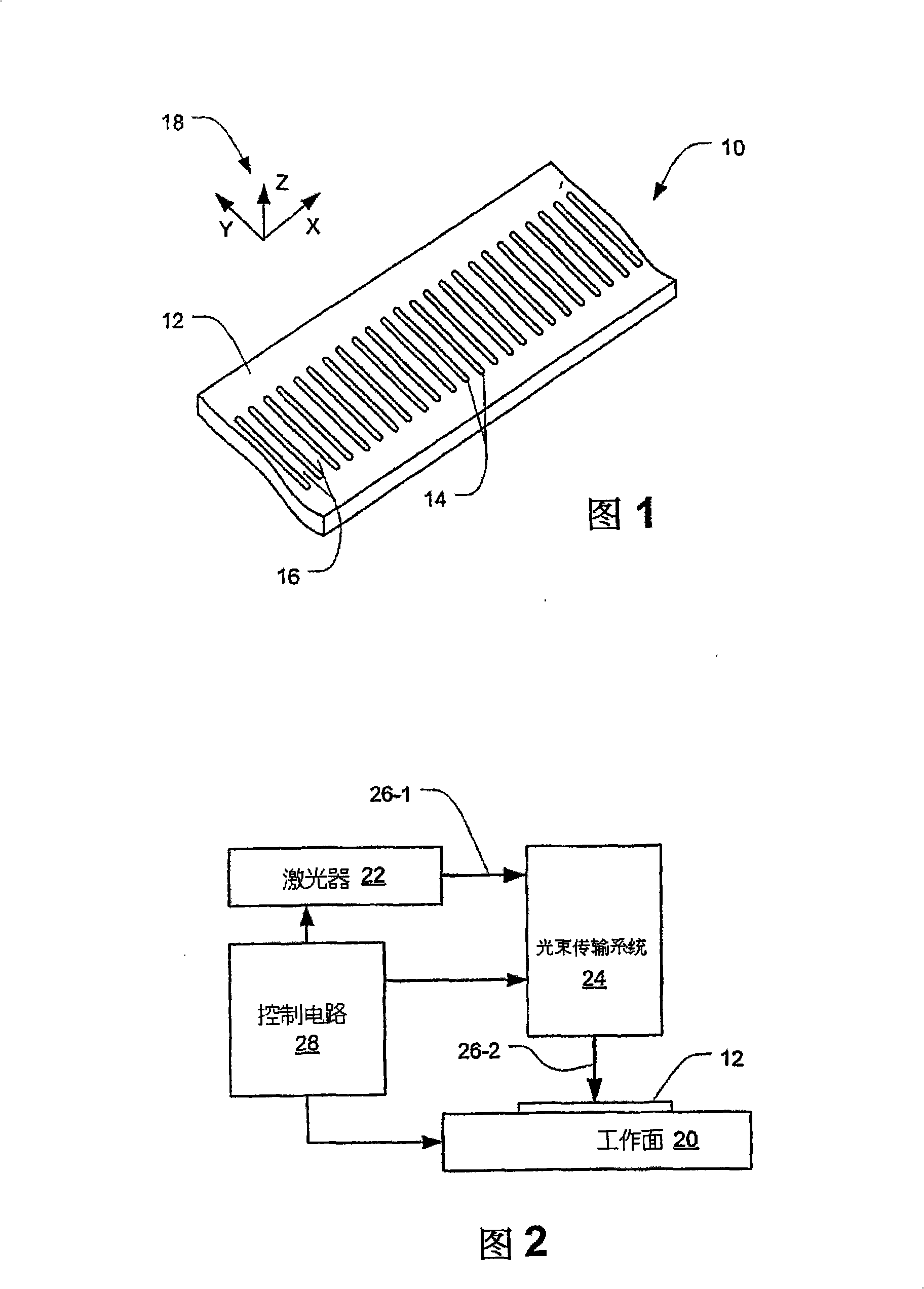

Optical metrological scale and laser-based manufacturing method therefor

An optical metrology and laser technology, applied in manufacturing tools, laser welding equipment, measuring devices, etc., which can solve problems such as unmentioned temperature problems and undisclosed problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

