Lower alloy steel laser-electric arc hybrid welding method

A low-alloy steel and composite welding technology, which is applied in laser welding equipment, welding equipment, metal processing, etc., to achieve the effects of improving weld formation and welding quality, large penetration depth, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

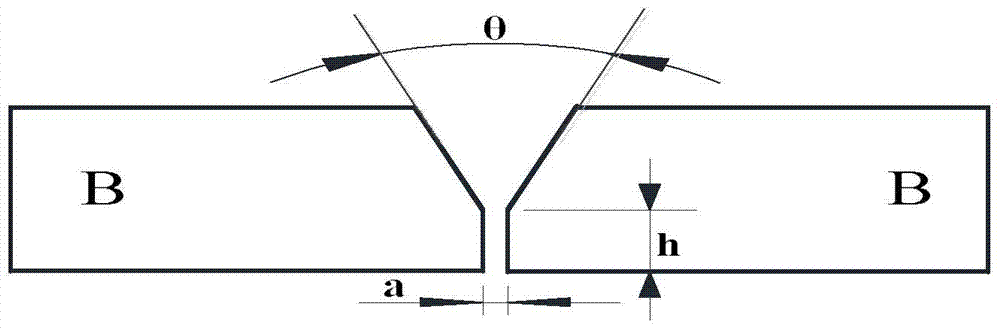

[0031] Embodiment 1. Laser-arc hybrid welding of Q355NH low-alloy steel plate is carried out by adopting the method of the present invention, and the thickness of Q355NH steel plate is 10mm. The joint form is Y-shaped groove butt joint, groove angle θ=32°, blunt edge height h=5mm; composite welding adopts H10MnSiCuNiⅡ welding wire (Φ1.2mm) and two-layer two-pass welding process; welding parameters of the first weld seam : Laser power 5kW, welding current 230A, welding speed 1.2m / min, welding parameters of the second weld: laser power 2kW, welding current 230A, welding speed 0.7m / min; 80%Ar+20% is used in the welding process CO 2 Gas protection, gas flow rate 20L / min. The weld seam of laser-arc hybrid welding is well formed, and there are no welding defects such as cracks, pores, undercuts, incomplete penetration, and incomplete fusion; the average tensile strength, yield strength, elongation, and impact energy of the joints are 558.6MPa and 409.1 .6MPa, 22.8%, 70J (-20°C), t...

Embodiment 2

[0032] Embodiment 2. Using the method of the present invention to carry out laser-arc hybrid welding of S355J2W weather-resistant steel plate, the thickness of the S355J2W steel plate is 12mm. The joint form is a Y-shaped groove butt joint, the groove angle θ=30°, and the height of the blunt edge h=6mm; NiCu1-IG welding wire (Φ1.2mm) and two-layer two-pass welding process; welding parameters of the first weld: laser power 6kW, welding current 230A, welding speed 1.2m / min, welding parameters of the second weld: The laser power is 2kW, the welding current is 240A, and the welding speed is 0.6m / min; the welding process is protected by argon (Ar), and the argon flow rate is 16L / min. The weld seam of laser-arc hybrid welding is well formed, and there are no welding defects such as cracks, pores, undercuts, incomplete penetration, and incomplete fusion; the average tensile strength, yield strength, elongation, and impact energy of the joints are 540.0MPa and 389.1 MPa, 23.5%, 78J ...

Embodiment 3

[0033] Embodiment 3, adopt the method of the present invention to carry out laser-arc hybrid welding of Q355NH low-alloy steel plate, the thickness of Q355NH steel plate is 16mm. The joint form is Y-shaped groove butt joint, groove angle θ=30°, blunt edge height h=7mm; H10MnSiCuNiⅡ welding wire (Φ1.2mm) and three-layer three-layer welding process are used; welding parameters of the first weld seam : Laser power 6kW, welding current 240A, welding speed 1.2m / min, welding parameters of the second weld: laser power 2kW, welding current 270A, welding speed 0.4m / min, welding parameters of the third weld: laser Power 2kW, welding current 290A, welding speed 0.4m / min; 85%Ar+15%CO is used in the welding process 2 Gas shielding, the shielding gas flow rate is 18L / min. The weld seam of laser-arc hybrid welding is well formed, without welding defects such as cracks, pores, undercuts, incomplete penetration, and incomplete fusion; the average tensile strength, yield strength, elongation, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com