Method for controlling generation of cold crack in welding process based on electromagnetic induction heating

An electromagnetic induction heating and welding process technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult control of flame power, increase welding production process, change the surface state of weld seam, etc., and achieve high efficiency Control welding cold cracks, improve welding production efficiency, and reduce the effect of hardened structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

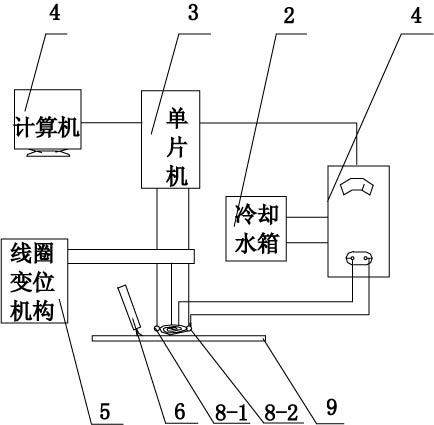

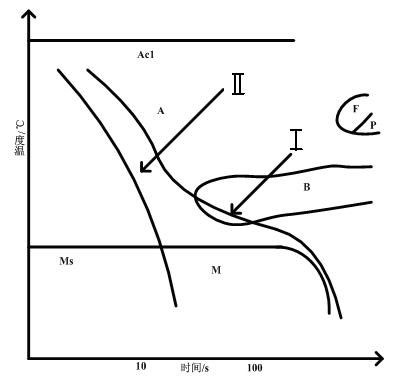

[0011] Specific implementation mode one: combine Figure 1-Figure 5 Description of this embodiment, the method of this embodiment is realized by the following steps: Step 1: Find the welding continuous cooling transition curve corresponding to the selected welding material; determine the austenite transformation temperature Ac 1 , martensite transformation temperature Ms, the longest time to form 100% martensite t 1 and the shortest time t to form 0% martensite 2 ;

[0012] Step 2: Determine the temperature field of the welding part of the workpiece to be welded; select a workpiece among the workpieces to be welded as the test piece, perform welding on the test piece, the welding process is consistent with the normal welding, and determine the quasi-stable temperature field of the test piece Ac 1 The distance between the points is L1, and the distance between the arc center on the center line of the weld and the point at the martensitic transformation temperature Ms behind ...

specific Embodiment approach 2

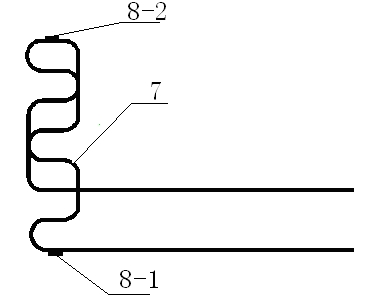

[0016] Specific implementation mode two: combination figure 2 Describe the present embodiment, the characteristic dimension of the electromagnetic induction coil 7 of the present embodiment is length, width and longitudinal tube spacing, and the length is L=V in the step 3 1 ·t 2 , the width is to cover the weld seam and the heat-affected zone, and the longitudinal tube spacing is 19-21mm. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 2 The present embodiment will be described. The electromagnetic induction coil 7 of the present embodiment is made of copper material. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com