System and method for automatic conveying of tire factory

A conveying system and tire factory technology, applied in conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of excessive labor intensity of workers, misuse of mixed rubber varieties, production waste, etc., and realize the informatization of the whole plant. The effect of management, labor intensity improvement, and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

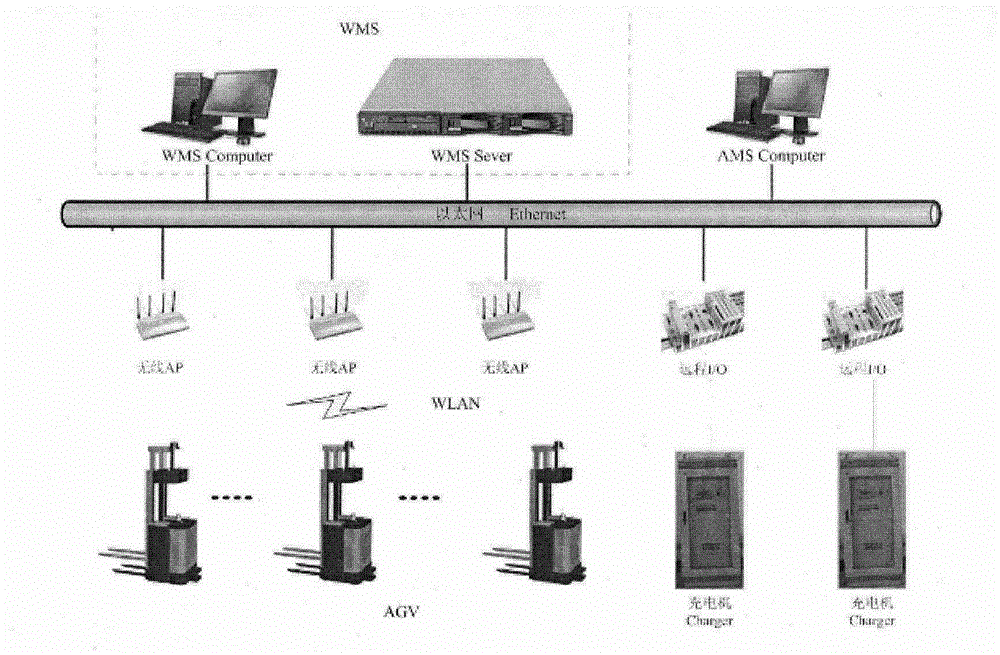

[0028] 1. Set up a wireless network system in the workshop and set up a computer control room.

[0029] 2. Build an automated warehouse for rubber mixing, and the control system is connected to the central control room to facilitate the automatic access of materials by AGV and the first-in-first-out of rubber materials.

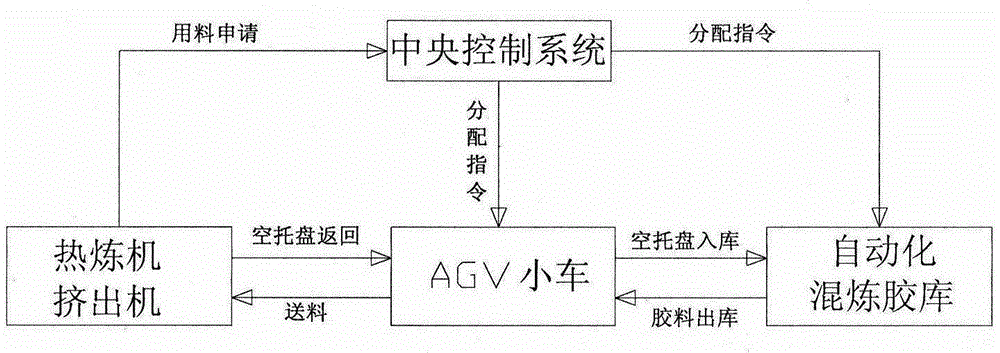

[0030] 3. An operation console is set in front of the equipment and connected to the central control room, and the automatic storage and withdrawal of rubber materials can be realized through one-button operation. The operation desk submits a material picking application to the central control system, and the central control system respectively issues outbound instructions to the self-controlled warehouse and the AGV trolley. tower.

[0031] 4. Design the structure of the AGV trolley according to the requirements. The main parameters include lifting height, load capacity, and moving speed.

[0032] 5. During the construction of the plant, electromagnetic tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com