Method for preparing inconel by using heavy metal sludge

A technology of inconel and heavy metal sludge, which is applied in the field of heavy metal sludge reuse, can solve the problems of no economic benefit, high cost of car manufacturing, secondary pollution, etc., achieve considerable economic benefits and avoid secondary pollution , The effect of saving resources and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

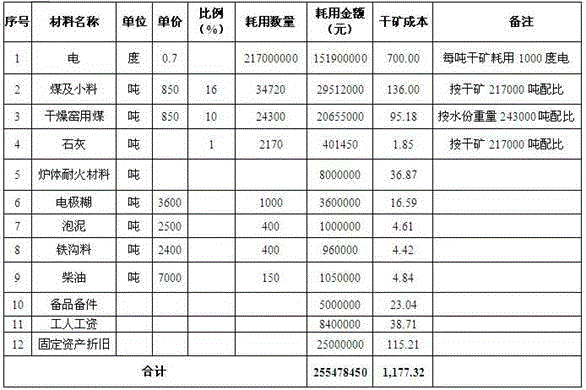

[0020] Table 1 Composition and ratio of each raw material

[0021] (1) Mix stainless steel sludge 1, stainless steel sludge 2, electroplating sludge 1, electroplating sludge 2, chromium sludge, dust ash produced in the production process of Inconel, and laterite nickel ore according to the mass ratio and add them to the ball making Balls are made in the machine, and the mixed balls are preheated and dried in a drying kiln (300 ℃);

[0022] (2) Add coke and limestone to the dried mixture, and carry out reduction roasting in a rotary kiln (1000 ℃) to obtain calcined sand; the flue gas generated by the rotary kiln is preheated and recovered by the waste heat boiler, and after the purification treatment reaches the standard Emission, the collected dust is returned to the raw material warehouse as dust;

[0023] (3) Put the calcined sand into the submerged arc furnace (1600 ℃) for smelting, and cast the molten Inconel into ingots to obtain Inconel alloy; the smelting slag is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com