Micro fluid control chip and preparation method and application thereof

A microfluidic chip and flow channel technology, applied in the field of microfluidics, can solve the problems of difficult control of liquid flow rate, complex chip processing, low mixing efficiency, etc., achieve stable flow rate, good detection effect, and improve mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

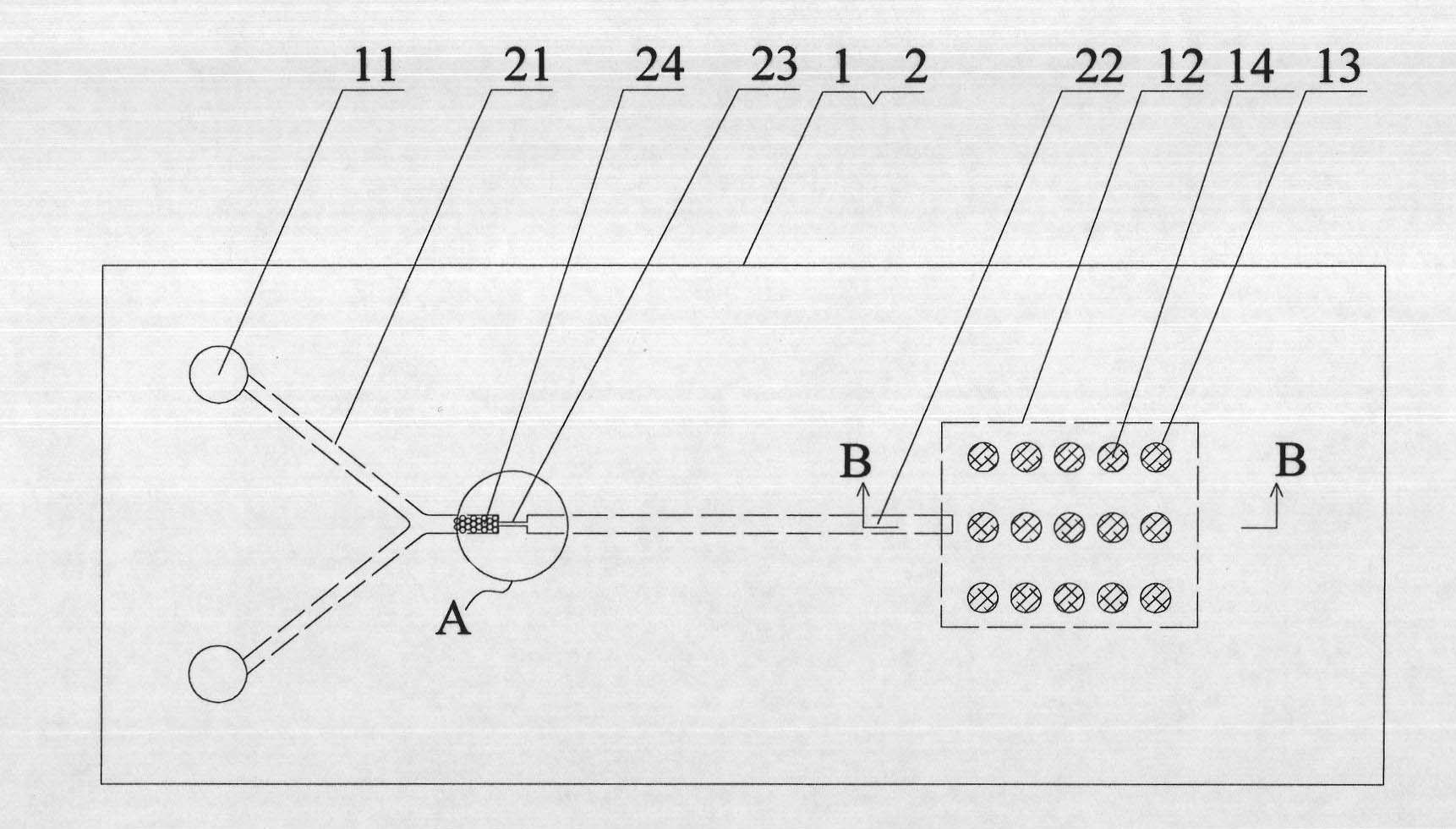

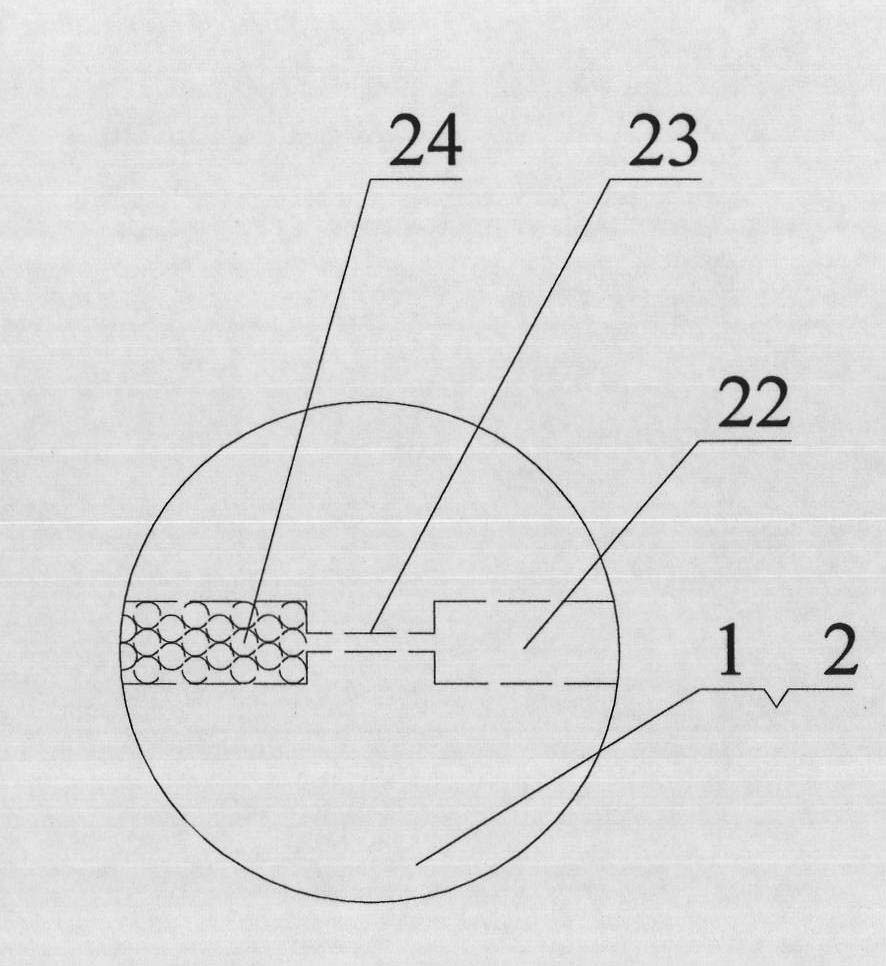

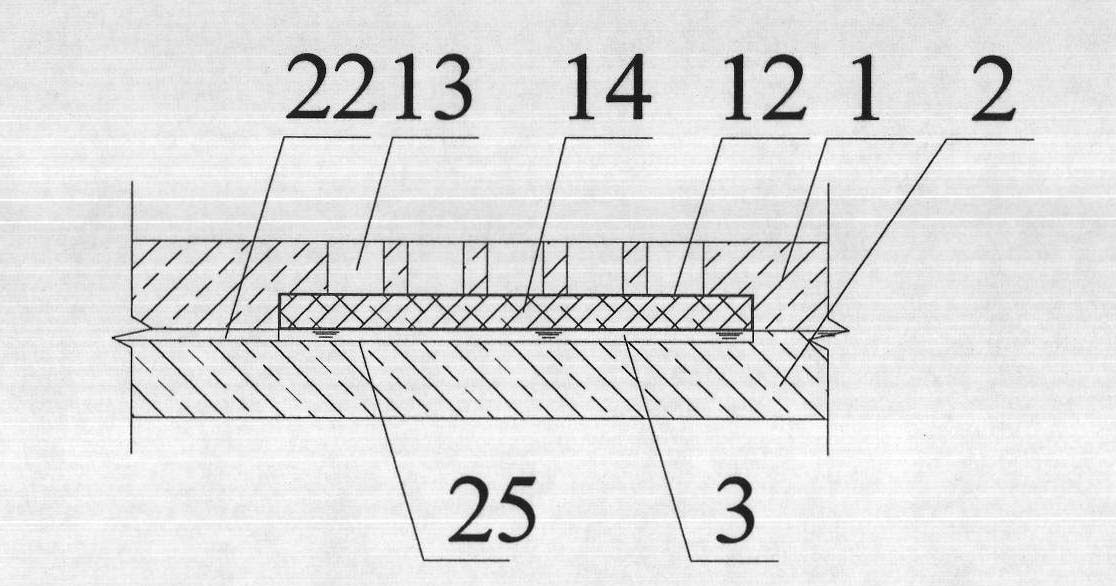

[0038] a kind of like Figure 1 ~ Figure 3 The shown microfluidic chip of the present invention includes a cover sheet 1 and a substrate 2 bonded to each other. The left side of the microfluidic chip is provided with two injection holes 11 with a diameter of 2 mm. Each injection hole 11 It is connected with a sample injection flow channel 21, and each sample injection flow channel 21 is connected to a main flow channel 22 after they meet. Flow channel 23, the narrow flow channel 23 has a width of 15 μm, and the main channel 22 before the entrance of the narrow flow channel 23 is filled with 1 mm long microbeads 24, and the microbeads 24 are made of bovine serum albumin-coated silica material Microbeads, microbeads 24 have a particle size of 20 μm; the substrate 2 is provided with a groove 25 as a waste liquid pool 3, and the outlet of the main channel 22 is connected to the waste liquid pool 3, and the cover sheet above the waste liquid pool 3 1 corresponds to an upper groove...

Embodiment 2

[0054] Nucleotide Fragmentation Sense (NTFS for short) was used to detect different concentrations of ATP in the microfluidic chip fabricated in Example 1 of the present invention.

[0055] The basic principle of the NTFS method is as follows Figure 10 As shown, this method relies on the high dependence of T4 DNA ligase on ATP; in the absence of ATP, nucleic acid fragment A (Oligo A) and nucleic acid fragment B (Oligo B) cannot completely bind to the loop site of the molecular beacon , the molecular beacon cannot be fully turned on, and no fluorescence-enhanced signal is produced. In the presence of ATP, T4 DNA ligase is activated by adenylation to form a ligase-AMP complex. The activated ligase uses the molecular beacon as a template to connect two short fragments of DNA, and the ligation product will be the molecular beacon On, produces a fluorescence-enhanced signal.

[0056] The specific steps for detecting the ATP concentration by using the NTFS method are as follows: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com