Valve element airtightness testing device

A technology of air tightness detection and valve core, which is applied in the direction of using liquid/vacuum degree to measure liquid tightness, and detecting the appearance of fluid at the leakage point, etc., which can solve the problems of cumbersome operation, poor air tightness, and pressing force Unstable size and other issues, to achieve the effect of improving detection efficiency, high detection efficiency, and reducing intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

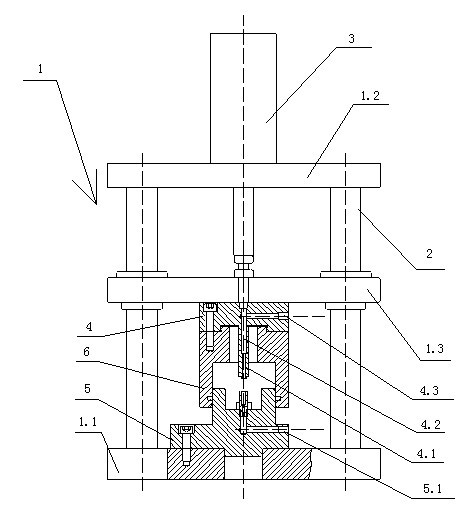

[0018] Such as figure 1 , the present invention relates to a valve core air tightness detection device, comprising a pressing device 1, the pressing device 1 includes a bottom plate 1.1, a top plate 1.2 and a moving beam 1.3, a number of guides are arranged between the bottom plate 1.1 and the top plate 1.2 Column 2, the moving beam 1.3 is nested between the guide columns 2, the moving beam 1.3 can slide up and down along the guide column 2, the top plate 1.2 is provided with a cylinder 3, the piston rod of the cylinder 3 and the moving beam 1.3 top connections.

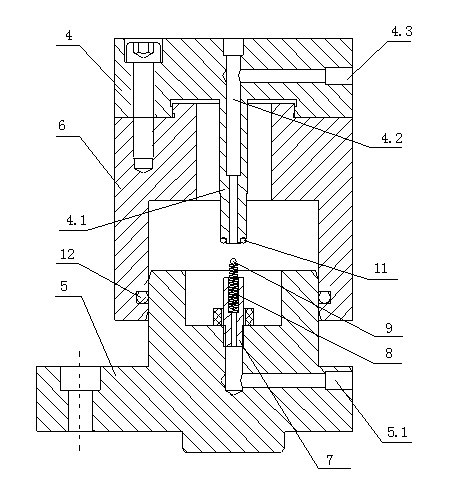

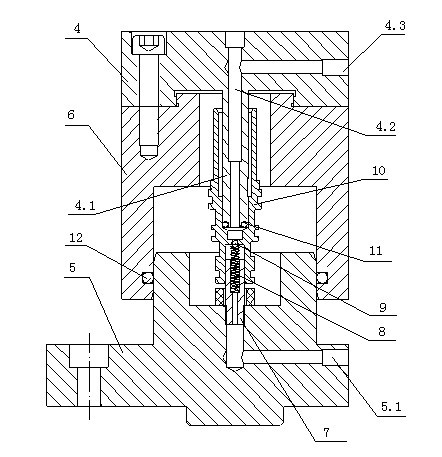

[0019] Such as figure 1 , figure 2 and image 3 , the bottom of the moving beam 1.3 is provided with a briquetting block 4, and the center of the bottom of the briquetting block 4 is extended downward with a strip-shaped fixing column 4.1, and the fixing column 4.1 is used to fix the valve core 10, and the fixing column 4.1 The outer edge of the bottom end of the column 4.1 is provided with a sealing ring I11, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com