Patents

Literature

48 results about "Build to order" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Build to Order (BTO: sometimes referred to as Make to Order or Made to Order (MTO)) is a production approach where products are not built until a confirmed order for products is received. Thus, the end consumer determines the time and number of produced products. The ordered product is customized, meeting the design requirements of an individual, organization or business. Such production orders can be generated manually, or through inventory/production management programs. BTO is the oldest style of order fulfillment and is the most appropriate approach used for highly customized or low volume products. Industries with expensive inventory use this production approach. Moreover, "Made to order" products are common in the food service industry, such as at restaurants.

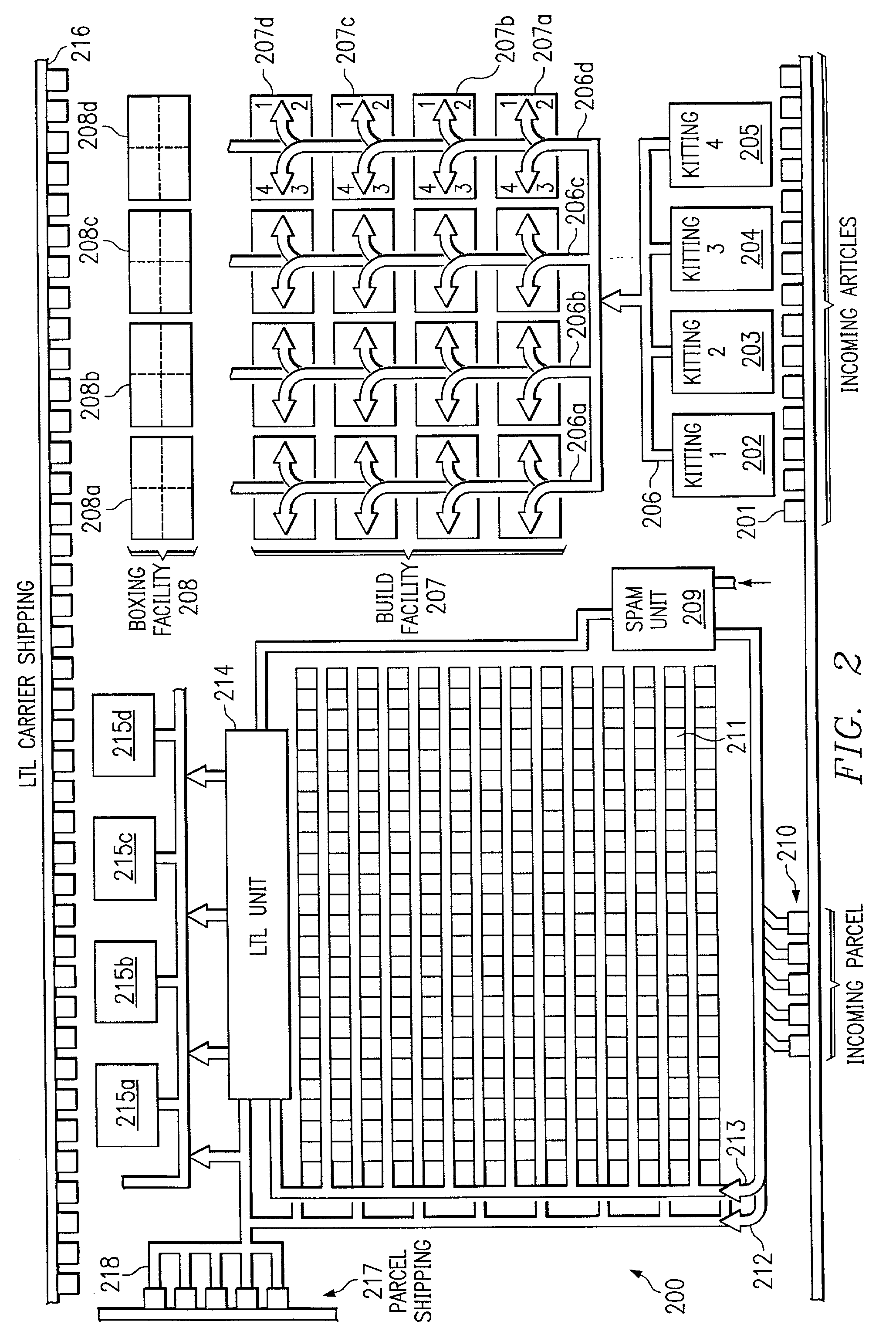

Method, system and facility for controlling resource allocation within a manufacturing environment

InactiveUS6615092B2Low production costDigital data processing detailsResourcesWork in processBuild to order

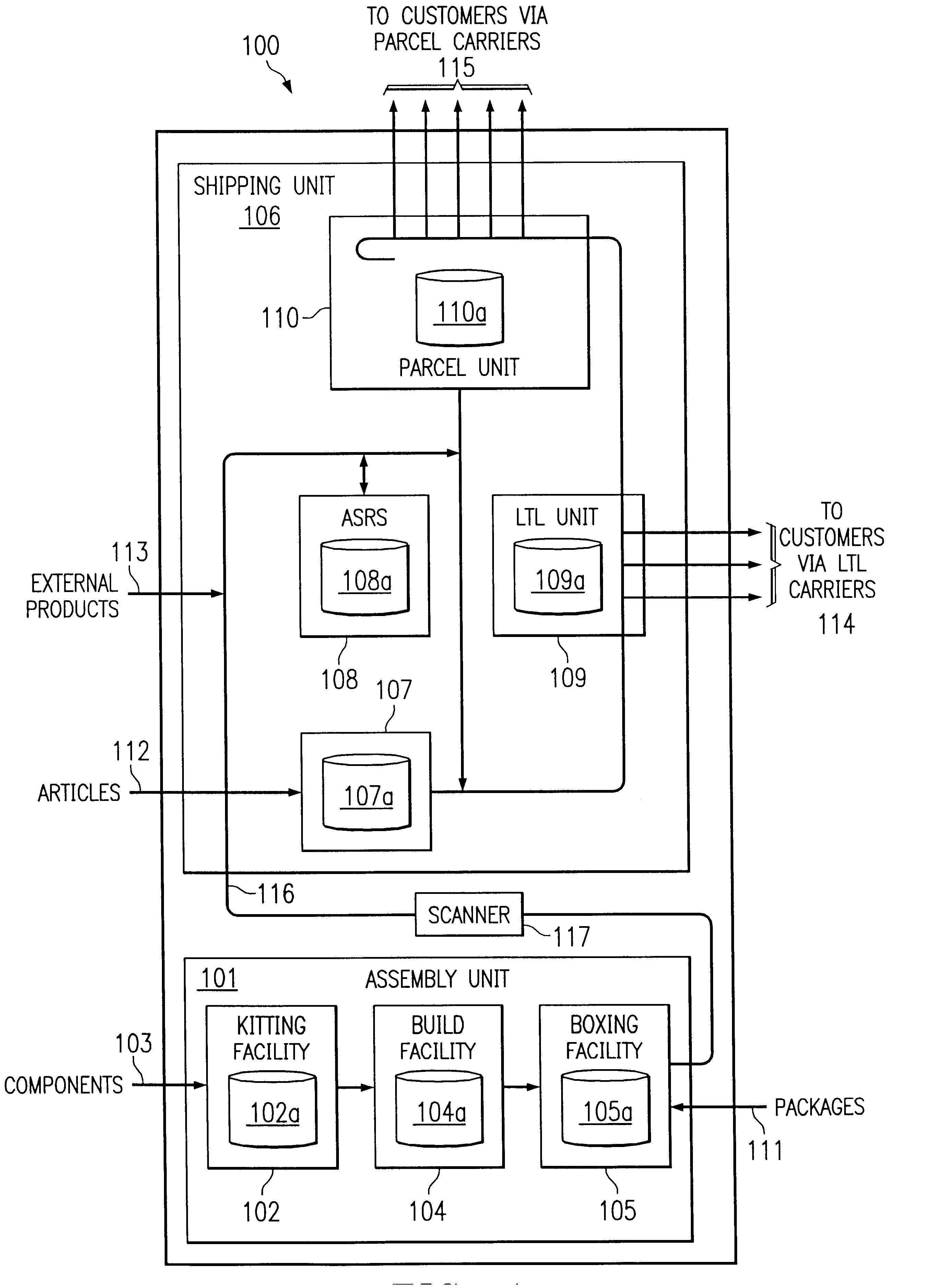

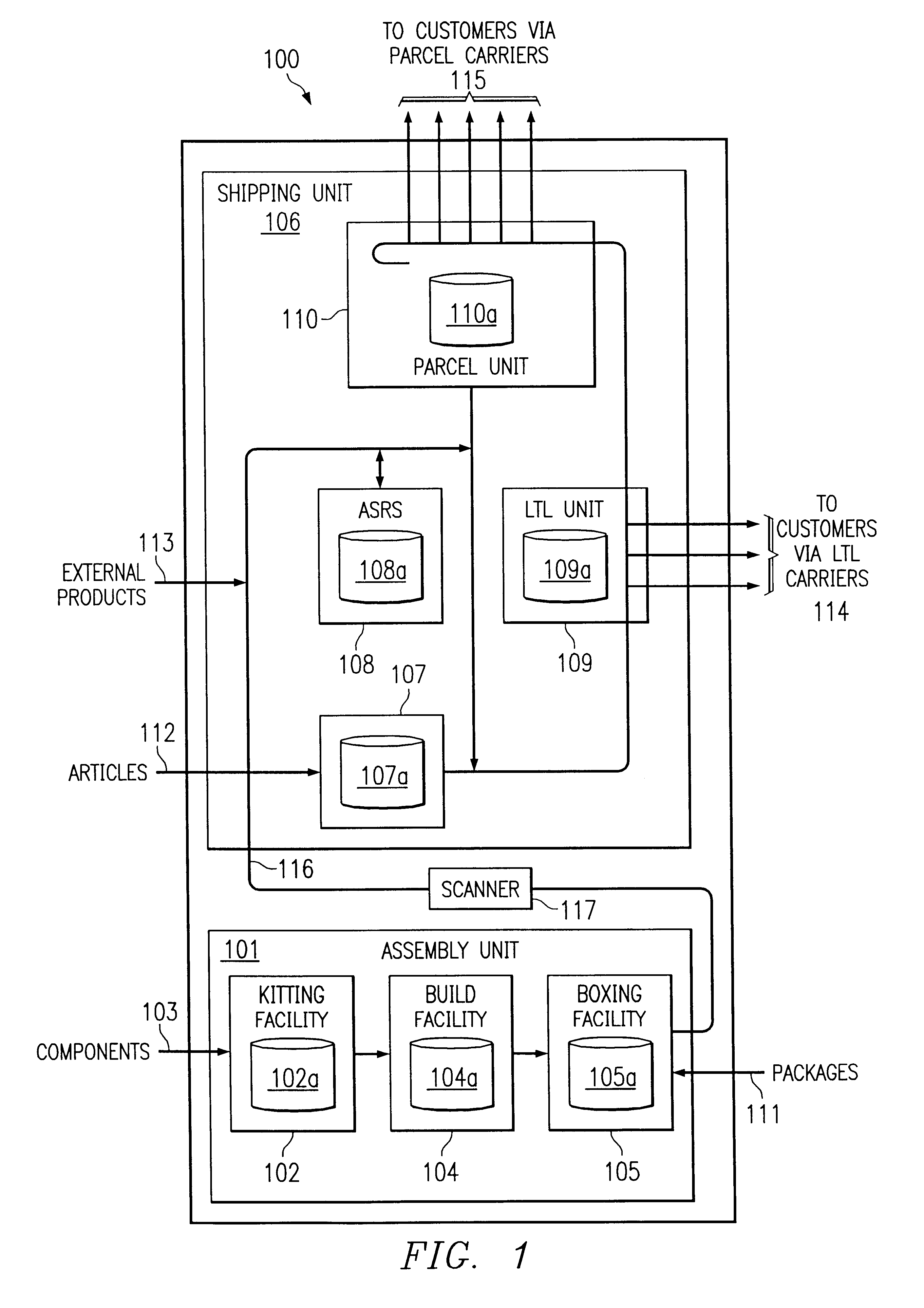

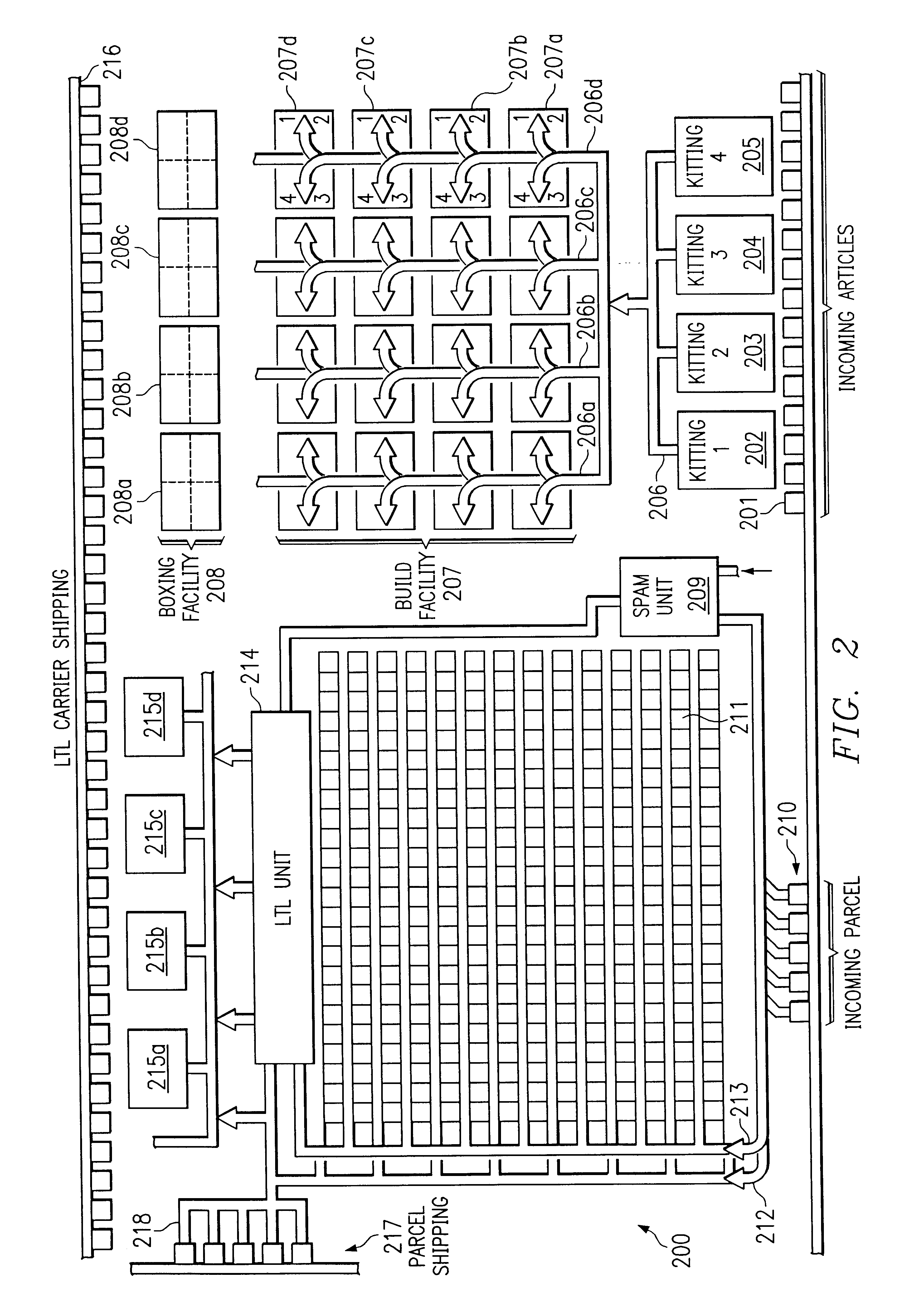

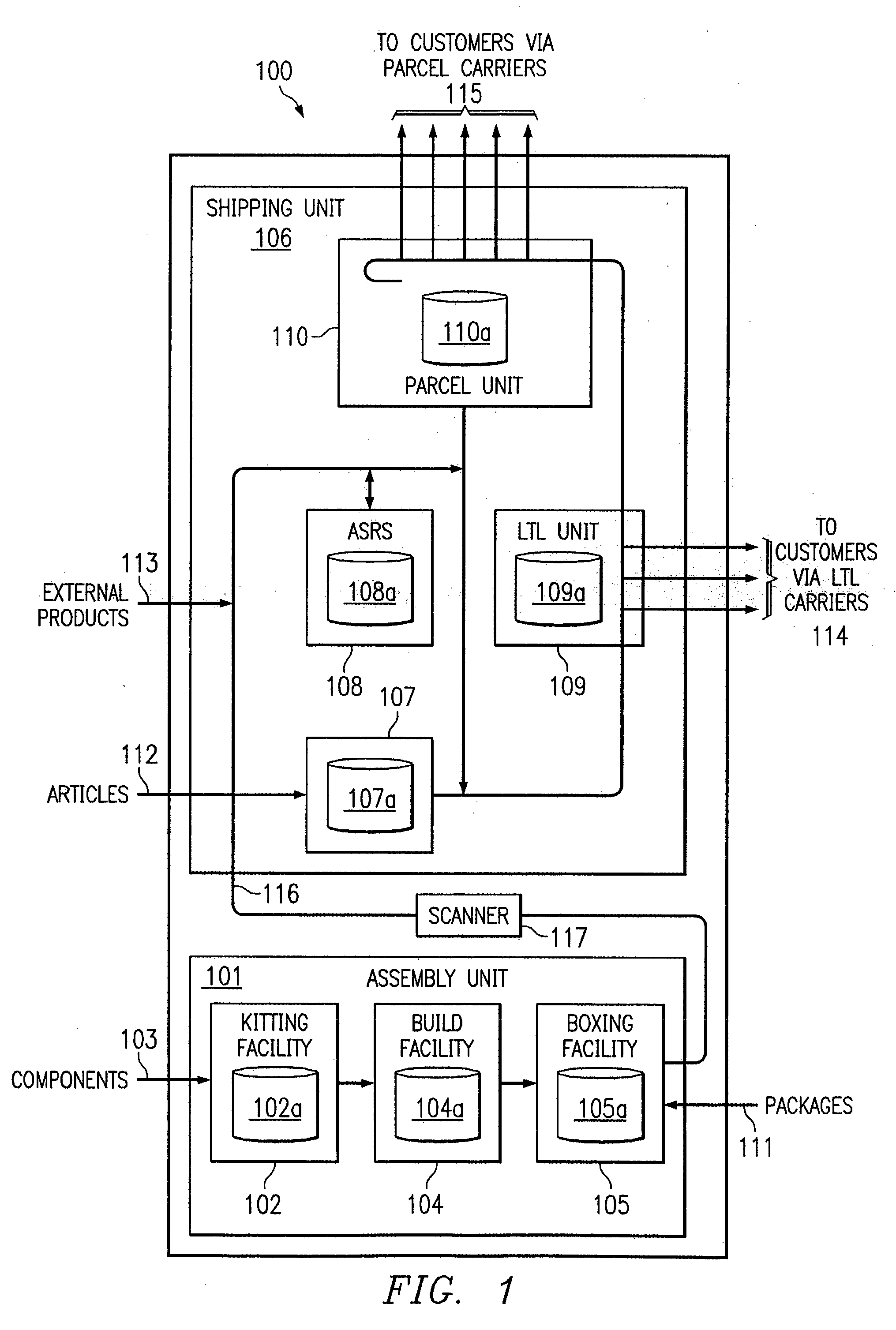

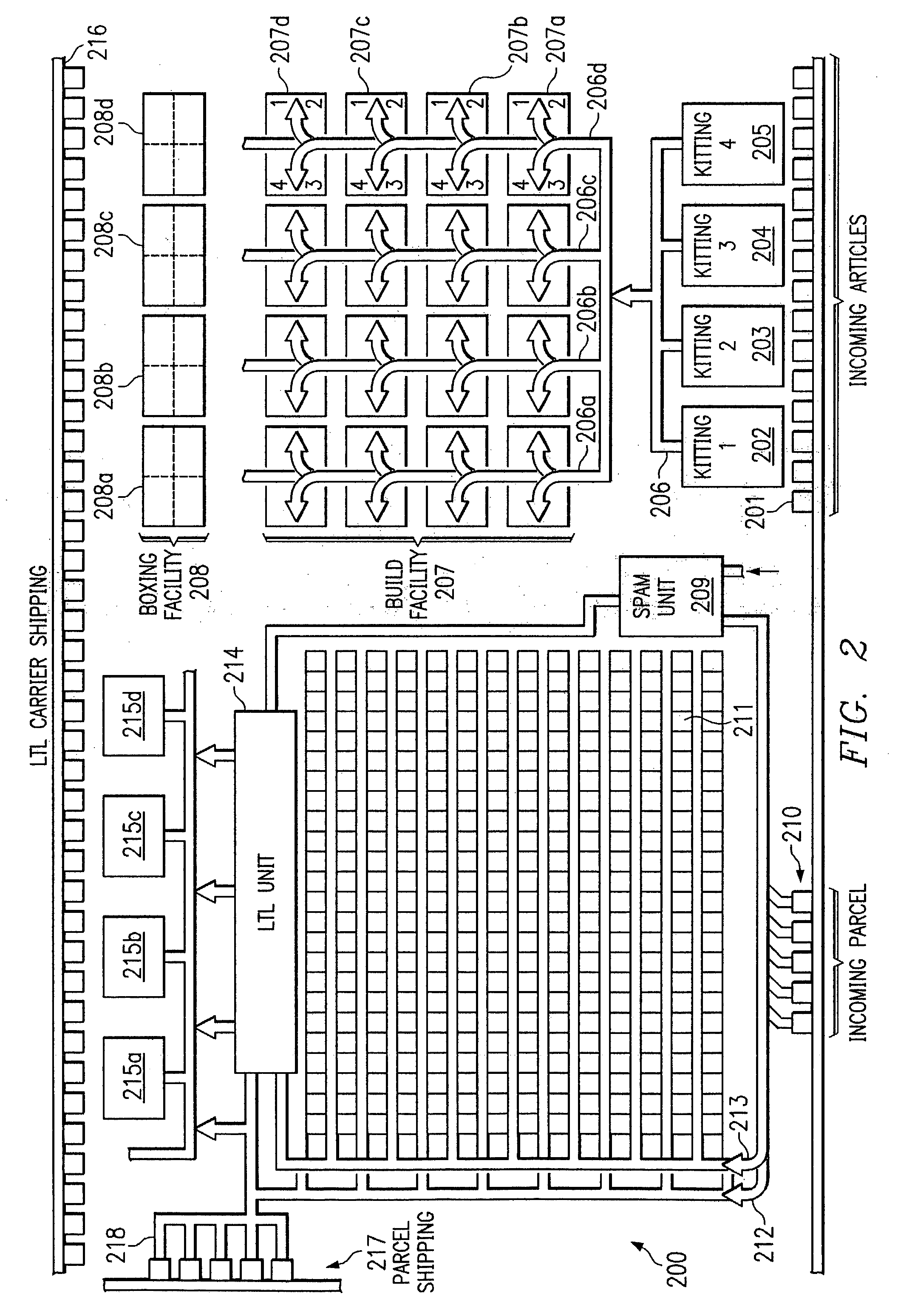

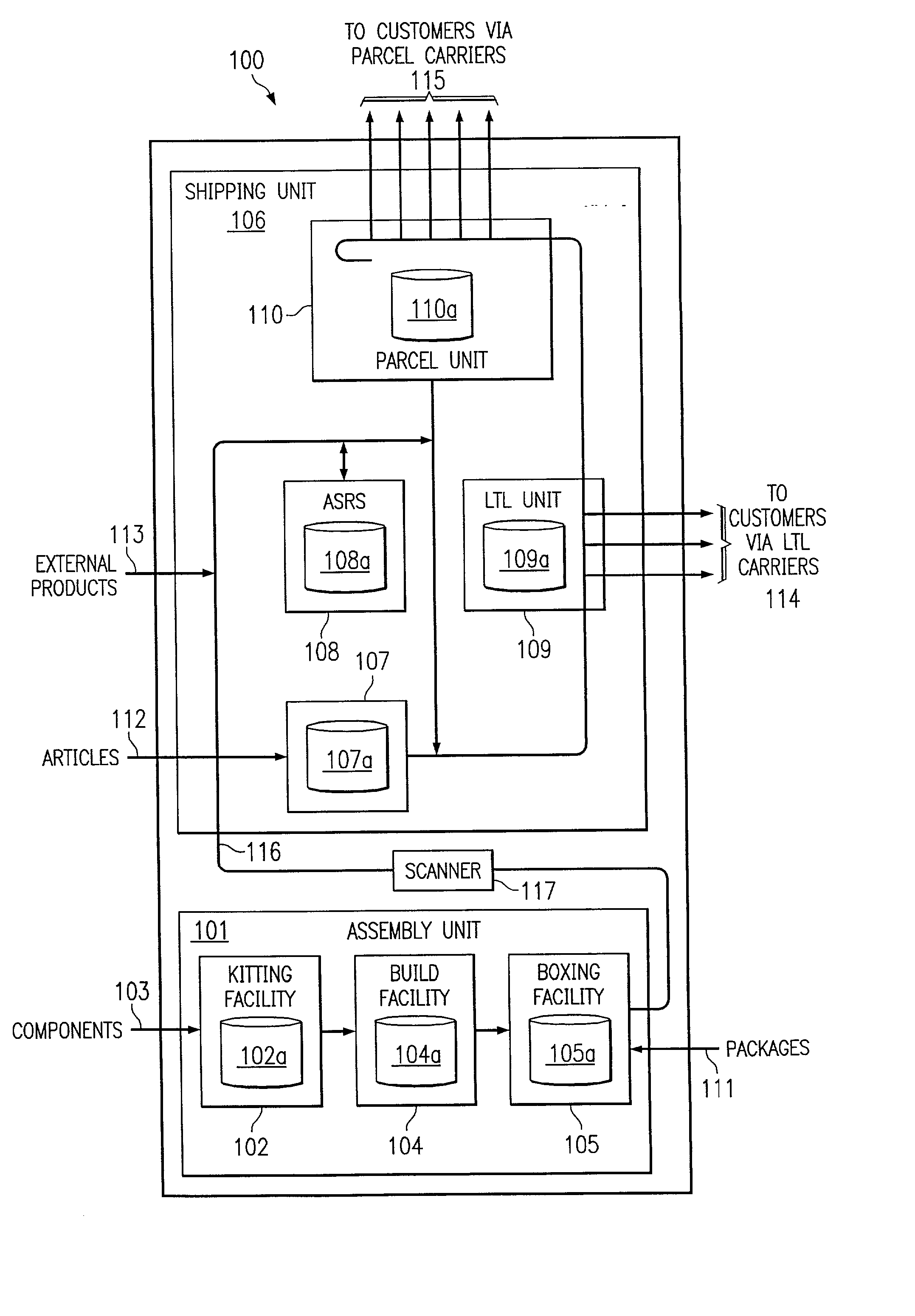

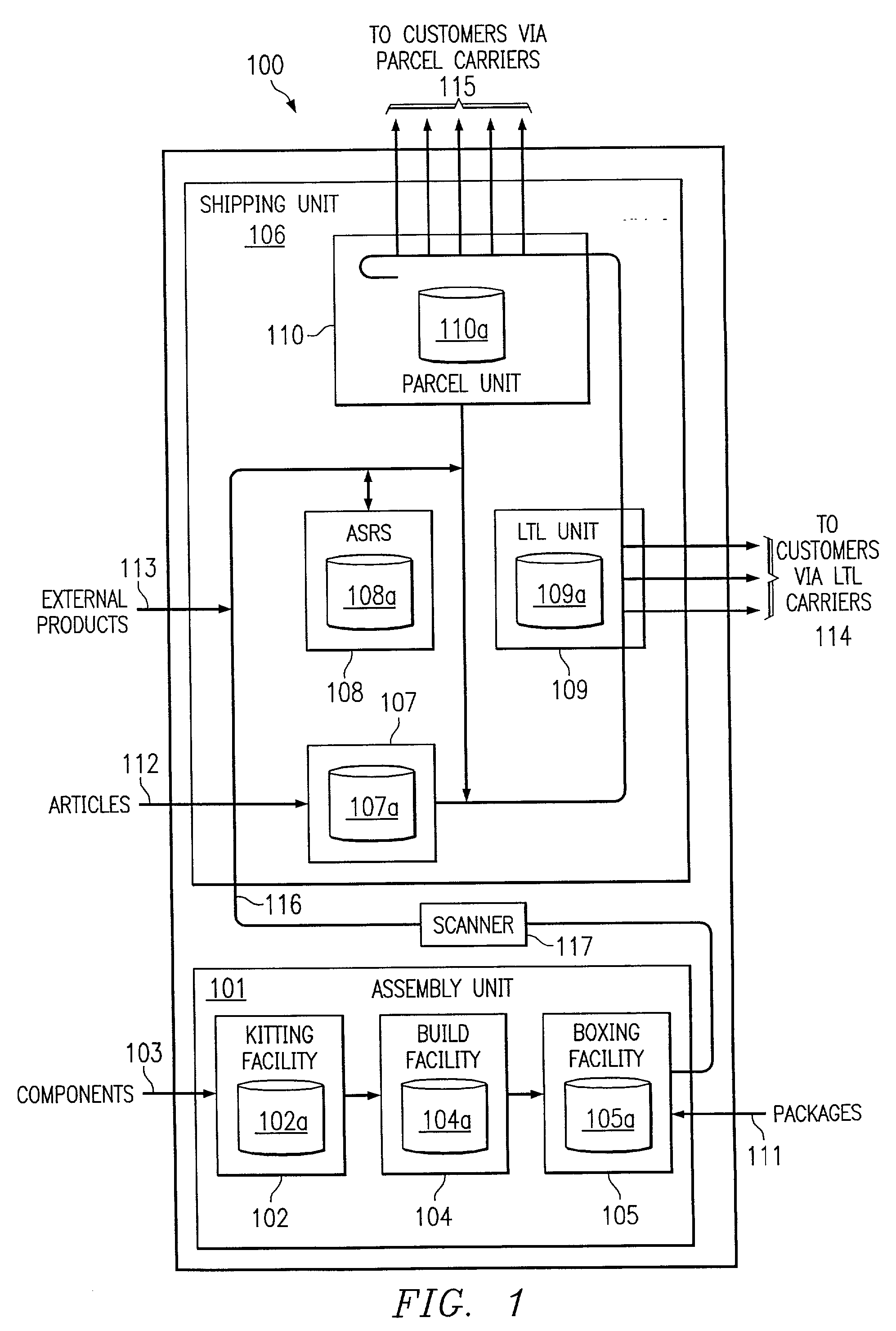

A method, a system and a facility provide for the control of resource allocation within a build to order manufacturing environment. A system for providing a control center for a manufacturing facility is disclosed. The system includes a plurality of information sources operably associated with manufacturing products within the manufacturing facility. A user interface of the system displays selective information associated with portions of the manufacturing facility within a control center operable to manage production within the manufacturing facility. The system further includes a resource allocator operably coupled to the control center and the plurality of information sources and the resource allocator is operable to monitor work in process within the manufacturing facility.

