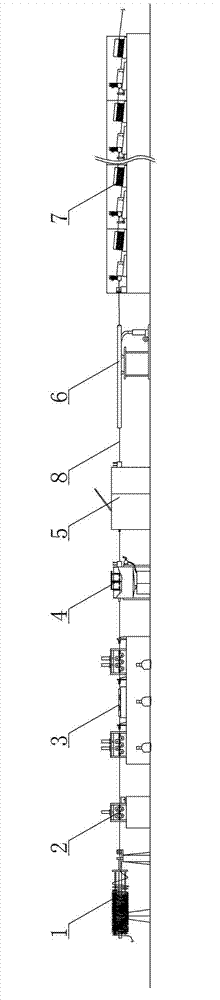

Prestressed steel strand pickling-free and phosphating-free drawing equipment and production process

A technology of prestressed steel strands and drawing equipment, which is applied in the field of non-phosphating drawing equipment and production technology, and prestressed steel strands without pickling, which can solve the problems of high labor costs, unfavorable sustainable development of enterprises, and poor drawing quality. In order to achieve reasonable structural design, improve shelling efficiency, and improve drawing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0048] Embodiment two: see Figure 1-Figure 10 , a production process utilizing the prestressed steel strand described in Embodiment 1 without pickling and phosphating drawing equipment, for the prestressed steel strand with a diameter of 5.5mm ~ 14mm, carry out no pickling and no phosphating The drawing production process, it comprises the following steps:

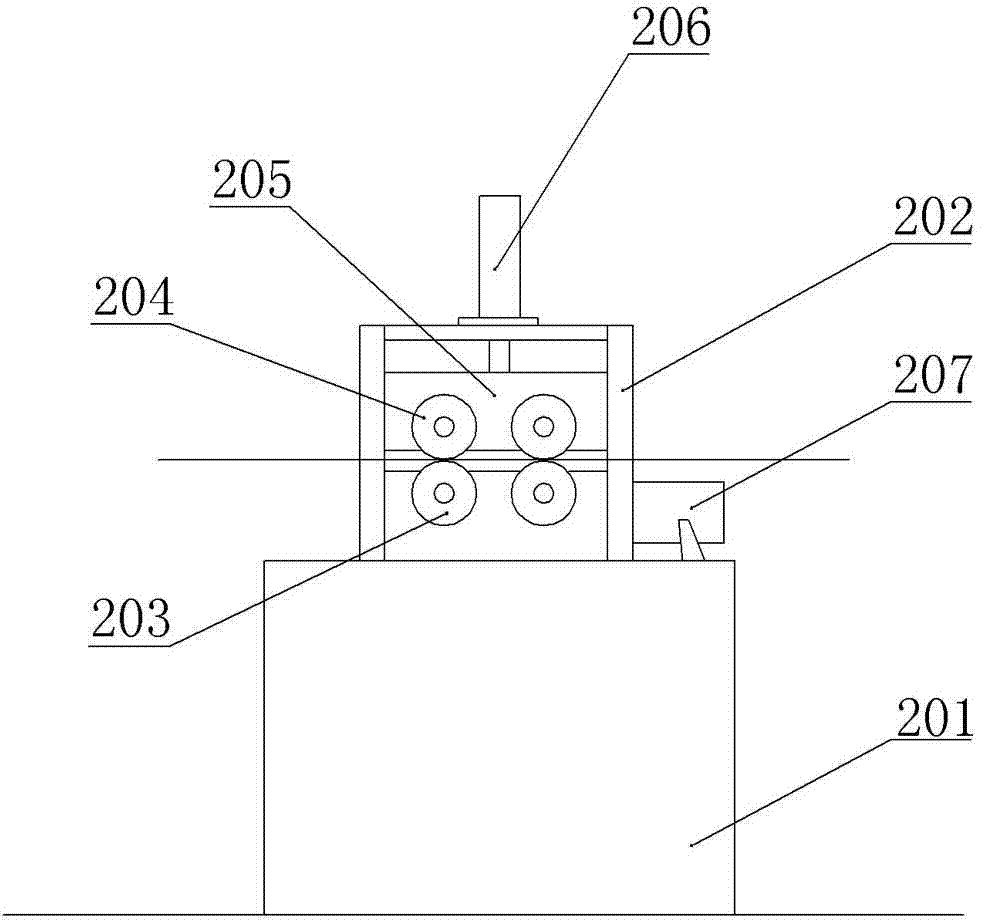

[0049] ① Pay-off and straightening of prestressed steel strands: Hang the prestressed steel strand coil rods on the pay-off frame, comb the coiled steel strands, and introduce the straightening traction device for straightening and then lead out ;

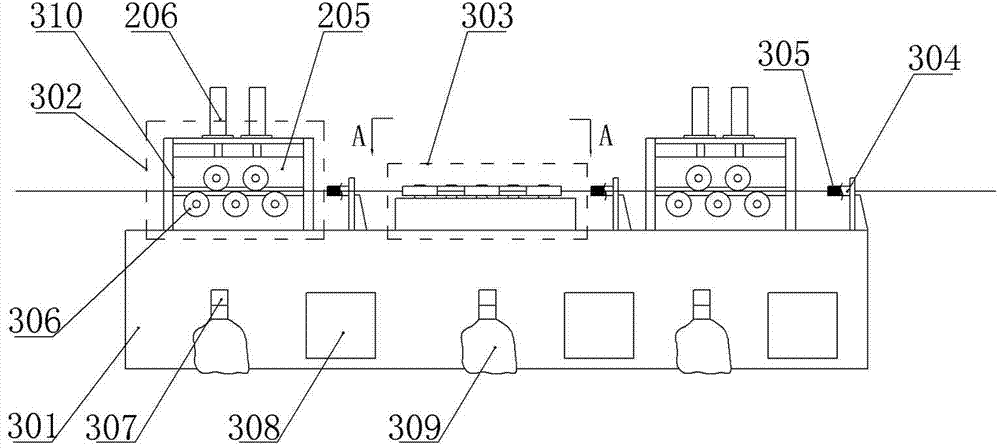

[0050] ② Shelling treatment of prestressed steel strands: according to the surface oxidation degree of prestressed steel strands, reasonably adjust the relative clearance of the shelling wheels of the peeling device, and introduce the straightened steel strands from the straightening traction device into the Physical shelling is carried out in the shelling device, and the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com