An acidless descaling process for cold rolled steel strip and manufacturing device thereof

A technology of acid-free descaling and cold-rolled strip steel, which is applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of high metal consumption, easy sand inclusion on the surface, and inconvenient maintenance, so as to achieve uniform surface and metal The effect of small consumption and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the drawings and embodiments.

[0028] The present invention is not limited to the following best embodiments. Under the enlightenment of the present invention, anyone can derive other products in various forms, but regardless of any changes in its shape or structure, any product with the same or Similar technical solutions are all within the protection scope of the present invention.

[0029] In addition to strip steel, the method and device of the present invention are also suitable for cut steel plates (or other metal plates). In the device of the present invention, the unwinding machine 1, the shearing machine 3, the welding machine 4, and the widening type can be omitted. Free looper 5, winder 13, another shearing machine 3.

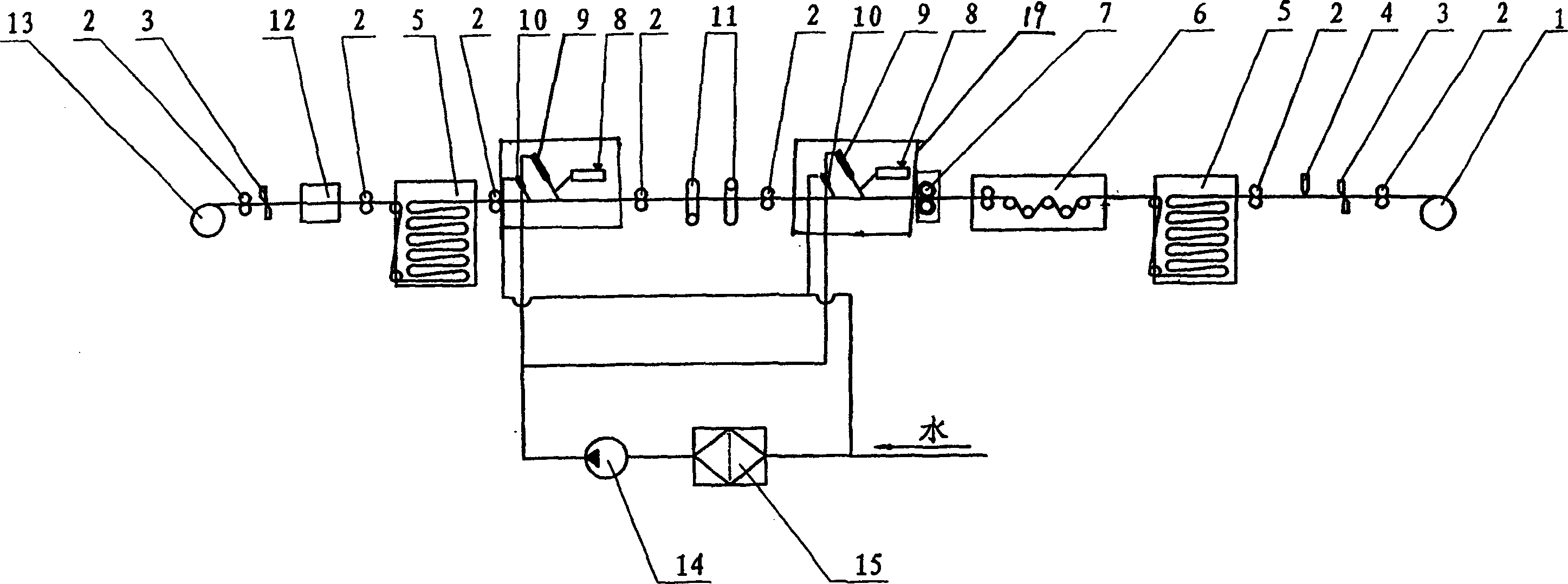

[0030] Such as figure 1 As shown, the process method for acid-free descaling of the present invention is:

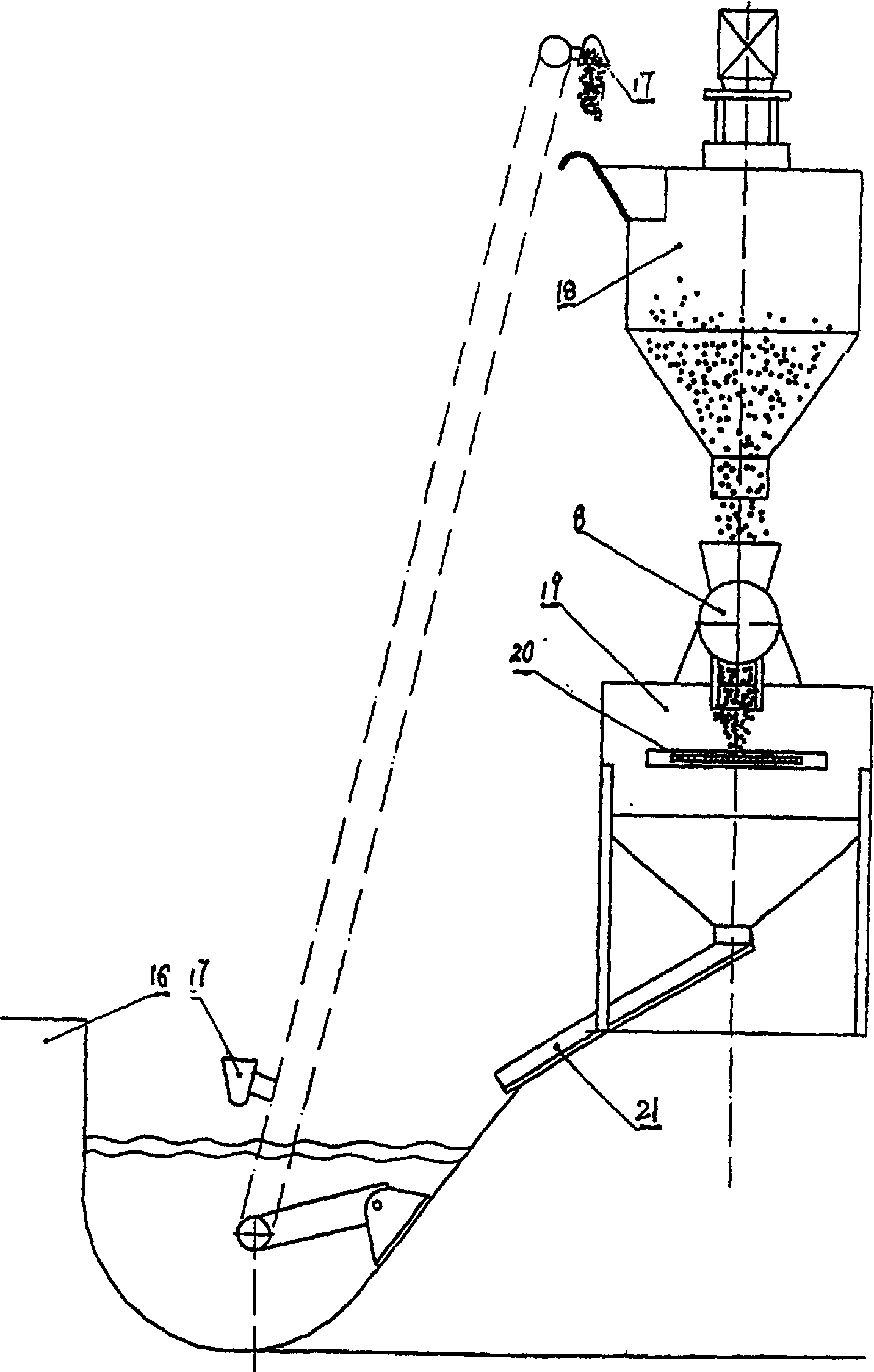

[0031] 1. The unscaled black belt steel 20 is hoisted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com