Owner:DELL PROD LP

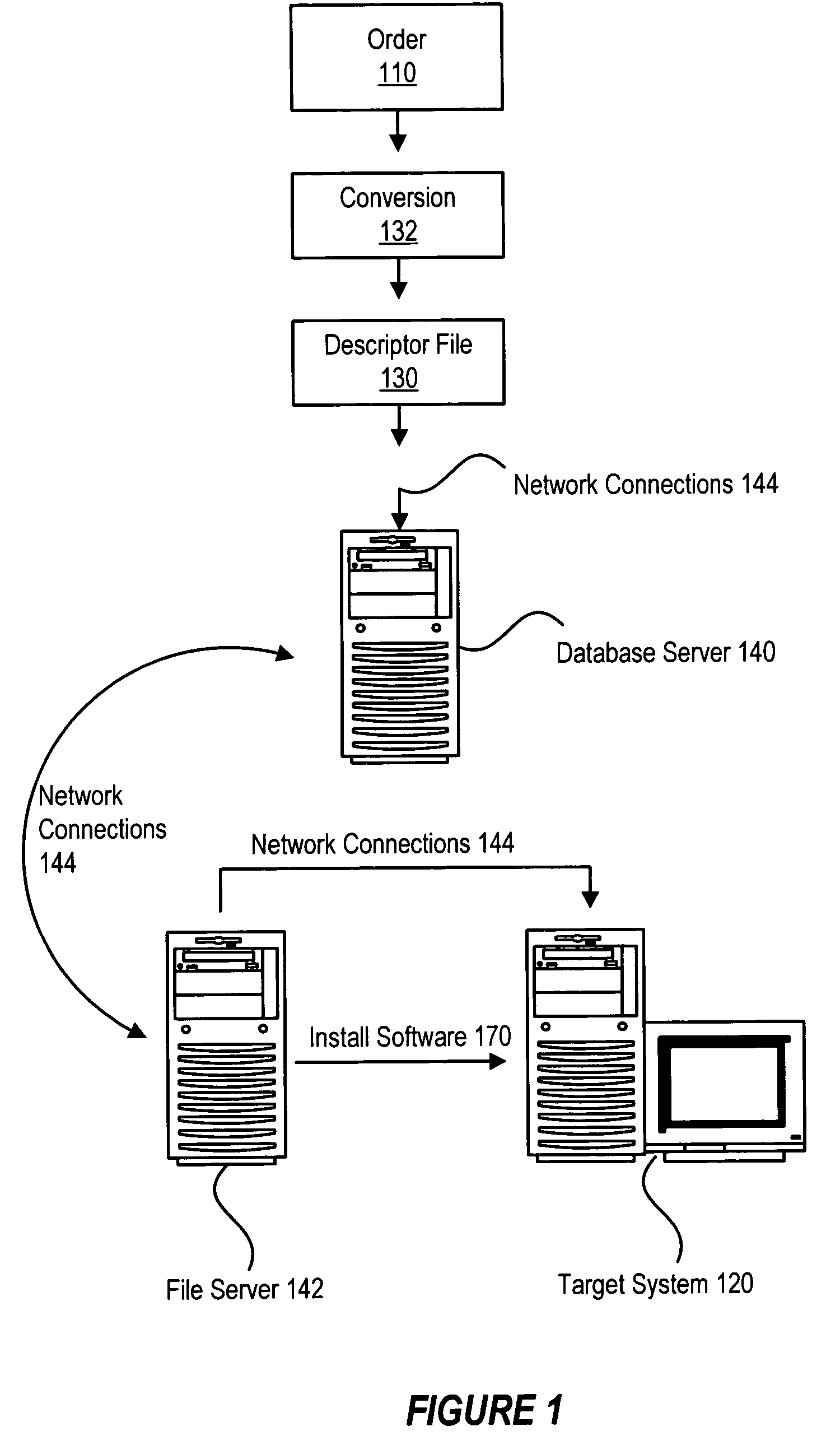

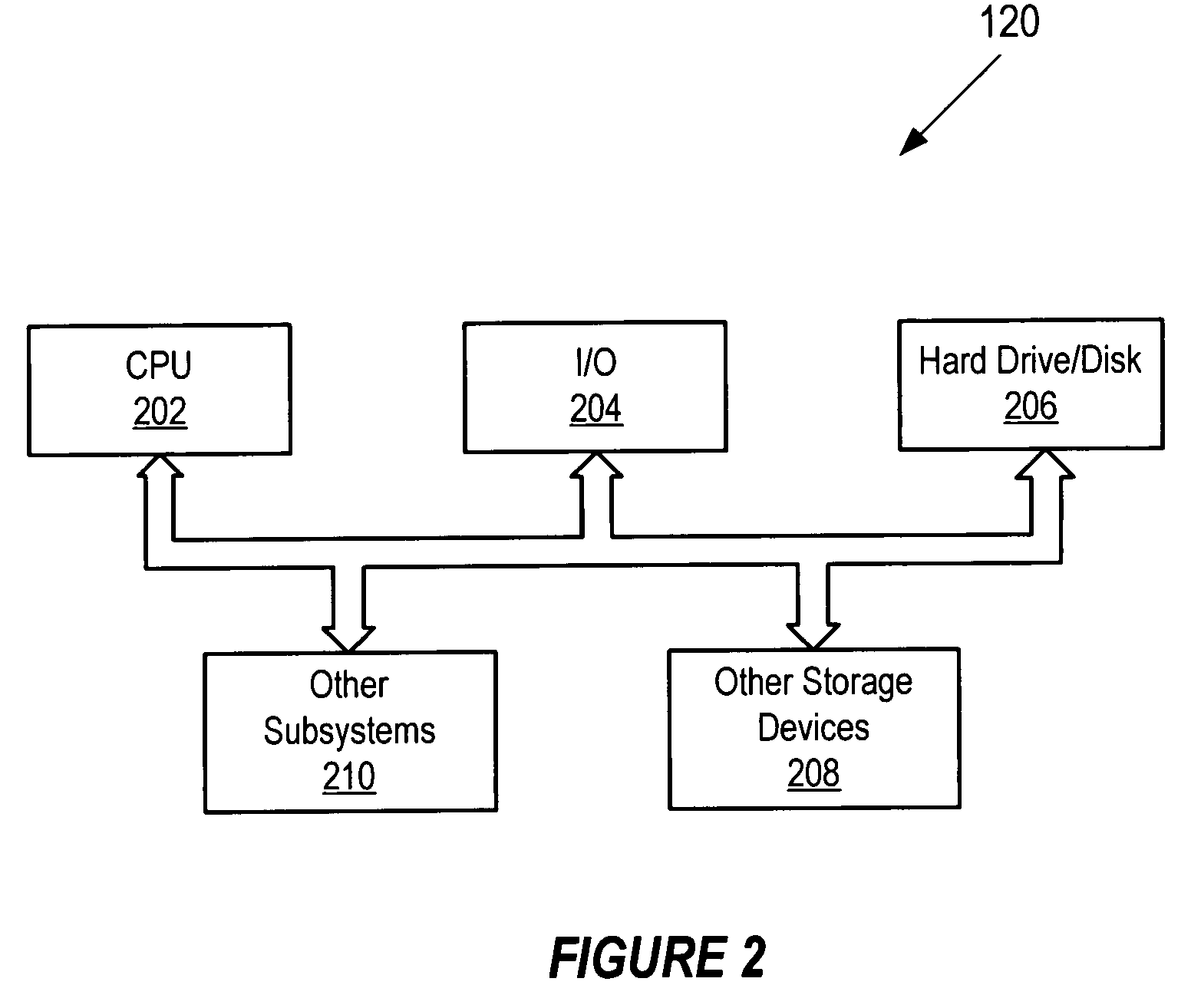

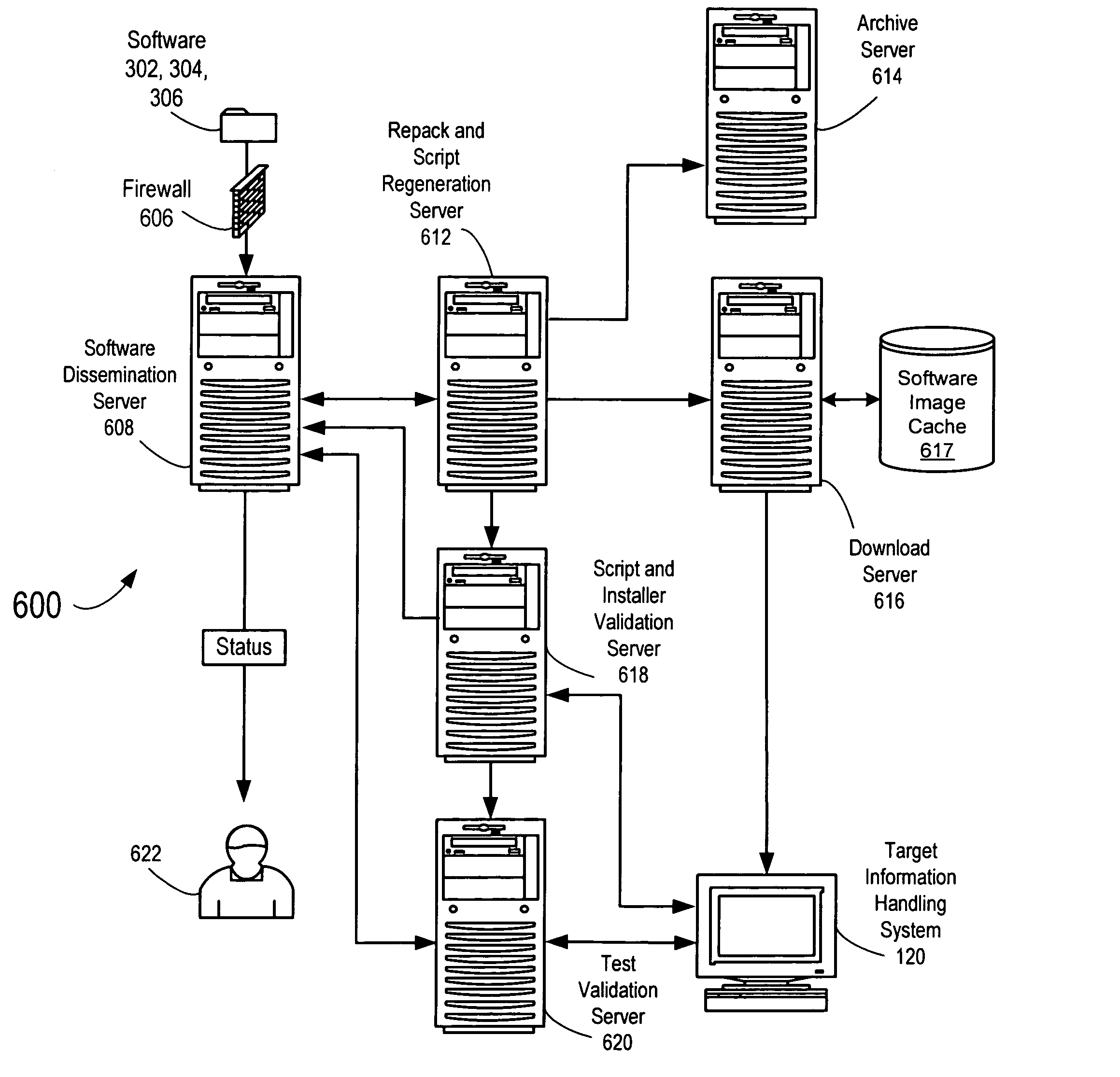

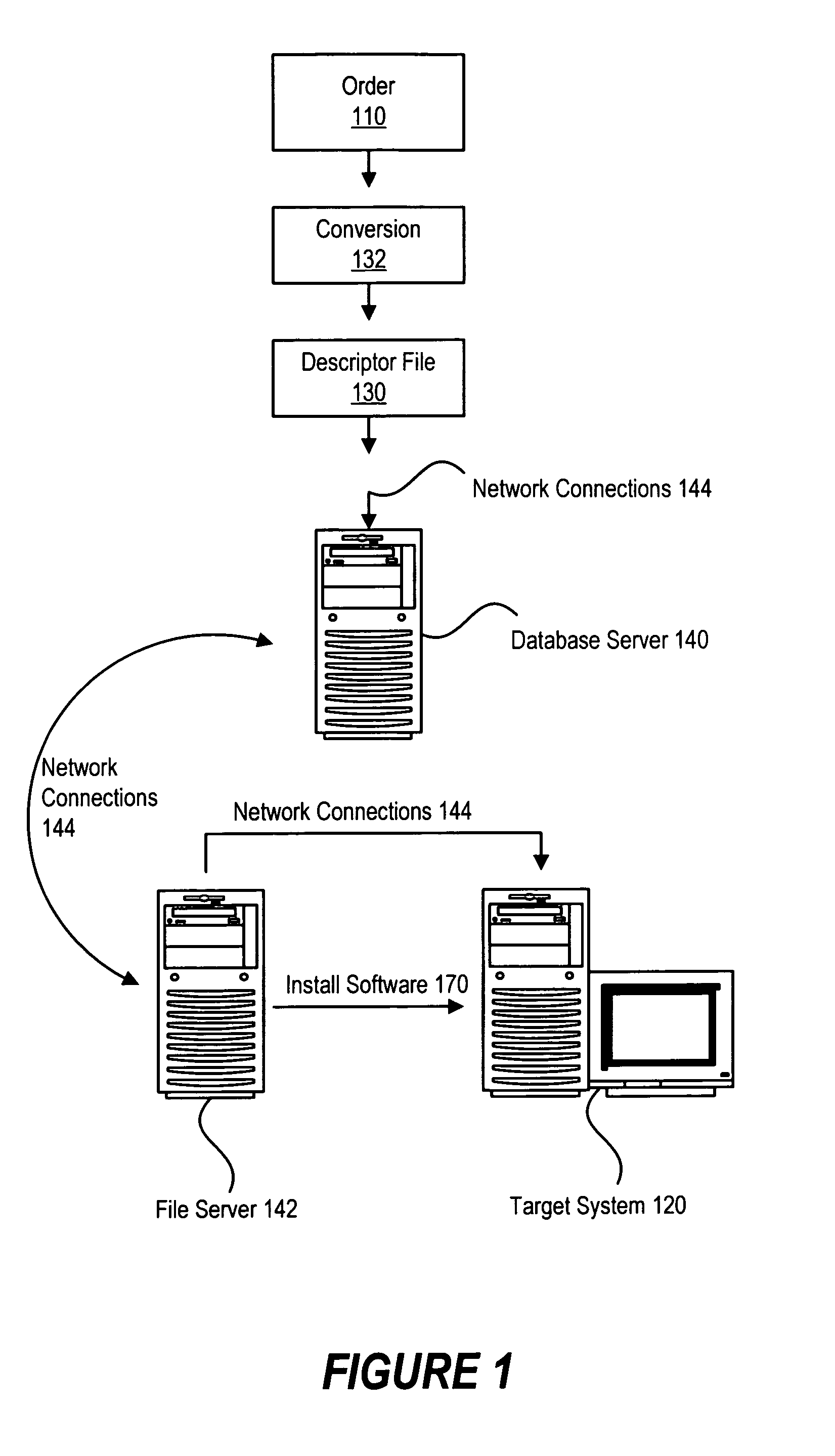

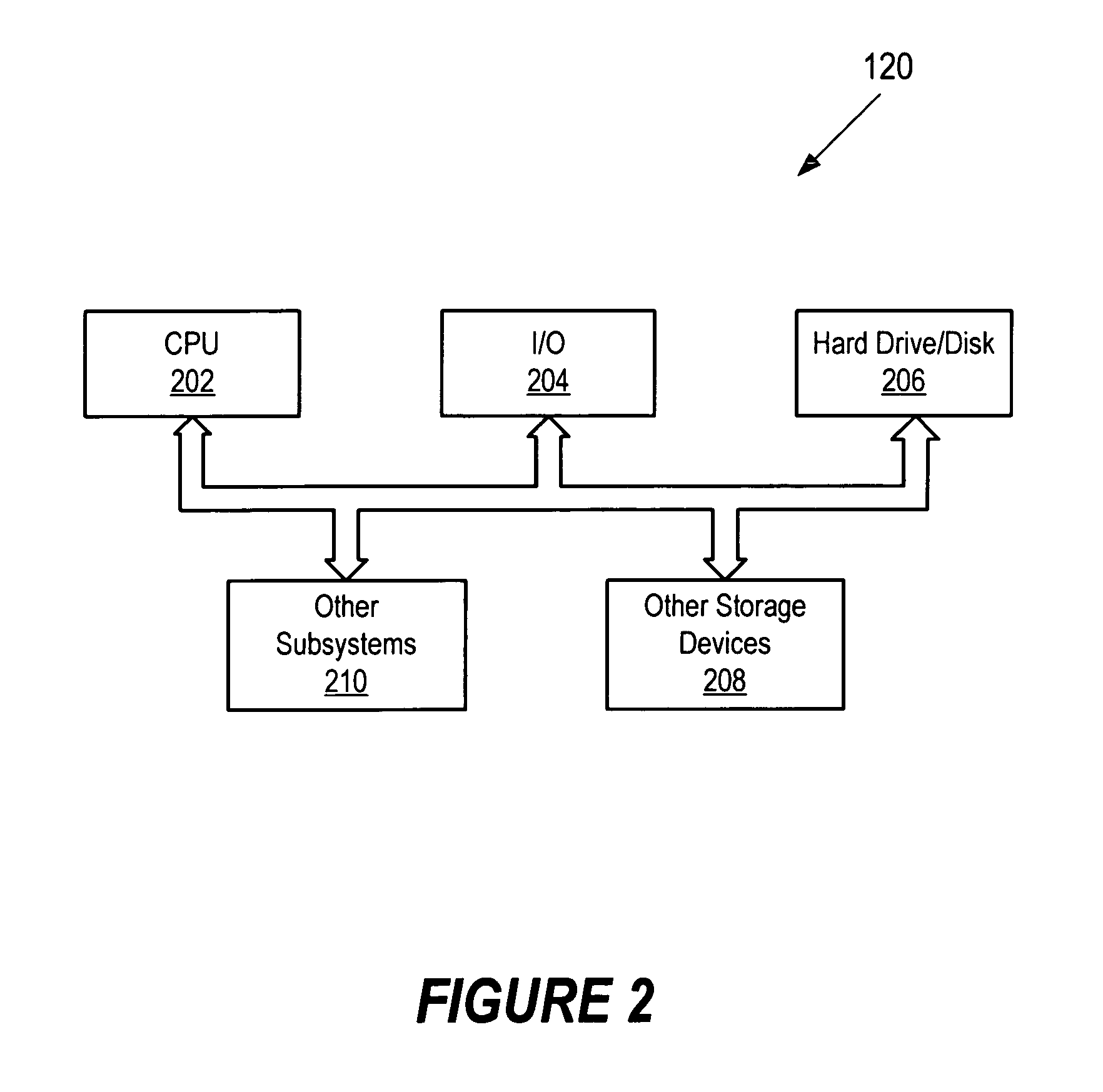

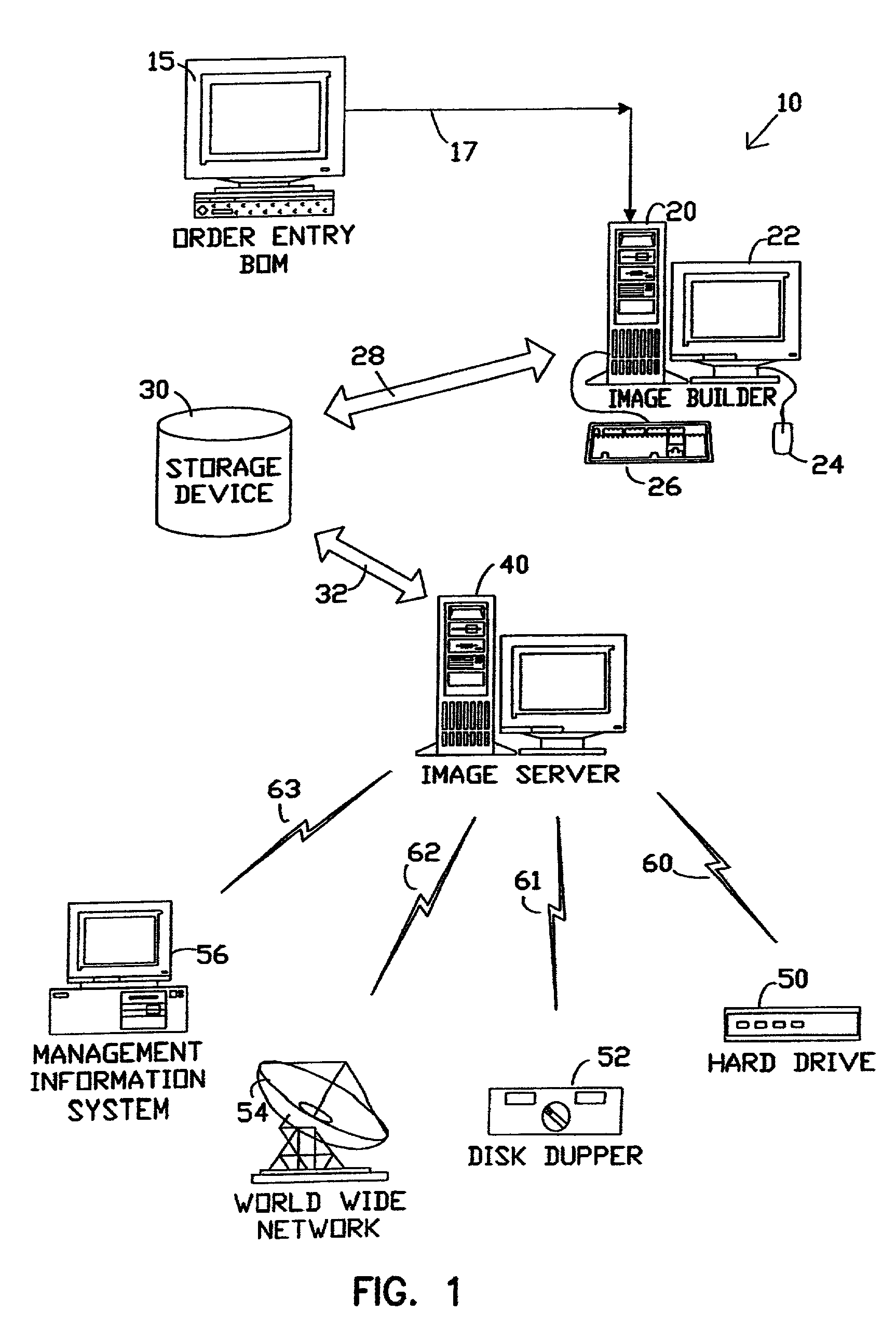

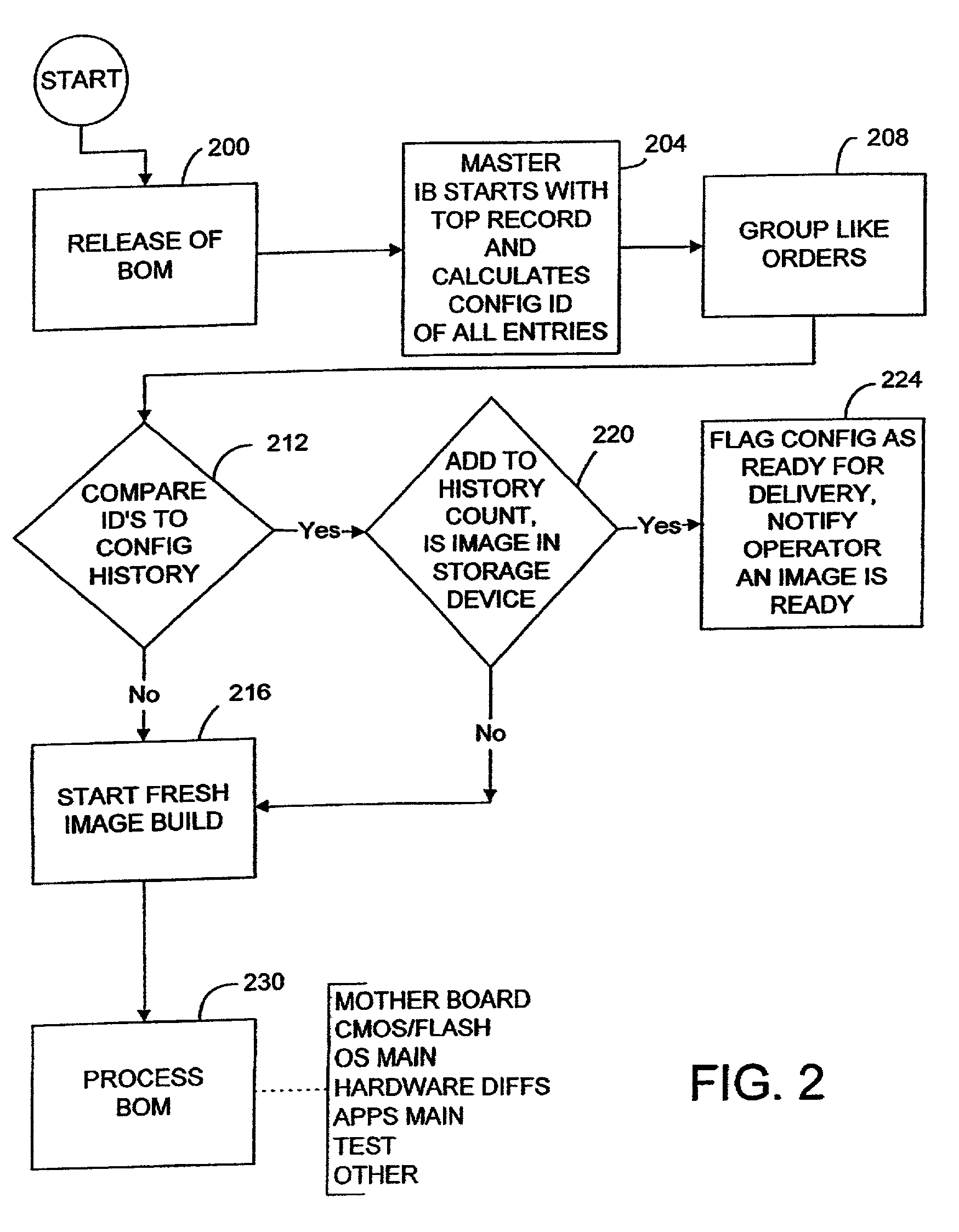

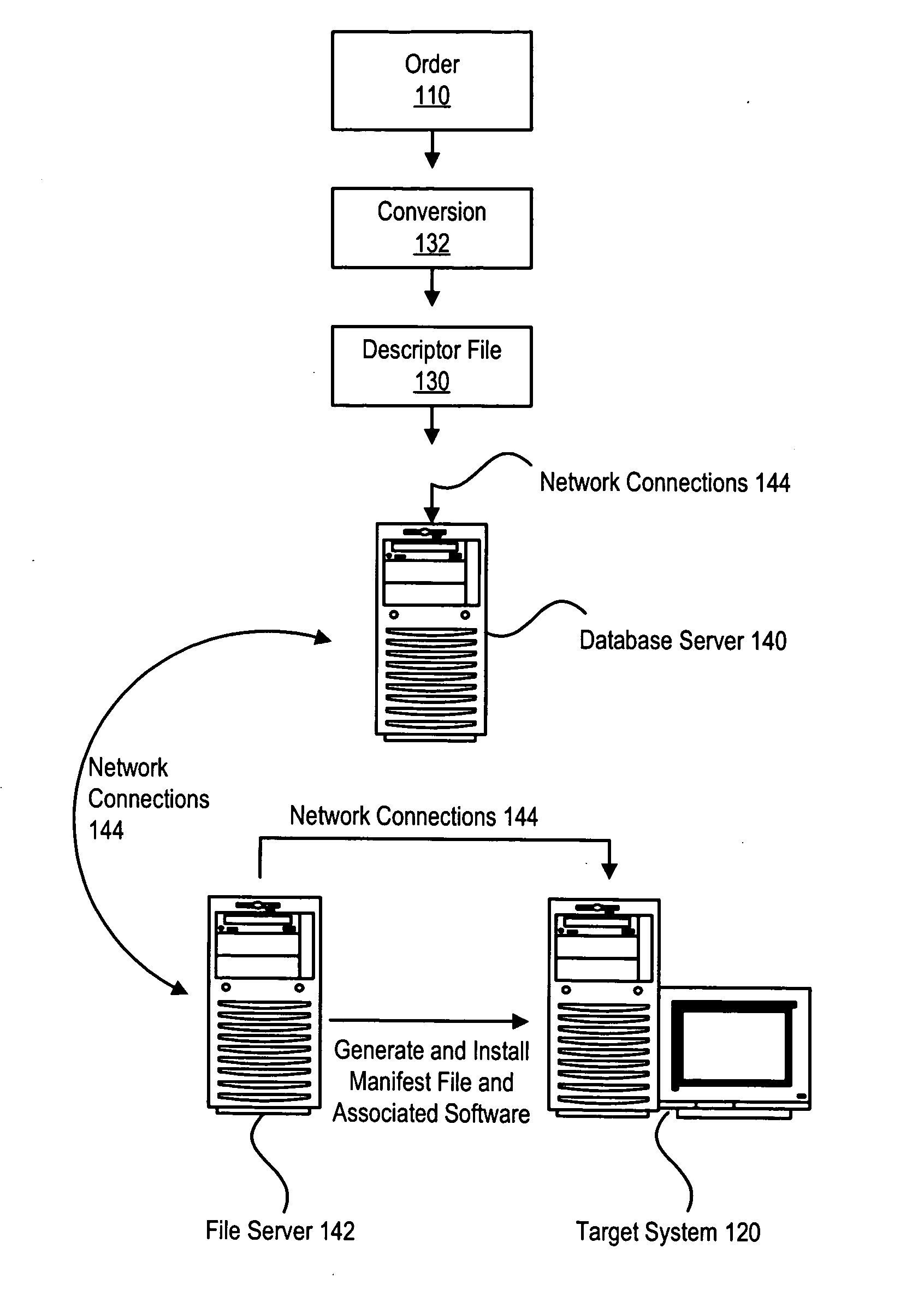

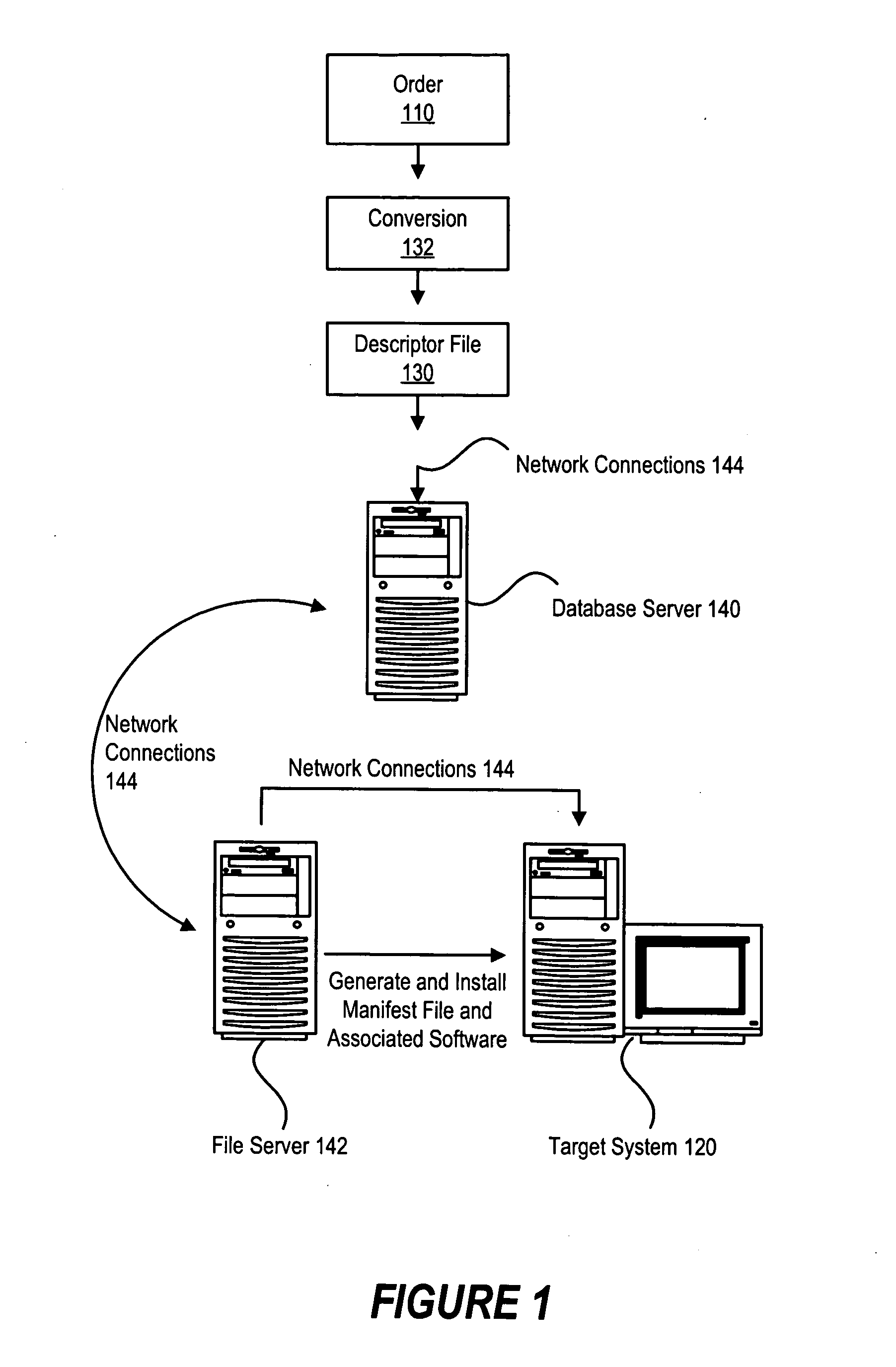

Method and system for automated generation of customized factory installable software

InactiveUS20050172284A1Reduce errorsShorten the timeProgram loading/initiatingMemory systemsInformation processingHandling system

