Soldering method of high volume fraction SiC particle-reinforced Al matrix composite and kovar alloy

A silicon carbide particle, high volume fraction technology, used in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as low joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

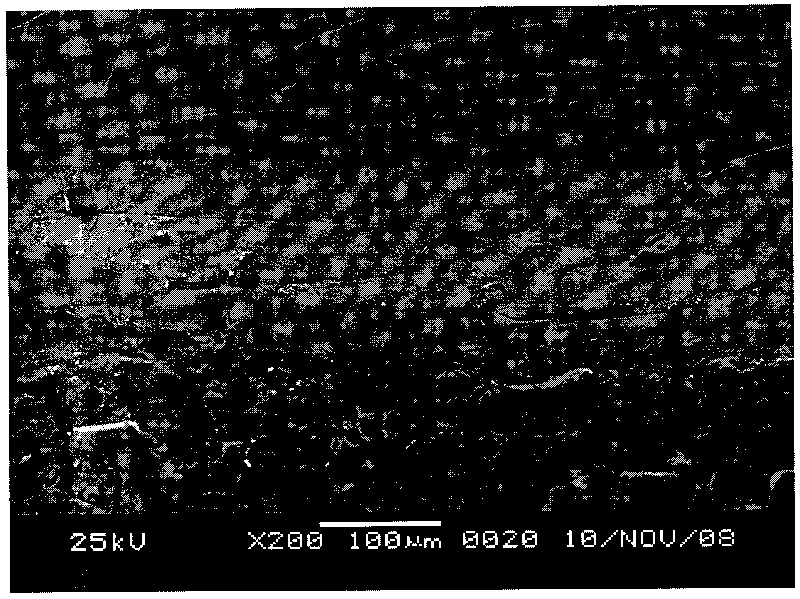

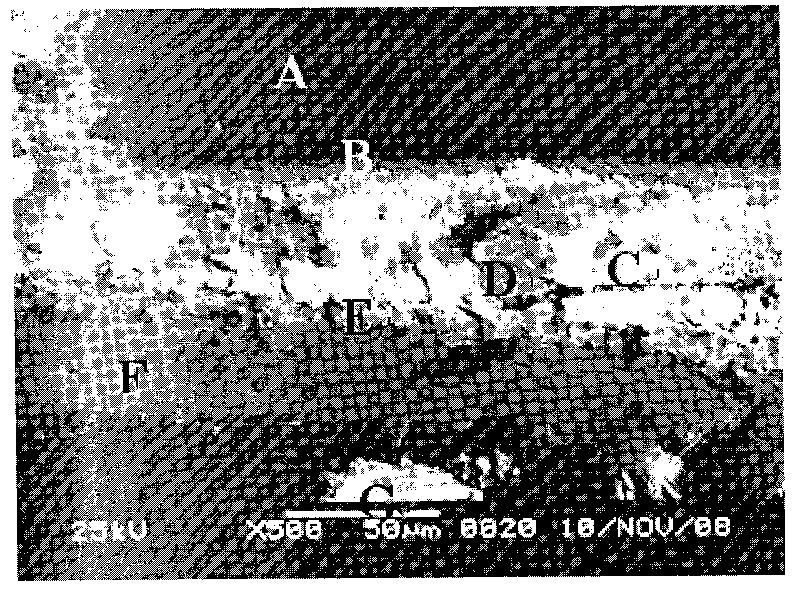

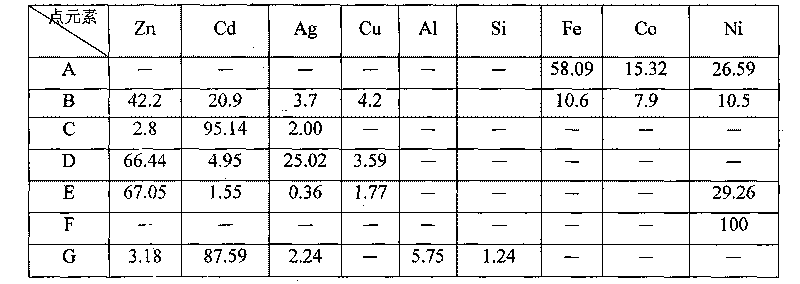

Image

Examples

specific Embodiment approach 1

[0008] Embodiment 1: In this embodiment, the soldering method of high volume fraction silicon carbide particle reinforced aluminum matrix composite material and Kovar alloy is carried out according to the following steps: 1. After a. degreasing, b. pickling roughening , c. sensitization, d. activation, e. reduction, f. the steps of acidic Ni-P plating on the surface of the SiCp / Al composite material with a volume fraction of silicon carbide particles of 55% to 75% for electroless Ni-P plating; 1. Degrease the SiCp / Al composite material and Kovar metal surface to be welded with acetone for 8 minutes respectively after step 1, make the flux into a paste with ethanol and apply it on both sides of the foil-shaped solder. A flux layer with a thickness of 40-80 microns is formed on both sides of the brazing filler metal, and then the foil-like brazing filler metal is placed between the SiCp / Al composite material and the Kovar metal surface to be welded, and the SiCp / Al composite mate...

specific Embodiment approach 2

[0009] Embodiment 2: This embodiment differs from Embodiment 1 in that: "a. Degreasing" described in step 1 is ultrasonically treated in acetone for 10 minutes at room temperature, washed with water, and dried. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the "b. pickling and coarsening" described in step one is at room temperature in HF and HNO 3 Corrosion coarsening in the mixed solution for 10 minutes, then washed with water and dried, wherein the HF and HNO 3 HF, HNO in the mixed solution 3 The mass of water and water is 1:3:1. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com