Stainless steel, stainless steel wire for bridge pull sling as well as preparation methods and application thereof

A technology of stainless steel and pulling slings, which is applied in the field of stainless steel and its preparation, can solve the problems of not being obtained, and achieve the effects of improving strength, reducing production costs, and reducing the amount of nickel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

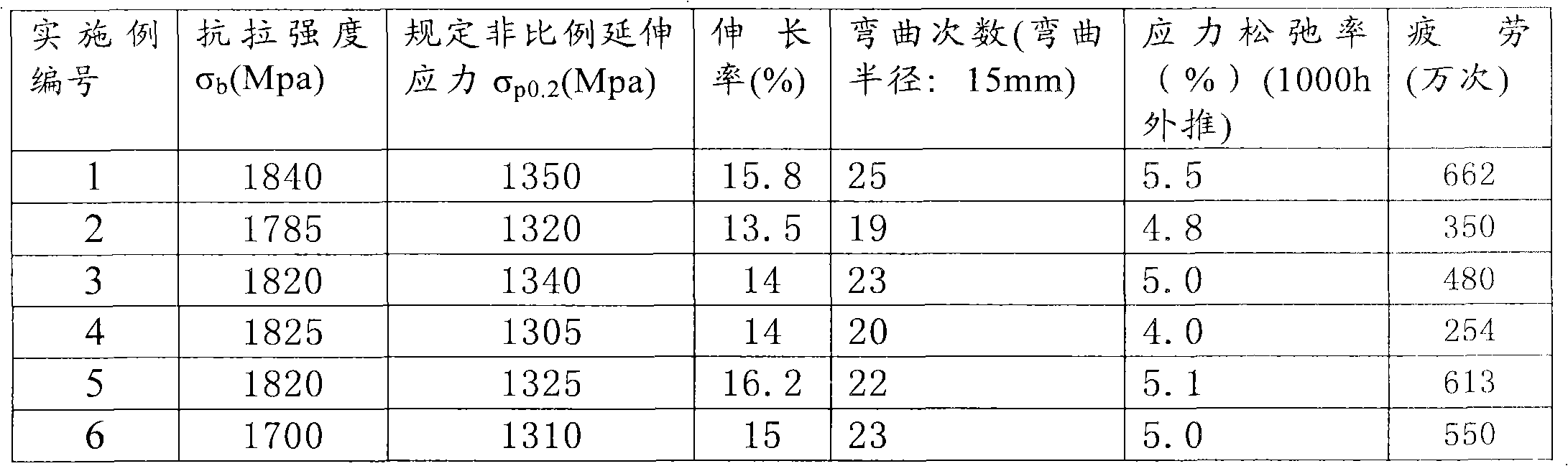

Examples

Embodiment 1

[0119] A: Smelting billets

[0120] 1) Electric furnace smelting

[0121] Add 15.7 tons of scrap steel, 5.8 tons of high-carbon ferrochromium, 2.6 tons of high-carbon ferromanganese, and 0.5 tons of metal nickel into the electric furnace, add electrochemical cleaning, and after adding the above substances, the chemical composition of the crude molten steel in the electric furnace is roughly controlled at 1.30% carbon, P≤ 0.028%, S≤0.025%, Cr: 18.0%, Ni: 1.0%, Mn: 10.0% when the steel is tapped; every furnace must be cleaned up to prevent the fluctuation of Cr and Ni components. Remove the slag from time to time, and measure the thickness of the slag in the ladle to 50 mm.

[0122] 2) Argon oxygen refining furnace refining

[0123] The molten steel obtained above is transferred to the argon-oxygen refining furnace for refining, and the refining oxidation period is expressed as N 2 and O 2 Gas ratioO 2 :N 2 = 3:1, the total blown volume of the gas is 900m 3 / h, followed b...

Embodiment 2

[0140] A: Smelting billets

[0141] 1) Electric furnace smelting

[0142] Add 14.9 tons of scrap steel, 6.0 tons of high-carbon ferrochrome, 3.0 tons of high-carbon ferromanganese, and 0.6 tons of nickel metal to the electric furnace, and add electrochemical cleaning. After the above-mentioned substances are added, the chemical composition of the crude molten steel in the electric furnace is roughly controlled at 1.5% carbon, P≤ 0.028%, S≤0.025%, Cr 18.5%, Ni 1.2%, Mn 12.0% when tapping; every furnace must be cleaned up to prevent fluctuations in Cr and Ni components, and cleaned when tapping For slag, measure the thickness of slag in the ladle to 40mm.

[0143] 2) Argon oxygen refining furnace refining

[0144] The molten steel obtained above is transferred to the argon-oxygen refining furnace for refining, and the refining oxidation period is expressed as N 2 and O 2 Gas ratioO 2 :N 2 = 4:1, the total blown gas volume is 1000m 3 / h, followed by nitrogen blowing throug...

Embodiment 3

[0161] A: Smelting billets

[0162] Add 14.4 tons of scrap steel, 6.5 tons of high-carbon ferrochrome, 2.8 tons of high-carbon ferromanganese, and 0.6 tons of metal nickel to the electric furnace, and add electrochemical cleaning. After the above-mentioned substances are added, the chemical composition of the crude molten steel in the electric furnace is roughly controlled at 1.60% carbon, P≤ 0.028%, S≤0.025%, Cr19.0%, Ni1.1%, Mn11.0% when the steel is tapped; in each furnace, it must be cleaned up to prevent the fluctuation of Cr and Ni components. Remove the slag from time to time, and measure the thickness of the slag in the ladle to be 45 mm.

[0163] 2) Argon oxygen refining furnace refining

[0164] The molten steel obtained above is transferred to the argon-oxygen refining furnace for refining, and the refining oxidation period is expressed as N 2 and O 2 Gas ratioO 2 :N 2 =2:1, the total blown gas volume is 900m 3 / h, followed by nitrogen blowing throughout the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com