Dismountable conveyer

A conveyor, detachable technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity and low work efficiency in loading and unloading, and achieve ingenious design, improve work efficiency, and reduce operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

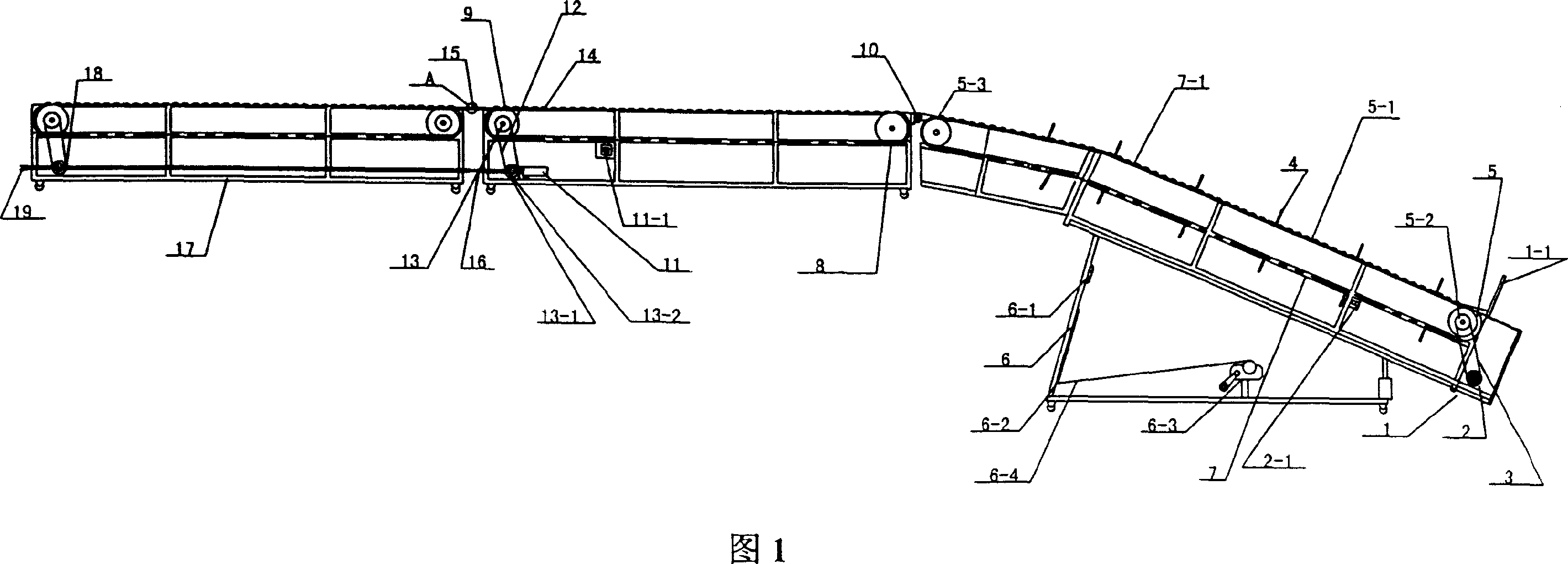

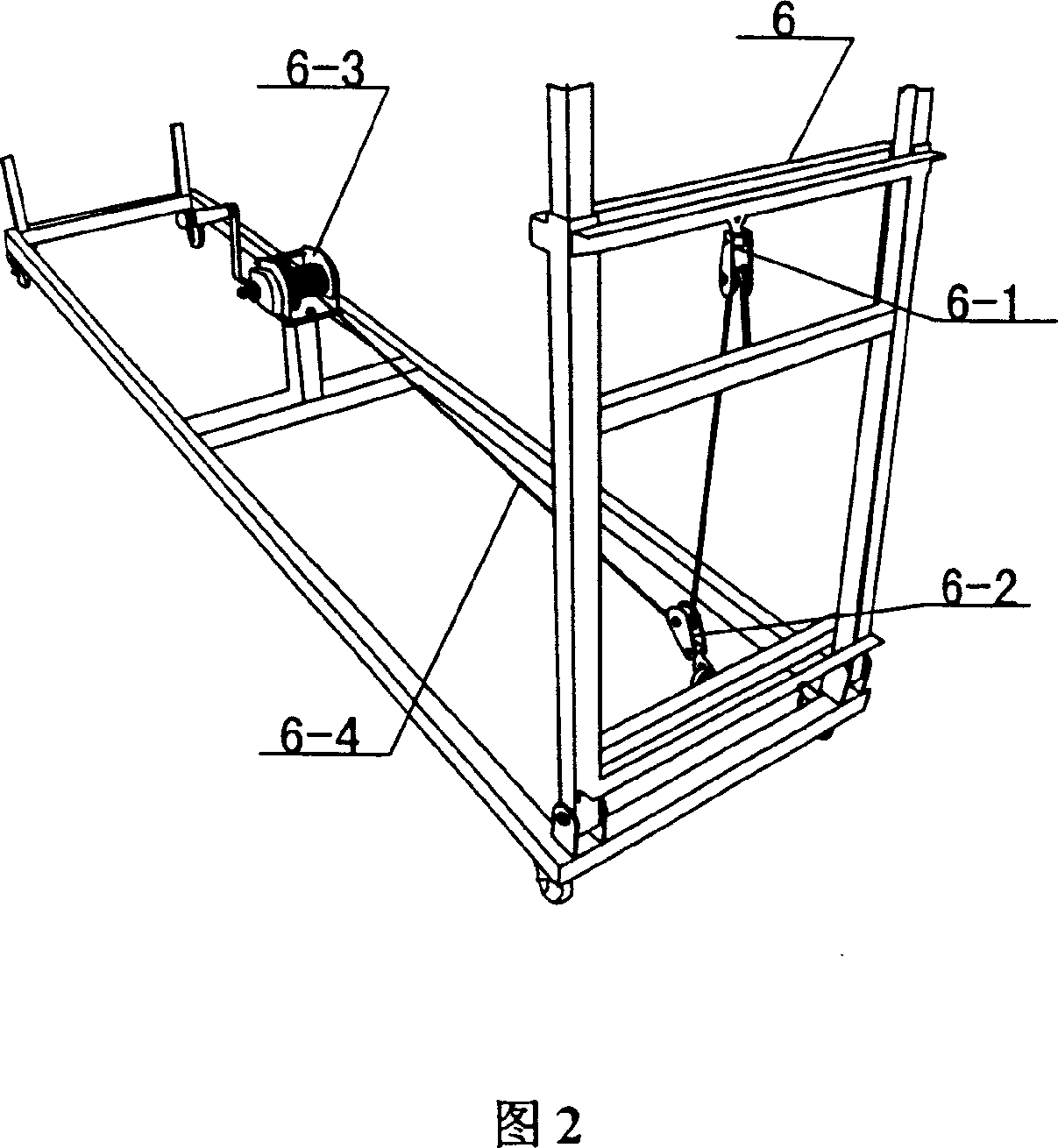

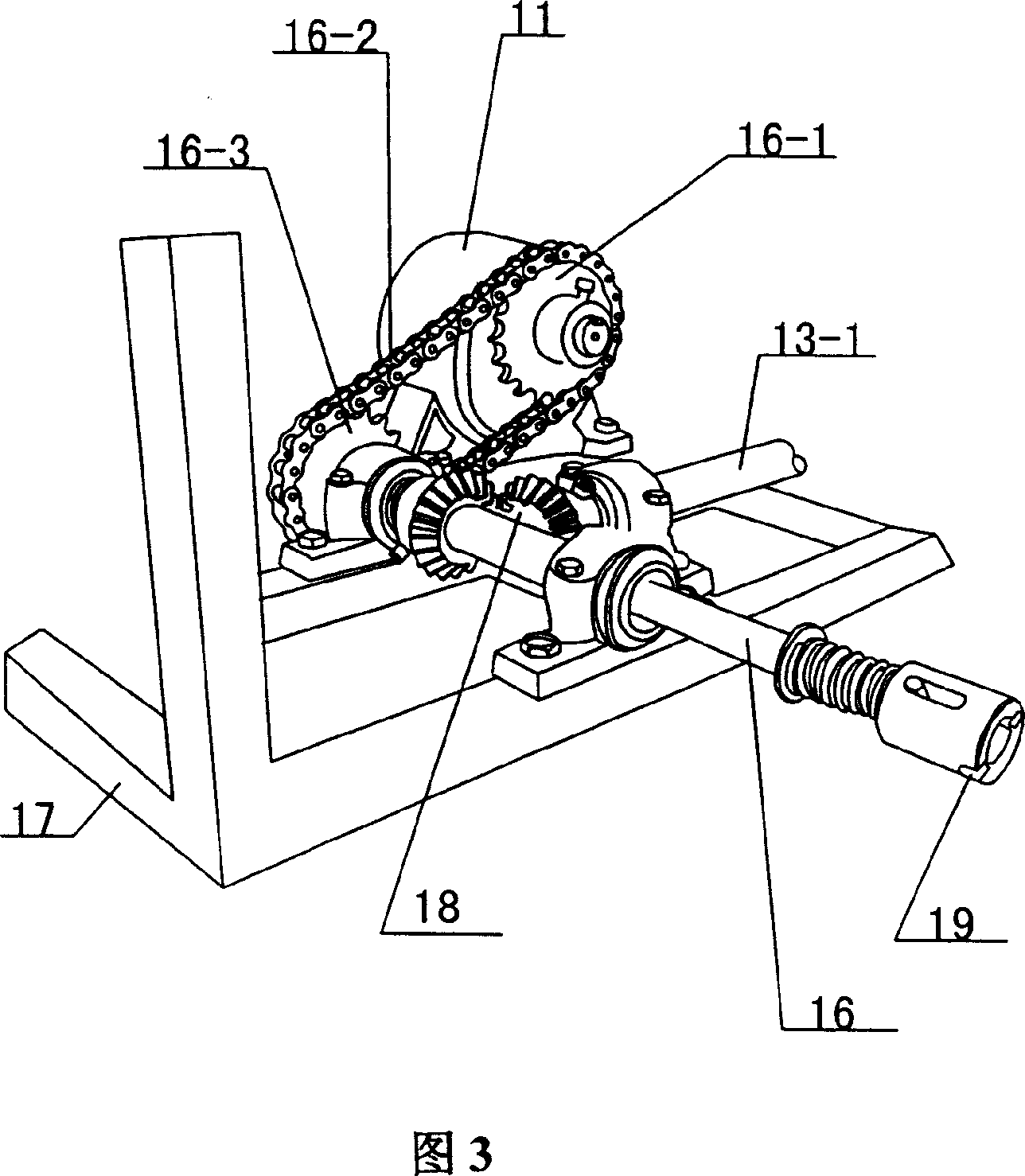

[0030] With reference to the above accompanying drawings, the working principle of the present invention is taken as an example. Before being put into practice, the present invention is arranged separately. When the conveying distance is long, the parallel conveying parts are provided with one section, two sections, three sections, and four sections. , the assembly depends on the place where the goods are loaded and unloaded. For example, loading in the container, as shown in Figure 1, the first section and the second section of the parallel conveying parts are just loaded into the container. The lock bolt 15-7 of the semi-automatic coupling device 15 of the first section collides with the inclined pin 15-3 of the second section and is connected; the parallel transmission shaft automatic coupling mechanism 19 is started by the B motor 11 and the motor b switch 11-1 Completed. The slope conveying part is adjusted by the lifter frame 6 according to the height of the vehicle ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com