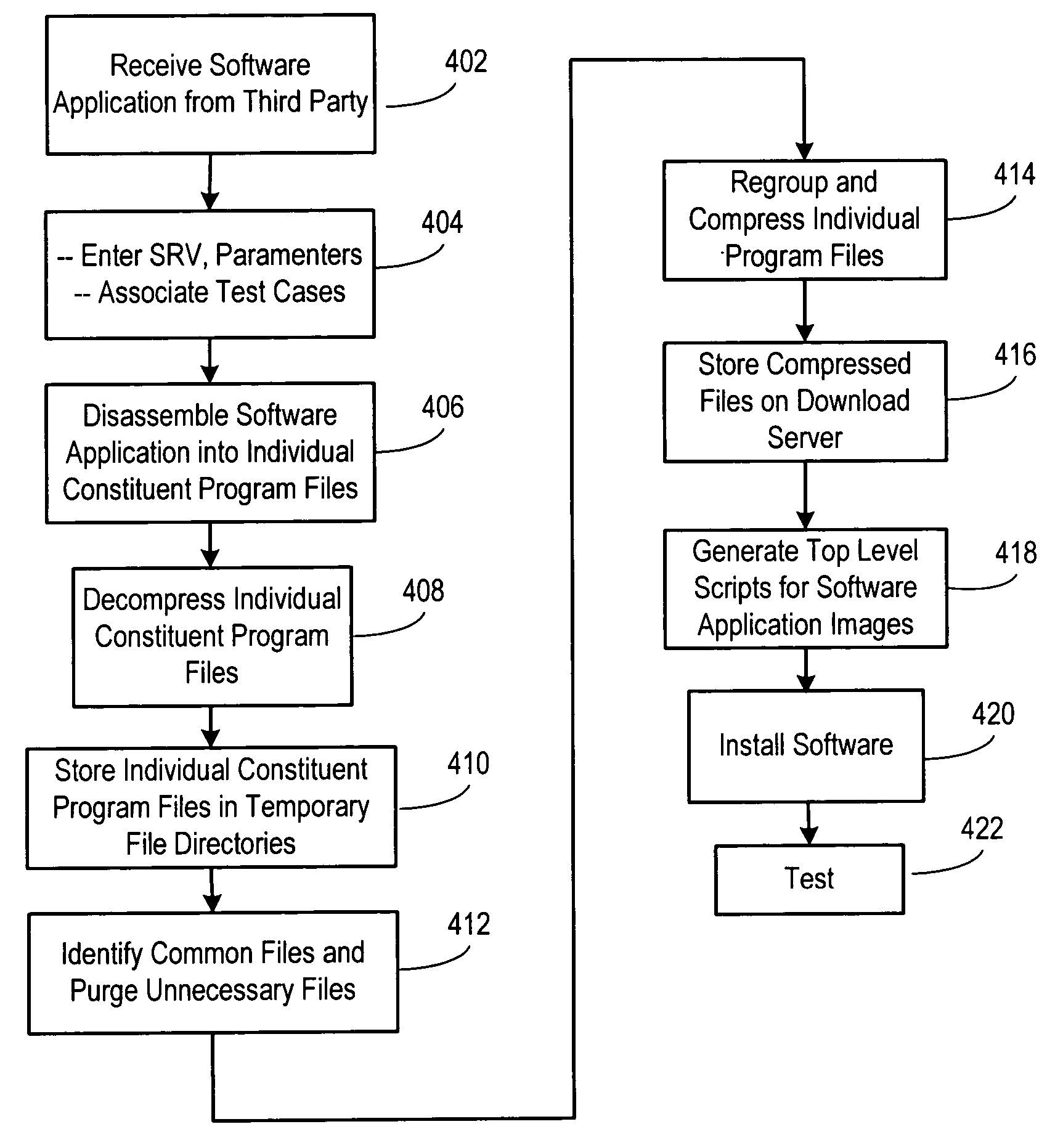

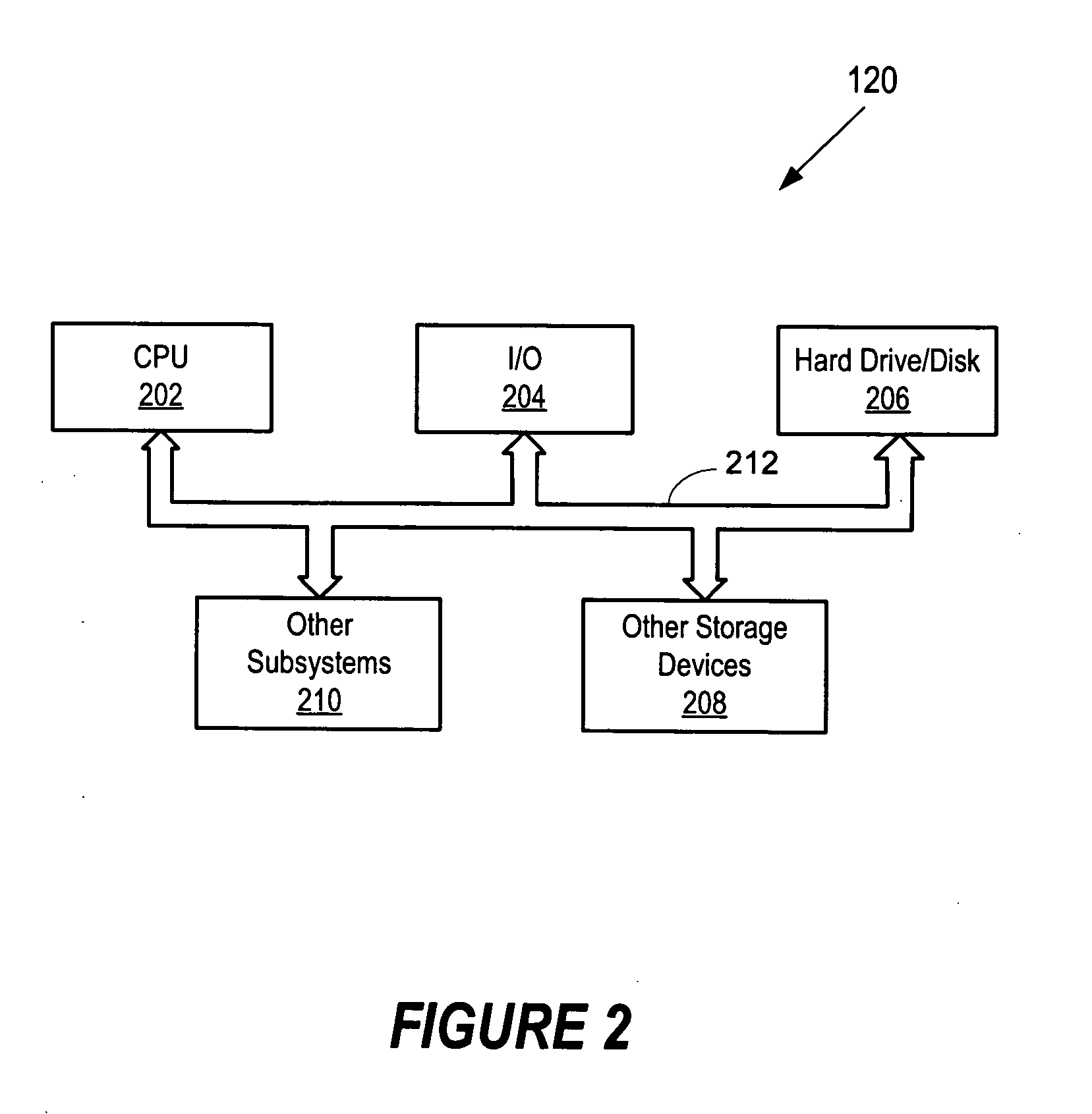

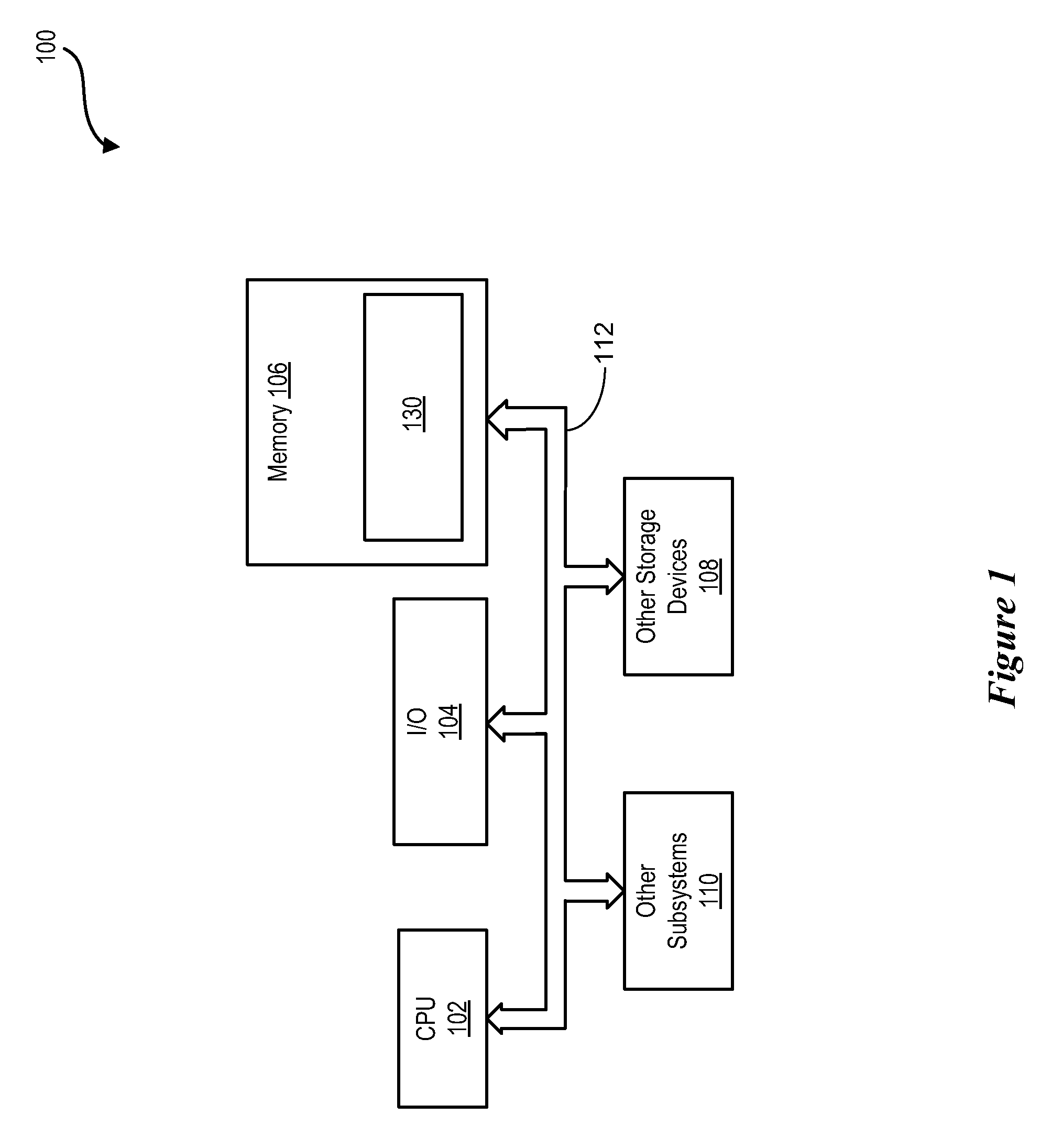

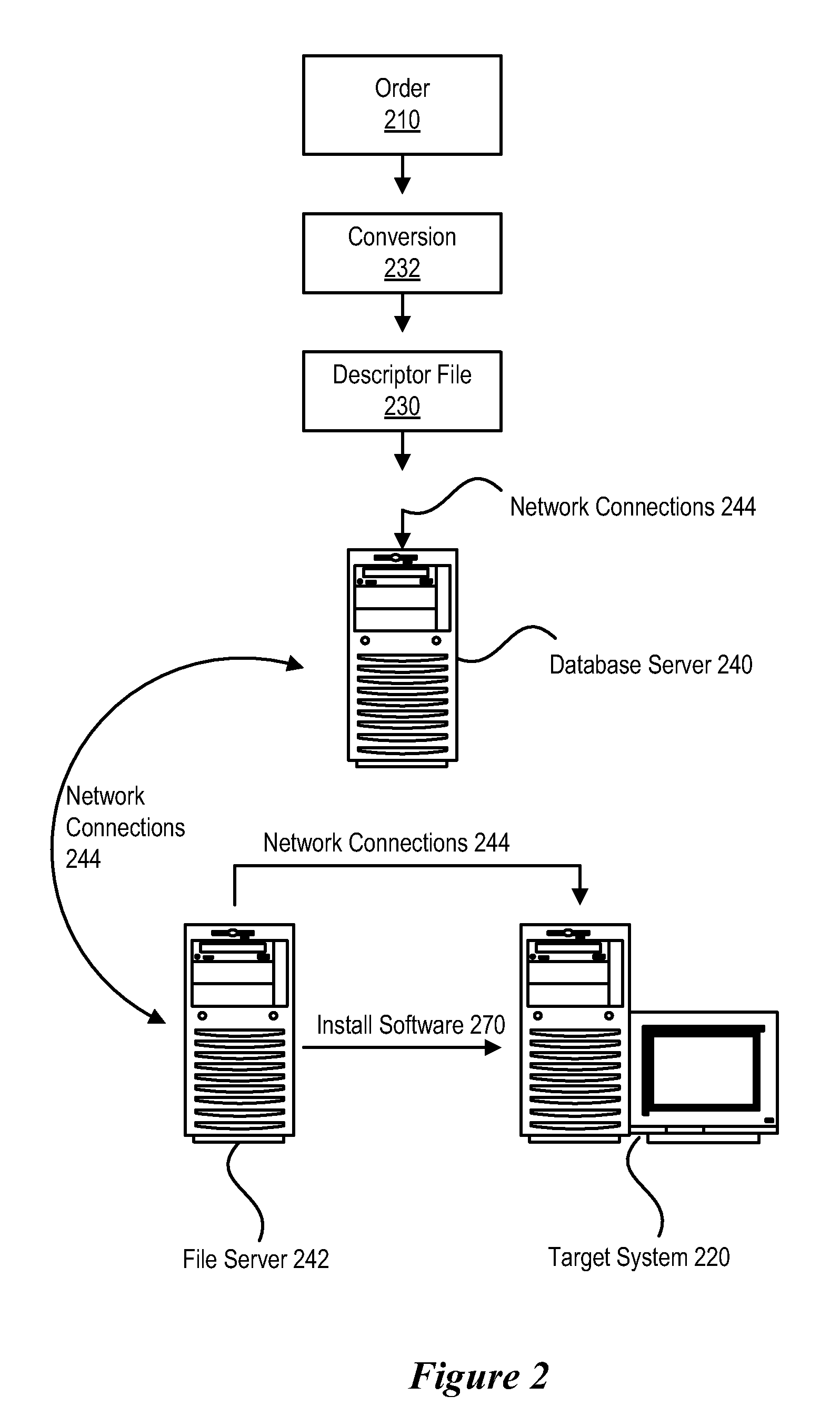

An automated system for software installation in a build-to-order information handling system. In one embodiment of the invention, a plurality of software applications are received and are disassembled to separate the individual constituent program files. These program files are decompressed and are stored in temporary file directories. Program files that are common to each of the software applications are identified and indexed. After the file analysis, the files are regrouped and a stored as a new set of compressed files. Once the new set of compressed files has been created, the top level scripts for the software application images are updated for use with the new compressed files to allow the desired combinations of software applications to be regenerated. The regenerated compressed files are then loaded into the factory servers for use in manufacturing information handling systems.

Owner:DELL PROD LP

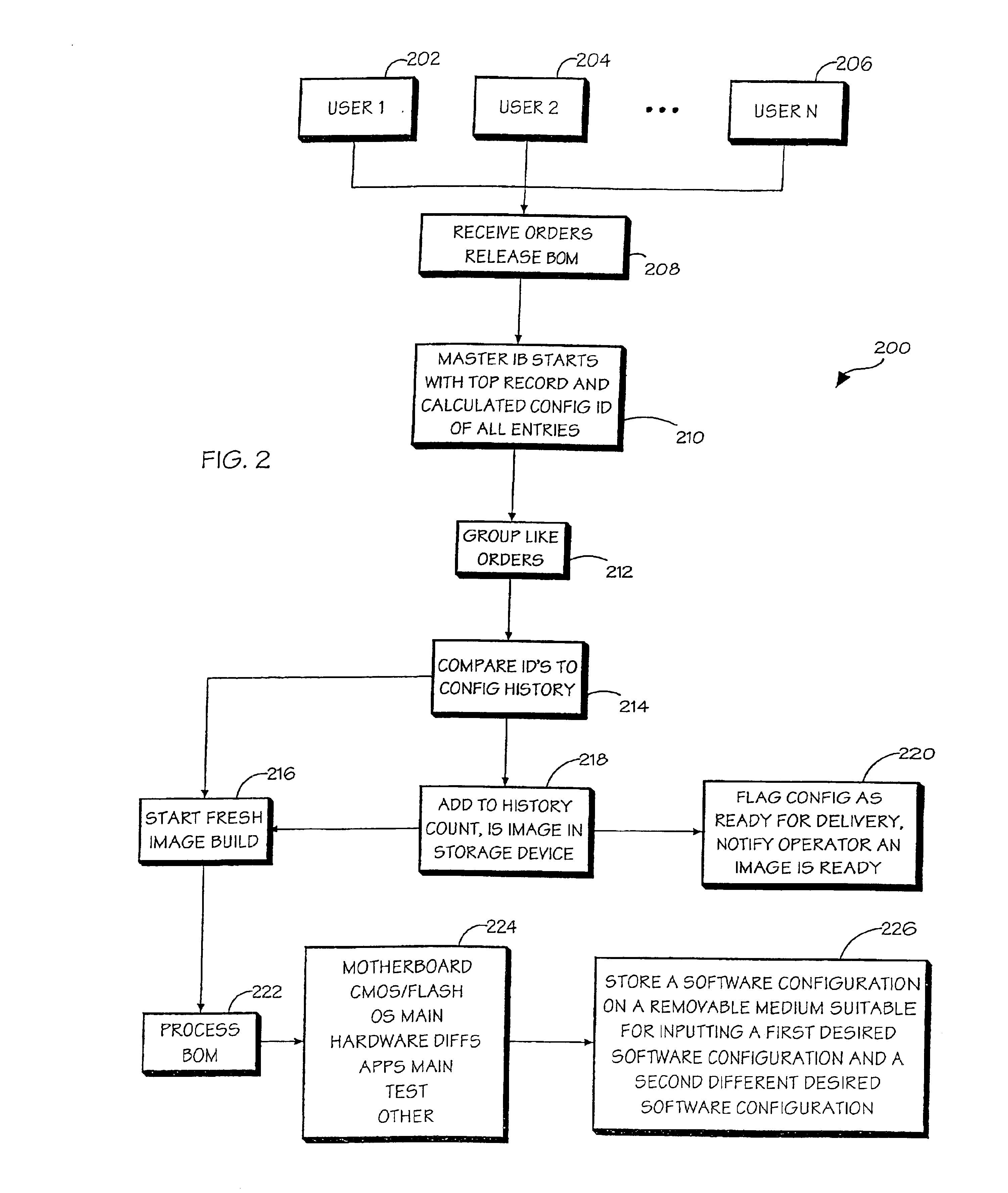

Method for configuring software for a build to order system

The present invention is directed to a method of building a custom software configuration, which may include receiving a first customer order for a first information handling system and a second customer order for a second information handling system. The first customer order including a first list of hardware configuration components and a first list of software configuration components and the second customer order including second list of hardware configuration components and a second list of software configuration components. At least one of the first list of hardware configuration components is different from the second list of hardware configuration components and the first list of software configuration components is different from the second list of software configuration components. At least one software configuration is stored on a removable medium, the at least one software configuration suitable for loading at least one of the first list of software configuration components and the second list of software configuration components onto at least one of the first information handling system and the second information handling system.

Owner:GATEWAY

Cache system in factory server for software dissemination

InactiveUS20050125524A1Minimizing size of cacheReduce the amount requiredCode conversionDigital computer detailsInformation processingFile comparison

A method and apparatus for minimizing the size of the cache that is required to store software packages for installation on an information handling system. An analysis is conducted on the individual program files contained in a software application file. In the analysis, the software application file is disassembled into the individual program files and each of the program files is decompressed and stored in temporary file directories. Files that are common to each of the software packages are identified. After the file comparison, the method and apparatus of the present invention is used to re-group the files to generate a composite program file library that contains all of the program files needed to regenerate the software application files. This composite program file library is then stored on a cache in a factory server used to manufacture information handling systems in a build to order process.

Owner:DELL PROD LP

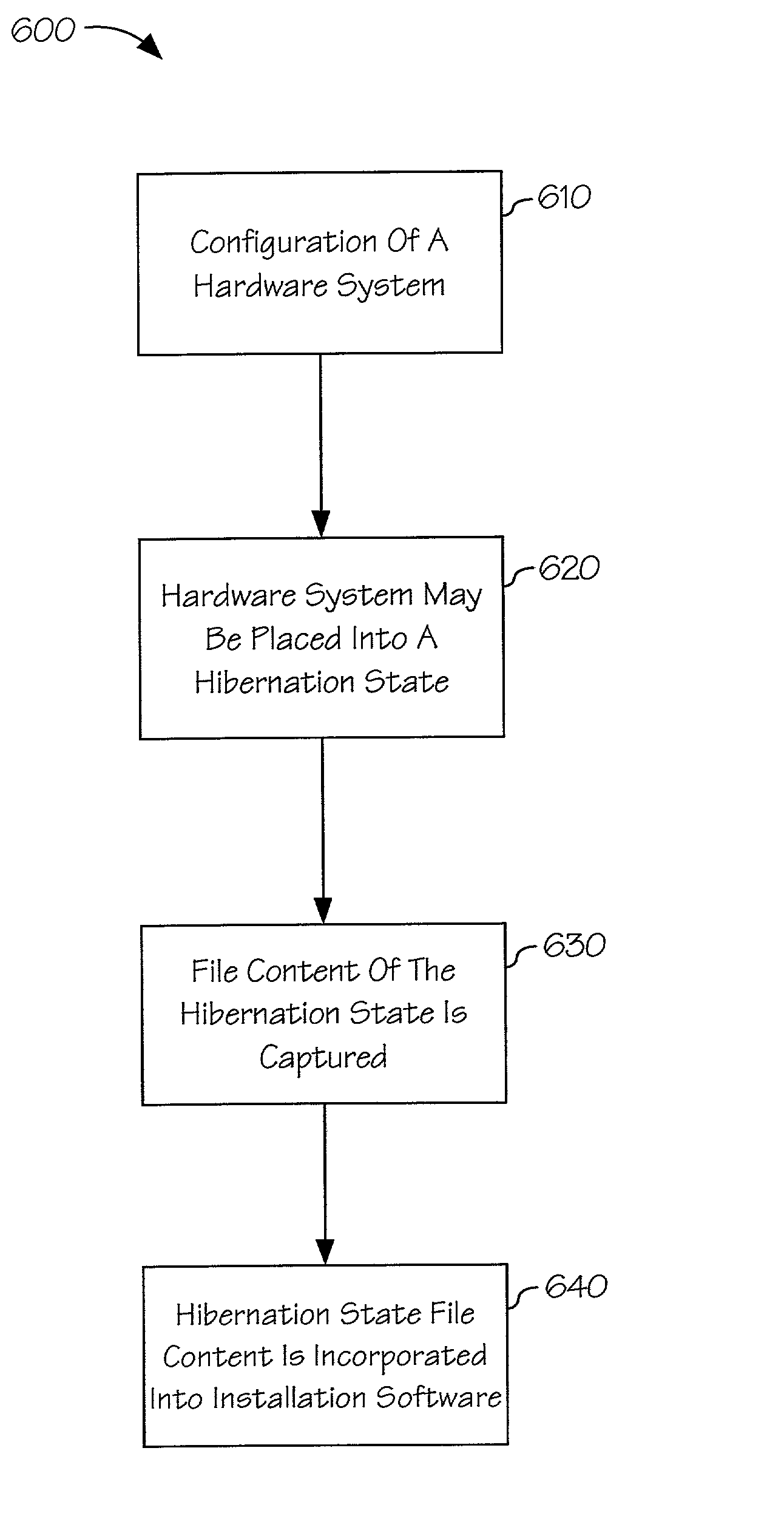

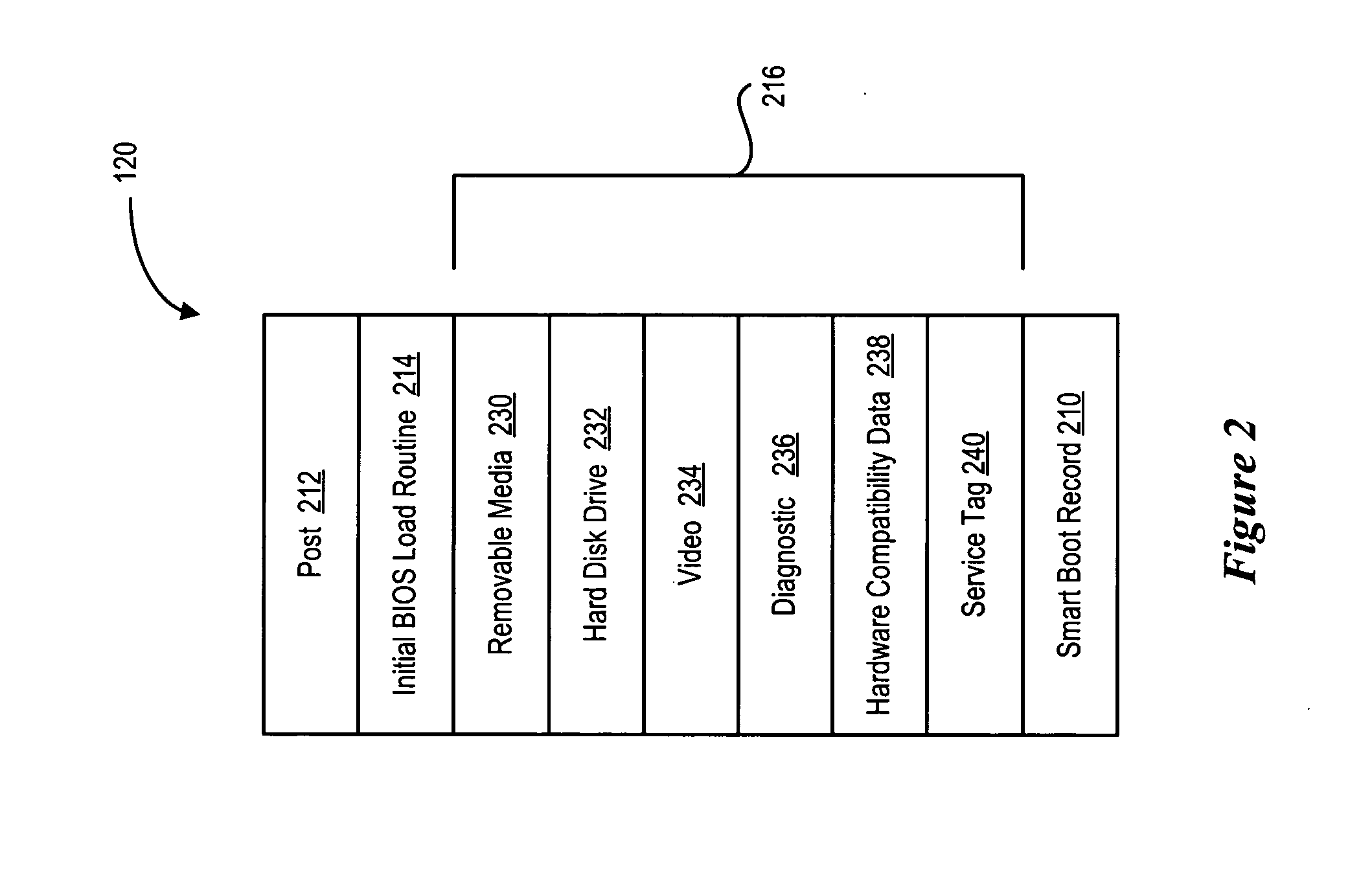

Build to order personal computer manufacturing fast boot method

InactiveUS7062645B2Start fastShorten unit timeDigital data processing detailsDigital computer detailsOrder formComputerized system

An apparatus and method for providing a quicker boot for computer systems is provided. The hibernation state file content of a similar computer system is captured and sent to a unit being manufactured. As a result, the unit being manufactured may operate according to the hibernation state. When the unit is operating in such a fashion, the time required for a reboot is reduced which may provide for more efficient software installation for build to order computer systems.

