Angle welding method of stainless steel sheet on basis of image processing

A technology of image processing and welding method, which is applied in the field of stainless steel thin plate fillet welding, can solve the problems of low welding efficiency, unsuitability for large-scale industrial production, and low yield, so as to improve production efficiency, realize welding automation, and reduce scrap rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053]The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

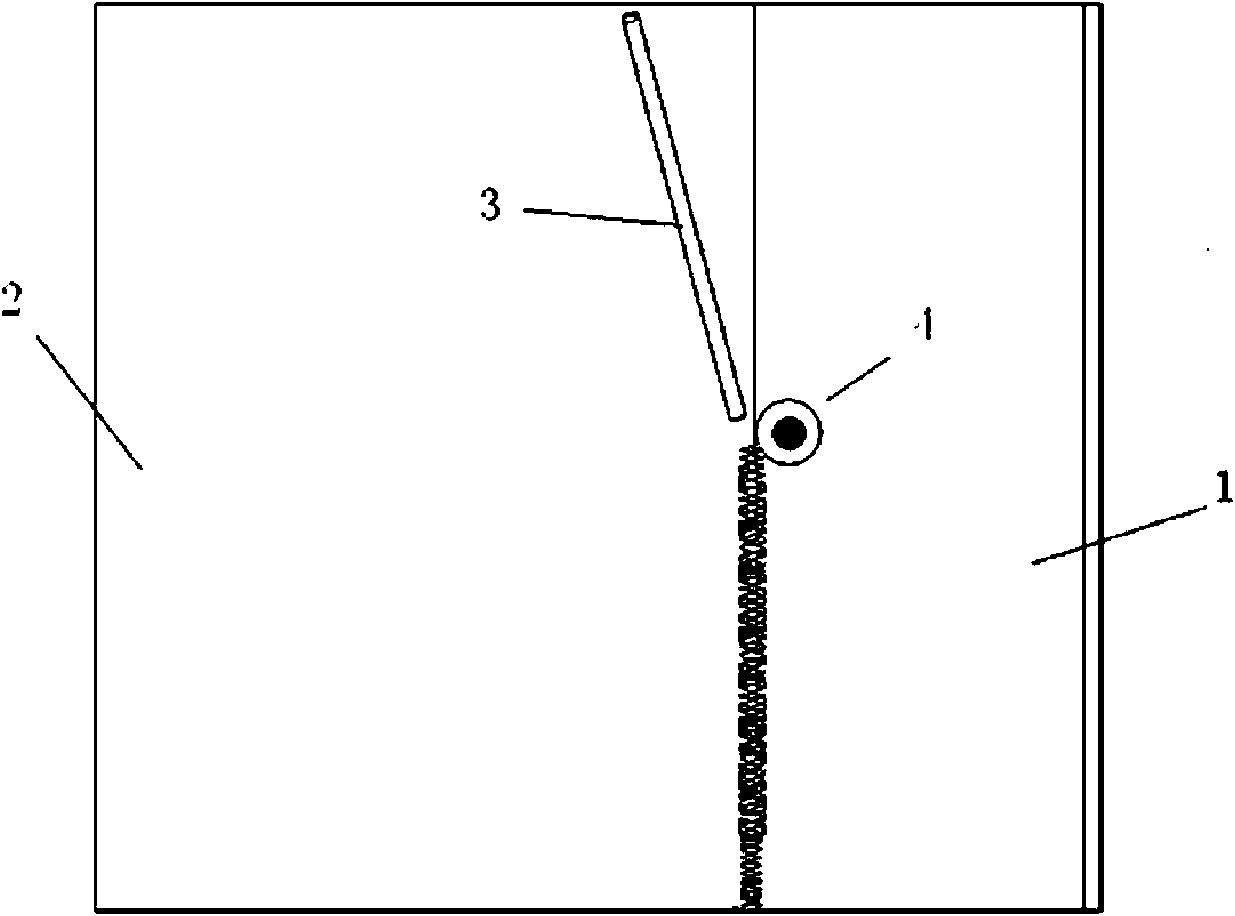

[0054] In this example, the welding object is a 0.9mm stainless steel sheet, the welding angle is 150°, and the welding frequency is 2Hz. The welding environment is set as follows:

