High strength stainless steel wire excellent in ductility-toughness and modulus of rigidity and method for production thereof

A technology of rigidity modulus and manufacturing method, applied in the direction of manufacturing tools, welding media, furnace types, etc., can solve the problems of ductility and toughness that have not been studied, popularized, and restricted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

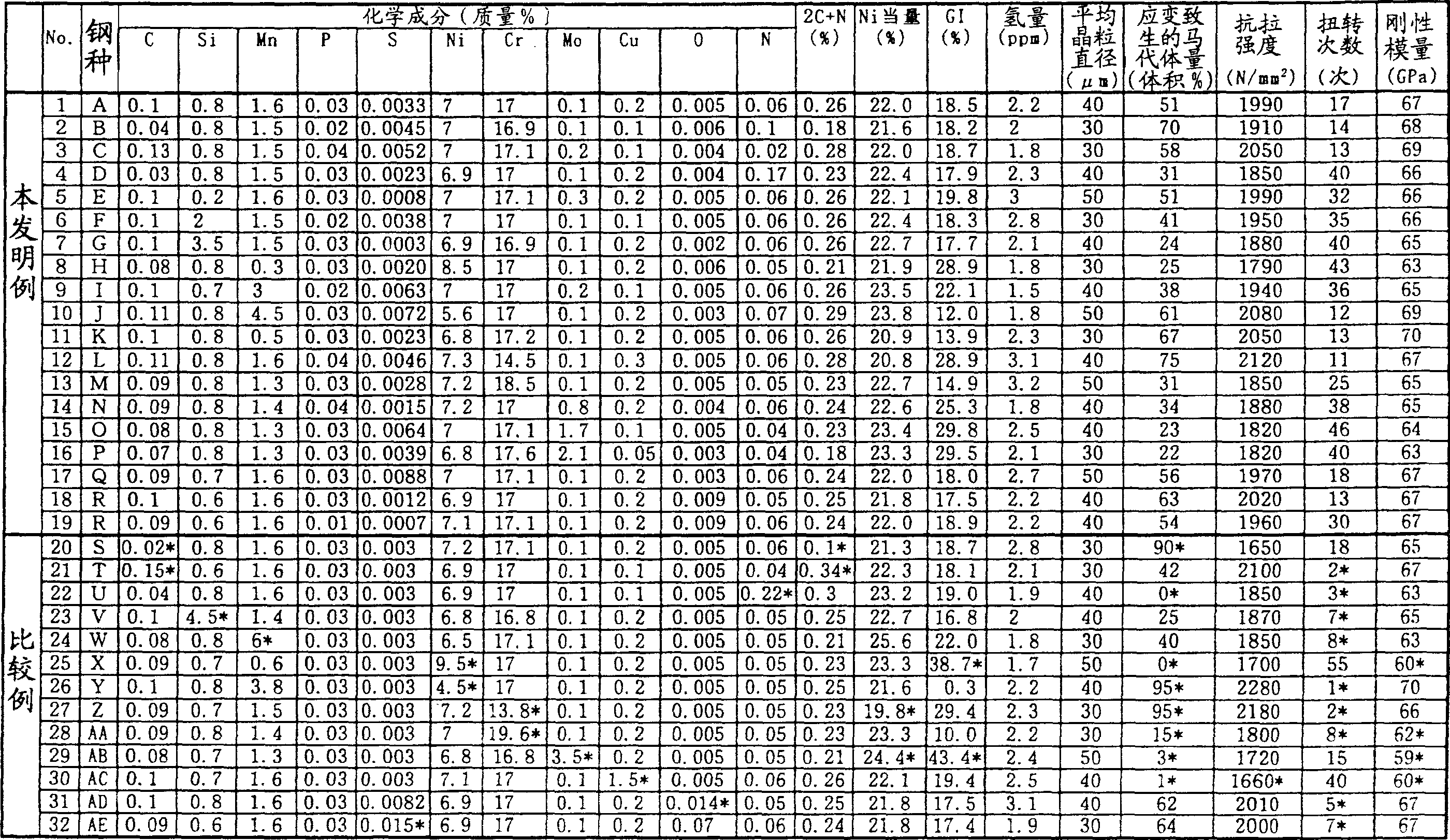

[0083] The present invention will be further specifically described below based on the examples of the present invention.

[0084] The present invention, especially as the target property of the steel wire after cold drawing, has a tensile strength of 1700 N / mm2 or 1700N / mm 2 As mentioned above, the number of torsions, which is an important factor in the ductility and toughness of the spring steel wire, is 10 times or more, and the stiffness modulus, which is an important factor in the elastic modulus of the spring steel wire, is 63 GPa or more. An important factor of the elastic modulus is Young's modulus, but in the present invention, the modulus of rigidity is specified as a representative value.

[0085] The materials for testing of the examples were obtained by smelting, hot wire rod rolling to Φ5.5 mm, and finish rolling at 1000° C. in a normal stainless steel wire rod manufacturing process. The obtained wire rod was subjected to heat treatment (solution treatment) at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com