Owner:GATEWAY

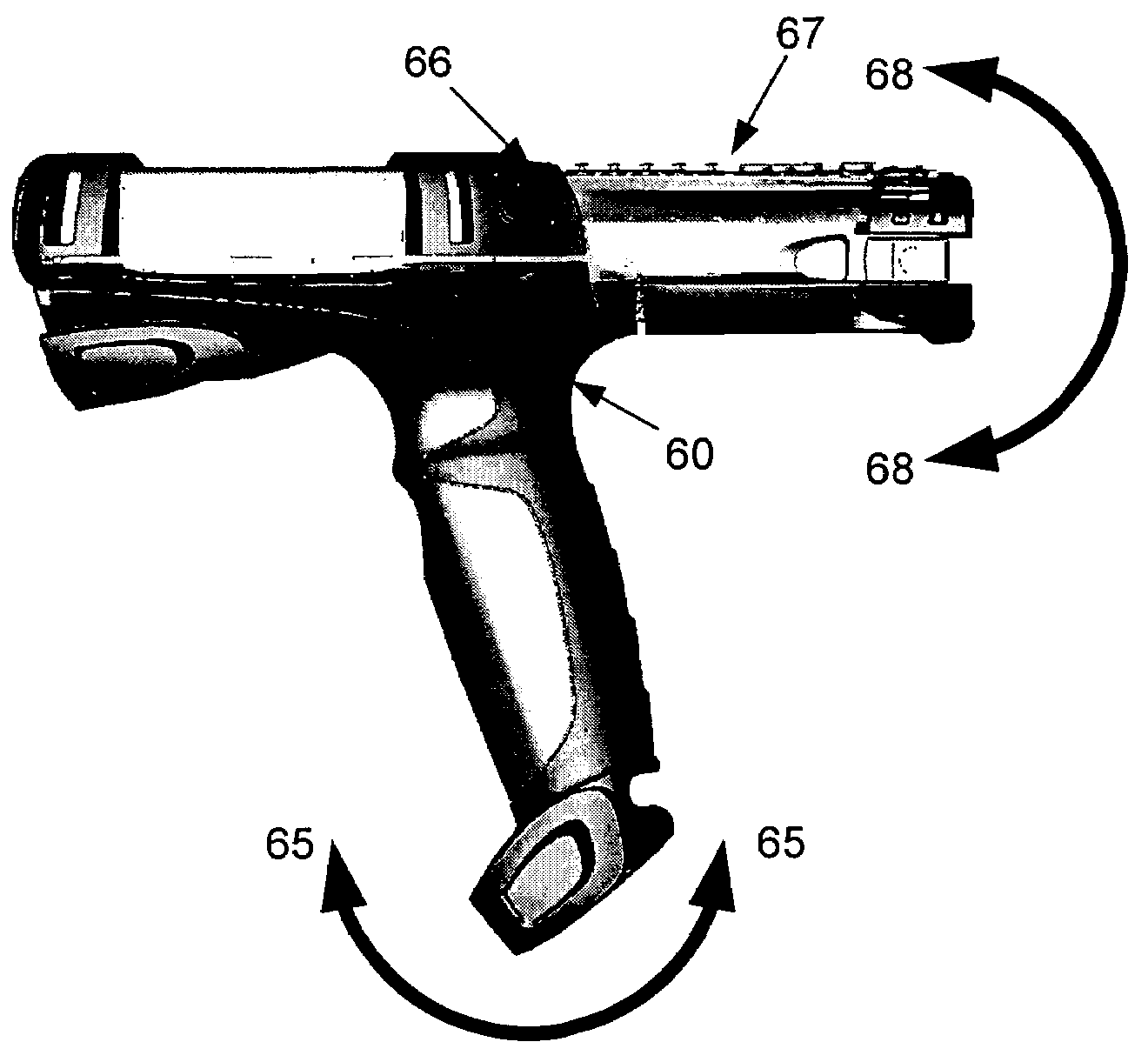

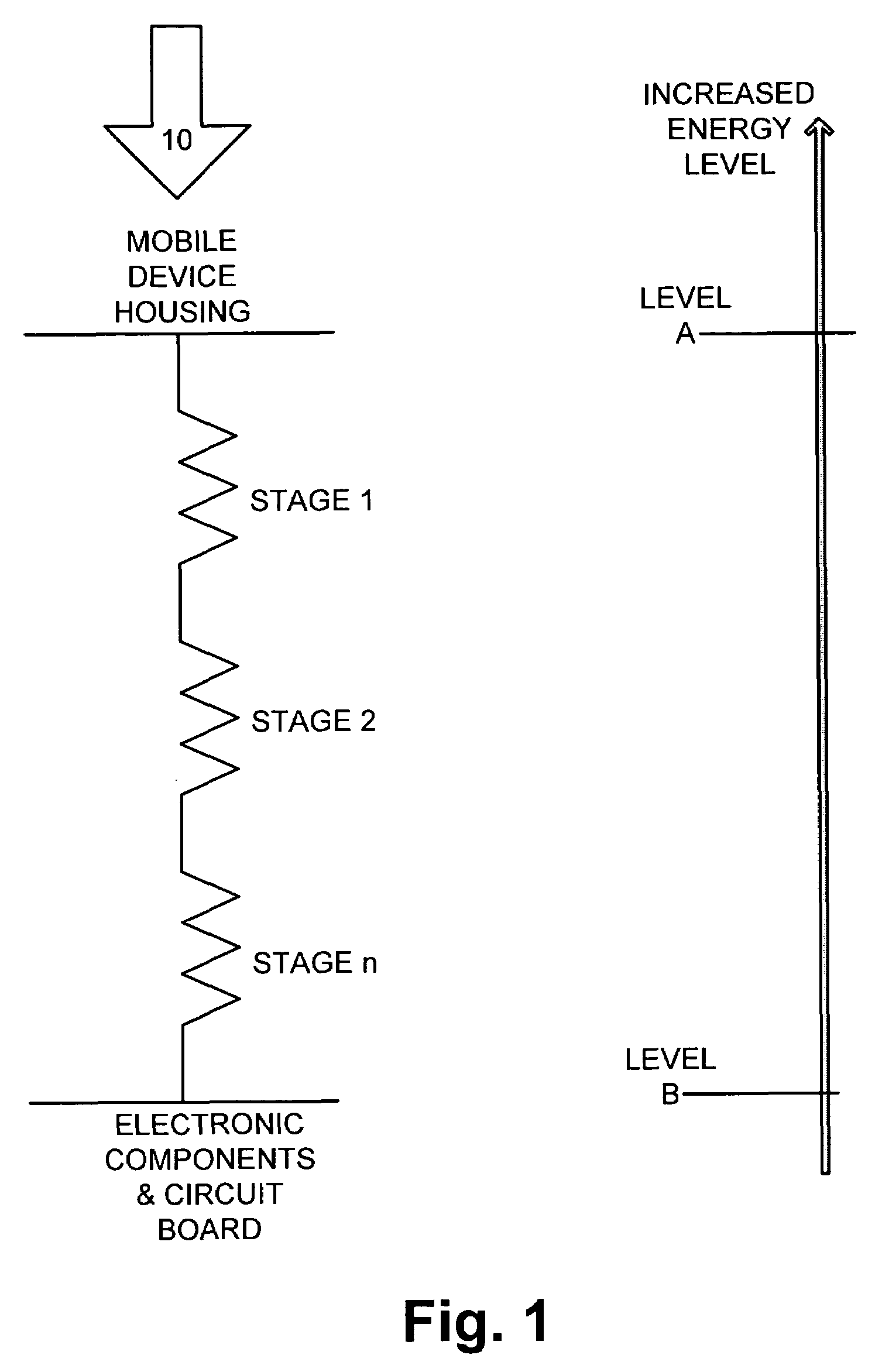

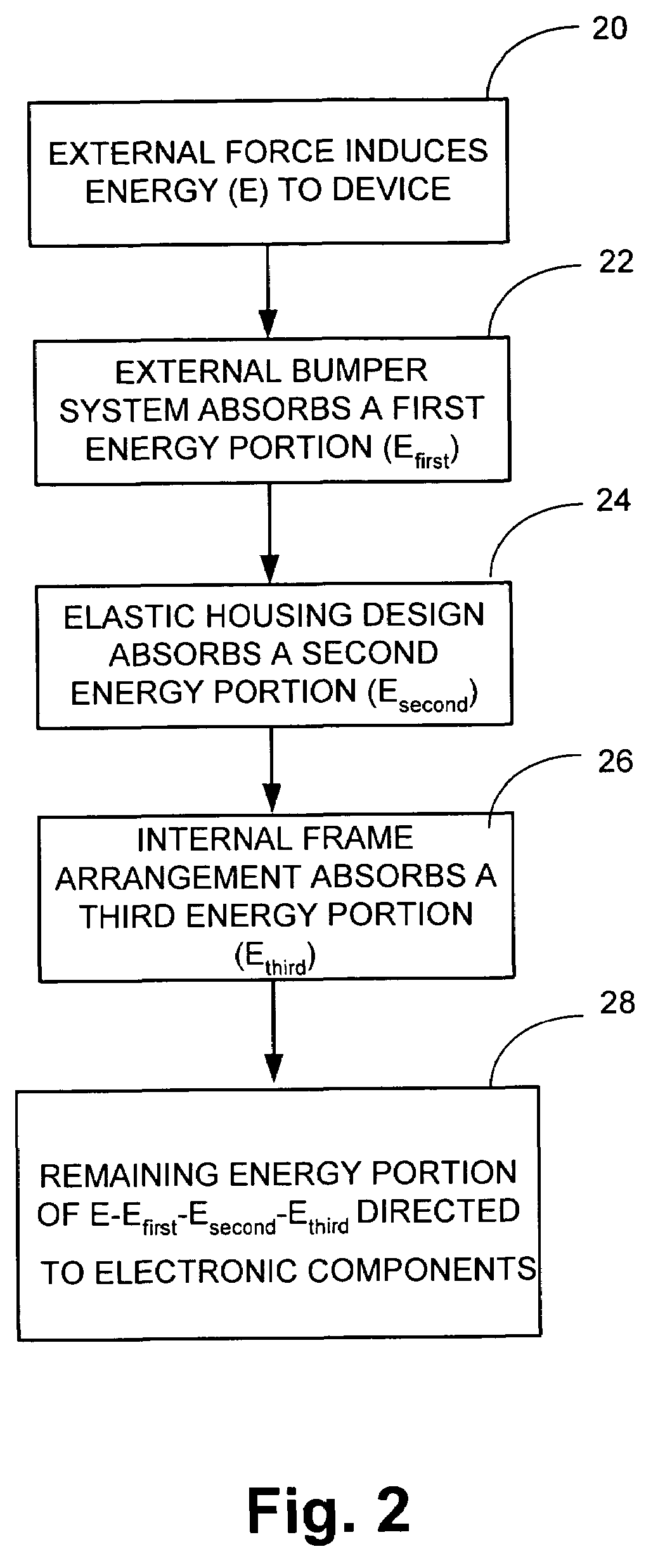

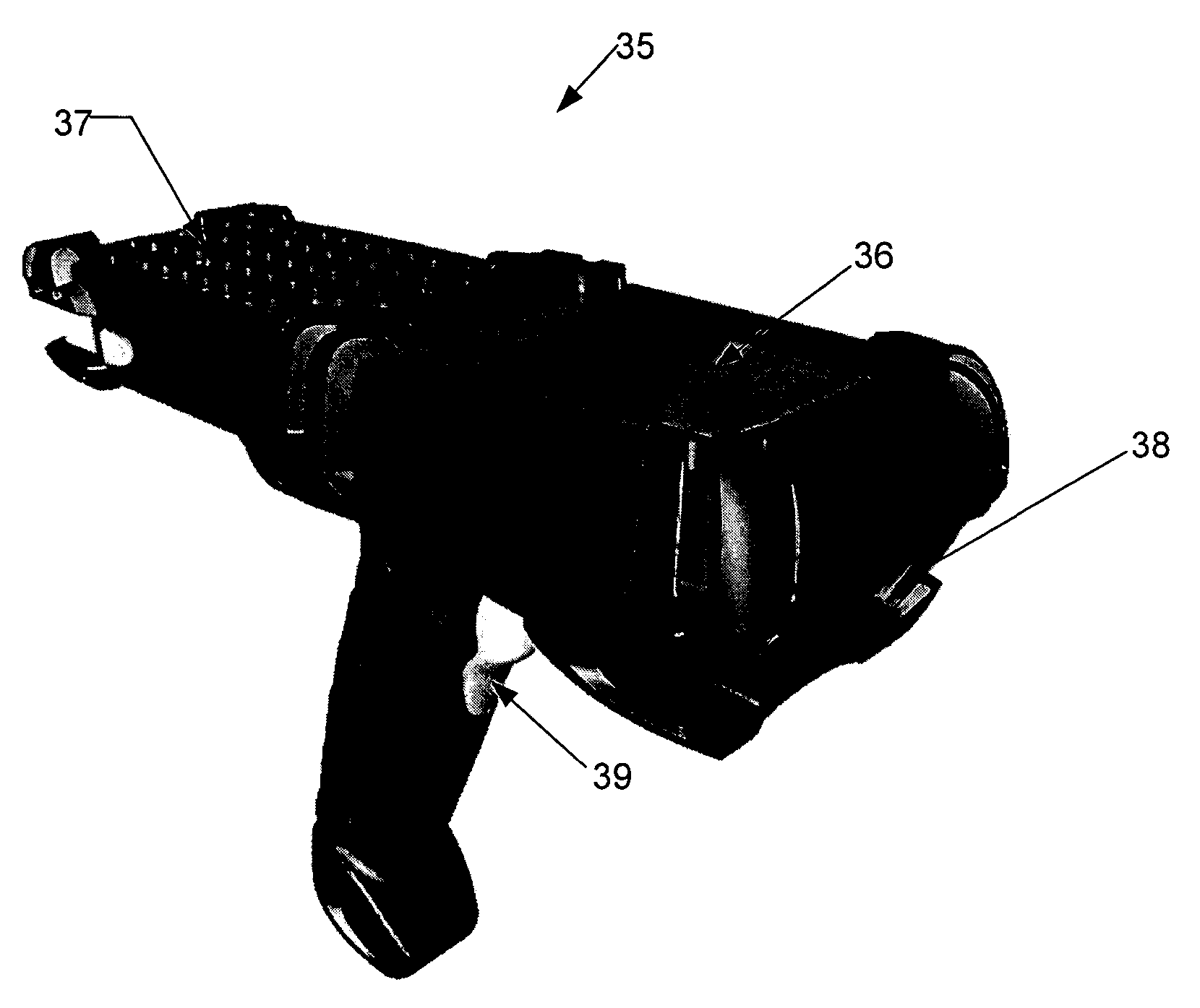

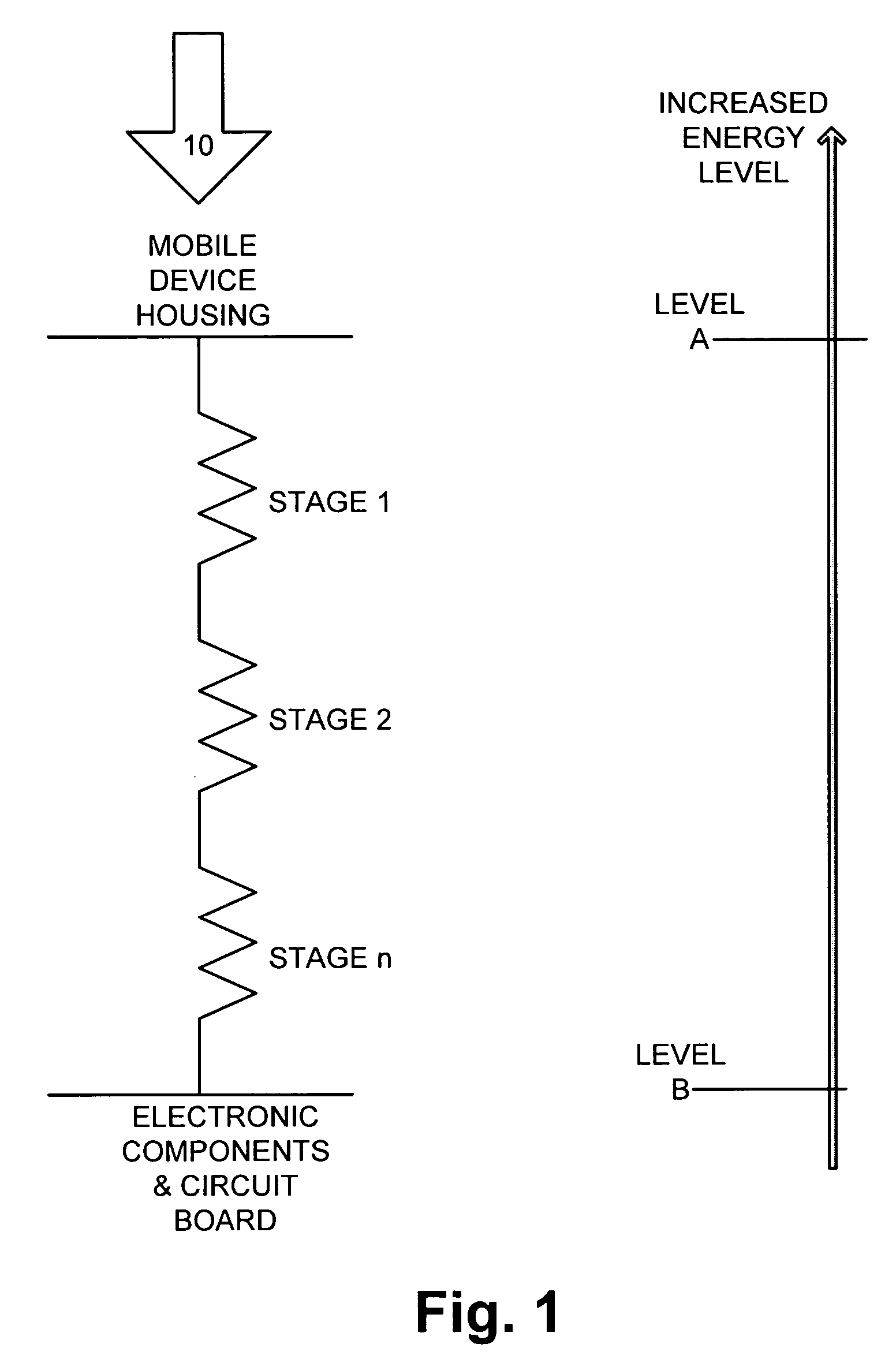

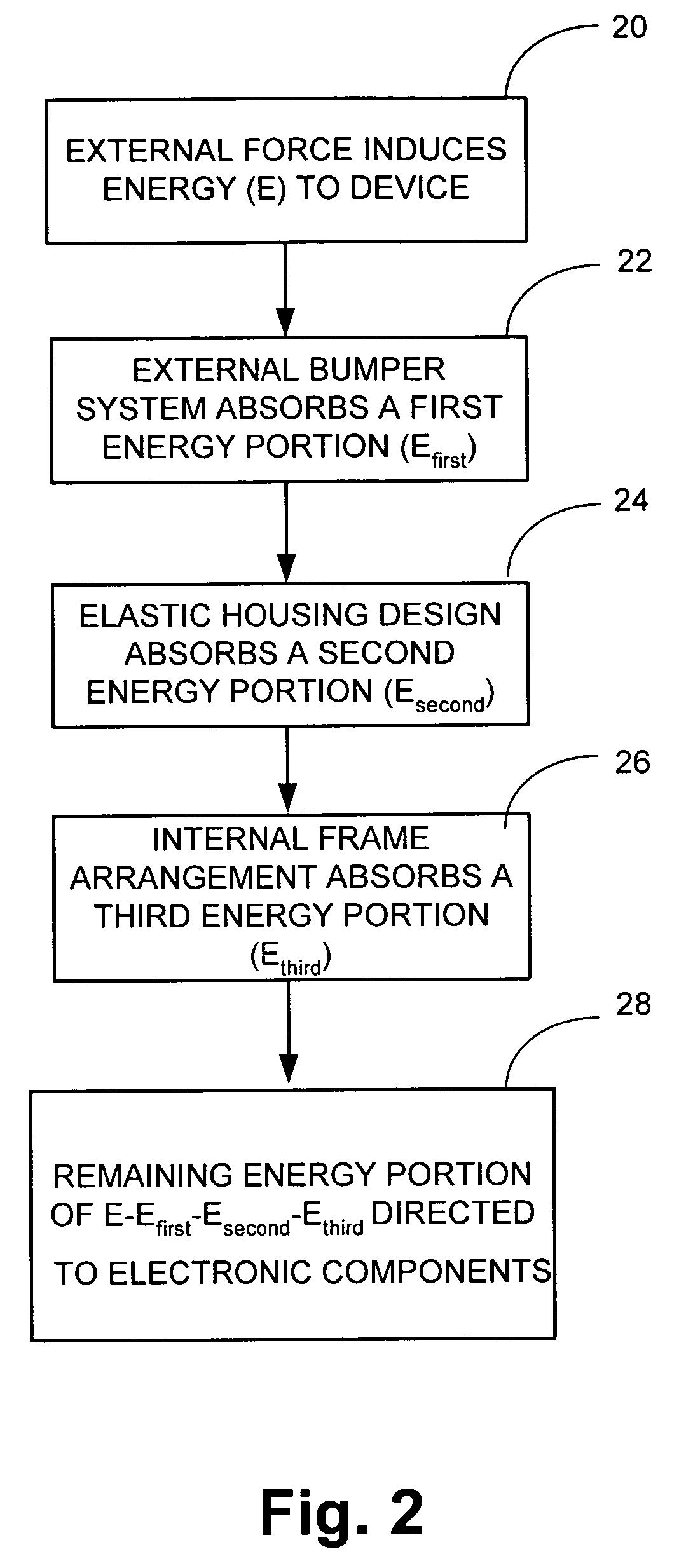

Terminal design with shock isolation assembly

ActiveUS7195168B2Less stressLess or no circuit board bendingDigital data processing detailsCharacter and pattern recognitionHand heldMechanical impact

Systems and methodologies are disclosed for isolating a portable hand held electronic unit from external mechanical shocks and / or vibrations by dampening them at several levels. The system can absorb an external mechanical shock at three different levels by employing an external bumper system, elastic housing design features, and an internal frame isolation. Moreover, such isolation assembly simplifies production of the portable electronic unit by enabling a “build to order process” according to a customer's specification.

Owner:SYMBOL TECH LLC

Terminal design with shock isolation assembly

ActiveUS20050001037A1Dampen external shockAvoid damageDigital data processing detailsCharacter and pattern recognitionHand heldMechanical impact

Systems and methodologies are disclosed for isolating a portable hand held electronic unit from external mechanical shocks and / or vibrations by dampening them at several levels. The system can absorb an external mechanical shock at three different levels by employing an external bumper system, elastic housing design features, and an internal frame isolation. Moreover, such isolation assembly simplifies production of the portable electronic unit by enabling a “build to order process” according to a customer's specification.

Owner:SYMBOL TECH LLC

Method and system for simulating production within a manufacturing environment

InactiveUS6611727B2Minimize impactResource allocatedDigital data processing detailsResourcesWork in processResource based

