Argon-enriched mixed gas protection welding method for high-strength abrasion-resistant steel

A high-strength wear-resistant steel, mixed gas technology, applied in welding media, welding equipment, welding equipment and other directions, can solve the problems of decreased crack resistance, increased cost, decreased plastic toughness of welds, etc., to improve impact toughness, reduce Production cost, effect of improving cold crack susceptibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) High-strength wear-resistant steel plate NM400 with a hardness level of HB400 produced by quenching and tempering treatment, and the combination of thick plates is 16mm+16mm. The size of the test plate is 450mm×400mm×16mm;

[0022] Matching welding materials:

[0023] The chemical composition and weight percentage of welding wire are: C: ≤0.10%, Mn: 1.30~1.80%, Si: 0.40~0.80%, P: ≤0.013%, S: ≤0.005%, Mo: 0.20~0.55%, Ni: 0.7%-0.9%, the balance is Fe and unavoidable impurities.

[0024] Protective gas: 80%Ar+20%CO 2 mixed composition

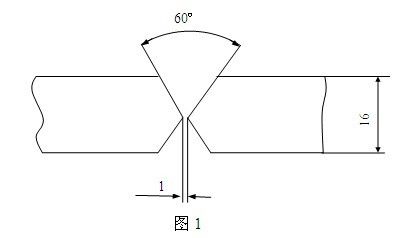

[0025] (2) The gas shielded welding groove adopts asymmetrical double-sided X-shaped groove, the groove angle is 60??, the groove gap is 0-1mm, and the blunt edge is 0mm;

[0026] (3) Preheat the NM400 wear-resistant steel to be welded to 75°C, and the preheating range is not less than 75mm on both sides of the welding groove;

[0027] (4) Welding process parameters: welding current 230A, arc voltage 25V, welding speed 33cm / min, w...

Embodiment 2

[0030] (1) High-strength wear-resistant steel plate NM400 with a hardness level of HB400 produced by quenching and tempering treatment, and the combination of thick plates is 40mm+40mm. The size of the test plate is 450mm×400mm×40mm;

[0031] Matching welding materials:

[0032] The chemical composition and weight percentage of welding wire are: C: ≤0.10%, Mn: 1.30~1.80%, Si: 0.40~0.80%, P: ≤0.013%, S: ≤0.005%, Mo: 0.20~0.55%, Ni: 0.7%-0.9%, the balance is Fe and unavoidable impurities.

[0033] Protective gas: 80%Ar+20%CO 2 mixed composition

[0034] (2) The gas shielded welding groove adopts symmetrical double-sided X-shaped groove, the groove angle is 60??, the groove gap is 0-1mm, and the blunt edge is 1mm;

[0035] (3) Preheat the NM400 wear-resistant steel to be welded to 100°C, and the preheating range is not less than 120mm on both sides of the welding groove;

[0036] (4) Welding process parameters: welding current 270A, arc voltage 29V, welding speed 30cm / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com