High-pressure water descaling system

A technology of high-pressure water descaling and descaling box, applied in metal extrusion, metal extrusion cleaning equipment, workpiece surface treatment equipment, etc., can solve the problems of heavy equipment weight, energy waste, affecting rolling rhythm, etc. Stable and reliable controllable maintenance-free use, improve reliability and stability, improve the effect of rolling rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

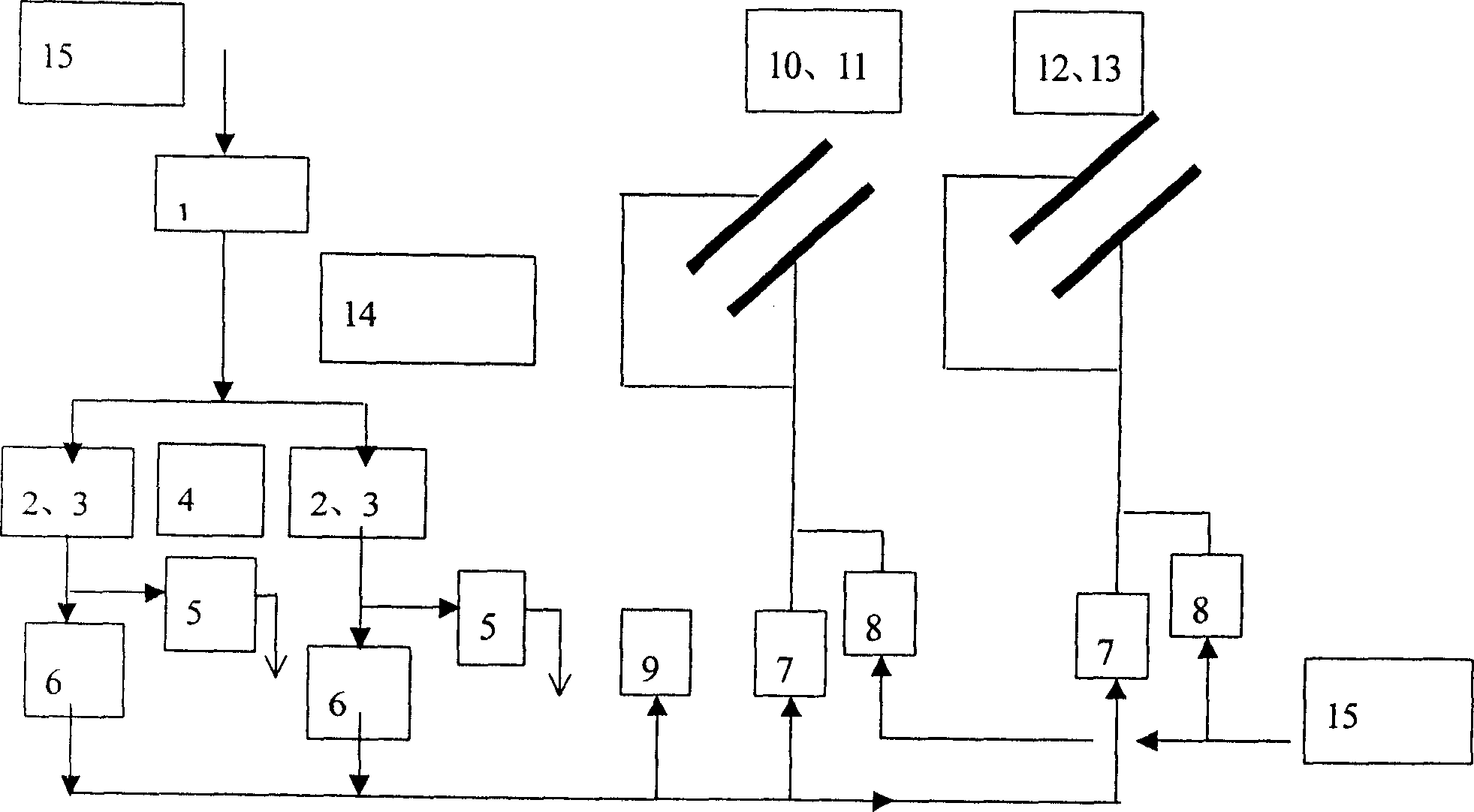

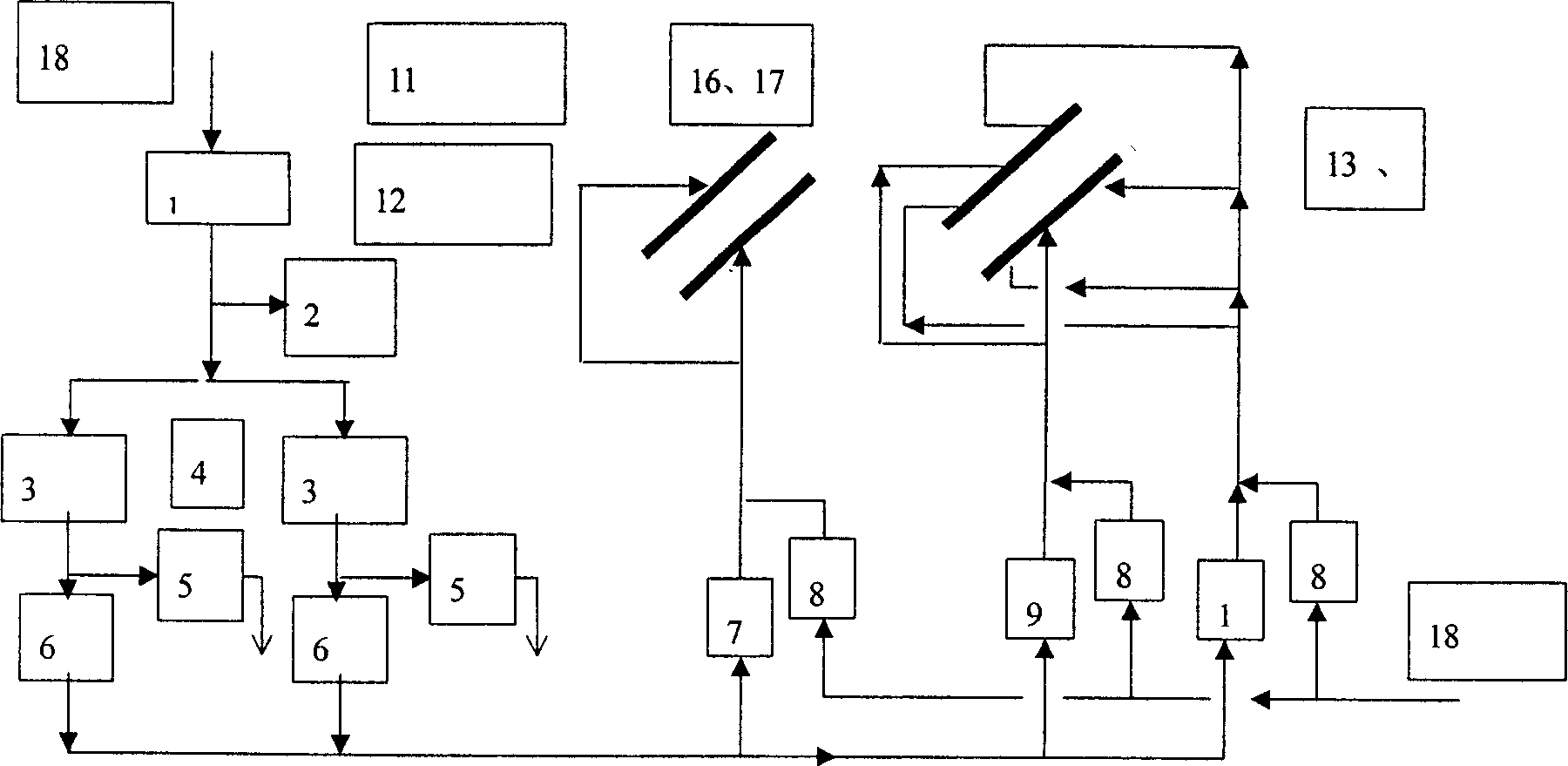

[0034] see figure 1 , a high-pressure water descaling system, the equipment configuration mainly includes a self-cleaning filter 1, a diaphragm type storage tank 2, a centrifugal pump group with double-shell impellers symmetrically arranged 3, a touch screen next to the machine 4, a minimum flow valve group 5, and an electric control Valve and check valve group 6, descaling box injection valve group 7, low pressure pre-fill valve group 8, narrow descaling injection valve group 9, wide descaling injection valve group 10, frequency conversion control system 11, L1, L2 level control operation System 12, wide descaling header 13, narrow descaling header 14, high-efficiency descaling nozzle 15, descaling box descaling header 16, turbid circulating water supply system 17.

[0035] When the system is not descaling, the injection valve group 7 of the descaling box and the descaling injection valve group 10 on the machine are closed, the minimum flow valve group 5 is opened, and the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com