Owner:DELL PROD LP

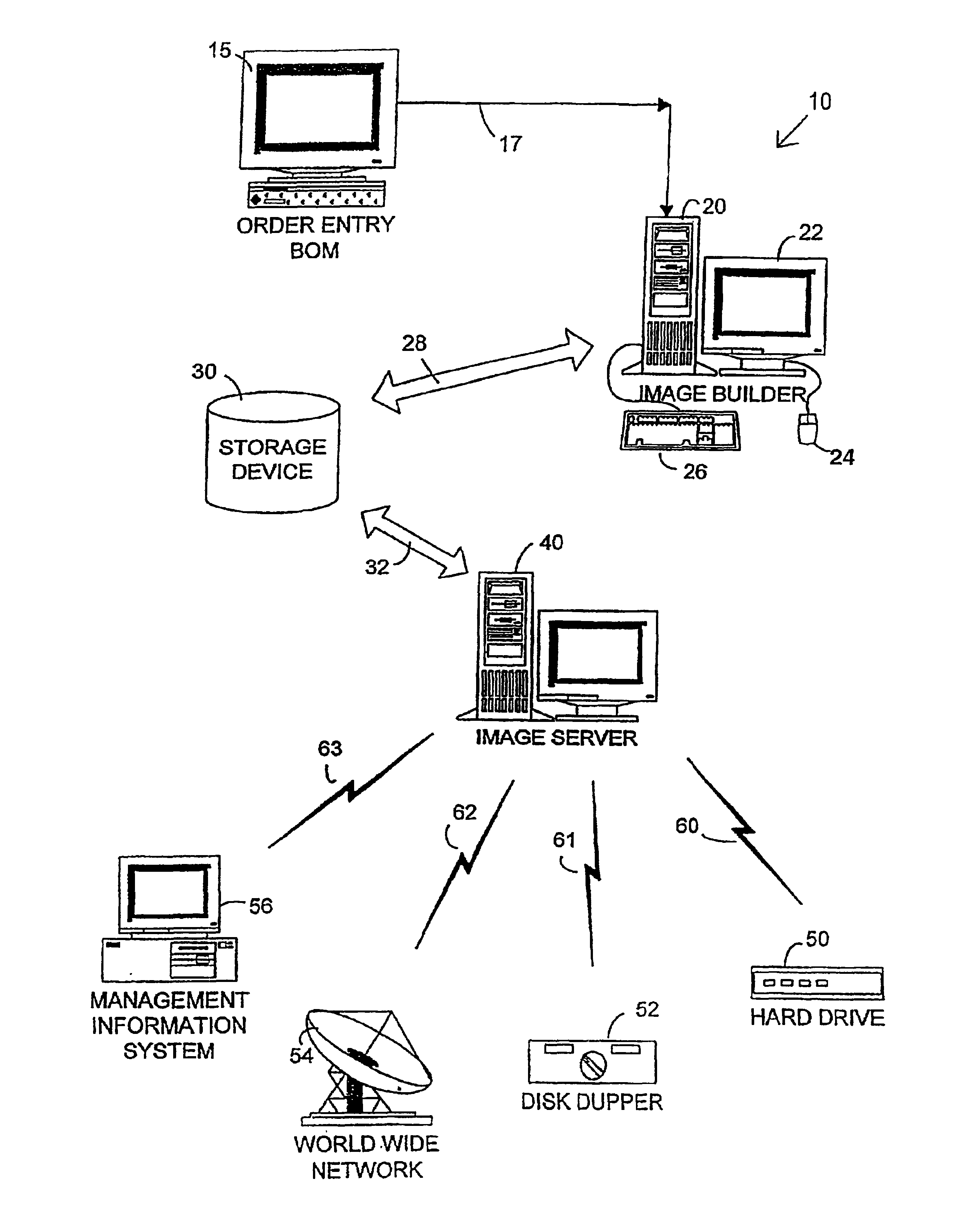

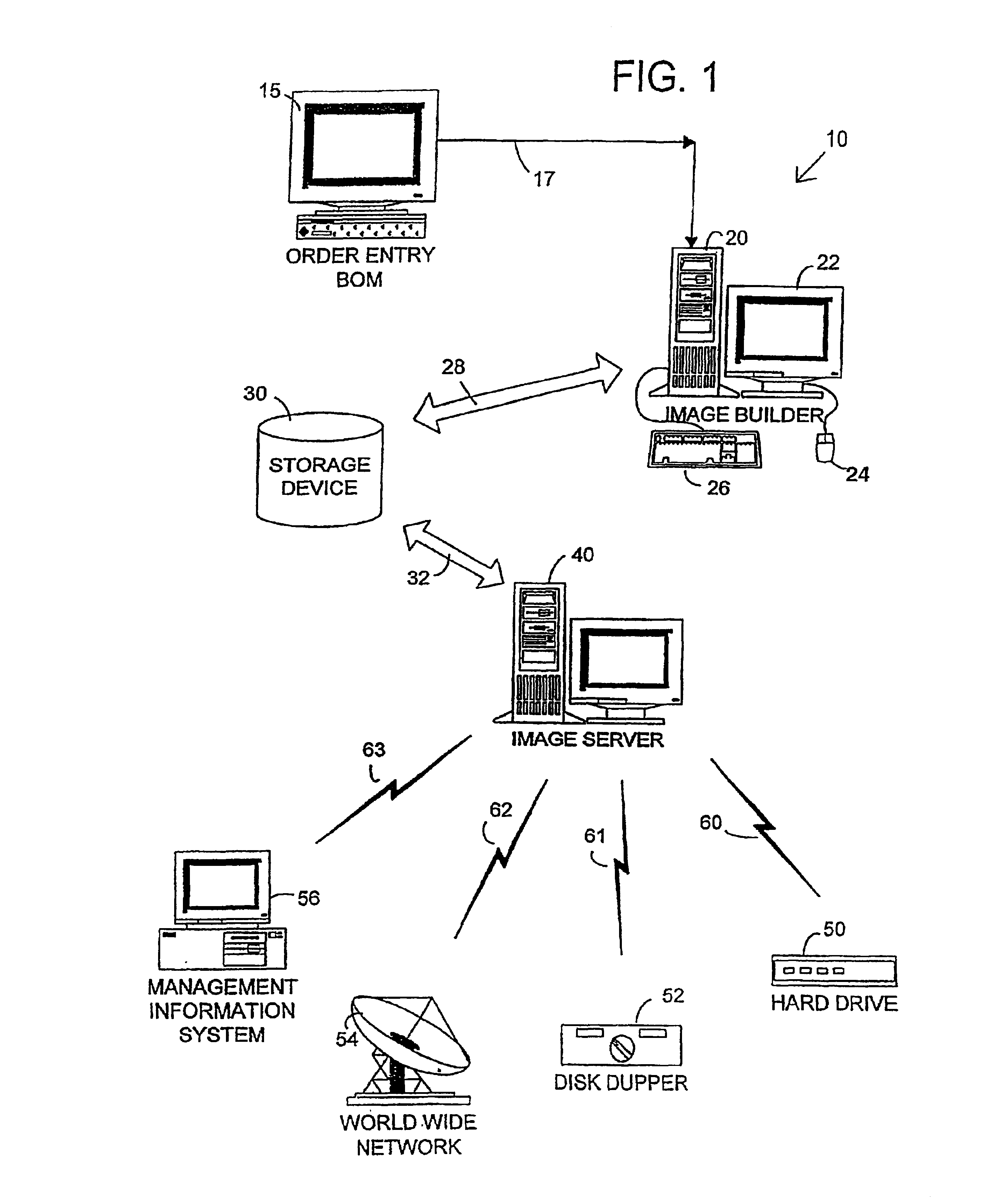

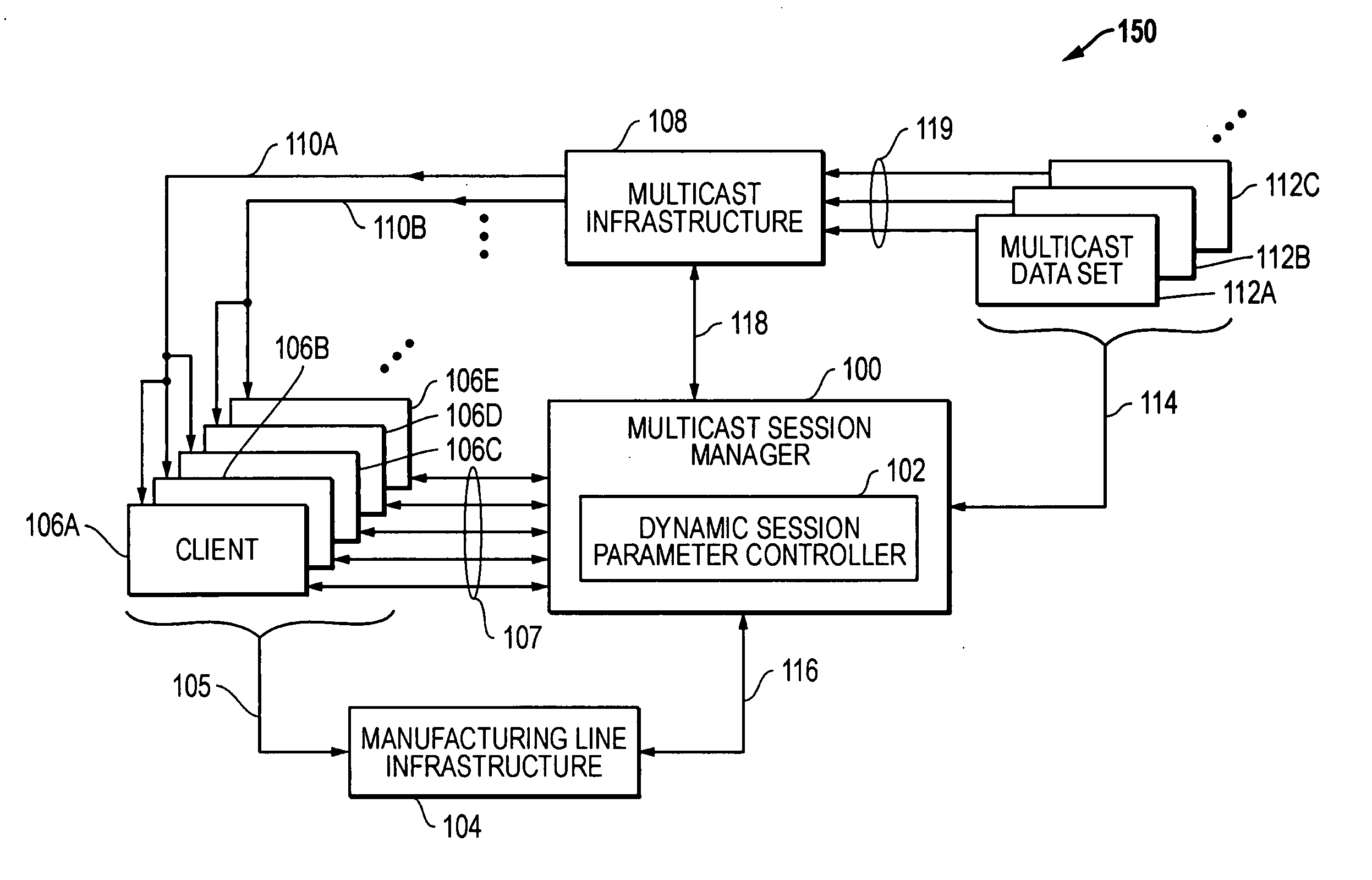

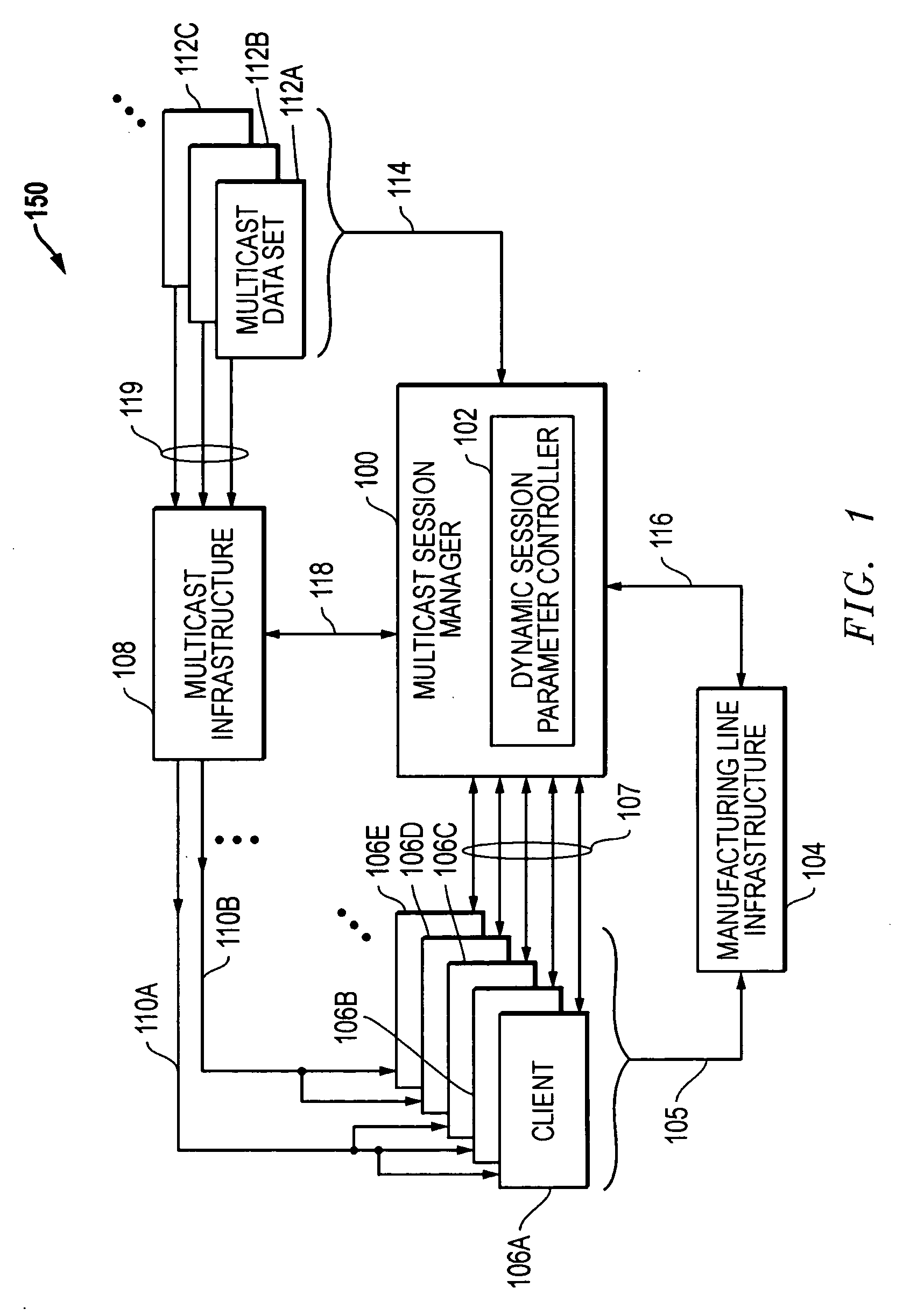

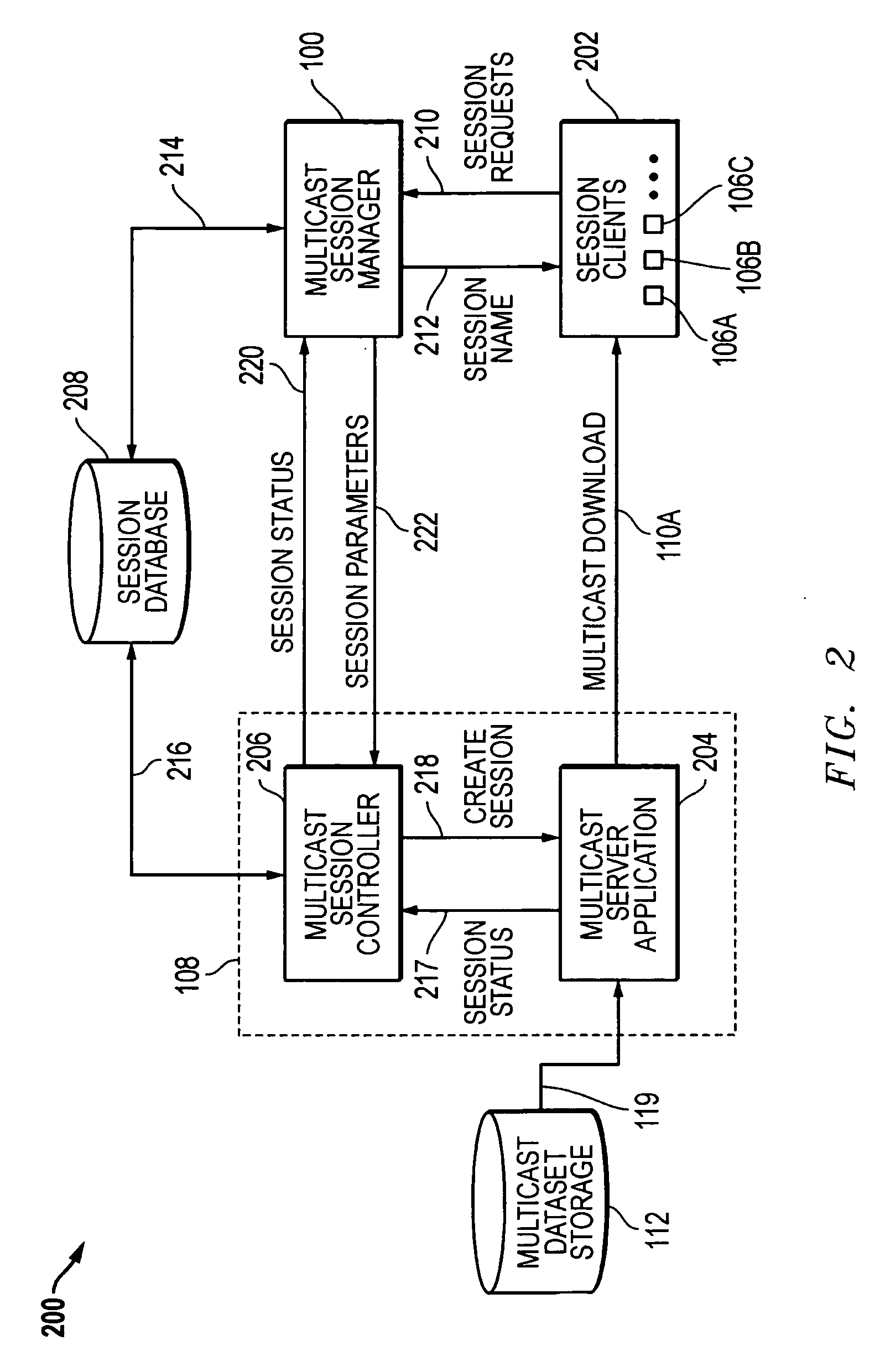

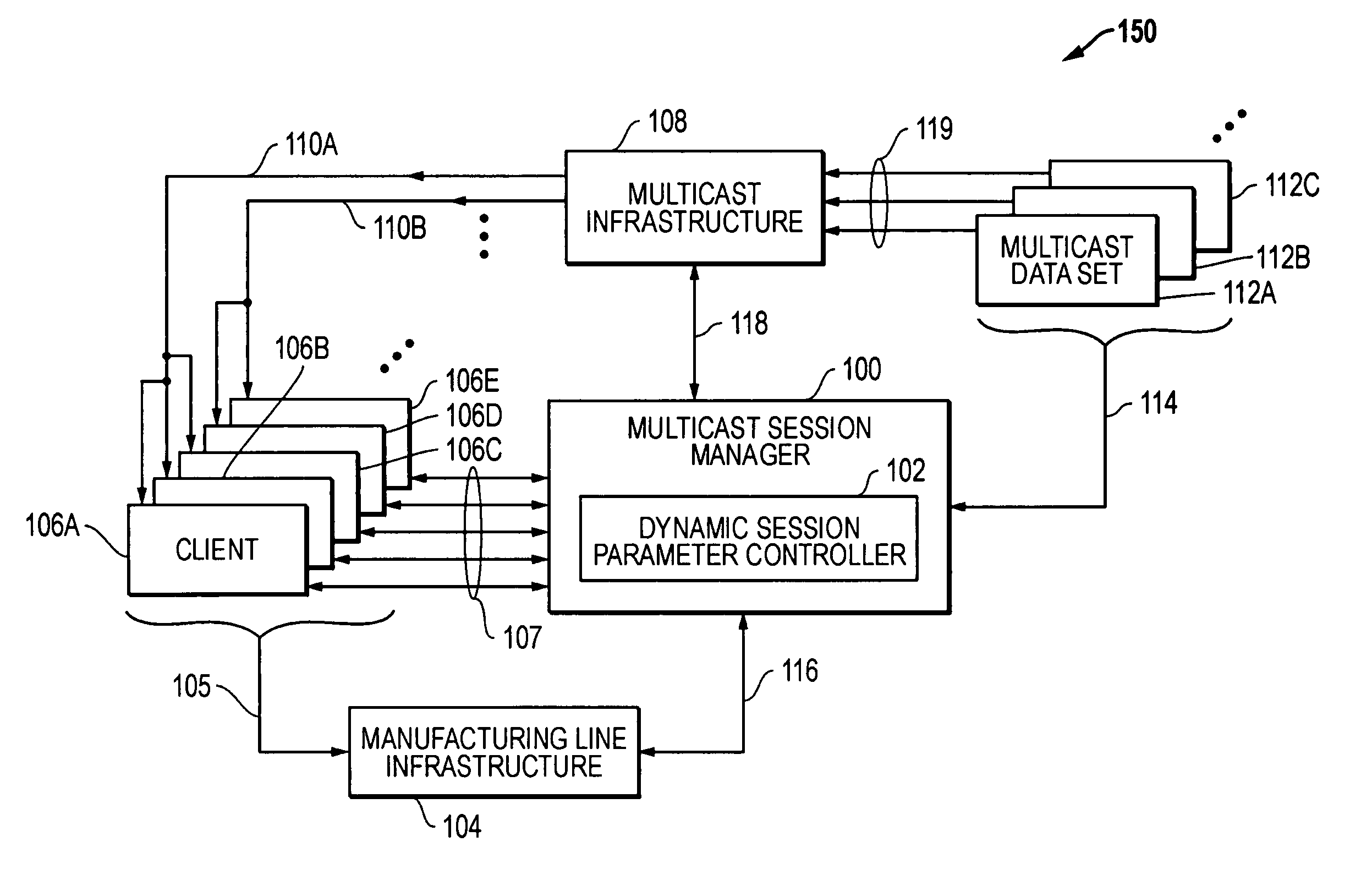

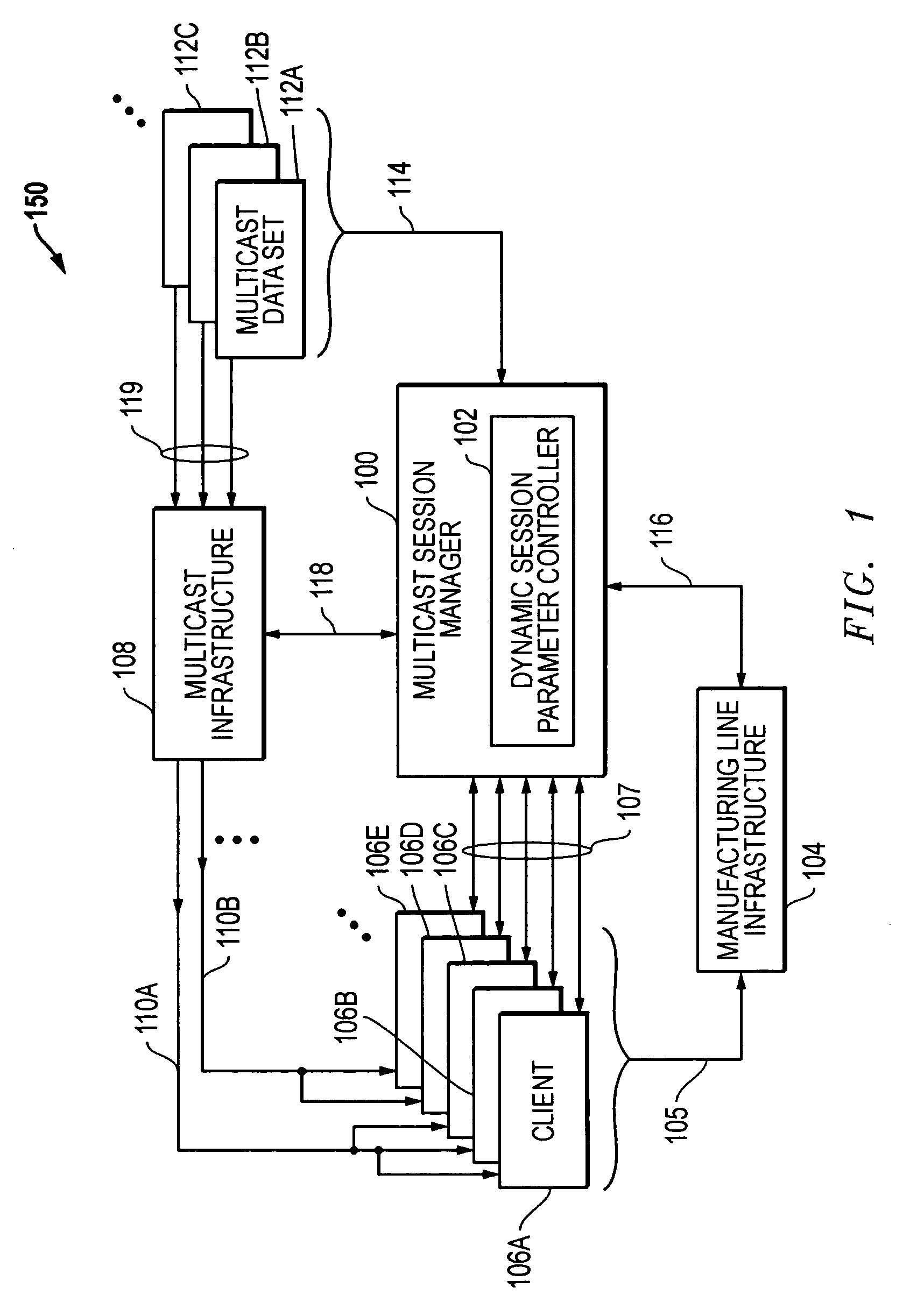

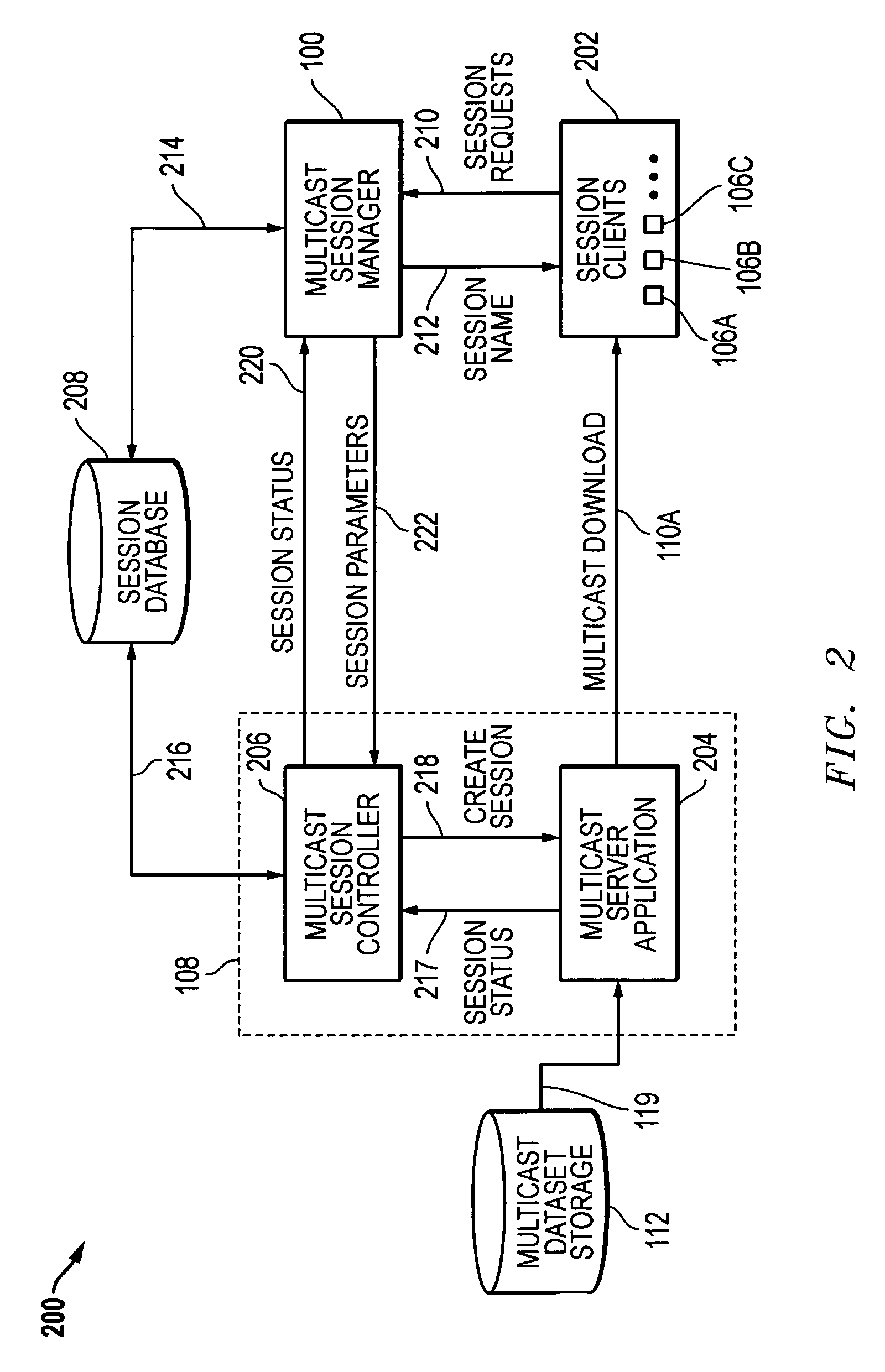

Method for dynamically managing multicast sessions for software downloads and related systems

ActiveUS20060265709A1High high environmentMultiple digital computer combinationsProgram loading/initiatingInformation processingStart time

Methods and systems are disclosed for dynamically managing multicast sessions for software downloads and, more particularly, for such software downloads used in build-to-order manufacturing information handling systems. Multiple multicast sessions are automatically managed simultaneously, where each session can have its own unique set of session parameters, in such a way as to support a high mix, high volume manufacturing build-to-order environment. Multicast session control parameters, such as start time and client count, are defined for each multicast session base upon download requests from the information handling systems as they reach the software installation phase.

Owner:DELL PROD LP

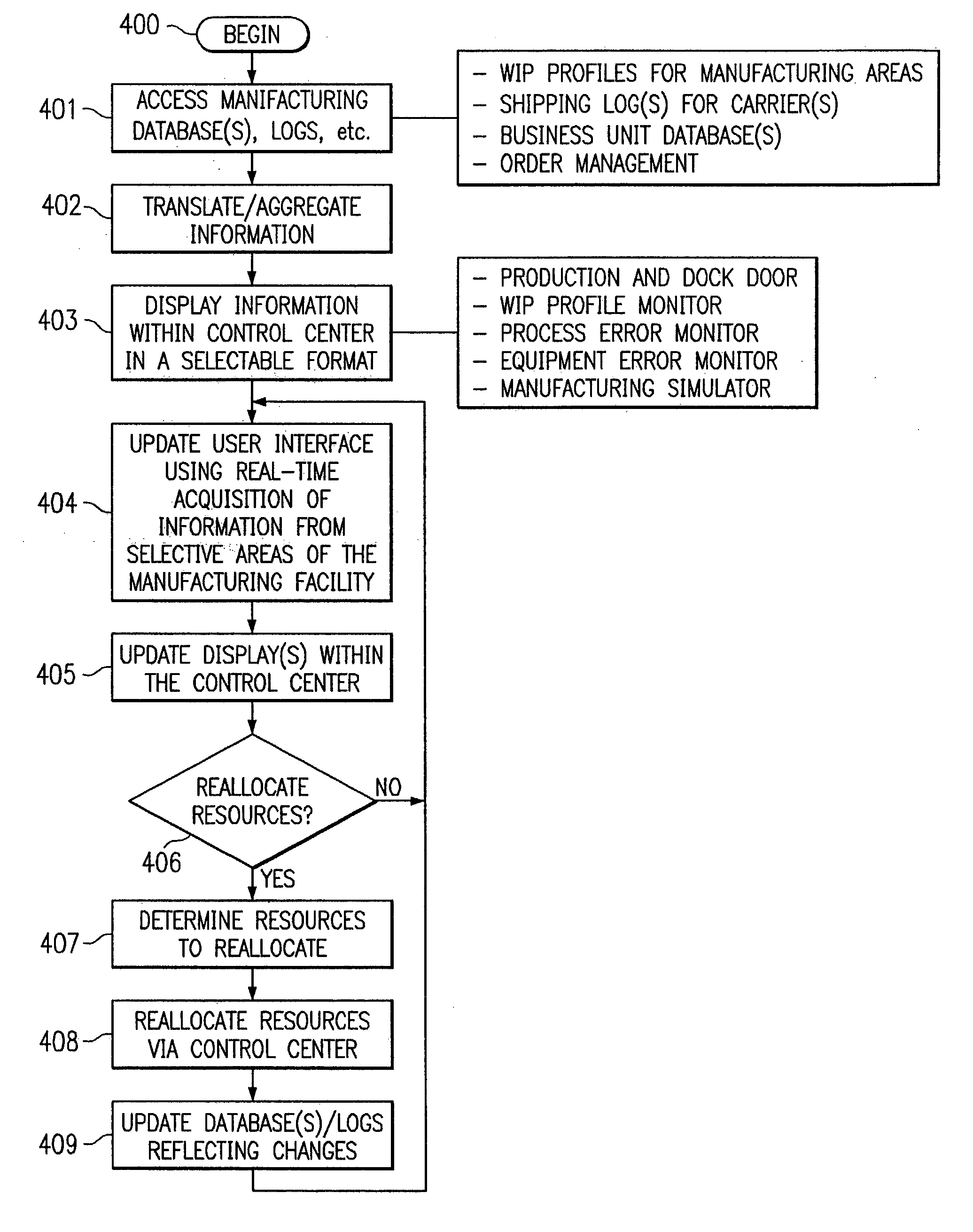

Method, system and facility for controlling resource allocation within a manufacturing environment

InactiveUS20040010334A1Low production costResourcesPoint-of-sale network systemsUser inputOrder form

A method and system provide for the control of resource allocation within a build-to-order manufacturing environment. One example embodiment of a method according to the present disclosure includes an operation for monitoring a work-in-process (WIP) profile that represents dynamic attributes of an area in a manufacturing facility. A user interface in a control center for the manufacturing facility may be automatically updated to depict one or more of the dynamic attributes in substantially real time, based on one or more of the WIP profiles. After the user interface is updated, user input that specifies a desired reallocation of resources for the manufacturing facility may be received. The user input may trigger communications with one or more areas in the manufacturing facility to implement the desired reallocation of resources. Alternative embodiments may include additional or alternative features, such as features for error detection and recovery.

