Wiring robot and wiring method for on-site calibration of mutual inductor

A technology of transformers and robots, applied in the parts, instruments, manipulators and other directions of electrical measuring instruments, can solve the problems of high safety hazards, complex tasks and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

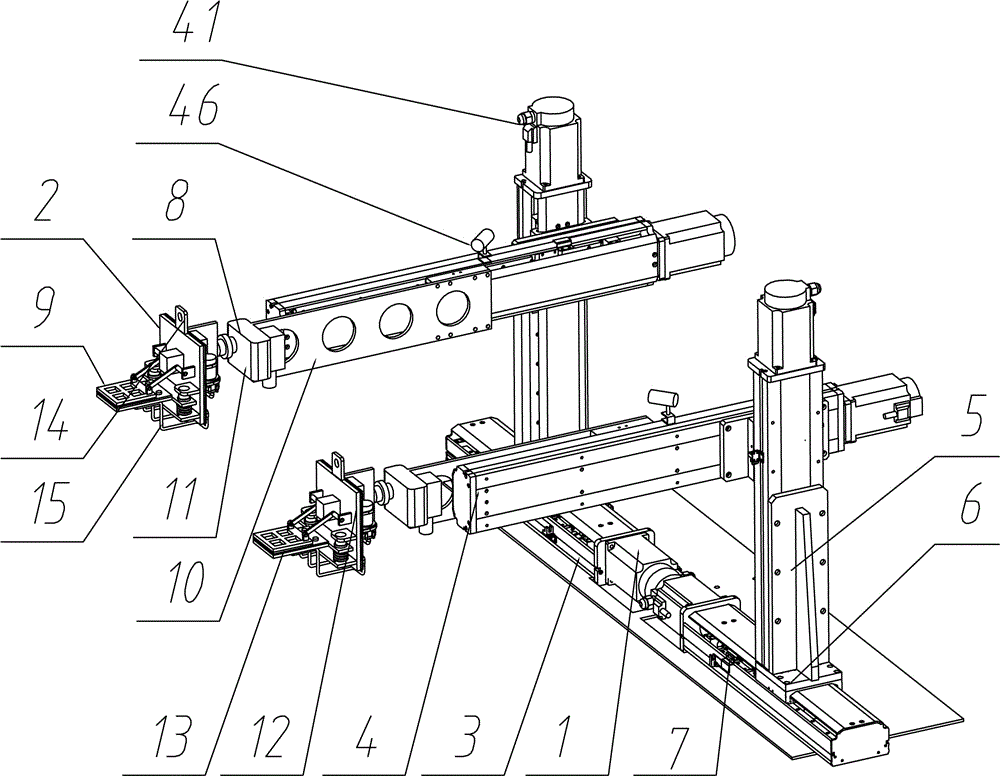

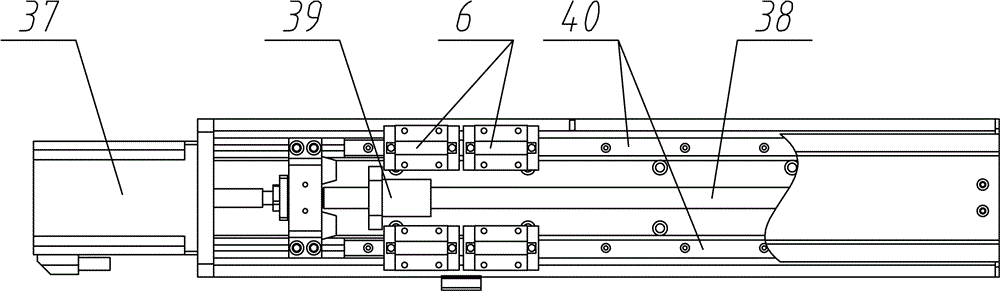

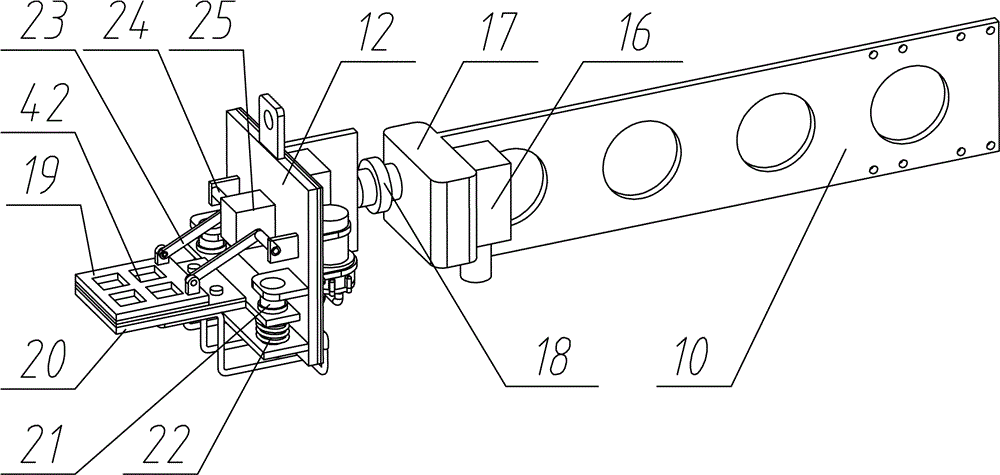

[0037] Such as figure 1 As shown, a wiring robot used for on-site verification of transformers includes a robot arm 1 and a robot arm 2. The robot arm 1 is divided into two groups, and each group of robot arms 1 includes an X-axis robot arm 3 and a Y-axis robot arm 4. and the Z-axis robotic arm 5, wherein two sets of X-axis robotic arms 3 are arranged on the same line, between each group of Z-axis robotic arms 5 and X-axis robotic arms 3, and between each group of Y-axis robotic arms 4 and Z-axis robotic arms 5 Both are slidably matched by the sliding workbench 6, and the position is adjusted by the ball screw mechanism 7; the manipulator 2 includes an angle adjustment device 8 and a wiring device 9, and the angle adjustment device 8 includes a Y-axis mechanical arm 4 that slides The connected wiring manipulator 10, the front end of the wiring manipulator 10 is connected to the wiring device 9 through the rotating mechanism 11, the wiring device 9 includes a mounting base 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com