Sealing method of borosilicate glass and kovar alloy of solar collector tube

A technology of solar collector tubes and high silicon boron, applied in the field of solar energy applications, can solve the problems of reduced air tightness of the device, increased production cost of the thermal collector tubes, and unsuitability for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

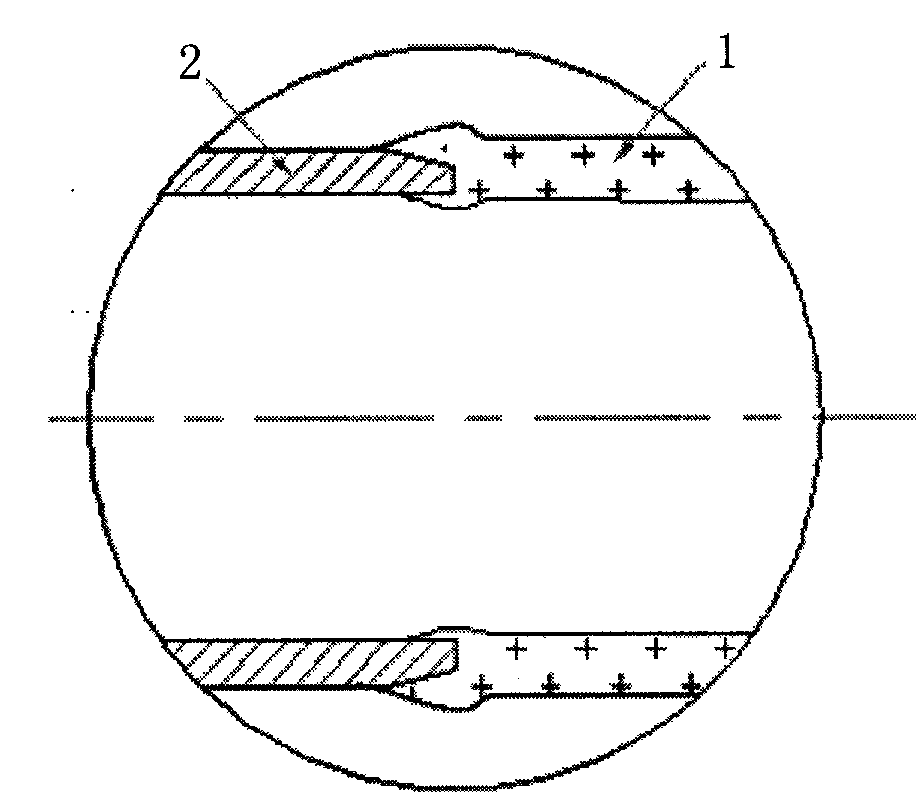

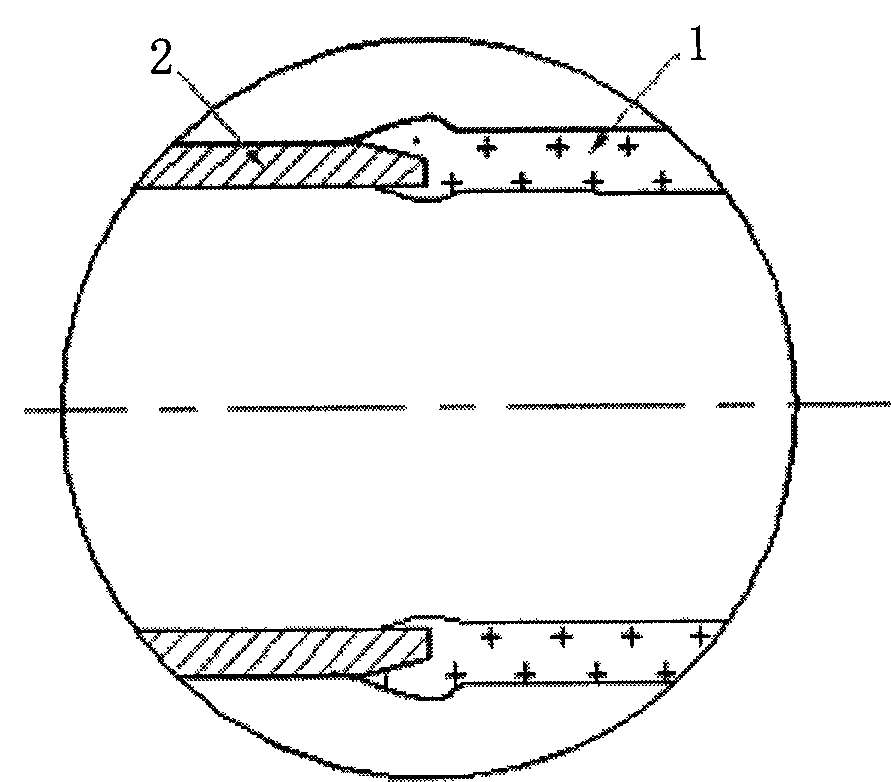

[0006] see figure 1 , High borosilicate glass 1, Kovar alloy 2 are directly sealed. The expansion coefficients of borosilicate glass 1 and Kovar 2 are 4.8-5.2×10 -6 / °C and 4.7-5.5×10 -6 / °C.

[0007] The direct sealing method of two materials is as follows:

[0008] 1). Pre-oxidize the Kovar alloy 2 first, put the Kovar alloy 2 on the flame and heat and oxidize it while rotating it. At a temperature of 700°C--1000°C, heat the Kovar alloy 2 to dark red. At this time A layer of oxide is uniformly attached to the surface of Kovar 2, and the main component of the oxide is ferrous oxide. The thickness of the oxide layer is 1-2μm, and the surface density is 0.3-0.7mg / m2, which is the best.

[0009] 2). Heat the high-silicon borosilicate glass tube to 450°C-650°C while rotating it. After the glass turns red and soft, insert the oxidized Kovar 2 into the wall of the glass tube by 5-8mm to make the molten glass The tube is evenly coated on the outer wall of the metal tube, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com