Owner:DELL PROD LP

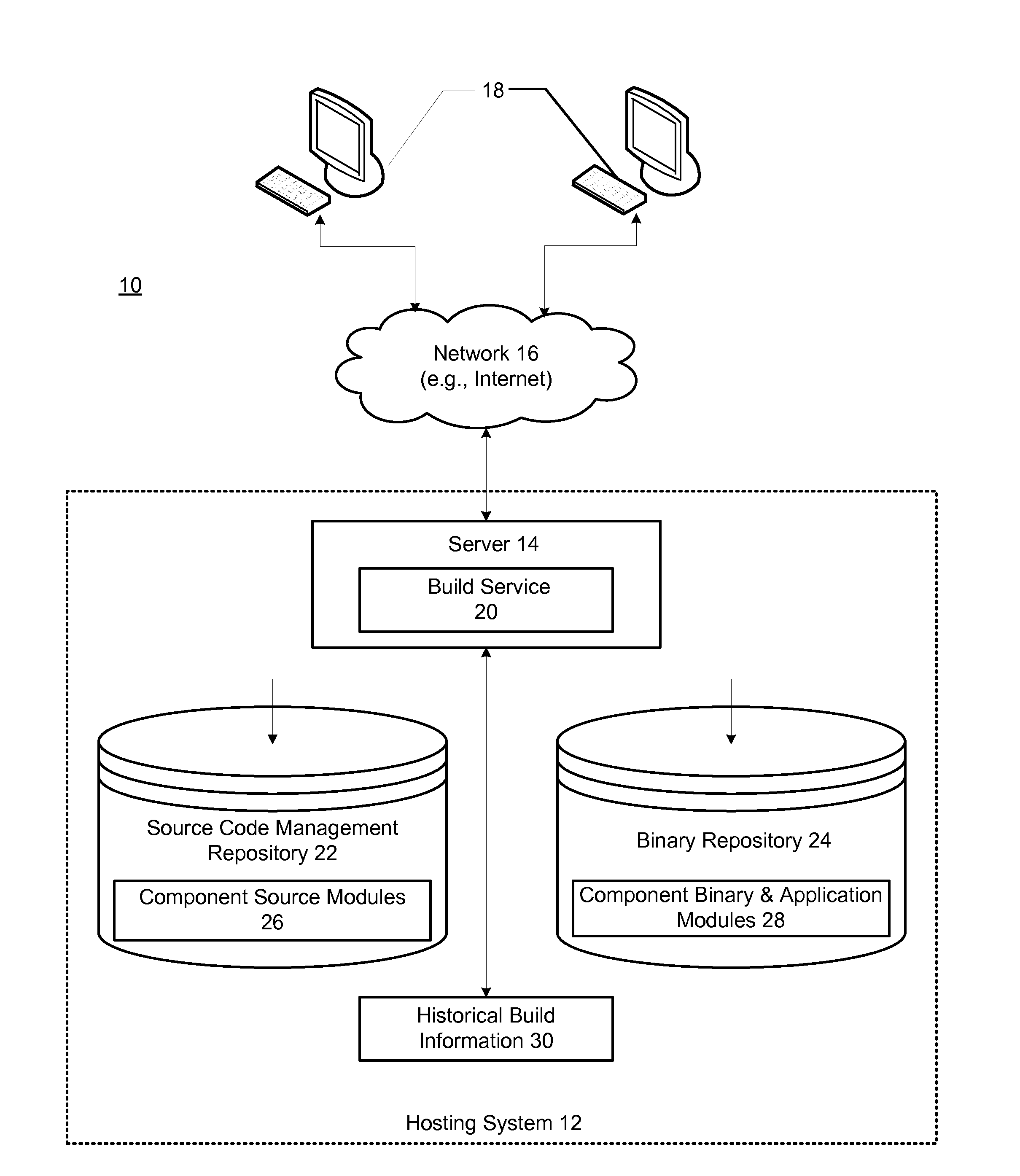

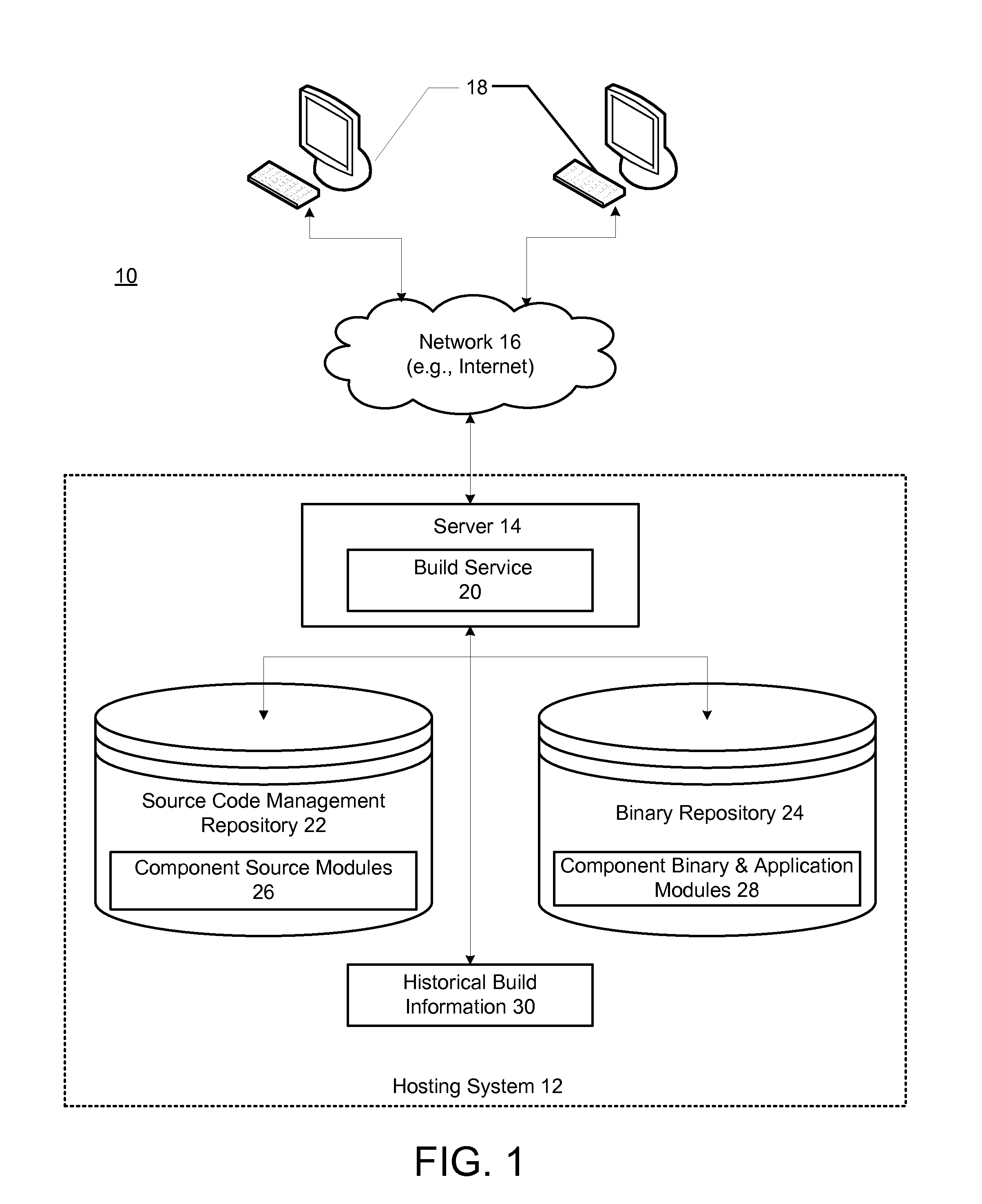

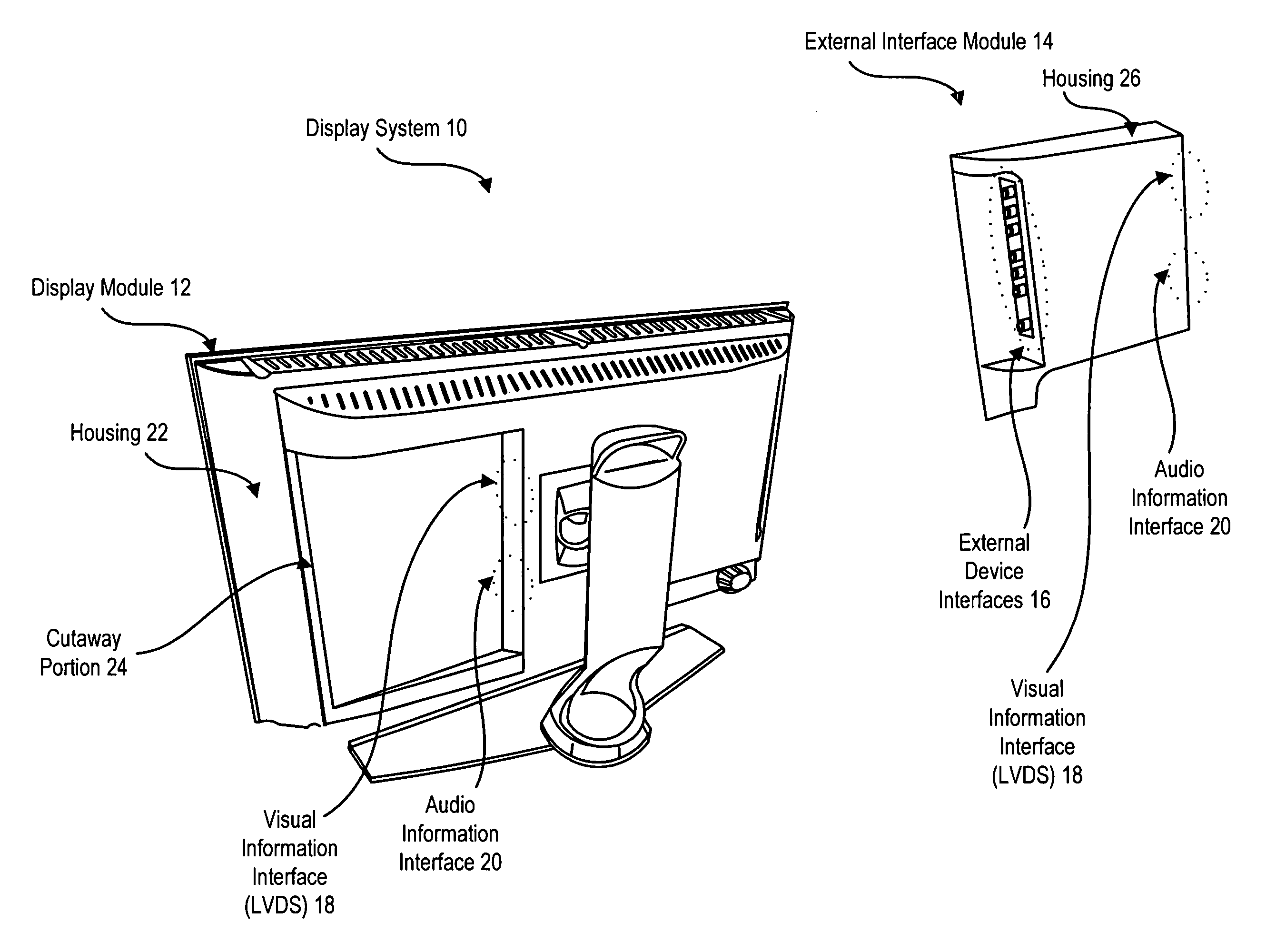

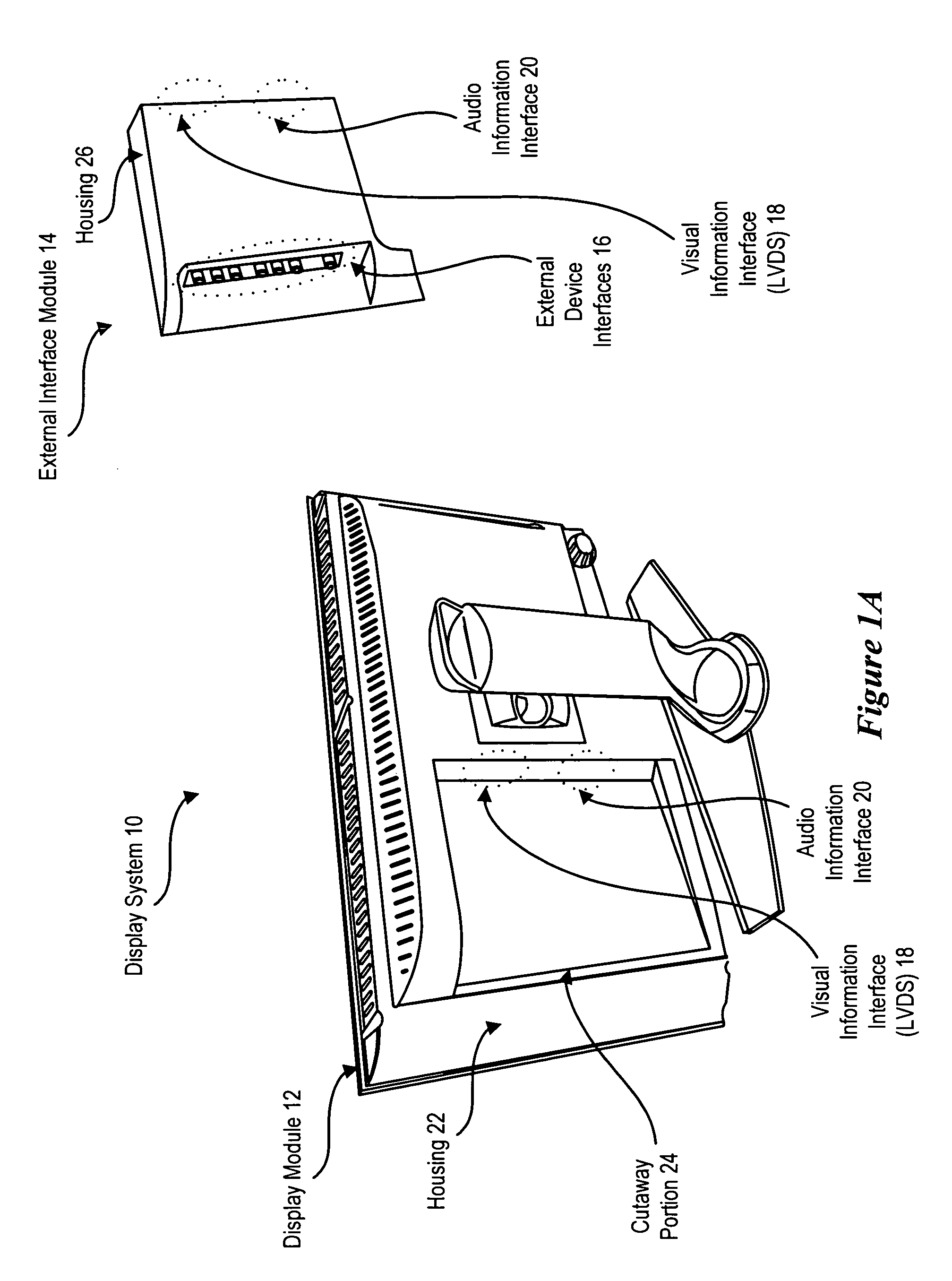

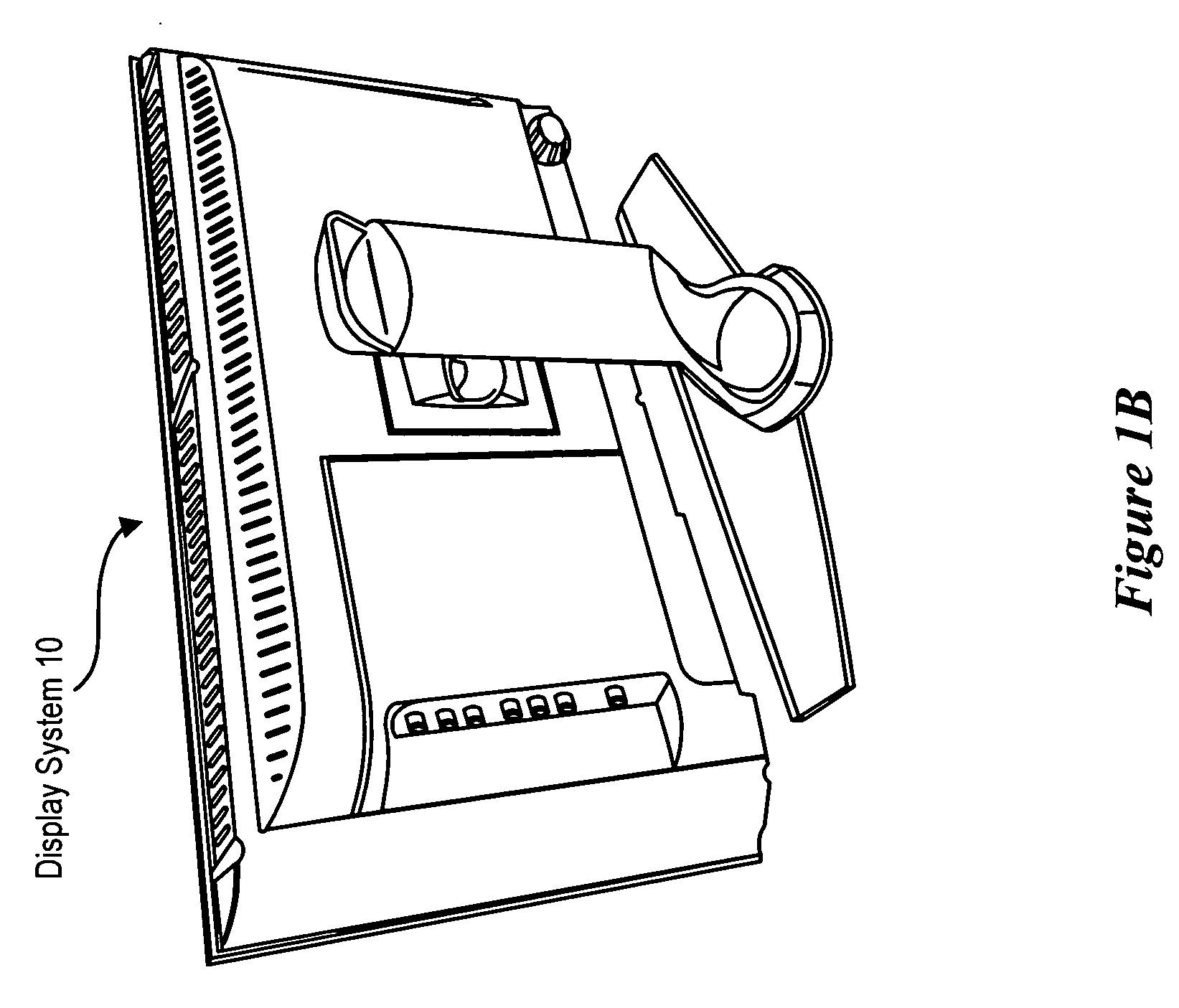

System and method for modular display

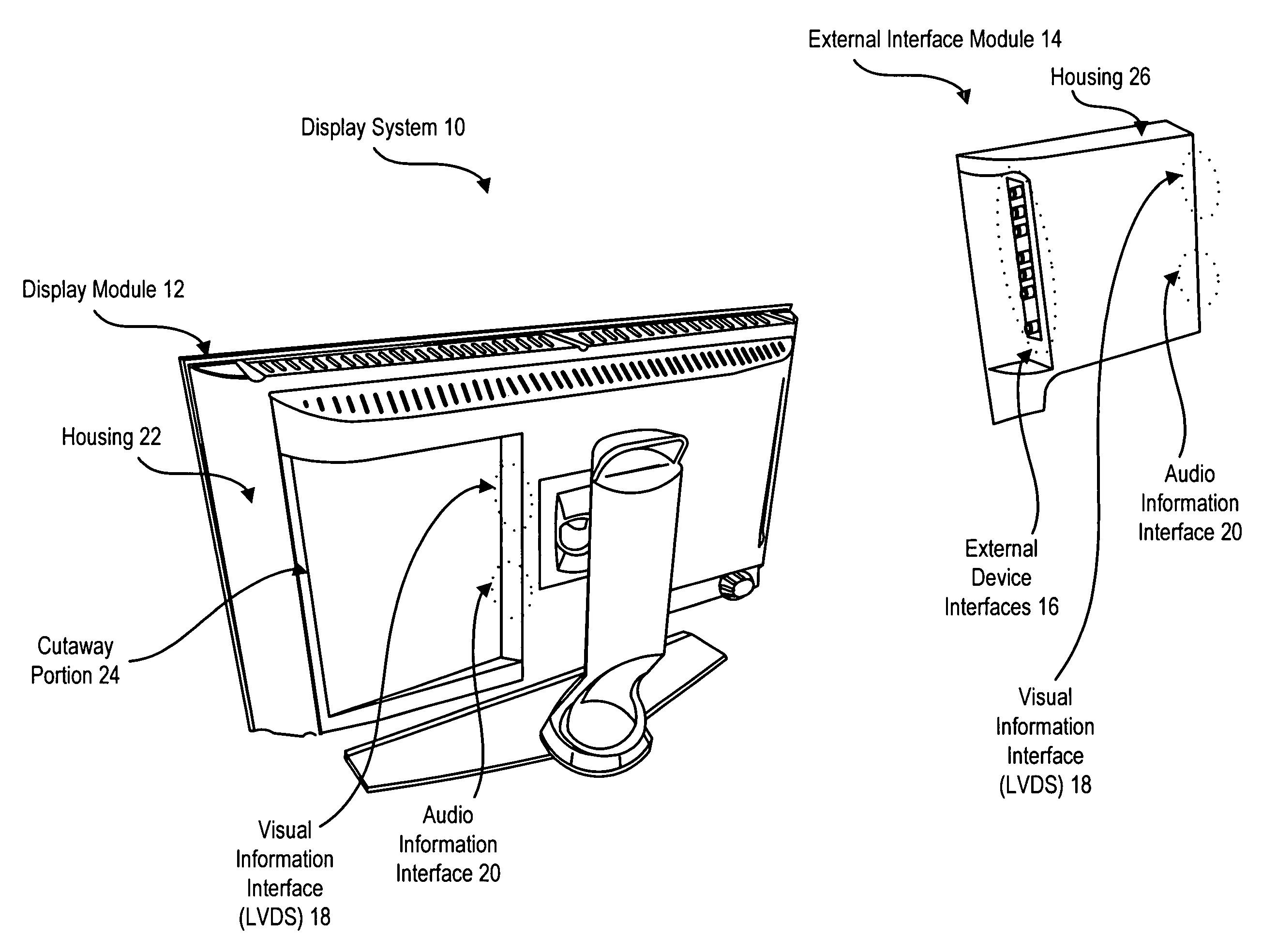

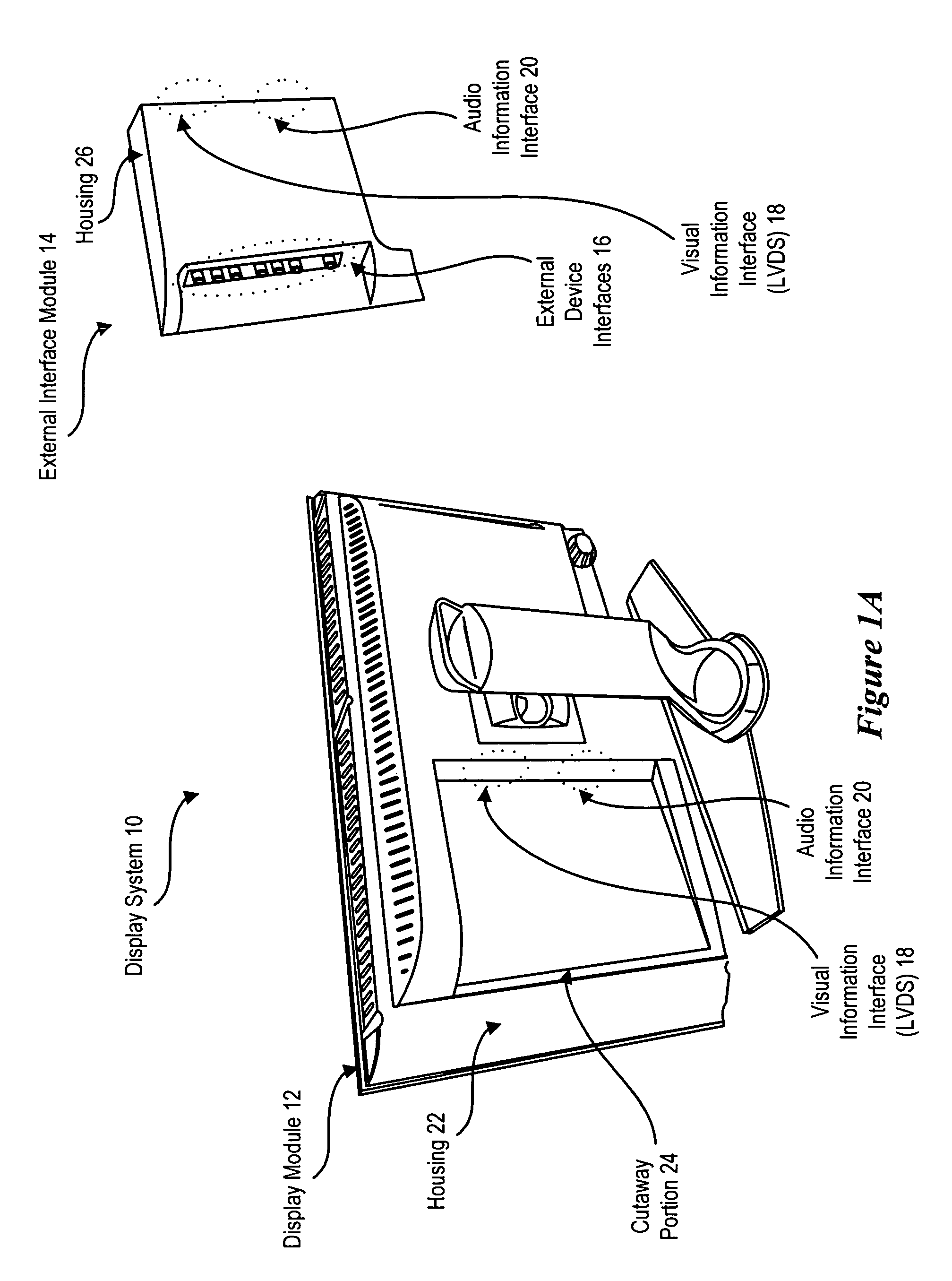

ActiveUS7518624B2Reduce disadvantagesReduce problemsTelevision system detailsData processing applicationsComputer moduleLoudspeaker

A modular display system and method assembles an external interface module with a display module to support built-to-order display configurations. The display module has display panel, timing controller and speaker components assembled in a display module housing that accepts a single LVDS and a single audio interface. The external interface module couples to the display module housing to form an integral display system. Selective assembly of the display system from plural types of external interface modules allows selective configuration of the display system with various television and information handling system display functionalities, such as to fill a purchaser order in a build-to-order manufacturing process.

Owner:DELL PROD LP

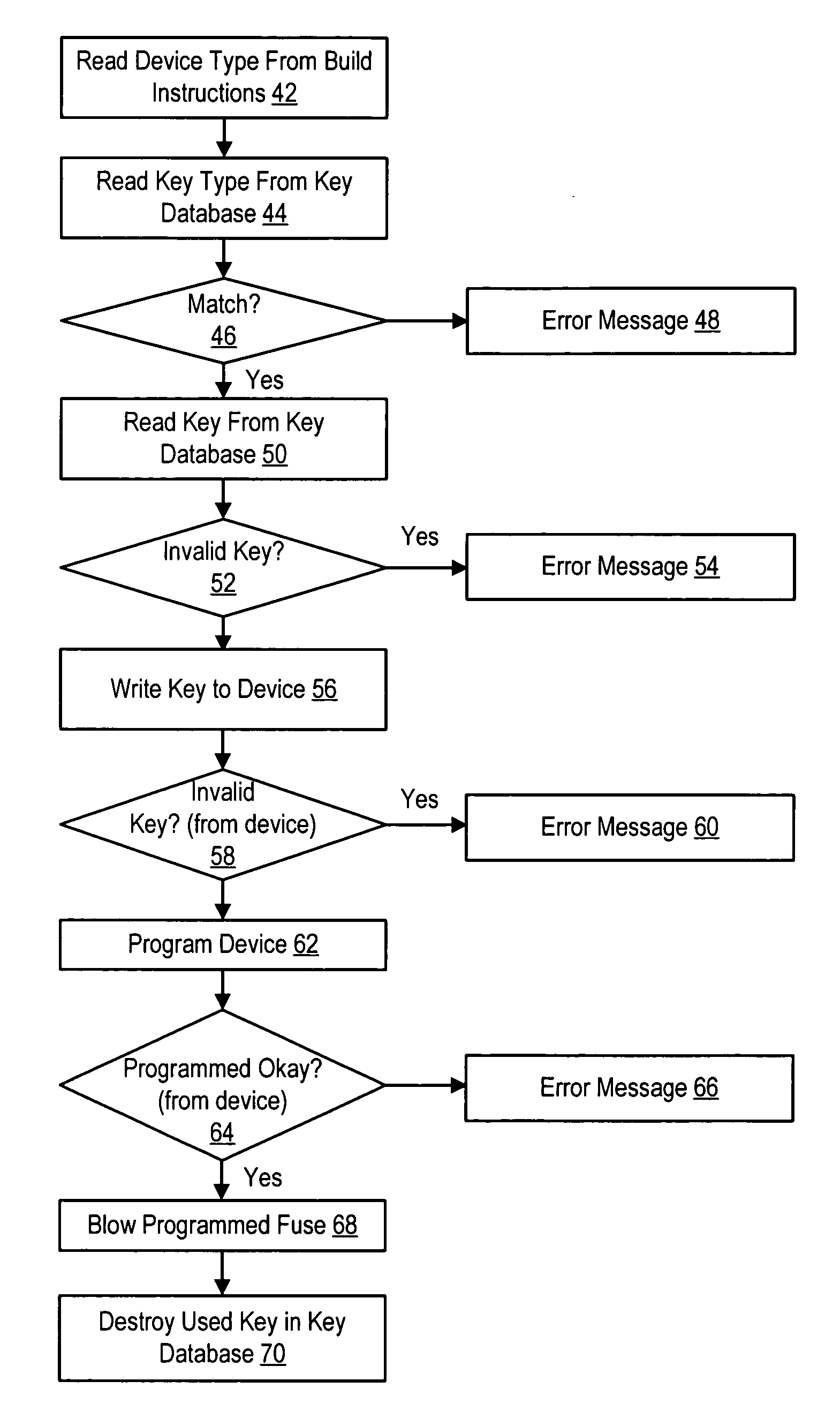

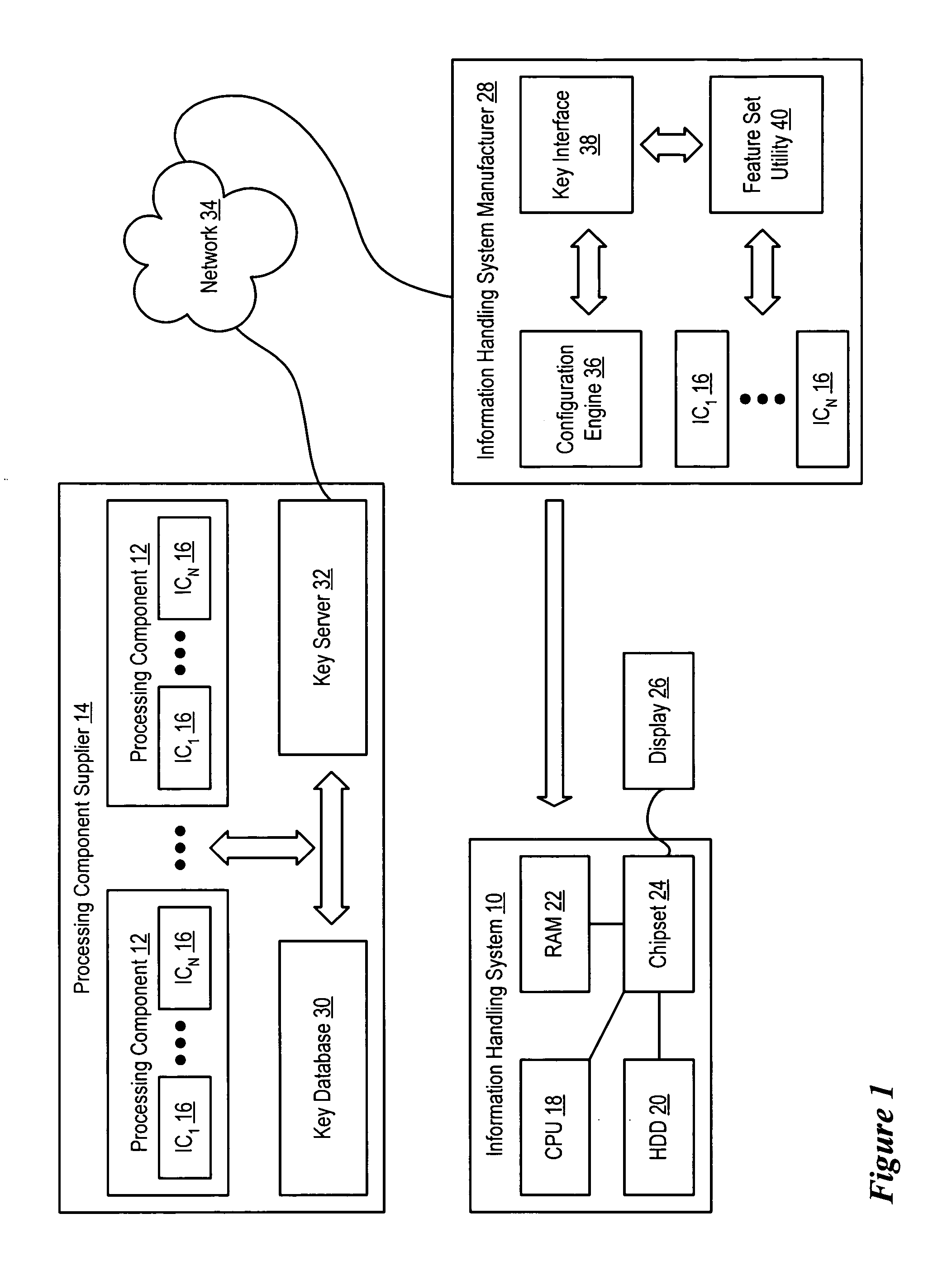

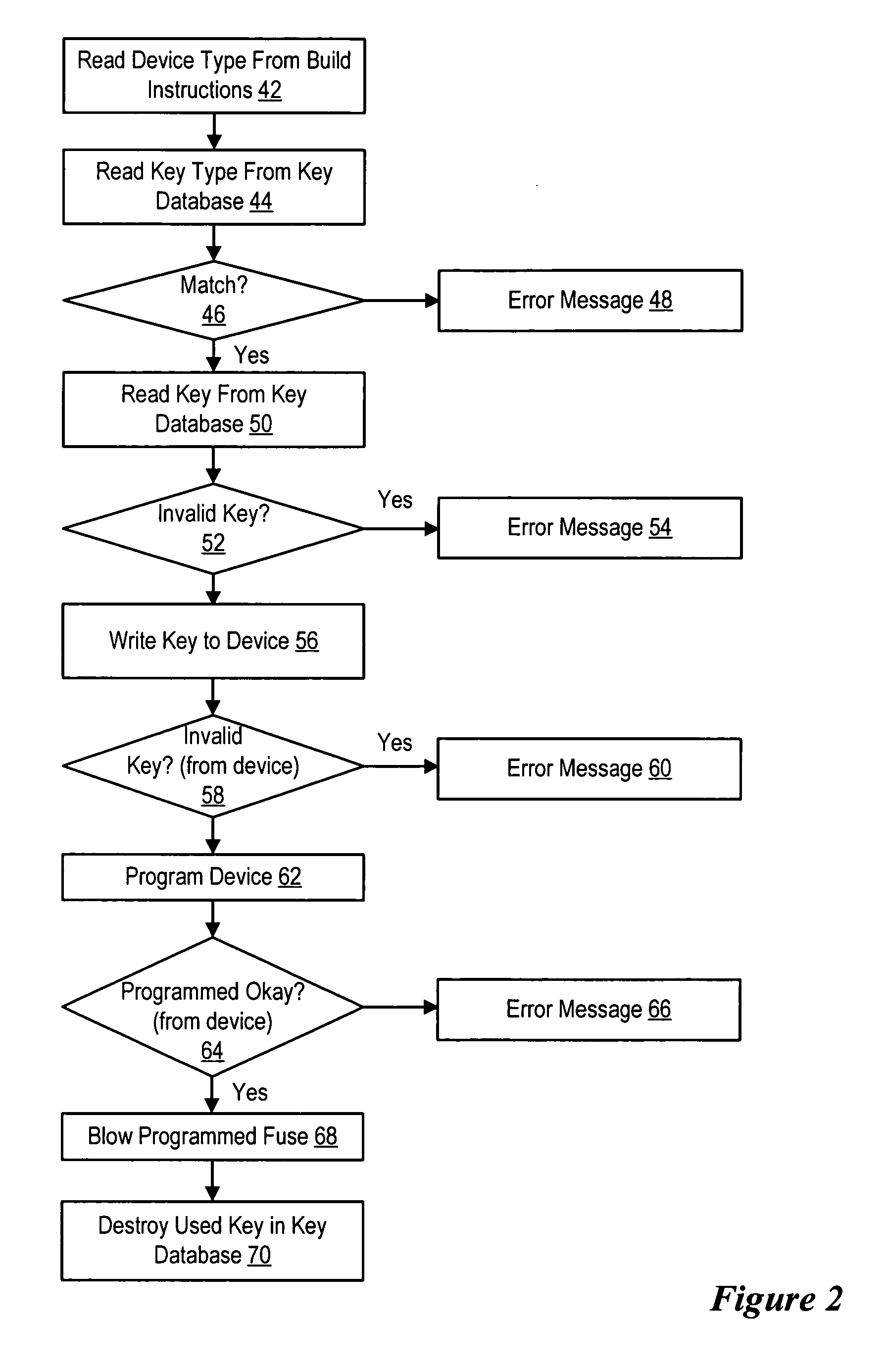

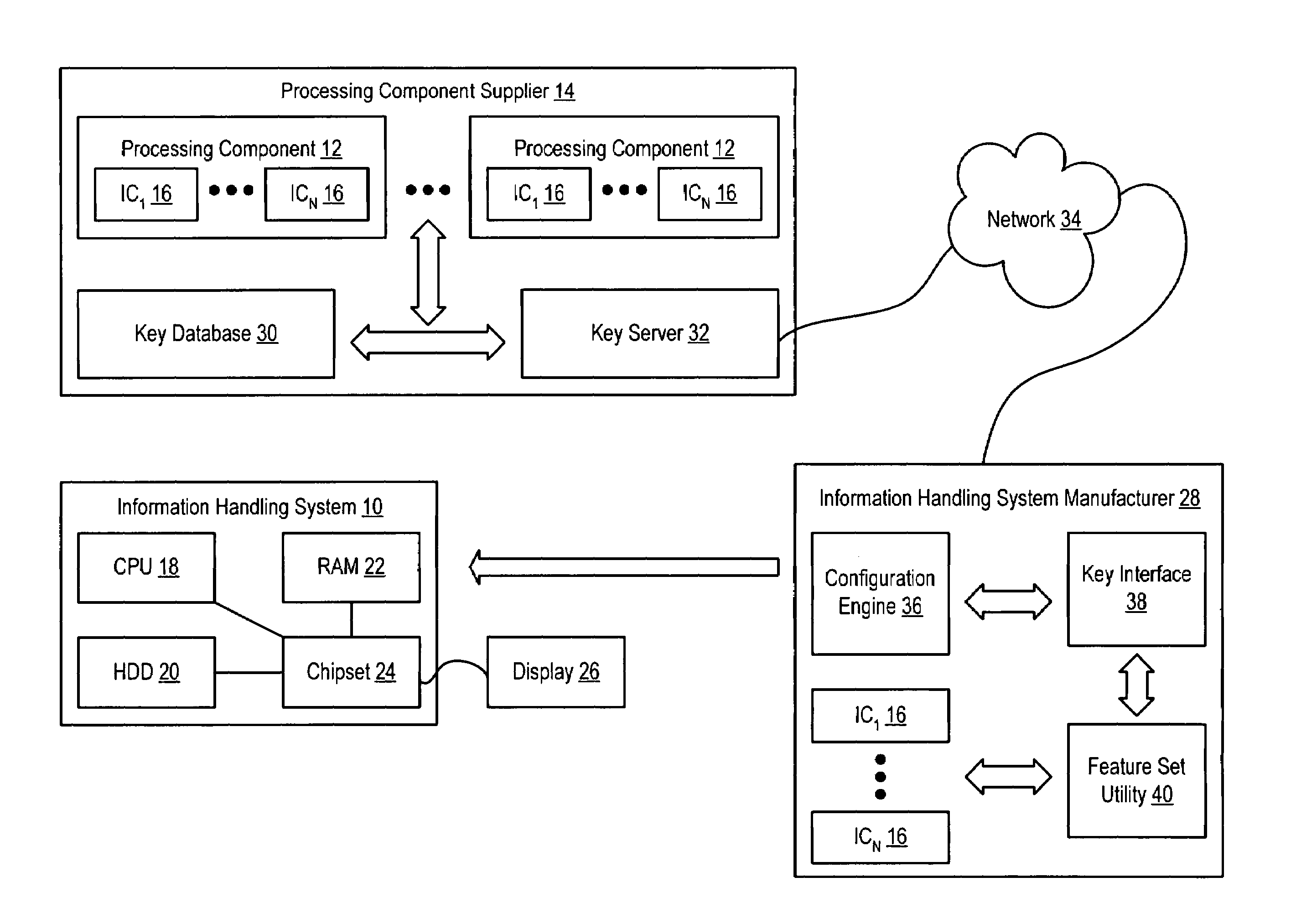

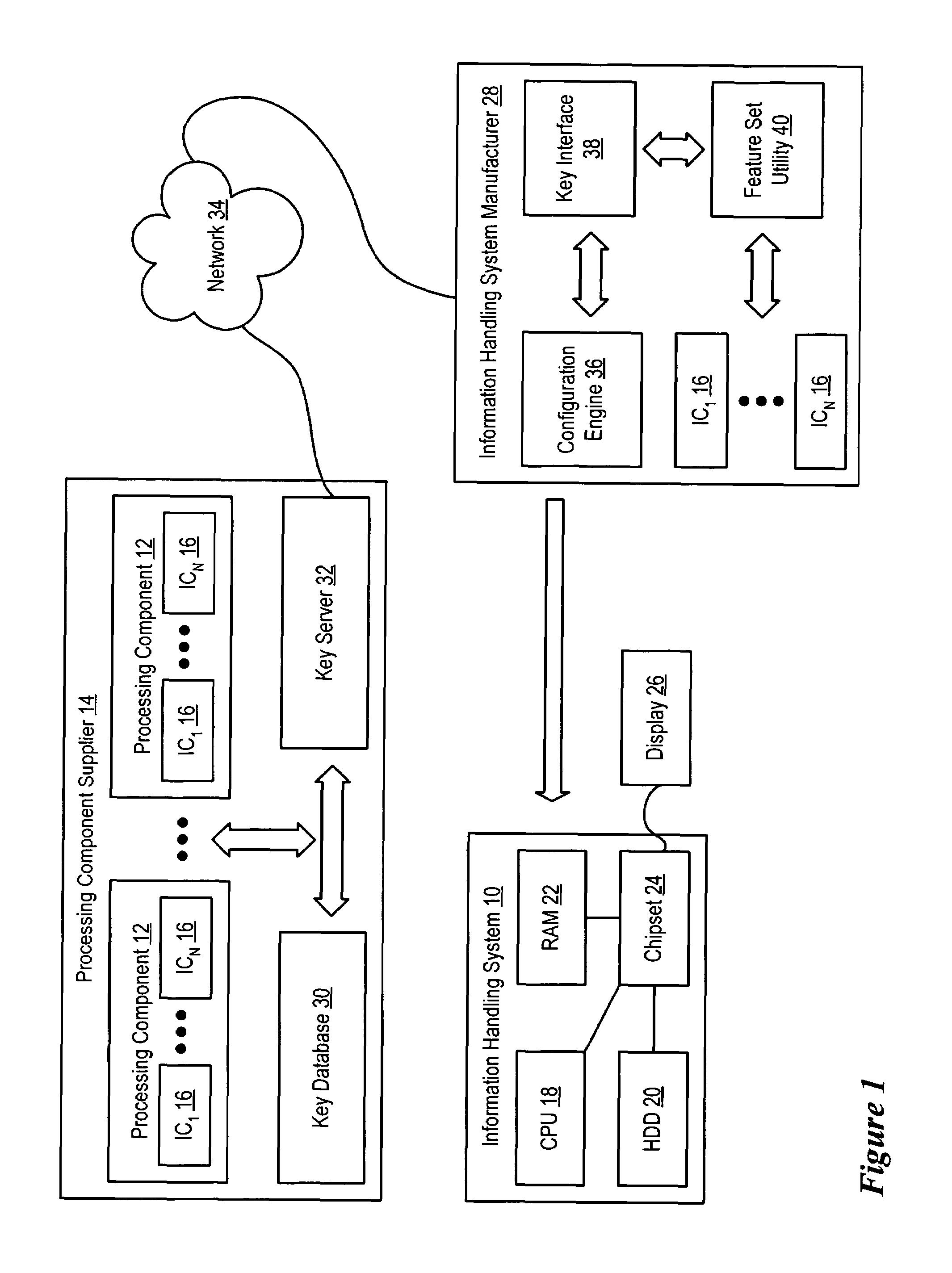

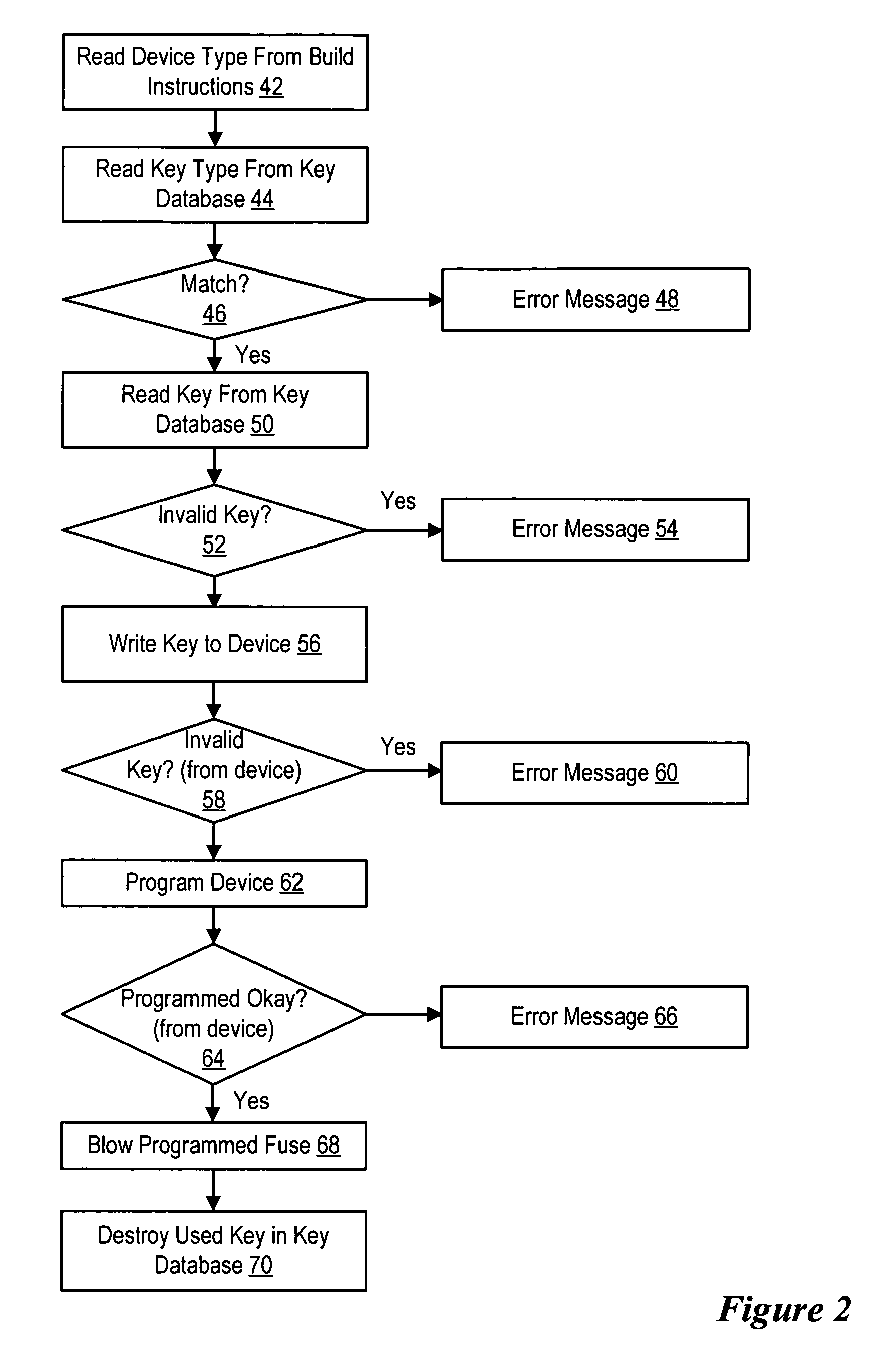

System and method for configuring information handling system integrated circuits

ActiveUS20070146005A1Increase flexibilityReduce manufacturing costDigital computer detailsCAD circuit designInformation processingFeature set

Processing components to manufacture information handling systems have build-to-order integrated circuits with plural selectively-enabled features set at the information handling system manufacture location. For instance, fuses integrated in the integrated circuits are selectively blown at the information handling system manufacture location to permanently disable features so that the processing components have a desired configuration. As another example, feature enable or disable states are programmed in flash incorporated in the integrated circuit, with the flash programmability subsequently disabled to permanently set the features so that the processing components have a desired configuration. Features are set with keys provided by the processing component manufacturer to track the information handling system manufacturer's use of the features.

