Poisonous waste treating method and special apparatus

A special device and waste technology, which are applied in the field of toxic and hazardous waste treatment methods and special devices, can solve problems such as secondary pollution of the environment, and achieve the effect of small exhaust gas treatment capacity and avoiding secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

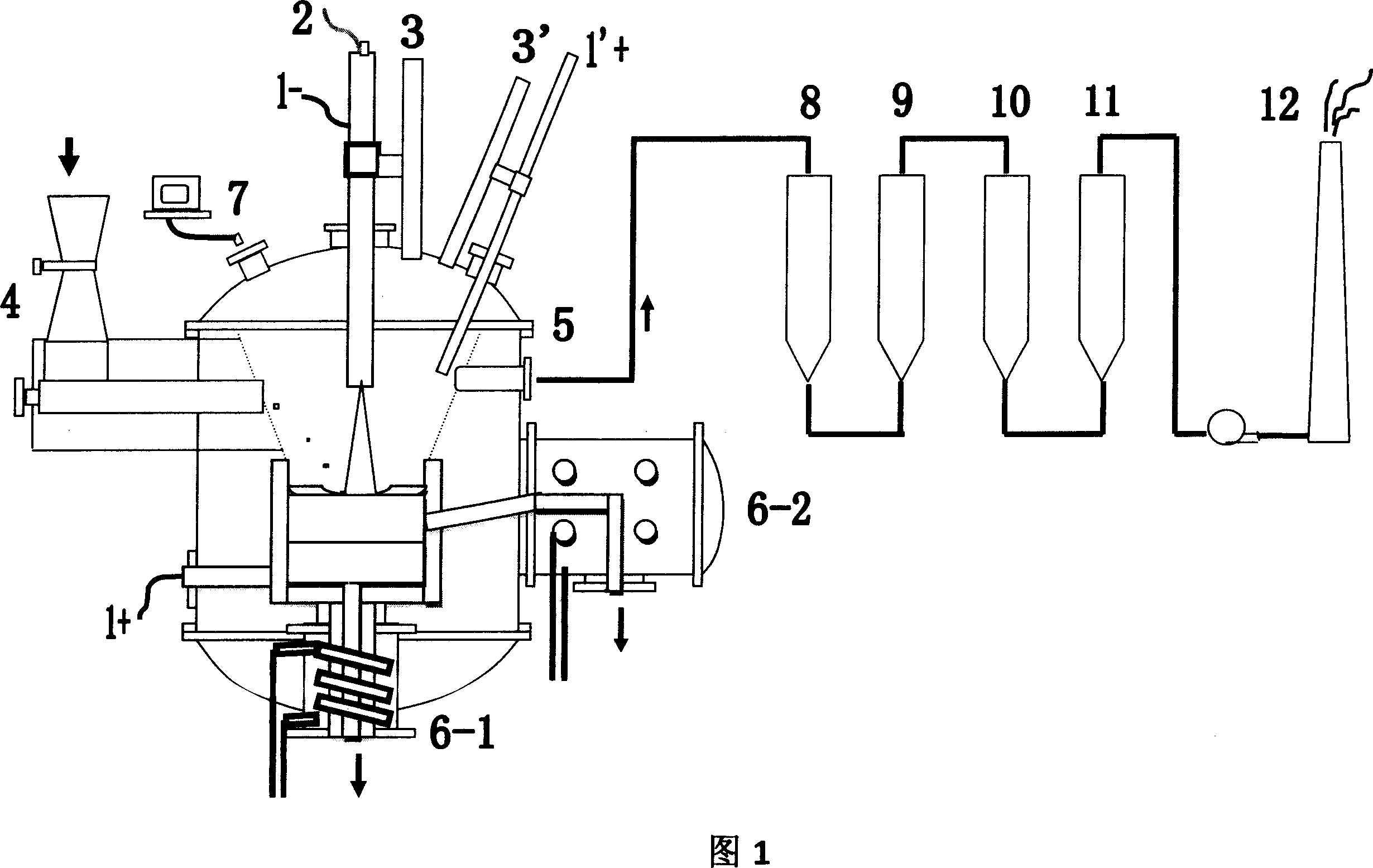

[0023] Embodiment 1: The device has a plasma device, a carrier fluid gas supplier, a main graphite electrode, an auxiliary graphite electrode, a feeder, a furnace body, a crucible, a glass discharge heat pump, a polymetallic enriched body melt heat pump, a liquid level sensor, and a sensor The controller and exhaust gas discharge system, the plasma device, the main graphite electrode and the auxiliary graphite electrode are connected to the furnace cover of the furnace body, the carrier fluid gas supplier is connected to the main graphite electrode, the feeder is located on the upper side of the furnace body, and the glass body discharges the heat pump Located on the other side of the furnace body, the metal-enriched body melt heat pump is located at the bottom of the furnace body, the crucible is located in the furnace body, the liquid level sensor is located at the upper end of the crucible, and is connected to the sensor controller, and the exhaust gas discharge system is con...

Embodiment 2

[0047] Example 2 The fly ash produced by the domestic waste incinerator contains a large amount of highly toxic dioxin and other components, and is fed into the plasma arc area through a feeder, and is rapidly melted at a temperature of 1300°C, and the highly toxic organic matter is instantly cracked and environmentally friendly. The inorganic small molecules, through the exhaust gas purification treatment, are emptied up to the standard. Turn on the power supply of the vitreous body discharge heat pump and the metal-enriched body melt heat pump, and the metal melt flows out of the furnace body after being heated by the metal-enriched body melt heat pump, and the heating temperature is 1300°C; ℃; the waste gas generated during pyrolysis and melting is discharged from the furnace body through the exhaust hole of the furnace body through the exhaust system, and the exhaust gas is discharged from the exhaust system through the tail gas secondary treatment room at 1250°C for high t...

Embodiment 3

[0048]Example 3: The waste Pt-containing noble metal catalysts produced in the petrochemical industry are sent into the plasma arc area together with the additives. At a temperature of 3000 ° C, the catalyst carrier Al 2 o 3 With CaO and SiO in additives 2 and other substances are vitrified together, discharged from the furnace body, and precious metals such as Pt and metal absorbers such as Cu are melted together to form a metal melt and discharged out of the furnace, which can be directly used to recover precious metals such as Pt. Turn on the power supply of the vitreous discharge heat pump and the metal-enriched body melt heat pump, and the metal melt flows out of the furnace body after being heated by the metal-enriched body melt heat pump, and the heating temperature is 1500°C; ℃; the exhaust gas produced during pyrolysis and melting is discharged from the furnace body through the exhaust hole of the furnace body through the exhaust system, and the exhaust gas is discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com