Preparation method for inconel alloy based self-lubricating corrosion and wear resistant coating

A corrosion-resistant and wear-resistant nickel-chromium alloy technology, applied in metal material coating process, coating, fusion spraying, etc., can solve the problem of poor wear resistance and corrosion resistance, large coating pores, and restrictions on supersonic flame spraying metal Problems such as the application range of alloy coatings, to achieve the effect of expanding the application range and improving the surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the nickel-chromium alloy-based self-lubricating corrosion-resistant and wear-resistant coating in this embodiment includes the following steps: (1) Spraying Ni-based diamond-like alloy powder on the substrate by supersonic flame spraying to obtain an initial coating;

[0030] In the Ni-based diamond-like alloy powder, by mass percentage, Ni 50%, Cr 20%, W 11%, Mo 11%, Cu 5% and Al 3%, the particle size of the Ni-based diamond-like alloy powder is 30 μm.

[0031] Before supersonic flame spraying, the substrate was cleaned with acetone for 5 minutes, and then Al with a particle size of 50 mesh 2 o 3 sandblasting;

[0032] In this embodiment, JK3000 type supersonic flame spraying is selected, and the main combustion gas O 2 The flow rate is 34SCCM, SCCM is standard cubic meters per minute, auxiliary combustion gas H 2 The flow rate is 57SCCM. The main combustion gas and auxiliary combustion gas are mixed with Ni-based diamond-like alloy powder...

Embodiment 2

[0049] In this example, the Ni-based diamond-like alloy powder contains 40% Ni, 30% Cr, 15% W, 8% Mo, 4% Cu and 3% Al by mass percentage, and the particle size of the powder is 45 μm.

[0050] In this embodiment, JK3000 type supersonic flame spraying is selected, and the main combustion gas O 2 The flow rate is 20SCCM, the auxiliary combustion gas H 2 The flow rate is 70SCCM. The main combustion gas and auxiliary combustion gas are mixed with Ni-based diamond-like alloy powder in the combustion chamber and sprayed onto the surface of the substrate. The injection distance is 10inch, the powder feeding rate is 50g / min, the combustion chamber pressure is 5bar, and the deposition rate It is 3 μm / min, and the initial coating thickness after spraying is 250 μm.

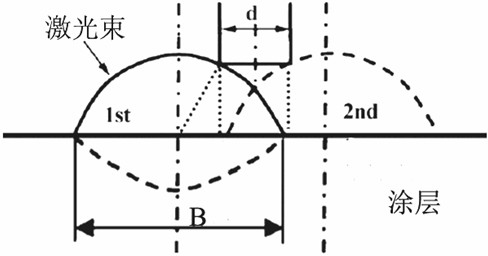

[0051] Laser beam scanning uses CO with a power of 4kW, a circular spot diameter of 4mm, and a scanning speed of 300mm / min. 2 continuous wave laser beam. The overlapping rate of two adjacent laser beams is 10%.

[0052]...

Embodiment 3

[0054] In this embodiment, the Ni-based diamond-like alloy powder contains 55% Ni, 15% Cr, 10% W, 9% Mo, 9% Cu and 2% Al by mass percentage, and the particle size of the powder is 15 μm.

[0055] In this embodiment, JK3000 type supersonic flame spraying is selected, and the main combustion gas O 2 The flow rate is 50SCCM, the auxiliary combustion gas H 2 The flow rate is 40SCCM, the main combustion gas and auxiliary combustion gas are mixed with Ni-based diamond-like alloy powder in the combustion chamber and sprayed onto the surface of the substrate, the injection distance is 5 inches, the powder feeding rate is 30g / min, the combustion chamber pressure is 10bar, and the deposition rate It is 7 μm / min, and the initial coating thickness after spraying is 350 μm.

[0056] Laser beam scanning uses a laser beam with a power of 4kW and an elliptical spot size of 5mm×4mm to move along the direction of the long diameter (5mm) at a scanning speed of V=600mm / min, and the overlapping r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com