Argon tungsten arc welding method for nickel-based alloy

A technology of argon tungsten arc welding and welding method, applied in welding equipment, arc welding equipment, metal processing equipment and other directions, can solve the problems of incomplete penetration and poor liquid fluidity of molten pool, etc., and achieve the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The manual argon tungsten arc welding process of Inconel 601 nickel-based alloy will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0039] Selection of welding materials

[0040] Use an alloy analyzer to measure the actual alloying element content of the Inconel 601 nickel-based alloy material, and select a straight welding wire with a slightly larger percentage of the alloying element composition than the base metal and relatively less harmful impurity elements such as S and P—the brand is ERNiCrFe-11, and the length is 1m, the diameter of the welding wire for backing welding is φ1.2mm, and the diameter of the welding wire for filling and covering welding is φ2.4mm; the weight percentage content of the main elements in the welding wire is as follows: C≤0.2%, Mn≤0.25%, Si≤0.5%, Cu≤0.1%, Al 1.5%-2.4%, Ti 0.1%-0.2%, Ni≥58%, Cr 21%-25%, Fe balance.

[0041] Groove preparation:

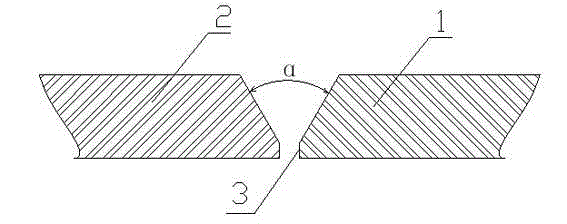

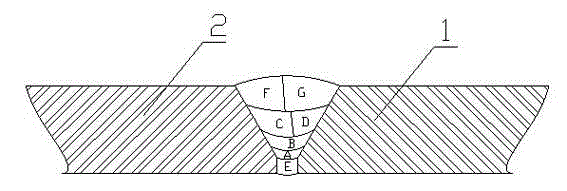

[0042] Such as figure 1 As sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com