[0055] 1. Fixing of the thin plate

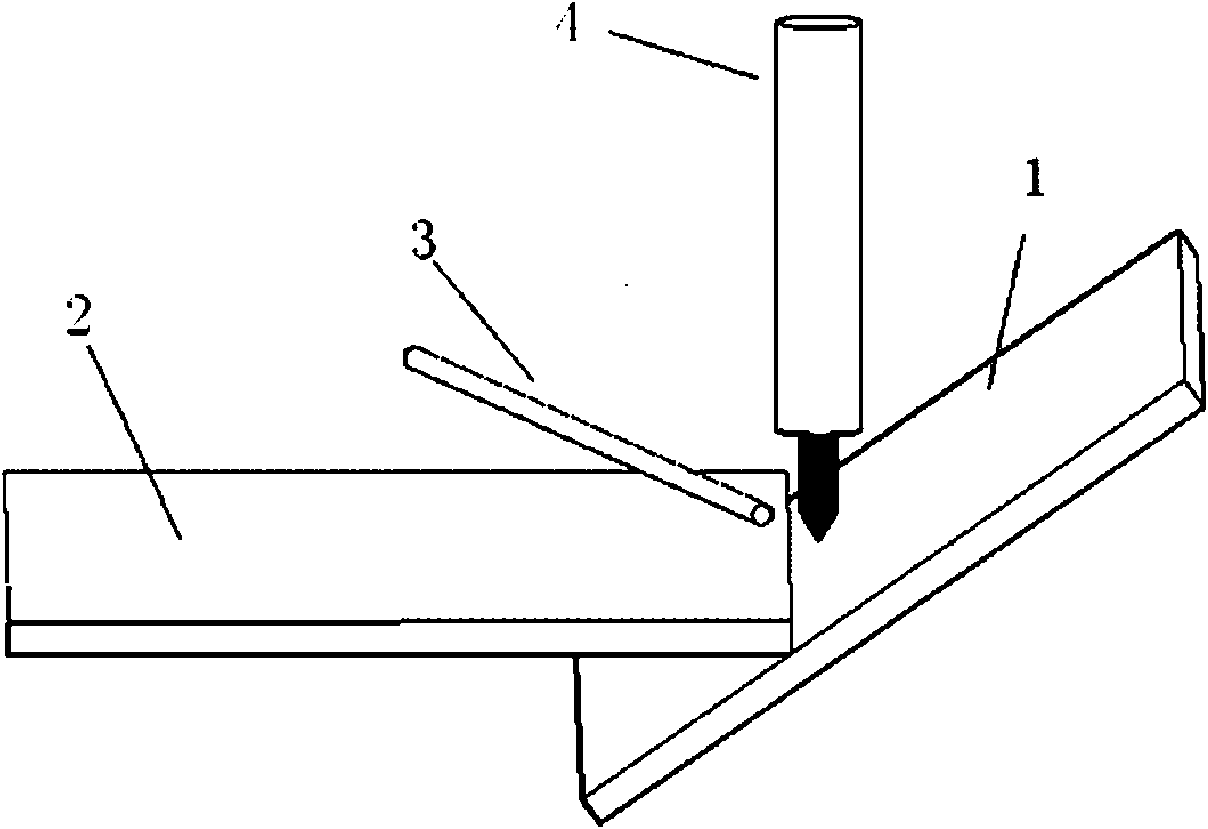

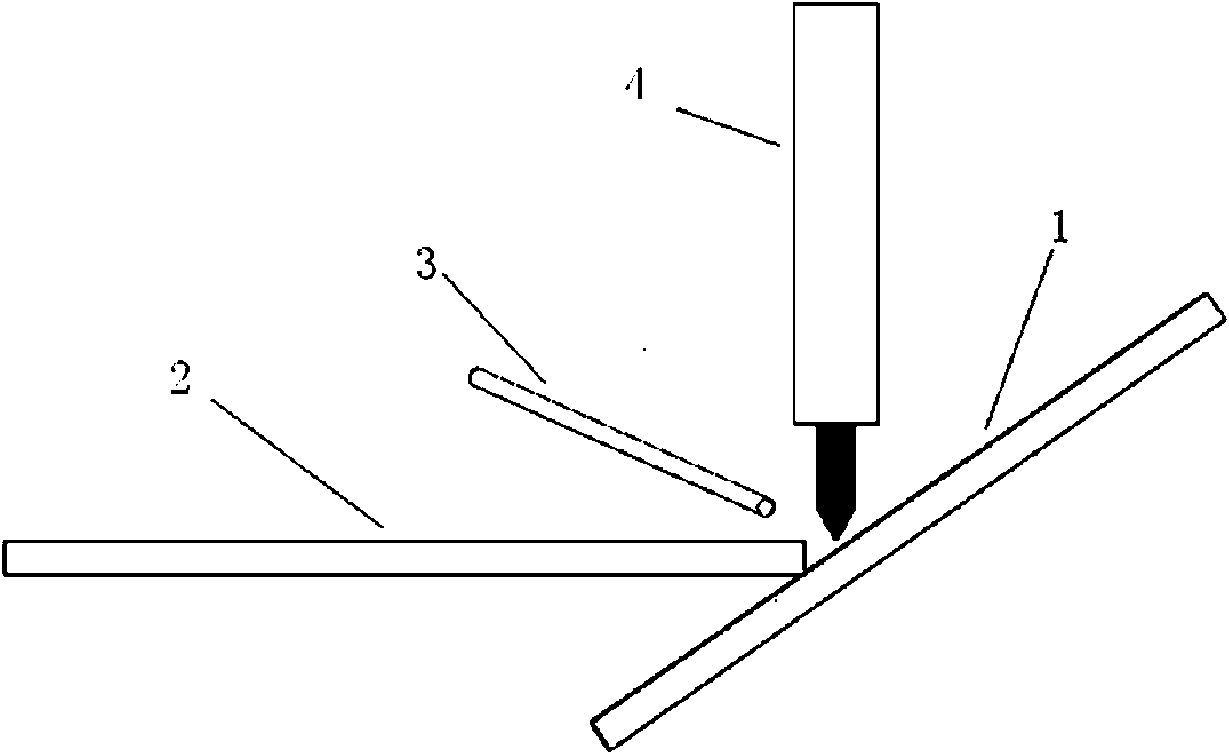

[0056] 1.1) If figure 1 As shown, fix the slant plate, adjust the slant plate clamp, and control the angle of the slant plate clamp. The adjustable range is 90°-180° with the other side of the plate clamp. After adjusting to the ideal angle, fix the slant plate to the on the fixture;

[0057] 1.2) If figure 1 As shown, fix the plate on the plate clamp. When fixing, the position of the flat plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com