Owner:DELL PROD LP

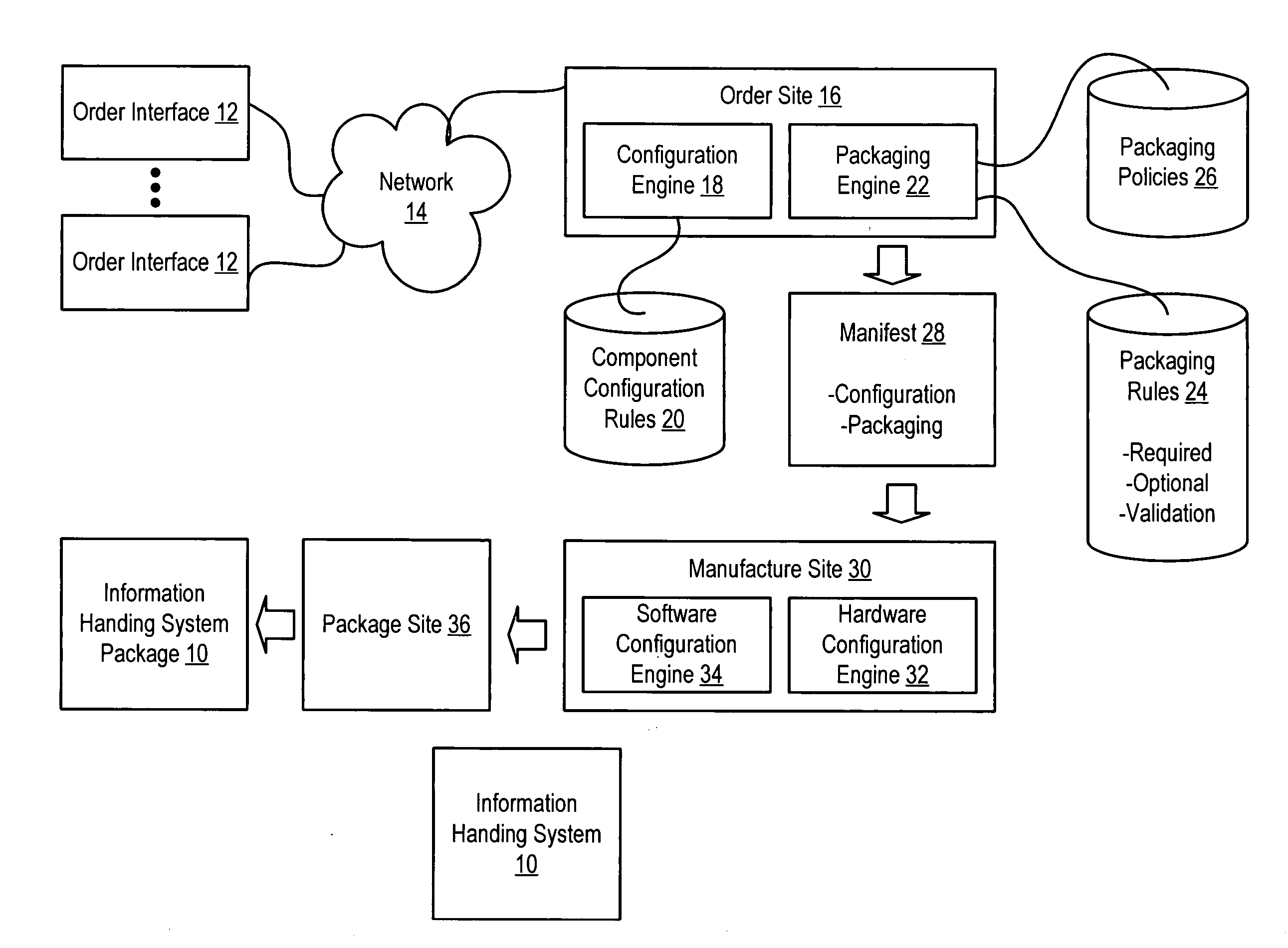

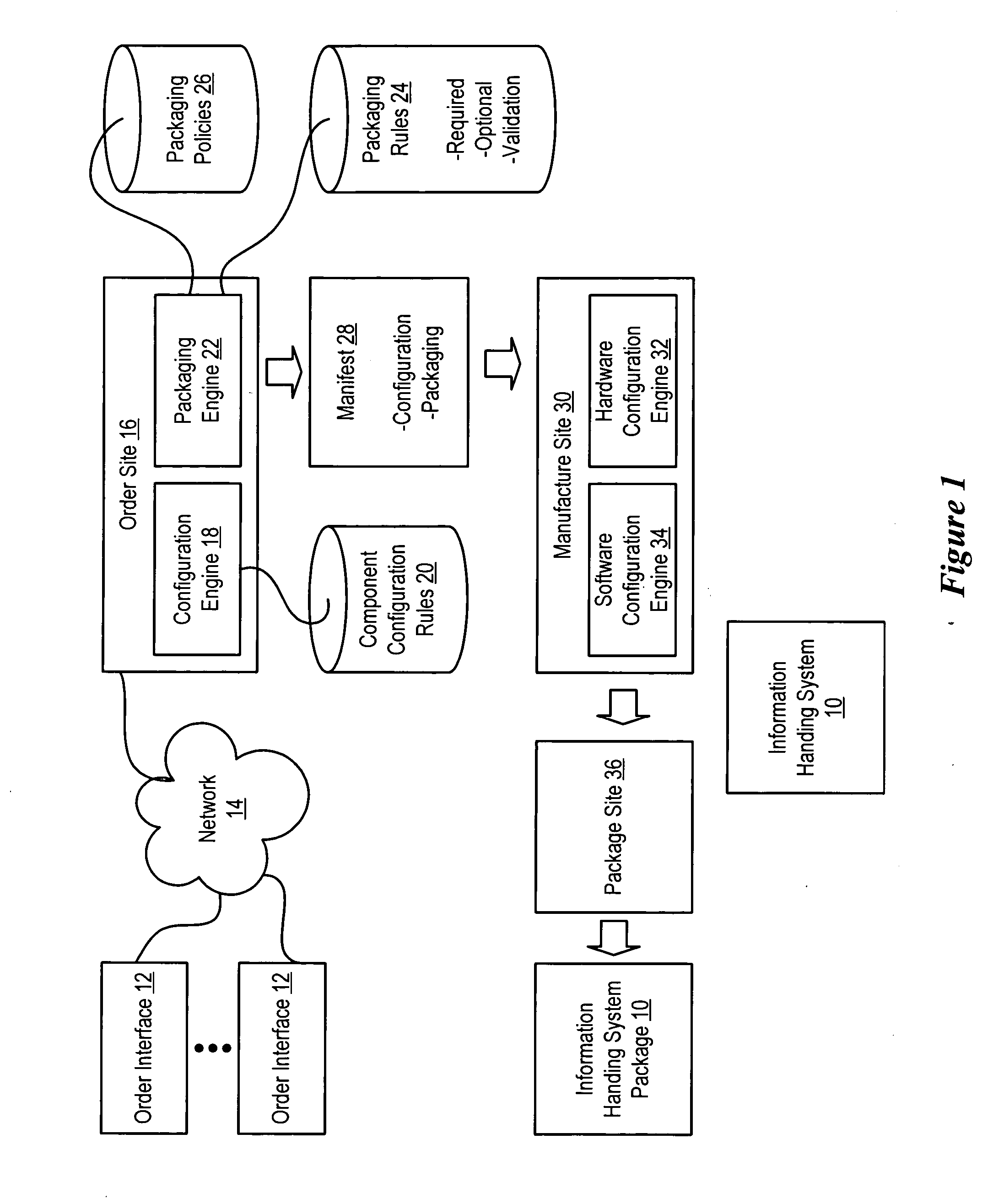

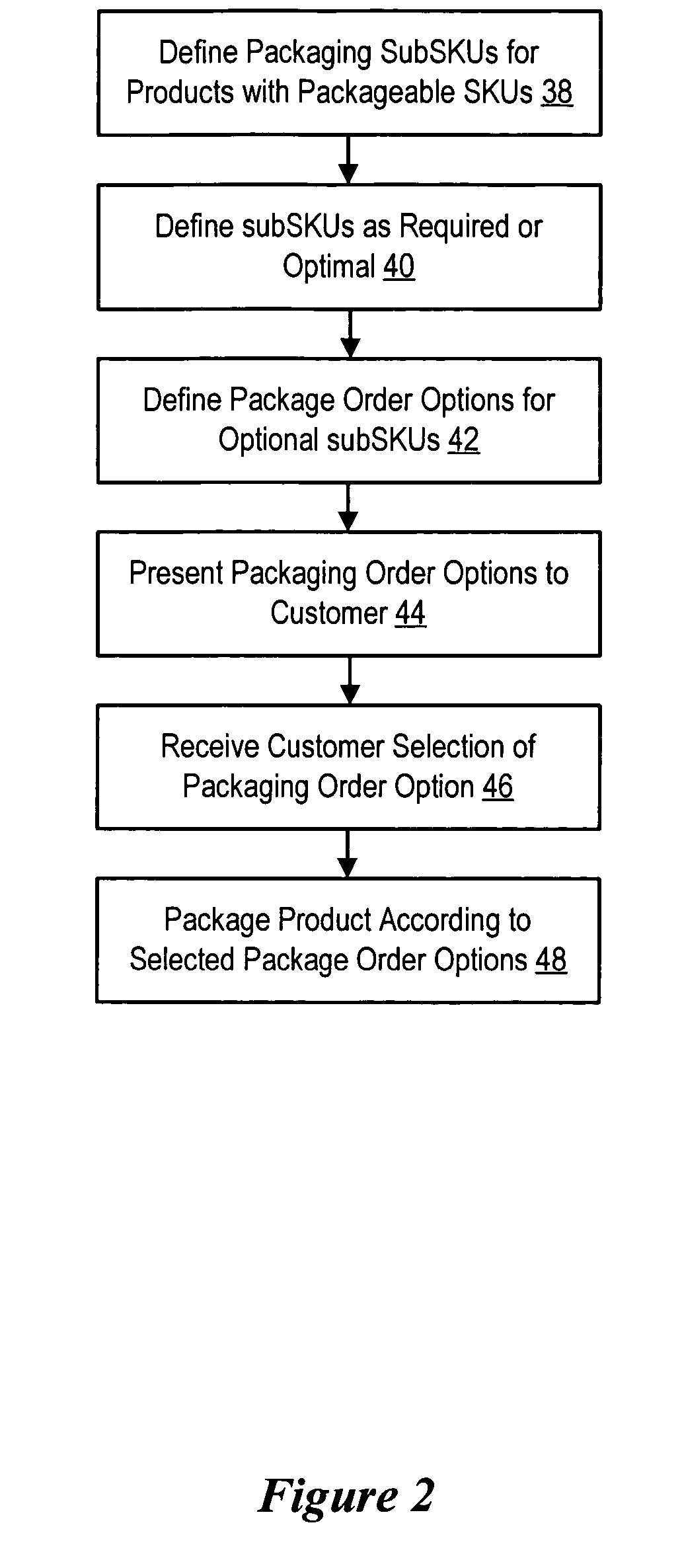

System and method for information handling system build-to-order packaging

InactiveUS20060229951A1Avoid wastingReduce packaging costsBuying/selling/leasing transactionsLogisticsInformation processingThe Internet

Built-to-order products, such as information handling systems, are packaged-to-order based on user preferences for reduced packaging waste. The user is presented packaging options at an order for one or more information handling systems and selects desired options, such as excluding recovery media, application media and user manuals. For instance, a corporate user ordering plural information handling systems has the user manual included in only one package, excludes recovery CDs and elects to have a recovery image with applications electronically available over the Internet, such as with the entry of license keys. Selected options are saved as a packaging policy associated with the user for use with subsequent orders by the user.

Owner:DELL PROD LP

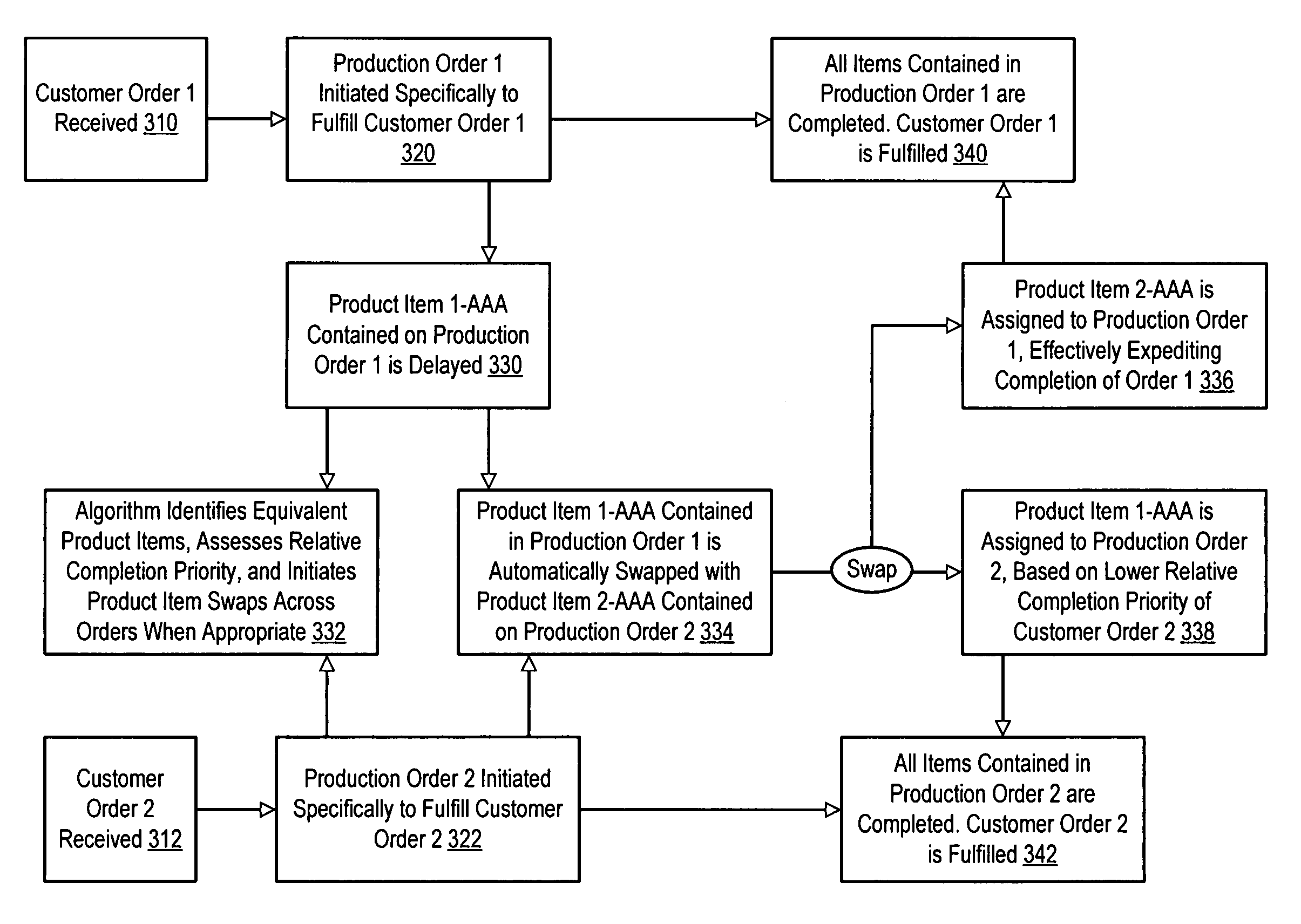

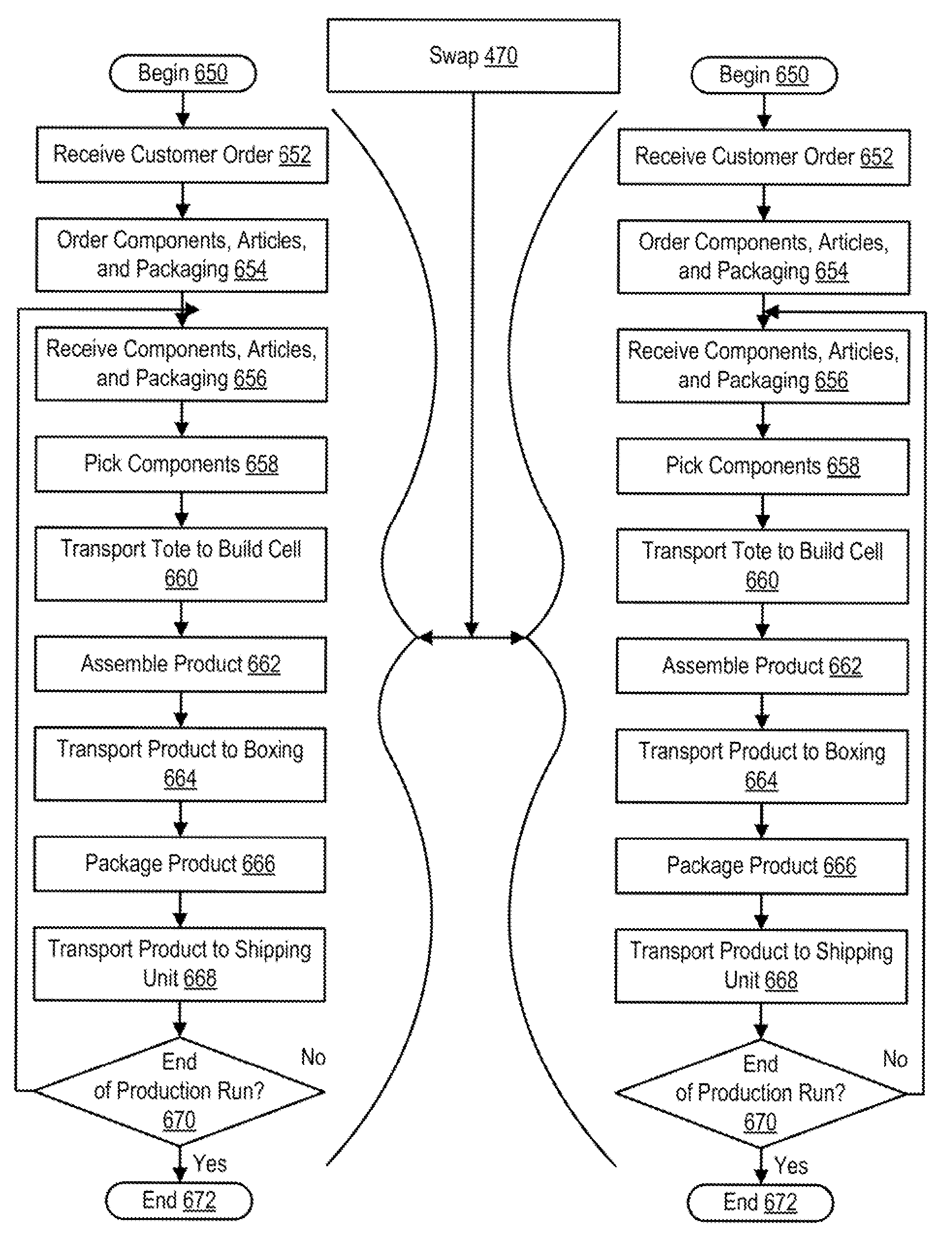

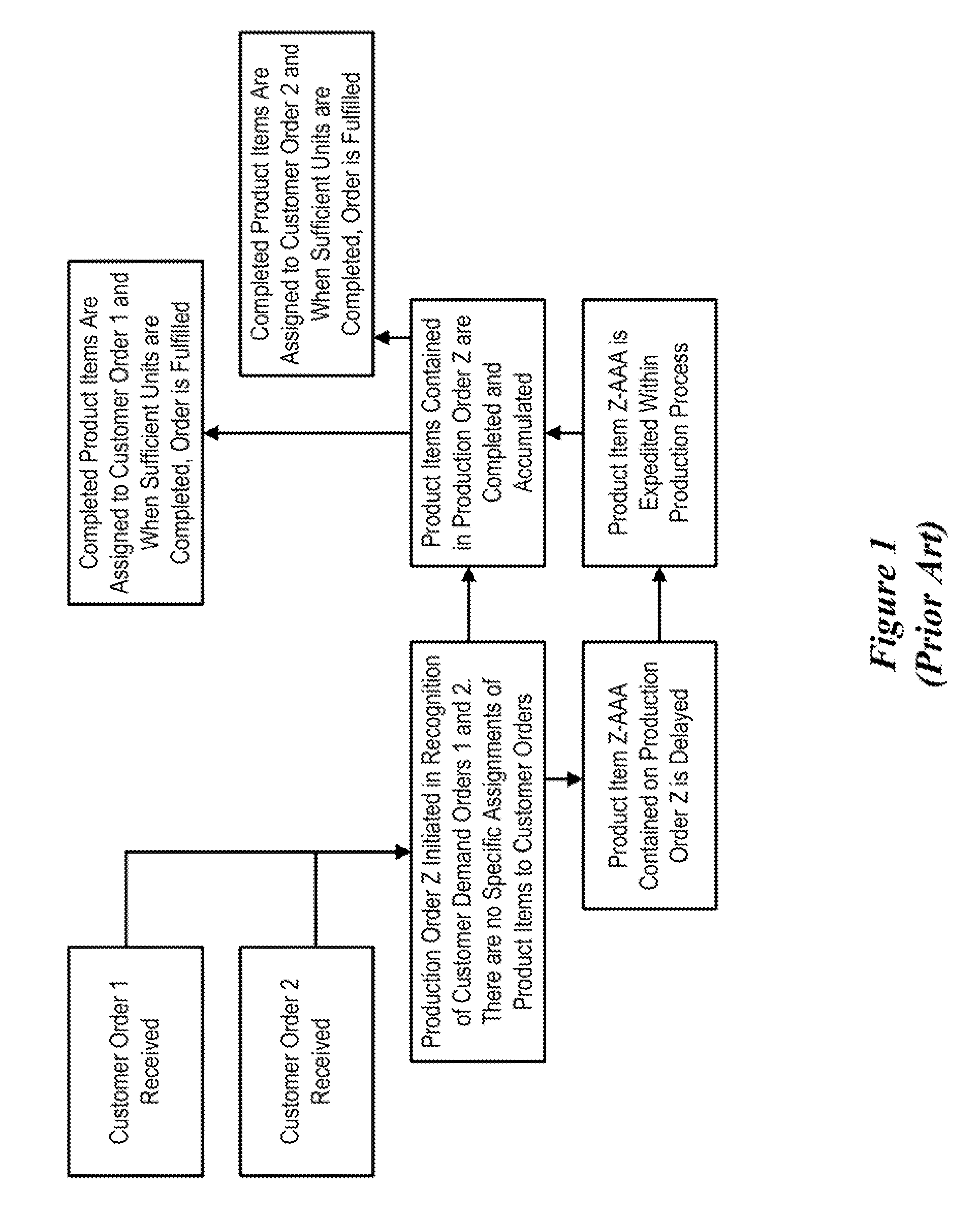

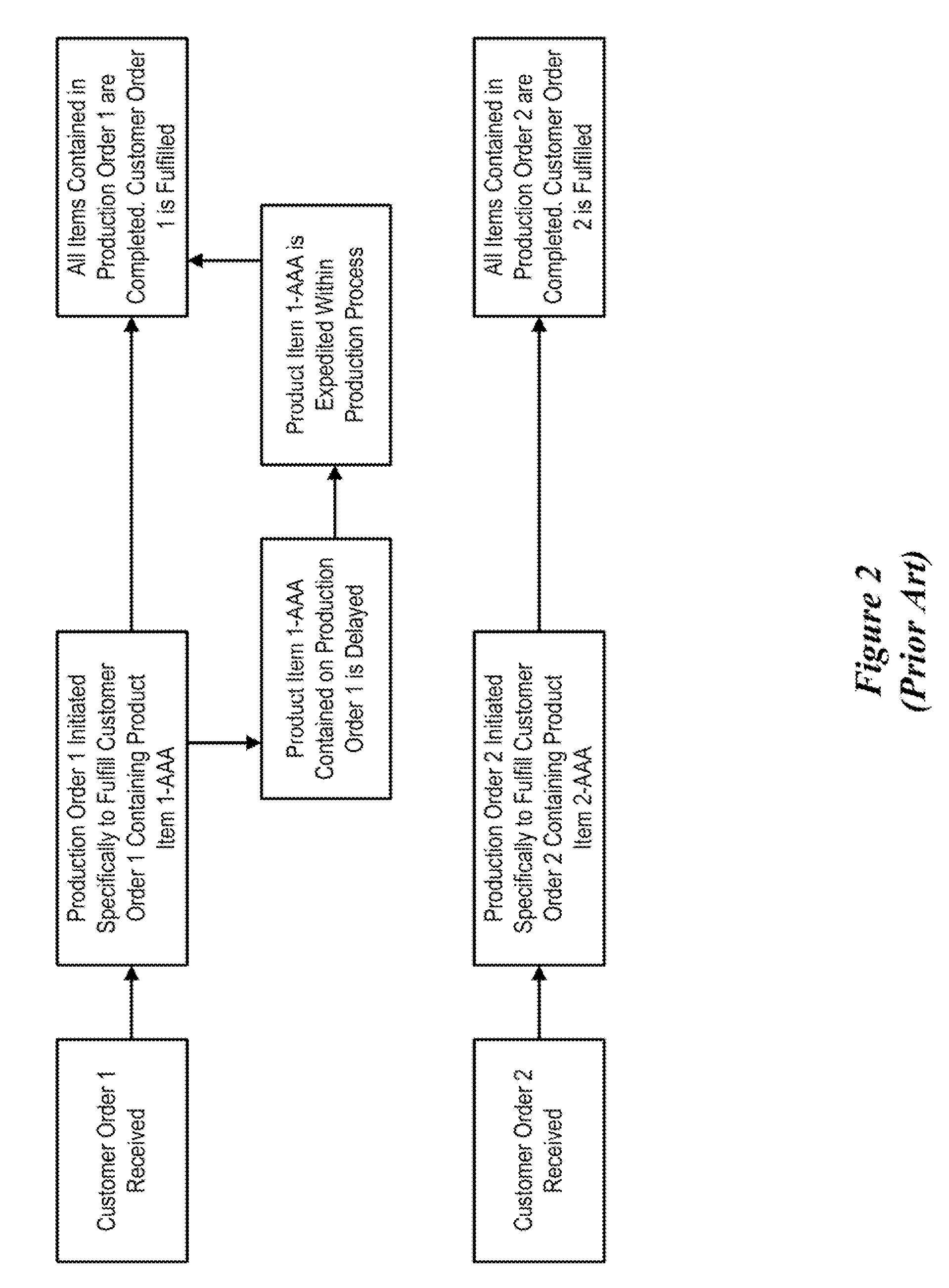

Dynamic order swapping in BTO environment

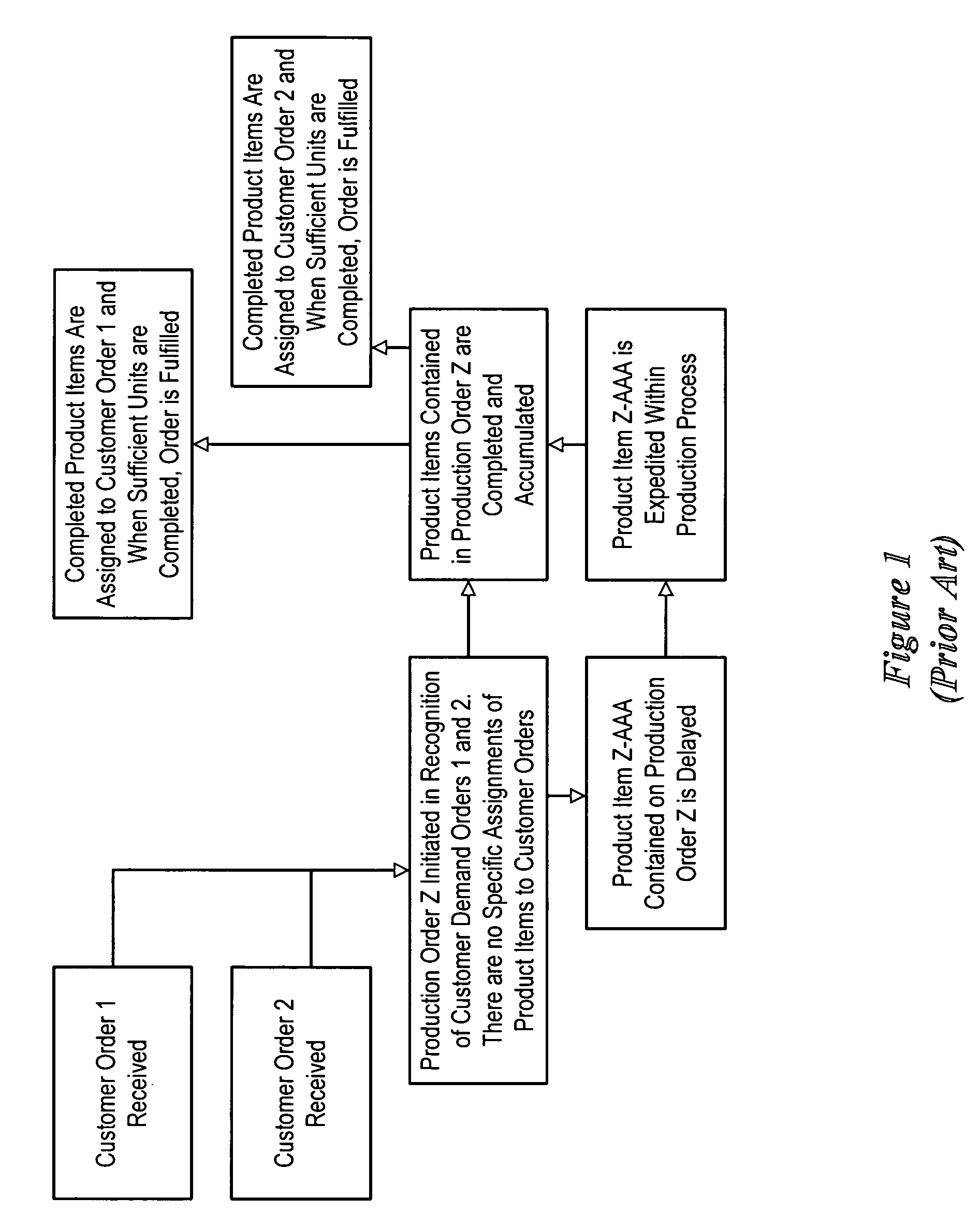

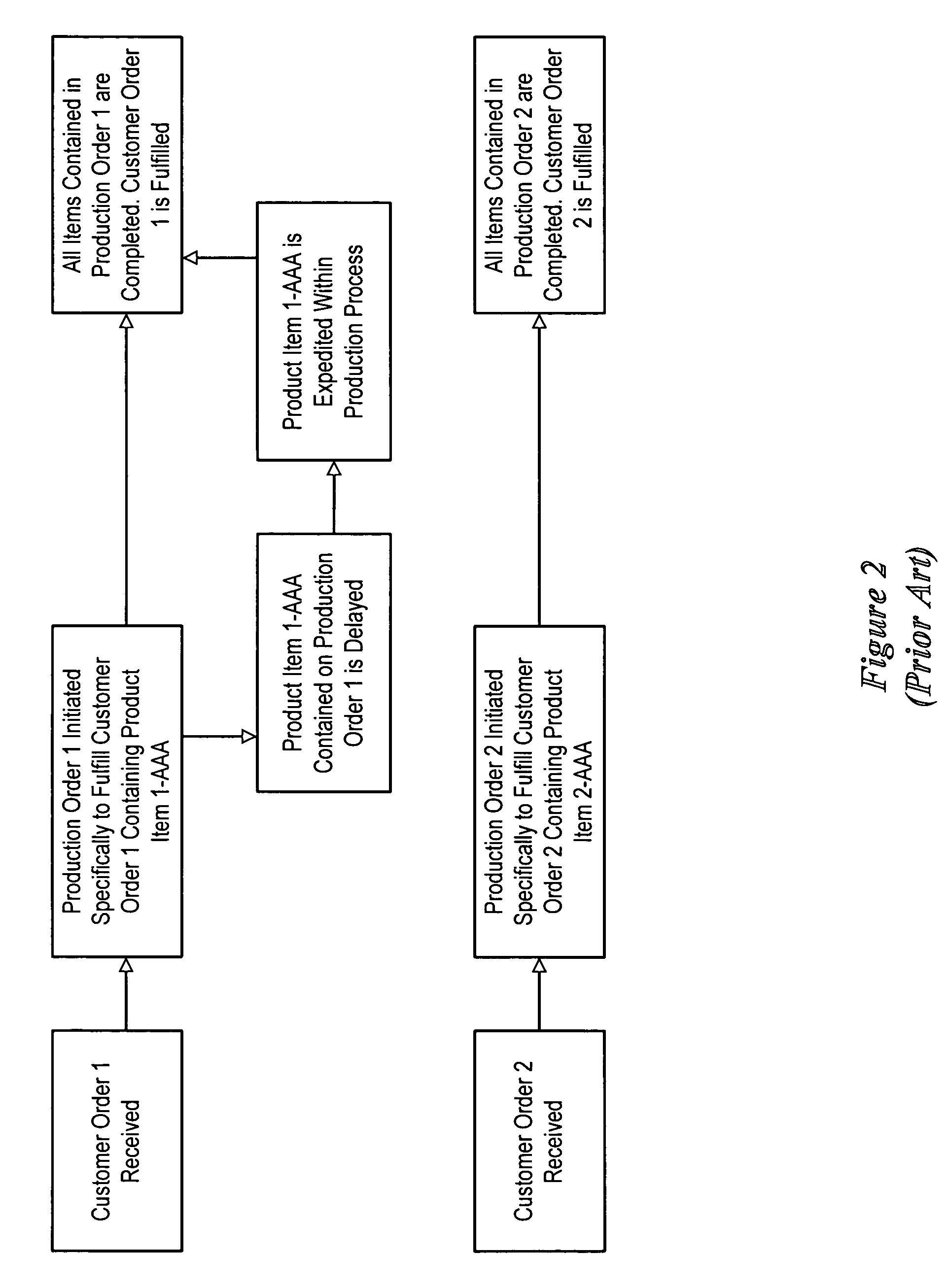

ActiveUS7308330B2Improve throughputImprove the level ofHand manipulated computer devicesDigital data processing detailsProduct orderMass customization

A method for addressing process variability in a build-to-order, mass customization production environment. The method includes receiving an order for a product having a particular configuration defined by the order, initiating a production order specifically assigned to the order, fabricating the product based upon the production order, determining if an unrelated product order contains an identical product item configuration and automatically swapping identical product items contained on unrelated production orders to optimize overall production process objectives.

