Electronics Vacuum Feedthrough

A feed-through and electronics technology, applied in the field of feed-throughs, can solve problems such as large volume, inability to meet gas detectors, and fewer communication channels, and achieve low outgassing rate, reliable structure, and improved thermal shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

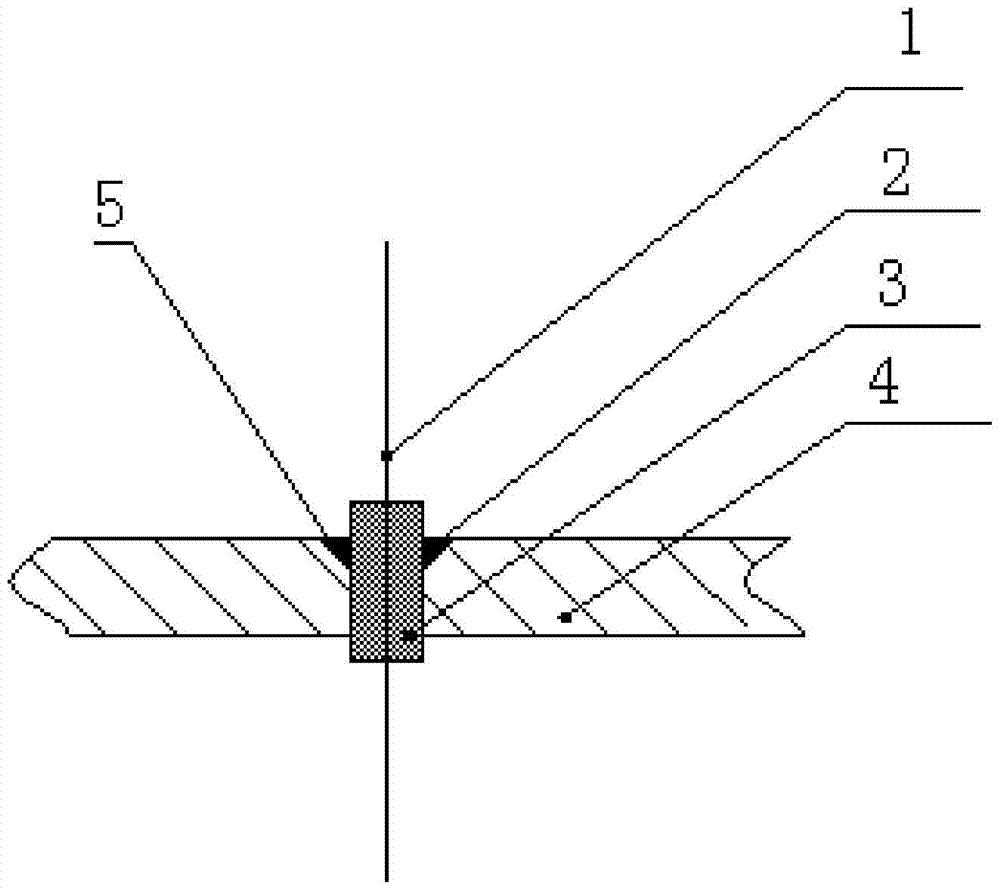

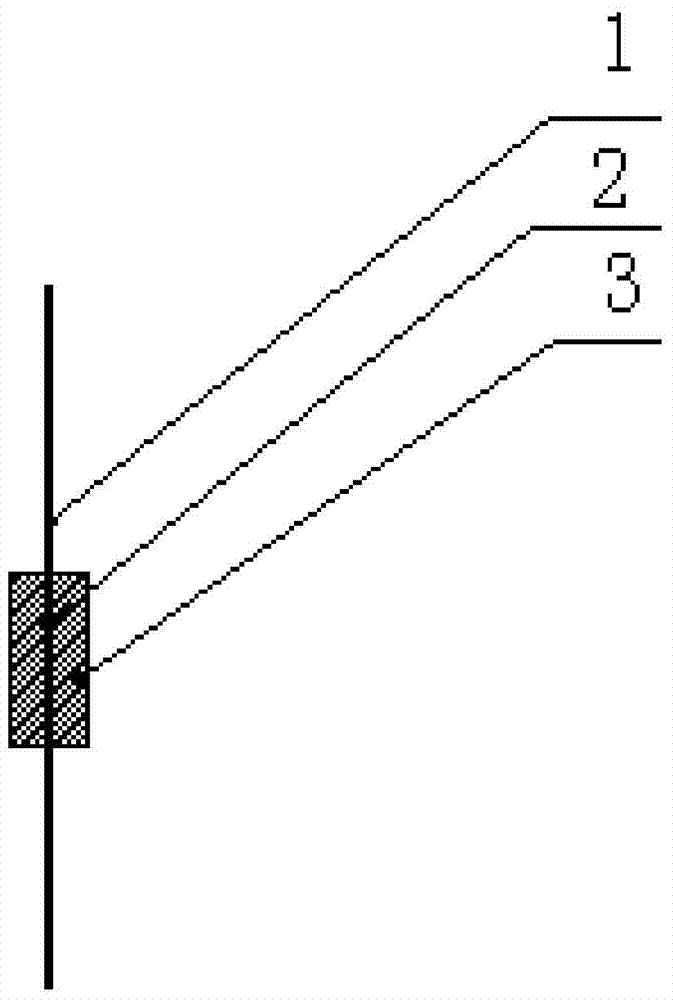

[0050] Such as Figure 1-2 As shown, an electronic vacuum feed-through of this embodiment includes:

[0051] The flexible circuit board 1, preferably the flexible circuit board 1 is a RO4000 series flexible circuit board with a frequency not less than 500 MHz. The selected RO4000 series flexible circuit board meets the NASA low outgassing low outgassing rate standard;

[0052] The substrate 4 is formed with a through hole, the flexible circuit board 1 is arranged in the through hole, and the inner wall of the through hole and the flexible circuit board 1 are sealed by setting a sealing gel, and the material of the substrate 4 Stainless steel or titanium is preferred. The sealing colloid is a colloid with good airtightness, low outgassing rate and good strength in vacuum, preferably epoxy resin glue 2.

[0053]The above-mentioned solution is the core solution of the present invention. Since the flexible circuit board 1 is used as the conductor material of the electronic vacu...

Embodiment 2

[0069] The difference between this embodiment 2 and embodiment 1 lies in the type, proportion and curing temperature of the double epoxy resin glue used. Specifically: the two-component epoxy resin glue is the Torr seal epoxy resin glue of Agilent; the A component and the B component of the Torrseal epoxy resin glue are proportioned according to the mass ratio of 2:1; The completed epoxy resin glue is mixed in a vacuum environment with a vacuum degree of <100Pa, and stirred evenly until there are no obvious bubbles on the surface of the sealant, and then pure nitrogen is introduced to 1 atmosphere.

[0070] In the flexible circuit board packaging step, the flexible circuit board-clamp assembly is placed in a vacuum drying oven for heating and curing. Preferably, the heating temperature is 60 degrees centigrade, and the heating time is 2 hours. In the overall packaging step of the feedthrough, the encapsulated feedthrough is heated and cured in a vacuum heating oven. Preferab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com