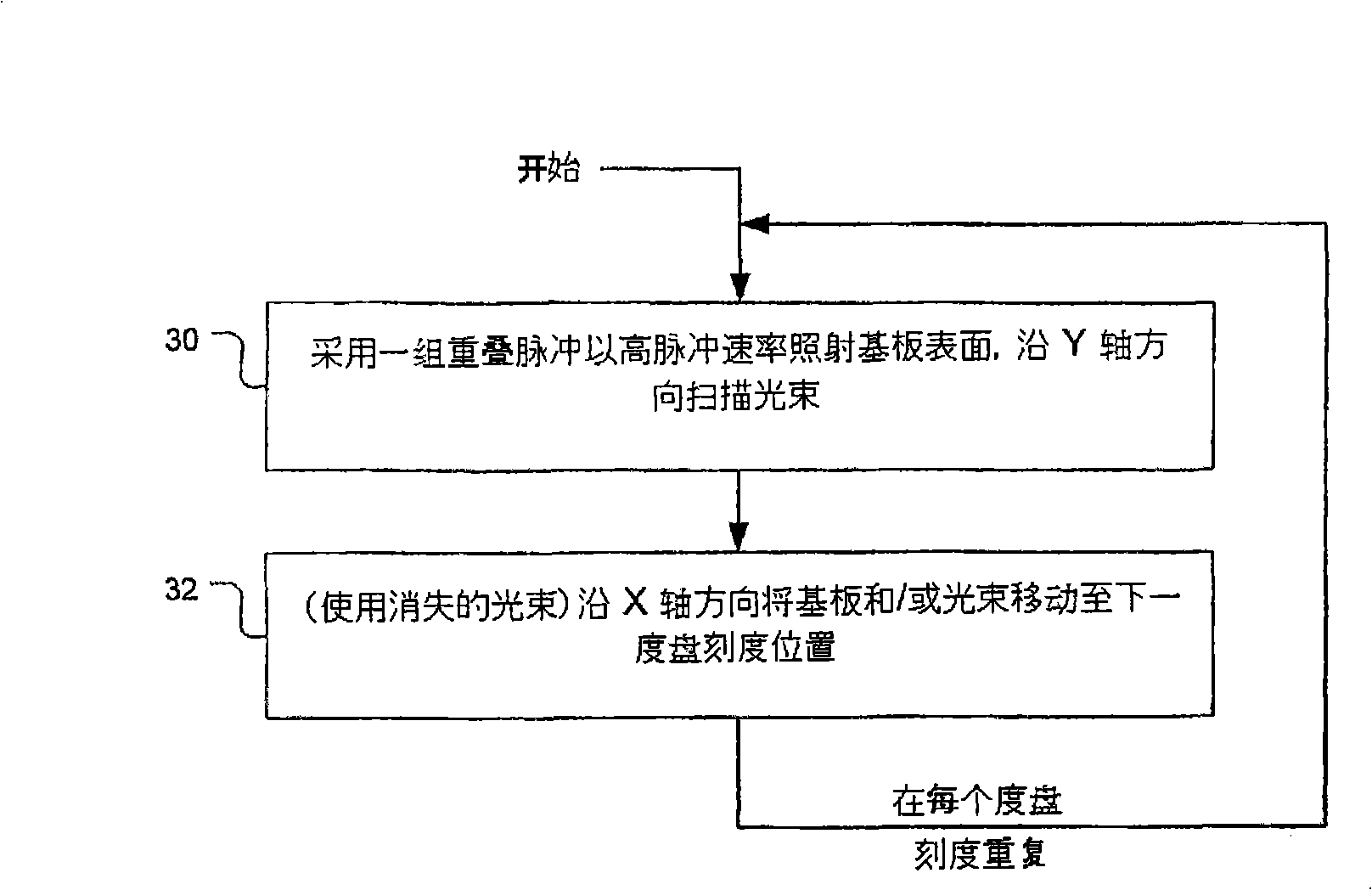

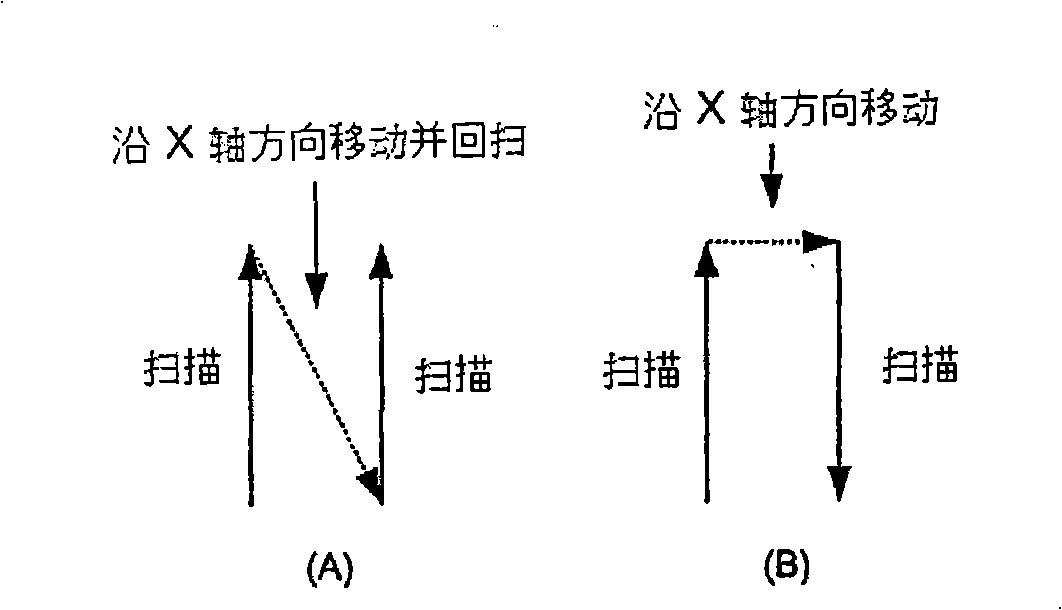

[0080] Terms used in the following descriptions are provided with brief descriptions and are intended to be explanatory rather than limiting. In the context of "chaotic" structures referred to in this specification, "chaos" generally refers to an observable structure characterized by the formation of a disorganized or chaotic mixture of matter at the location of laser impingement. By way of example, the chaotic structure may be a collection of molten matter with irregular shapes and varying reflectivities. To illustrate, "non-chaotic" or "well-structured" could be a region with a smooth measurable spatial profile, or a quasi-periodic spatial profile with regular regions of uniform color in a given direction. A "trench" or "trough-like" structure has a relatively long and narrow shallow concave shape, sometimes U-shaped or V-shaped in cross-section, relative to the surrounding plane. "Energy density" and "fluence" are a group of synonyms, which refer to the energy per unit are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com