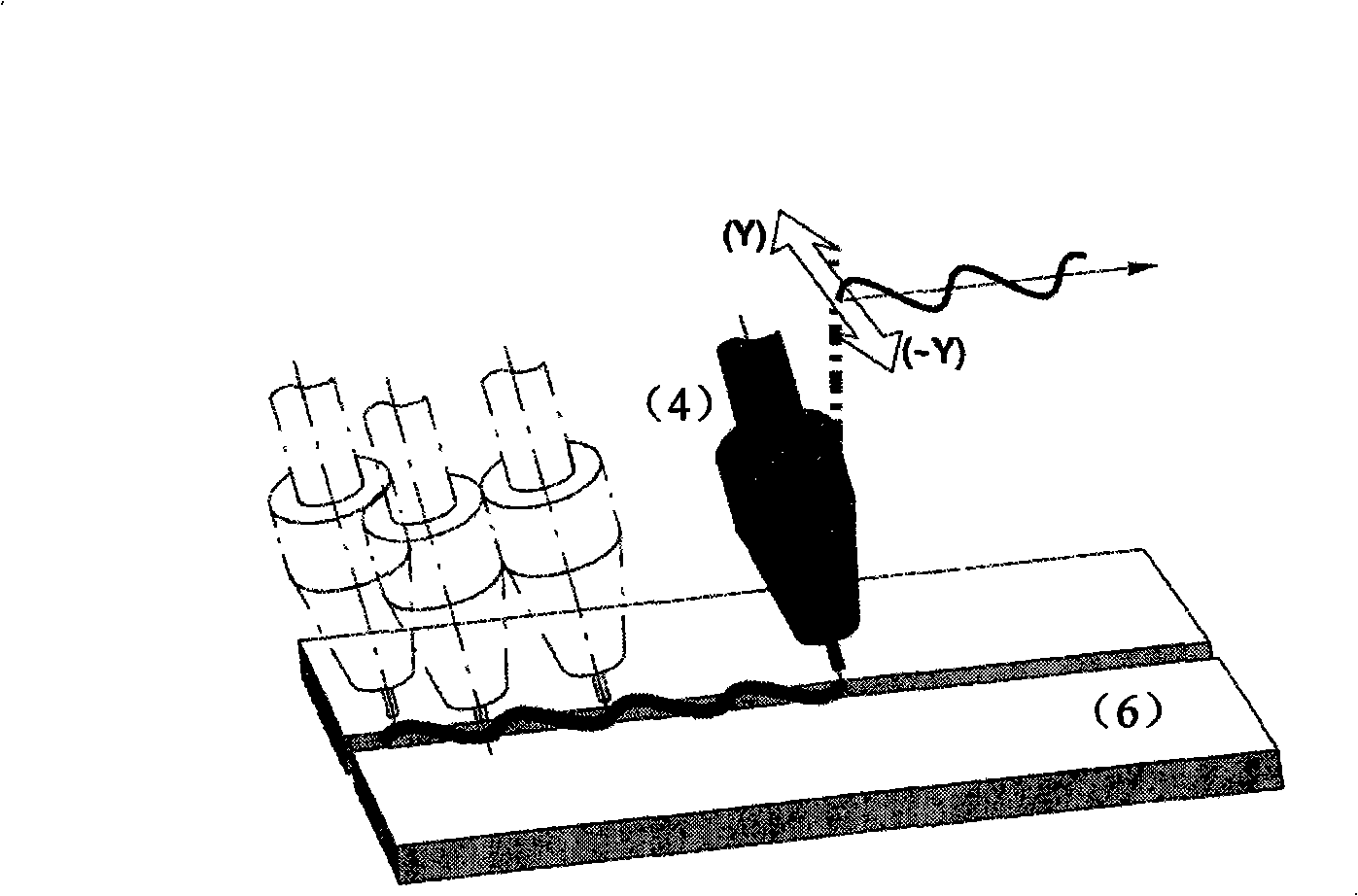

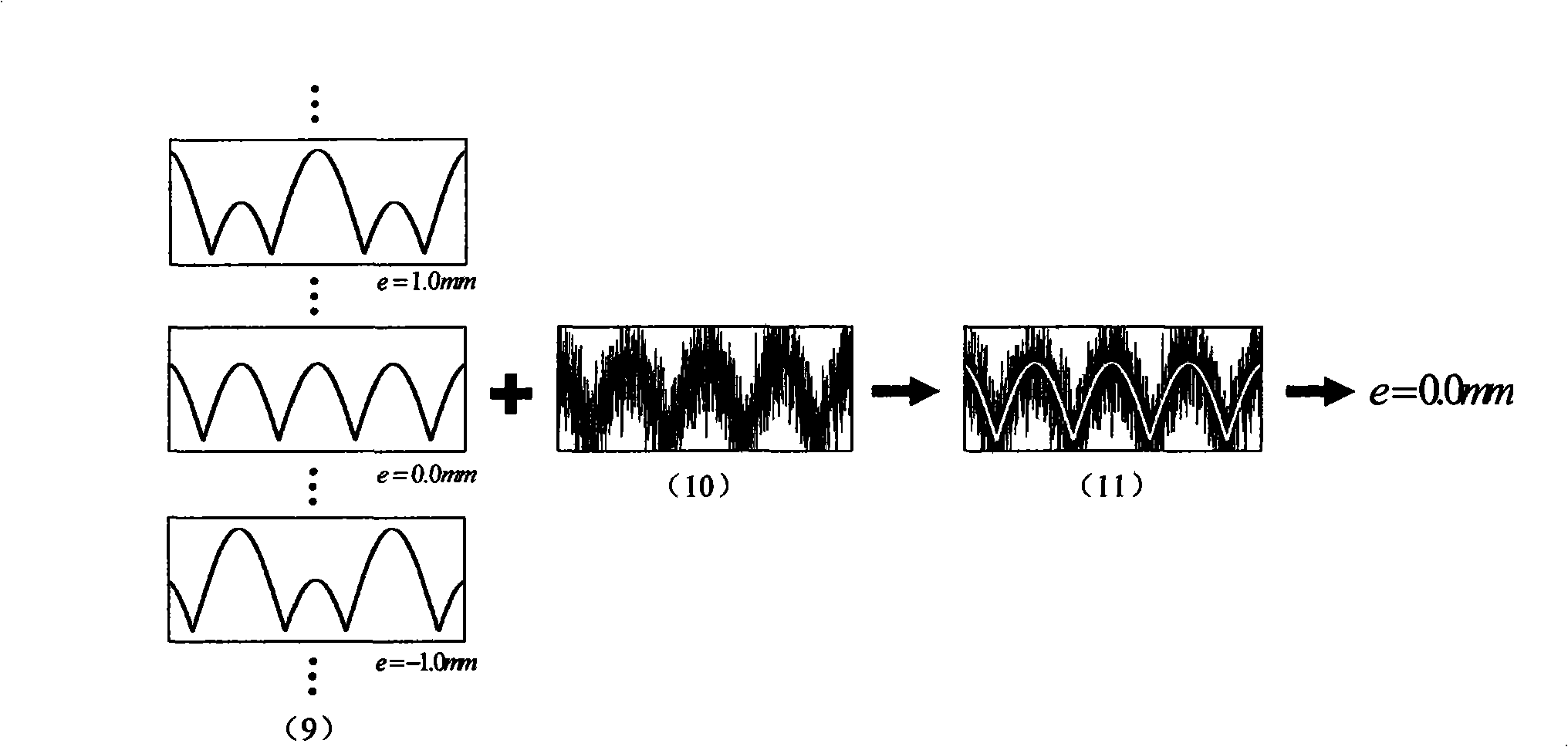

[0029] The present invention deduces the theoretical expression I (t, e) of welding current according to the motion form of welding gun and the relationship between welding torch height and welding current at first, and regards the sampling signal of welding current as a function in the continuous function space Z(t).

[0030] In order to use the sampling signal Z(t) of the welding current to solve the deviation value e of the welding torch position, first define a solution index J(e) that depends on the deviation e:

[0031] J(e)=‖Z(t)-I(t,e)‖ (1)

[0032] Among them, ‖·‖ represents the norm defined in the continuous function space, which is used to measure the similarity between two functions. The goal of the arc sensing deviation information extraction problem is to solve a deviation value e * ∈R such that:

[0033] J ( e * ) = min e ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com