Vacuum seal welding method for window and optic window of low temperature metal Dewar

A technology of optical window and welding method, applied in welding equipment, metal processing equipment, vacuum evaporation coating and other directions, can solve the problems of increased permeability, contamination of detectors, high temperature resistance, etc., and achieves a small outgassing rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

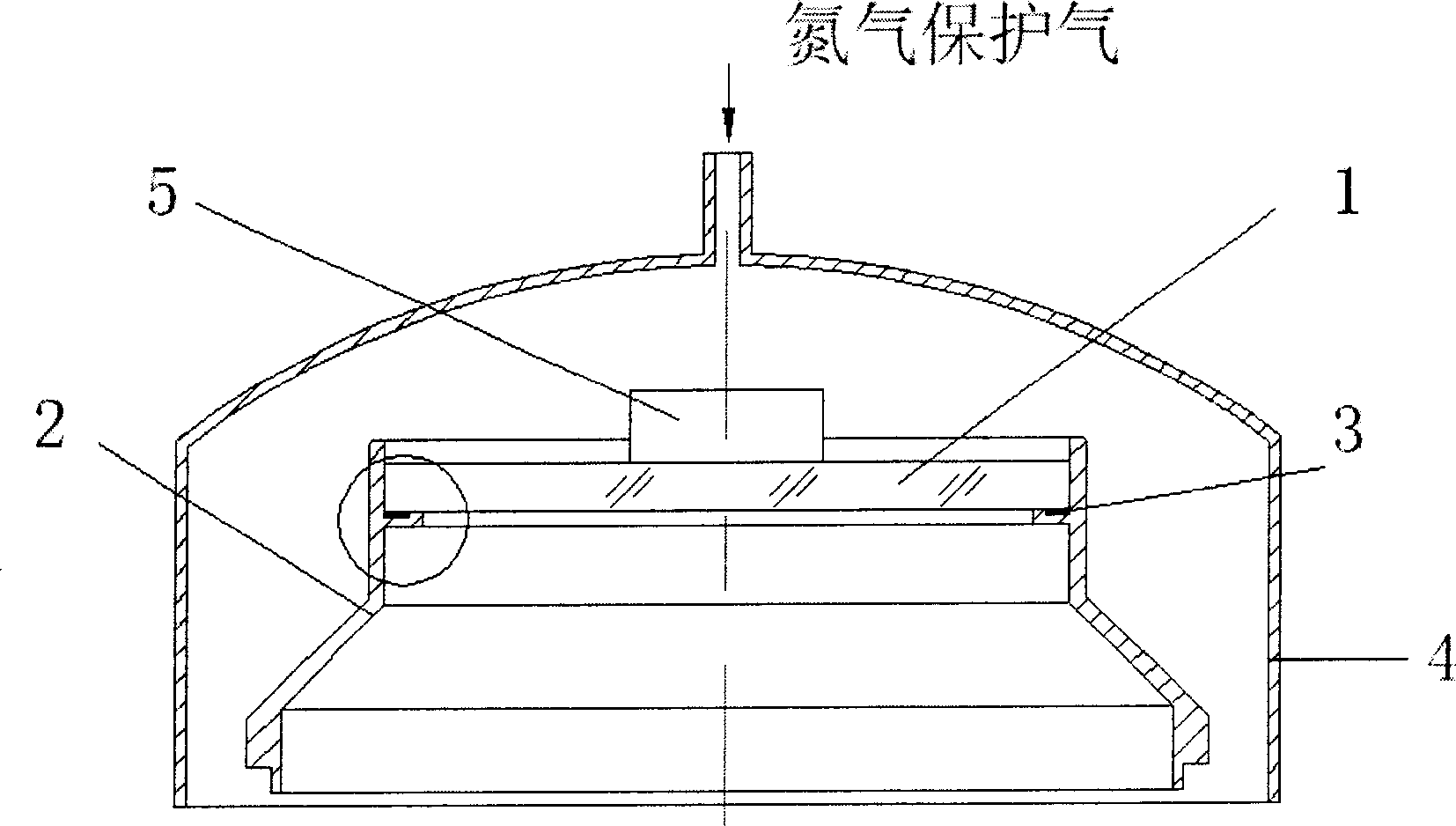

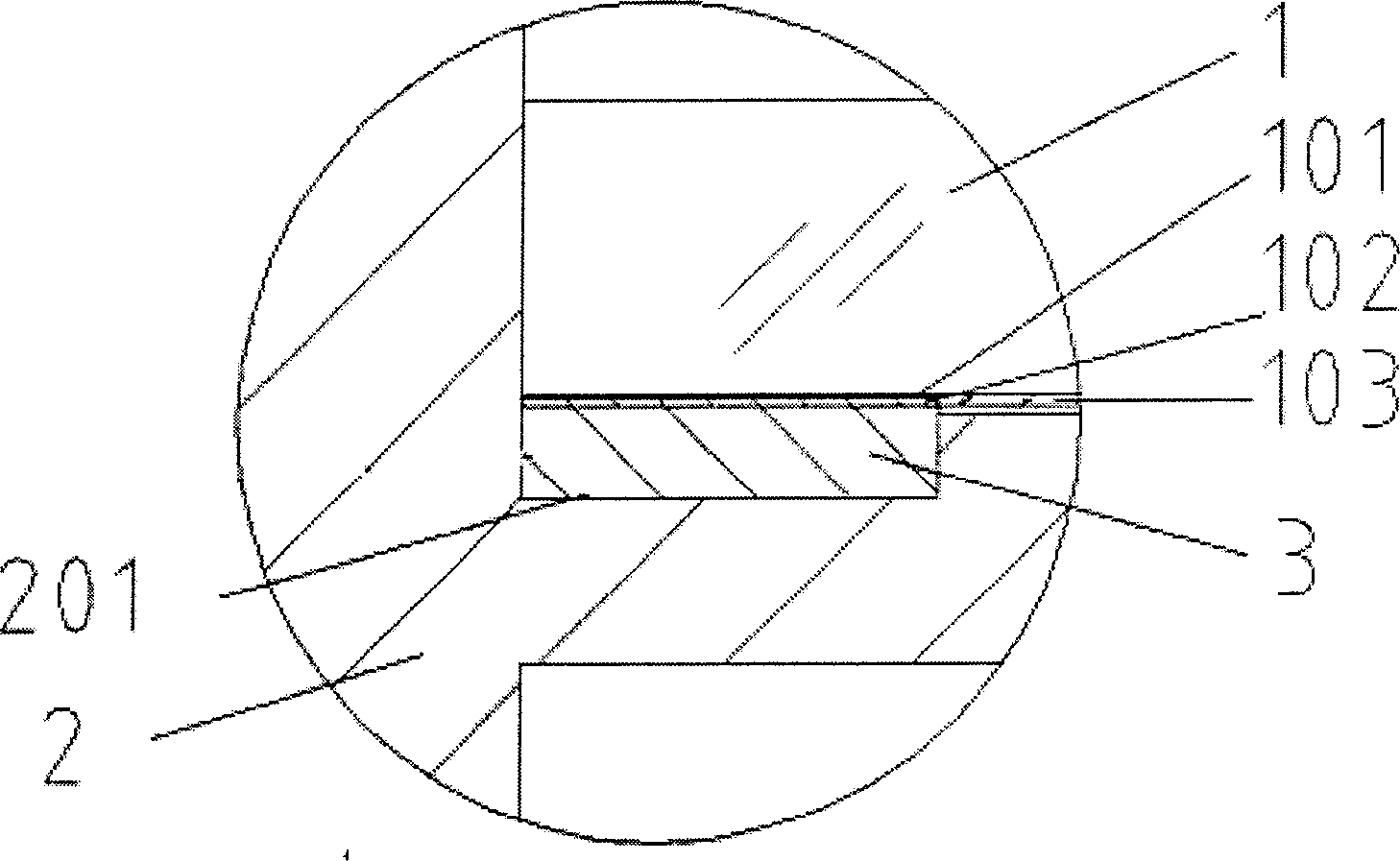

Method used

Image

Examples

Embodiment 1

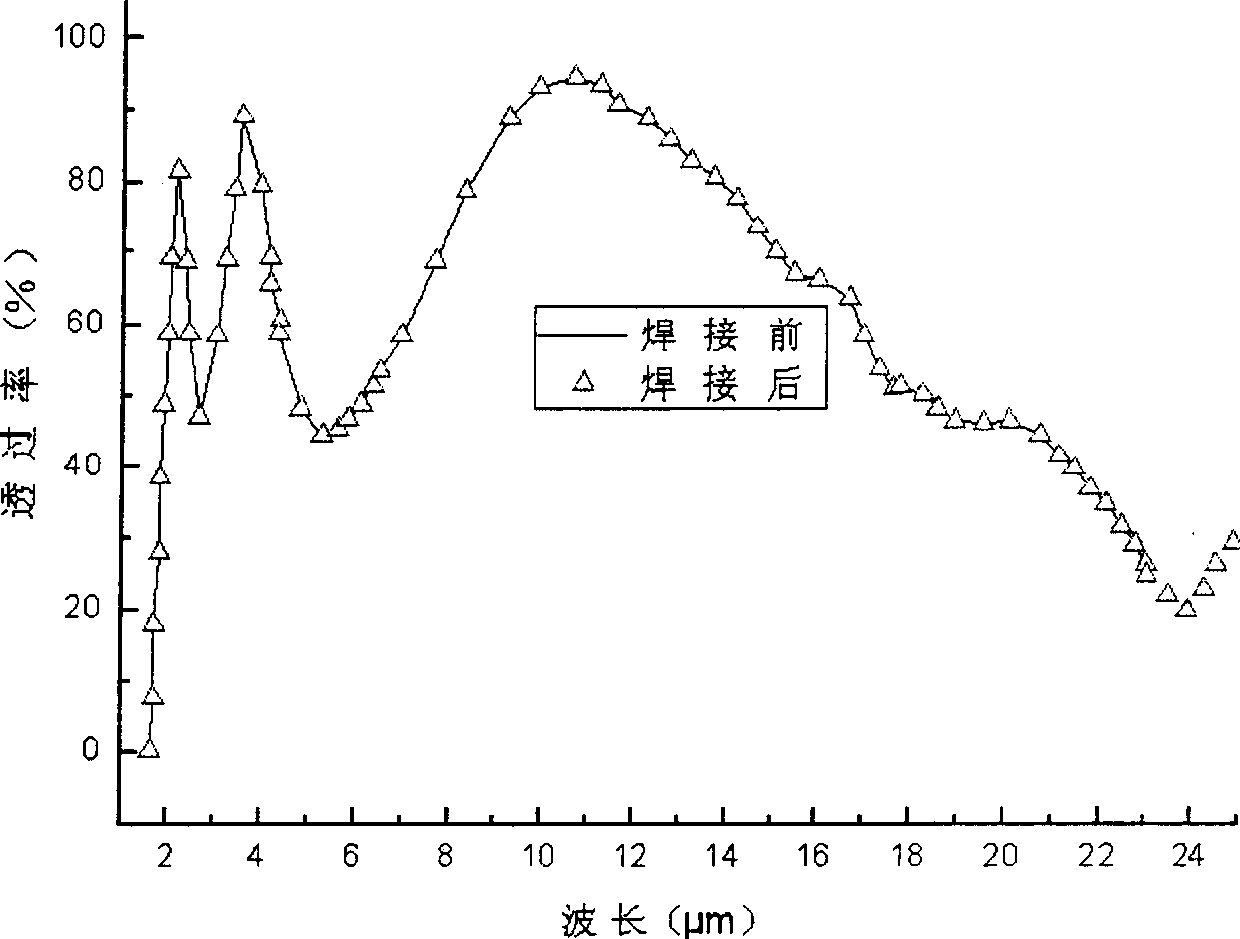

[0023] Embodiment 1: germanium optical window (long wave infrared, with ocean satellite window sample welding statistics)

[0024] sample number

Embodiment 2

[0025] Embodiment 2: Zinc sulfide optical window (welding statistics of mid-wave infrared window sample used by No. 7 satellite)

[0026] sample number

Embodiment 3

[0027] Embodiment 3: Quartz optical window (with the sample welding statistics of the short-wave infrared window used by No. 7 satellite)

[0028] sample number

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com