Device for removing dust and solder splash from electricity meter

A technology for removing tin slag and electric meters, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve problems that affect the reliability and accuracy of meter measurement, restrict the speed of modern production lines, and affect the welding quality of electric meter components. Poor standardization, high level of automation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

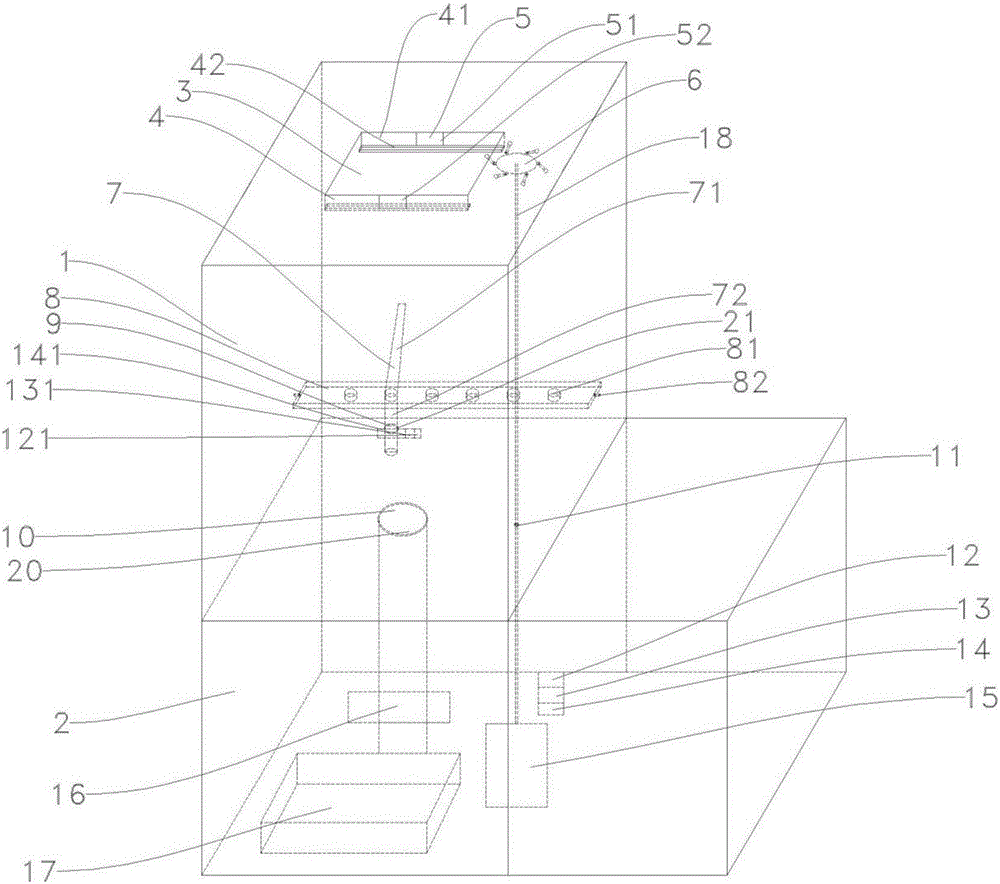

[0026] In order to have a clearer understanding of the technical features, purposes and beneficial effects of the present invention, the technical solution of the present invention is described in detail below, but it should not be construed as limiting the scope of implementation of the present invention.

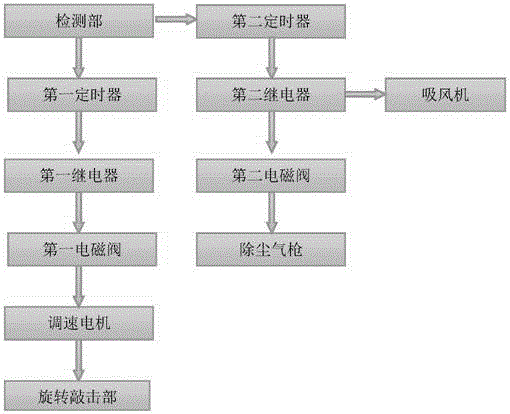

[0027] Such as figure 1 As shown, this embodiment provides a device for removing dust and tin slag from an electric meter, which includes a first box body 1 and a second box body 2 fixedly connected to the bottom surface of the first box body 1 .

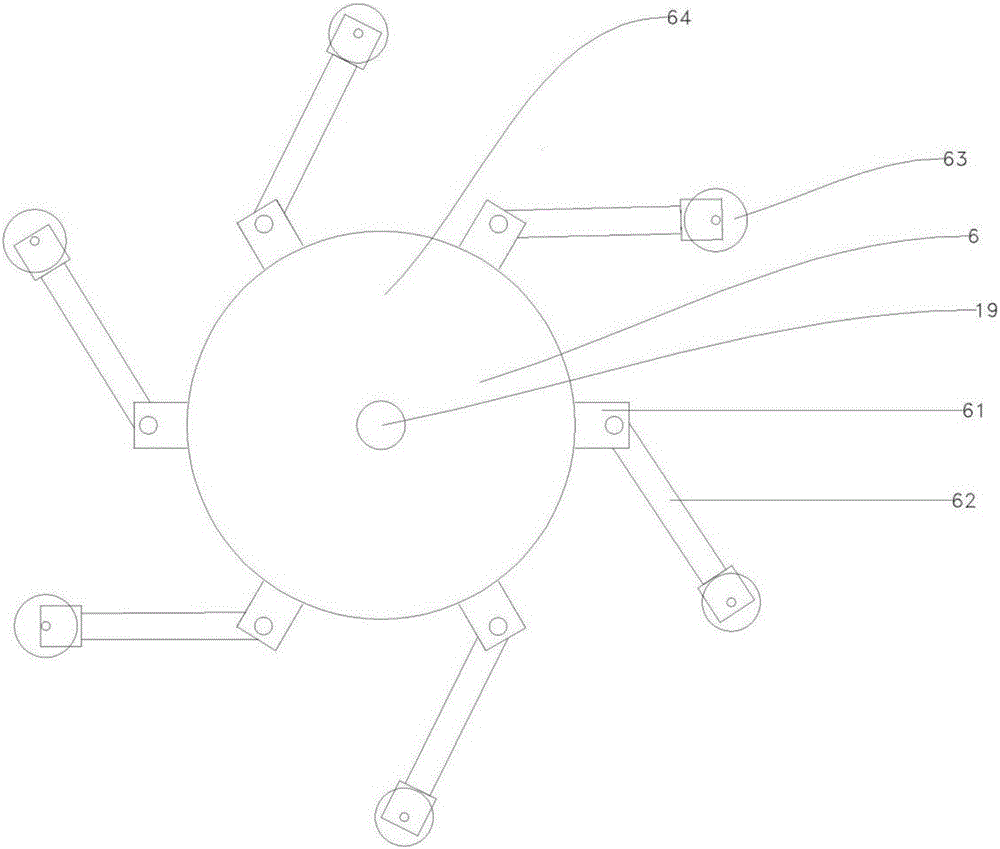

[0028] The top of the first box body 1 is provided with an opening 3 for placing the ammeter to be processed, and the opening 3 is provided with a limiter 4 for limiting the position of the ammeter and a detection portion 5 for detecting whether the ammeter is placed in place; the limiter 4 It includes two side edges 41 and two bottom edges 42, the width between the two side edges 41 is equivalent to the width of the ammeter cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com