Owner:DELL PROD LP

Method, system and facility for controlling resource allocation within a manufacturing environment

InactiveUS20020123814A1Low production costDigital data processing detailsResourcesWork in processBuild to order

In accordance with teachings of the present disclosure, a method, system and facility are described for controlling resource allocation within a build to order manufacturing environment. A system for providing a control center for a manufacturing facility is disclosed. The system includes a plurality of information sources operably associated with manufacturing products within the manufacturing facility. A user interface of the system displays selective information associated with portions of the manufacturing facility within a control center operable to manage production within the manufacturing facility. The system further includes a resource allocator operably coupled to the control center and the plurality of information sources and the resource allocator is operable to monitor work in process within the manufacturing facility.

Owner:DELL PROD LP

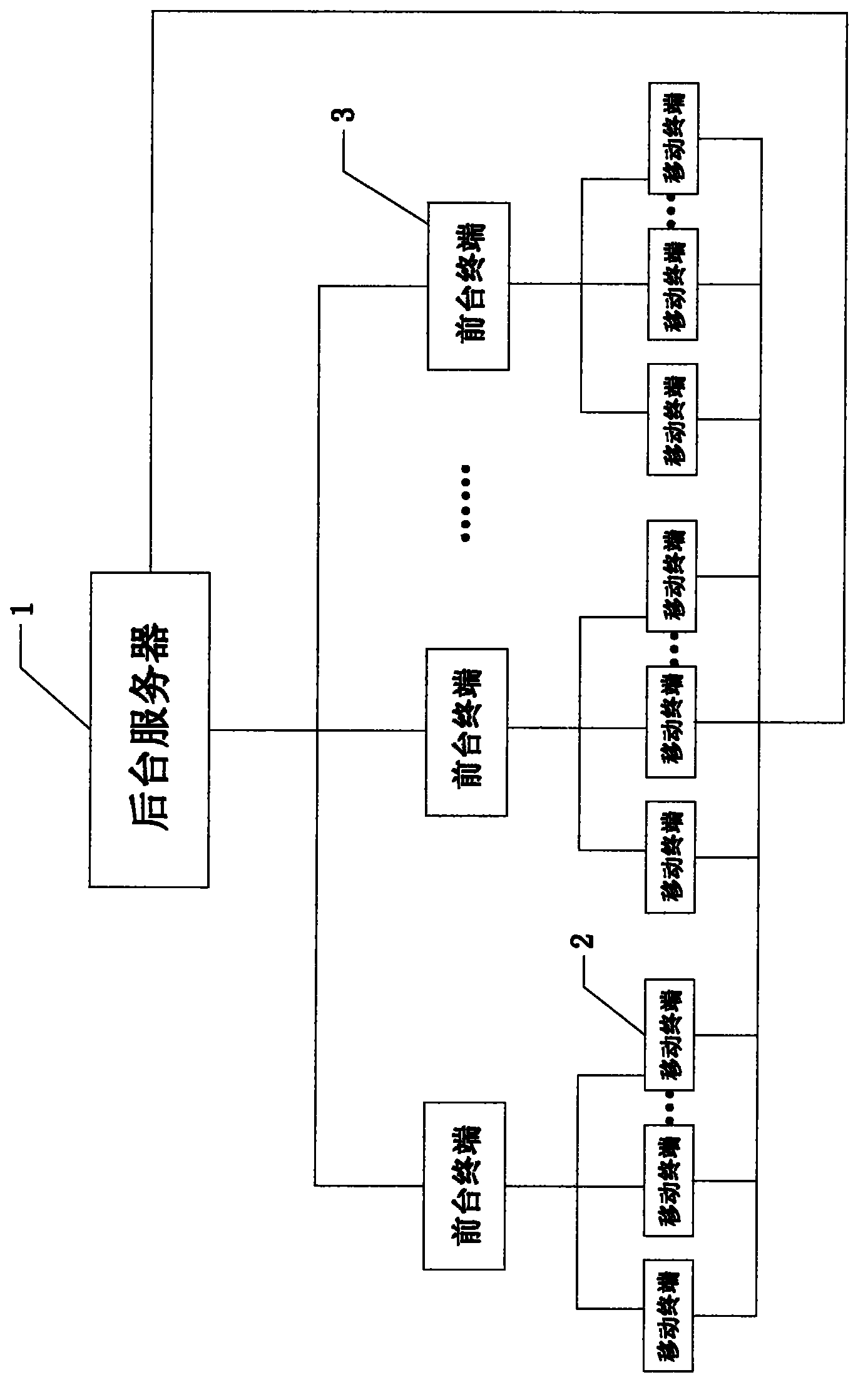

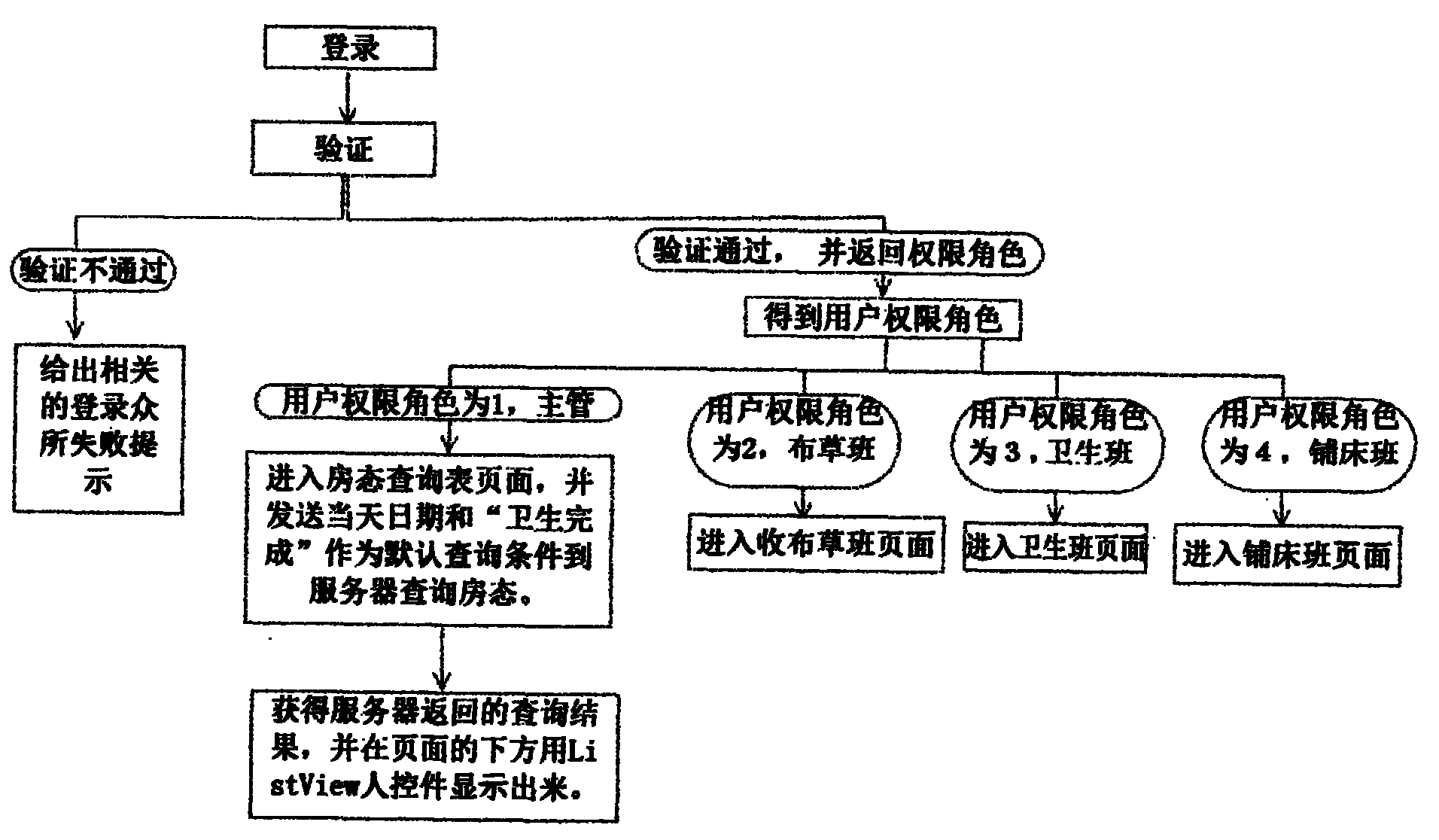

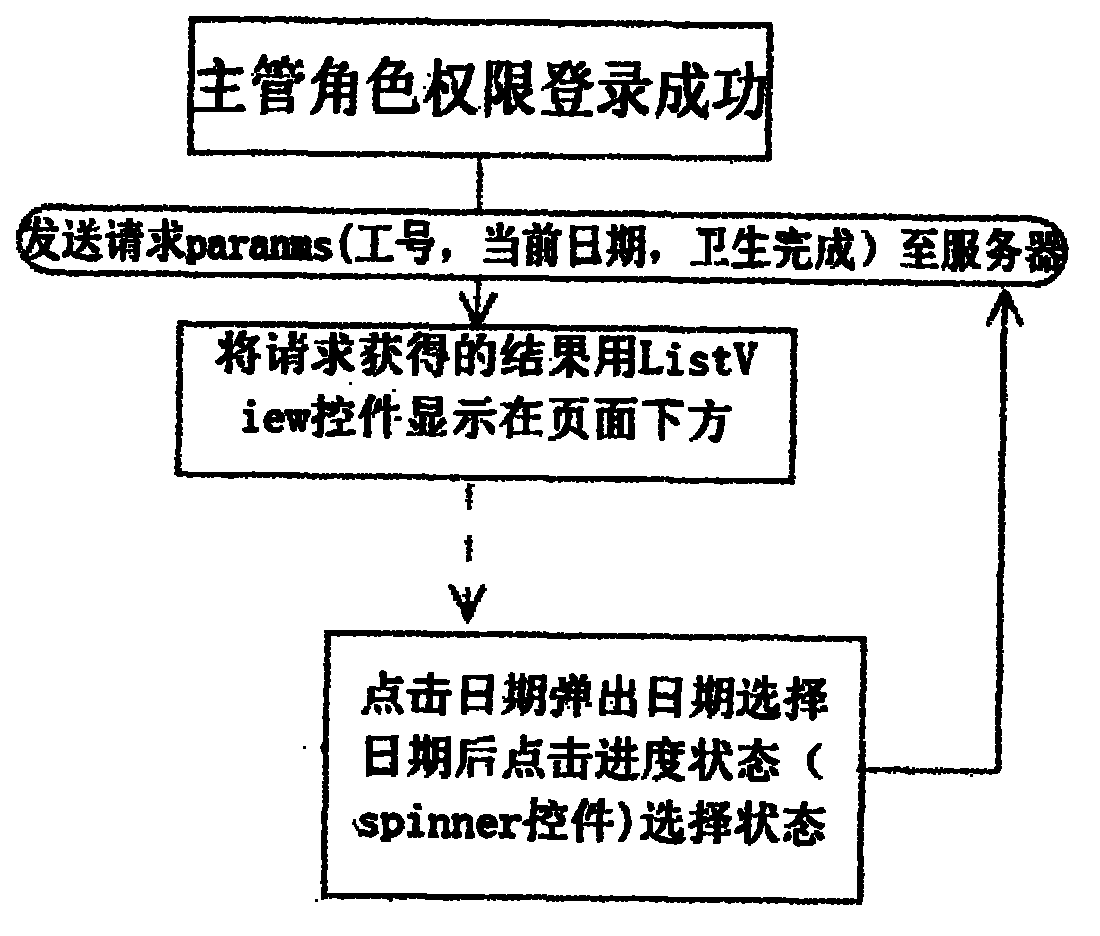

Intelligent hotel workflow management system, process management method and check-in registering method

ActiveCN102938110AAchieve fairnessEliminate the disadvantages of subjective judgmentResourcesWorkflow management systemComputer science

The invention discloses an intelligent hotel workflow management system, a process management method and a check-in registering method. The management system comprises a mobile terminal, a backstage server and a reception terminal, wherein the mobile terminal is respectively connected with the backstage server and the reception terminal, and the backstage server is connected with the reception terminal. The process management method comprises the steps of: logging in a system platform on a mobile terminal, judging a logged privilege role after verification and then carrying out corresponding operation. The check-in registering method comprises the process of: generating an order in the reception terminal, prearranging rooms, finishing check-in registering preparation, handling check-in procedures, serving customers during the process the customers are in the hotel, carrying out check-out procedures by the customers, clearing up check-in records of the customers and confirming the correctness of the check-in records with the customers. According to the management system, the working achievements of staff can be recorded objectively and accurately, the shortage of subjective judgment by supervisors is overcome, and the fairness of the management can be realized to the maximum extent.

Owner:广州市赢商住电子商务有限公司

Secure electronic delivery seal for information handling system

InactiveUS20060048222A1Minimizes vulnerabilityMaximize flexibilityMemory loss protectionError detection/correctionInformation processingManifest file

A method and apparatus for ensuring the security of a particular configuration of hardware and software for an information handling system that is assembled using a “build-to-order” system. The present invention ensures the security and integrity of data on an information handling system from the point of manufacture to the final destination at the customer's facility. The information handling system is then manufactured with the operating system and a predetermined set of software being installed thereon. A manifest file is constructed comprising a predetermined set of data files and configuration information. The manifest file is electronically signed with at least one electronic key. When the information handling system performs its initial boot, a second electronic key is used to extract information from the manifest file and the existing data files and configuration information is compared to the information contained in the manifest file. If any of the information compared to the manifest has been altered, the initial boot is designated as “invalid” and the user is notified of the potential for a breach of security.

Owner:DELL PROD LP

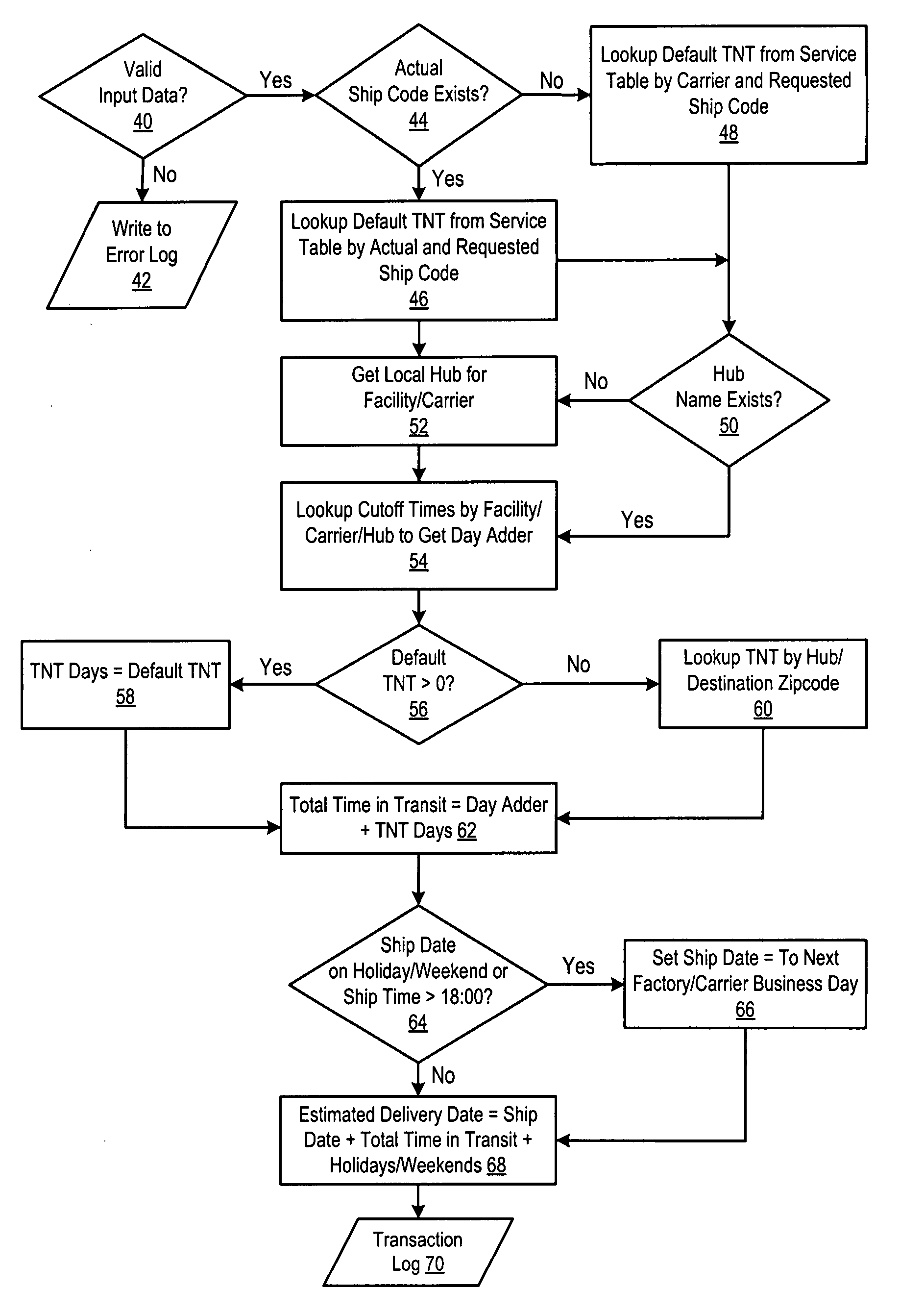

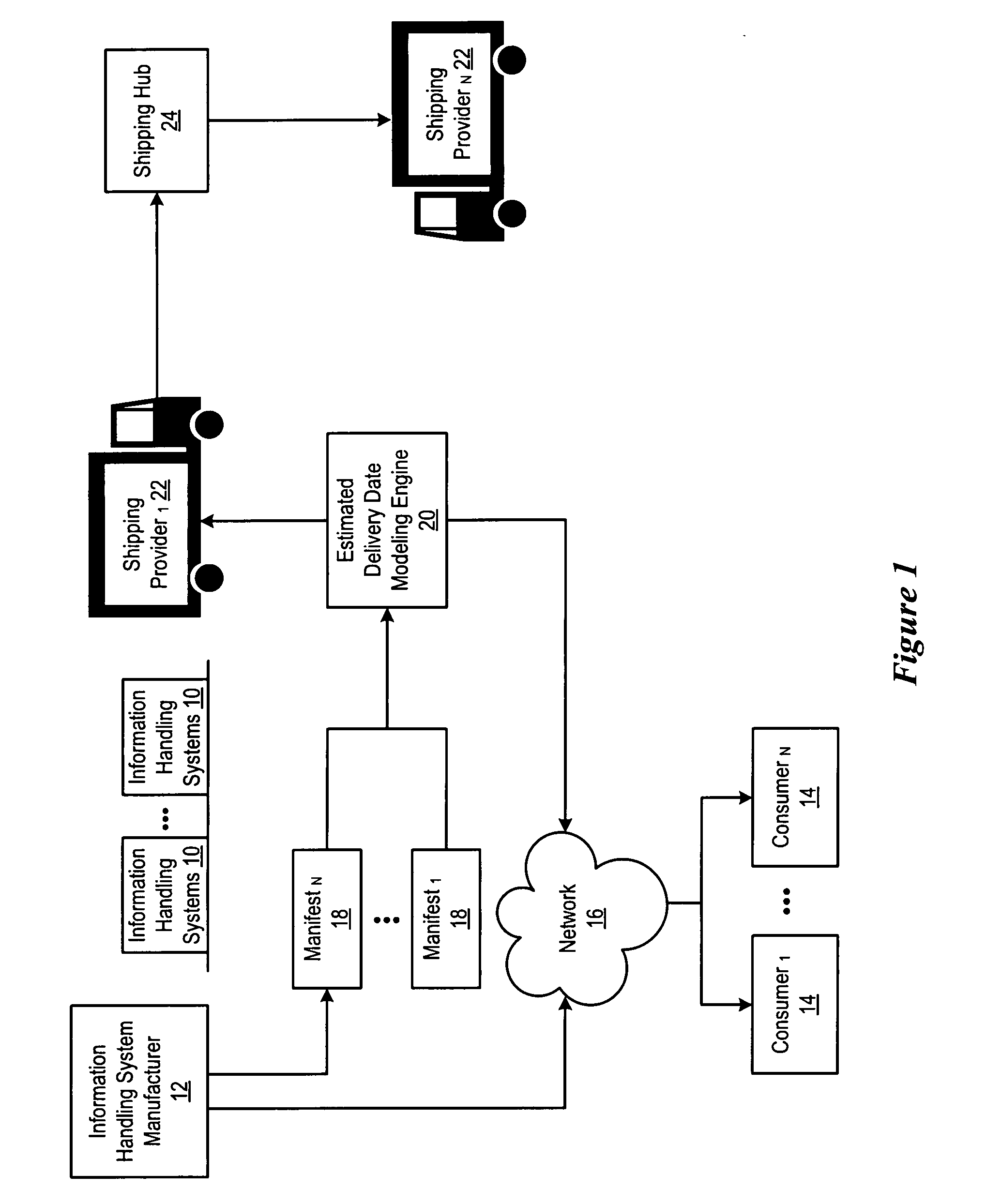

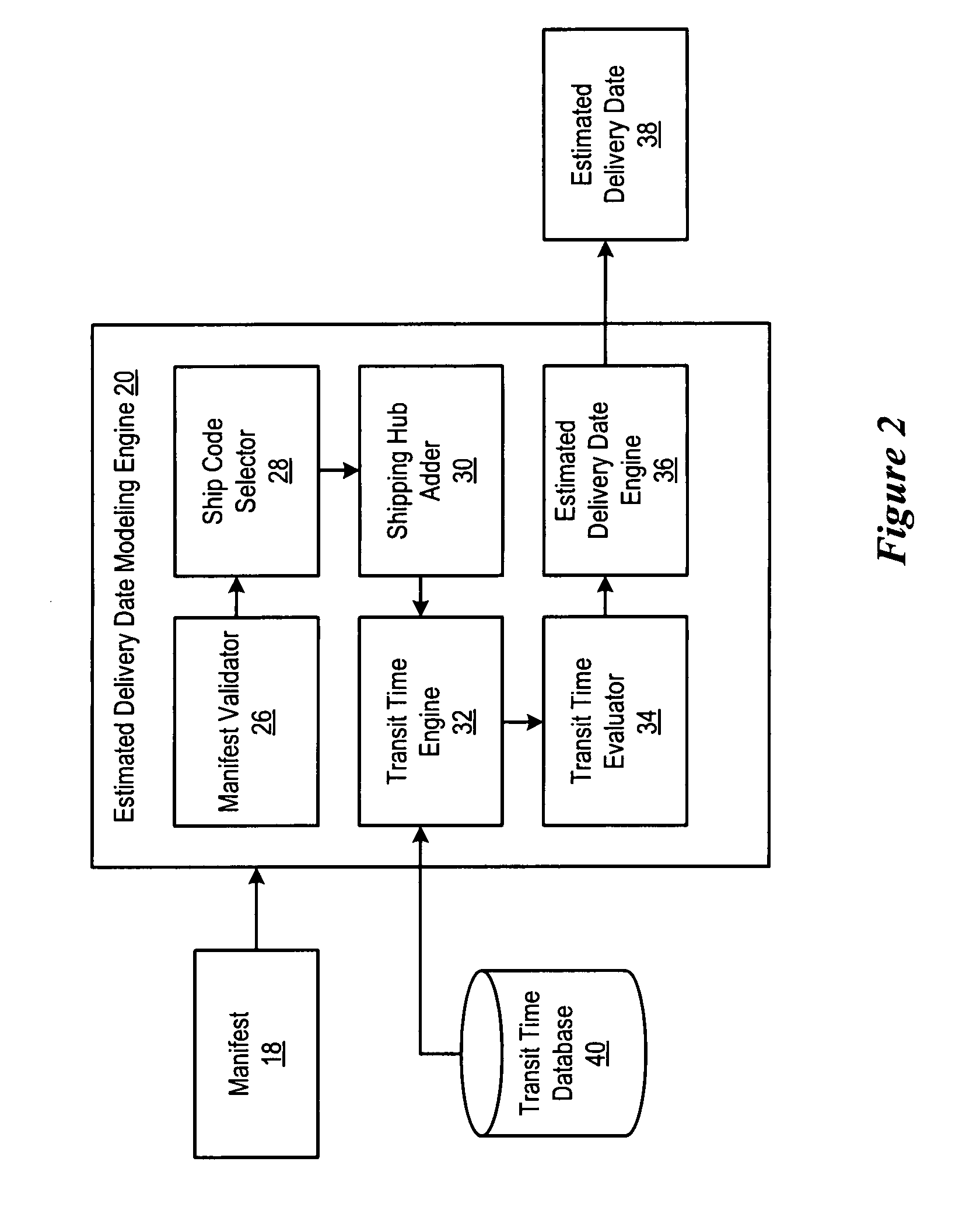

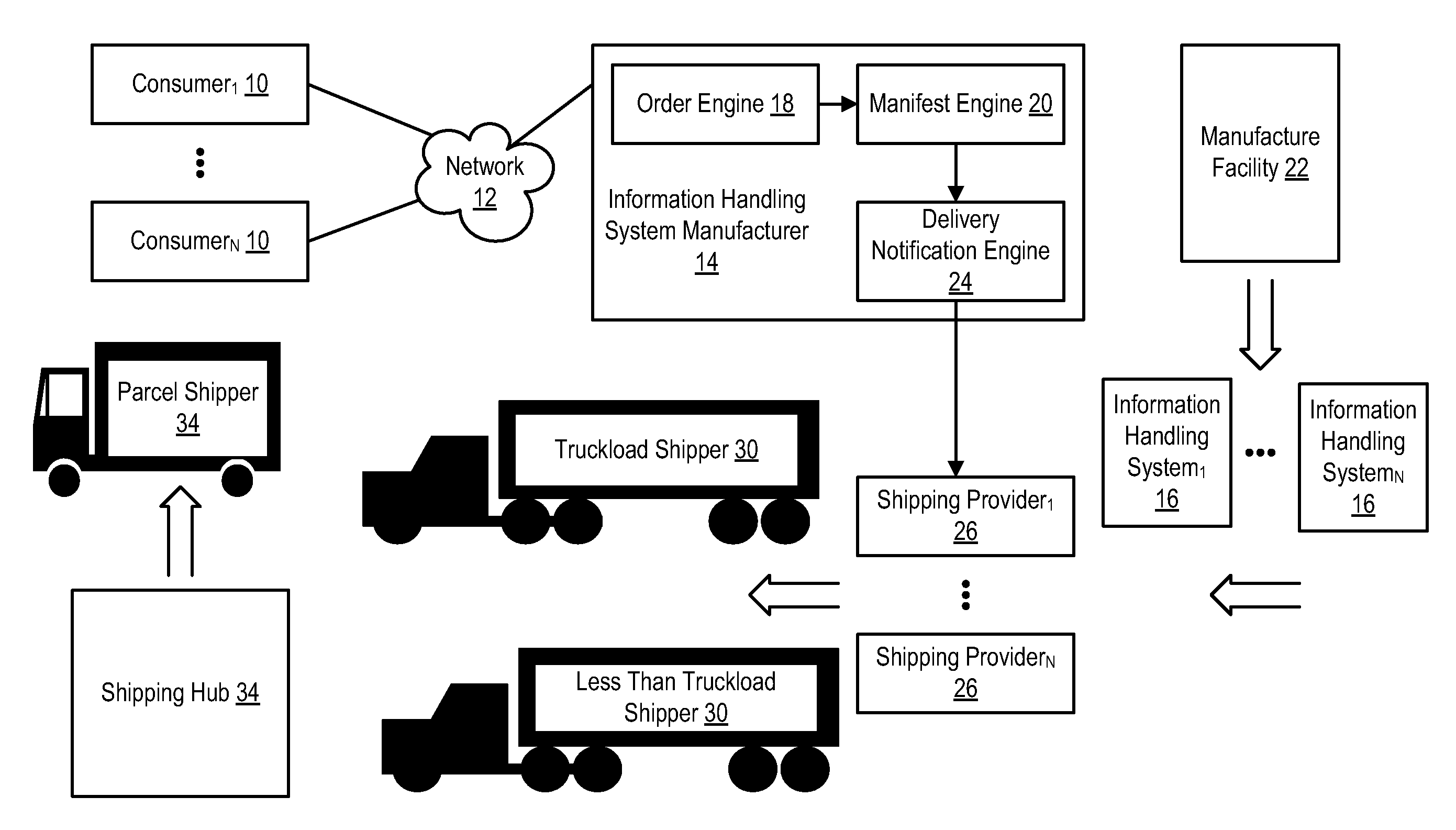

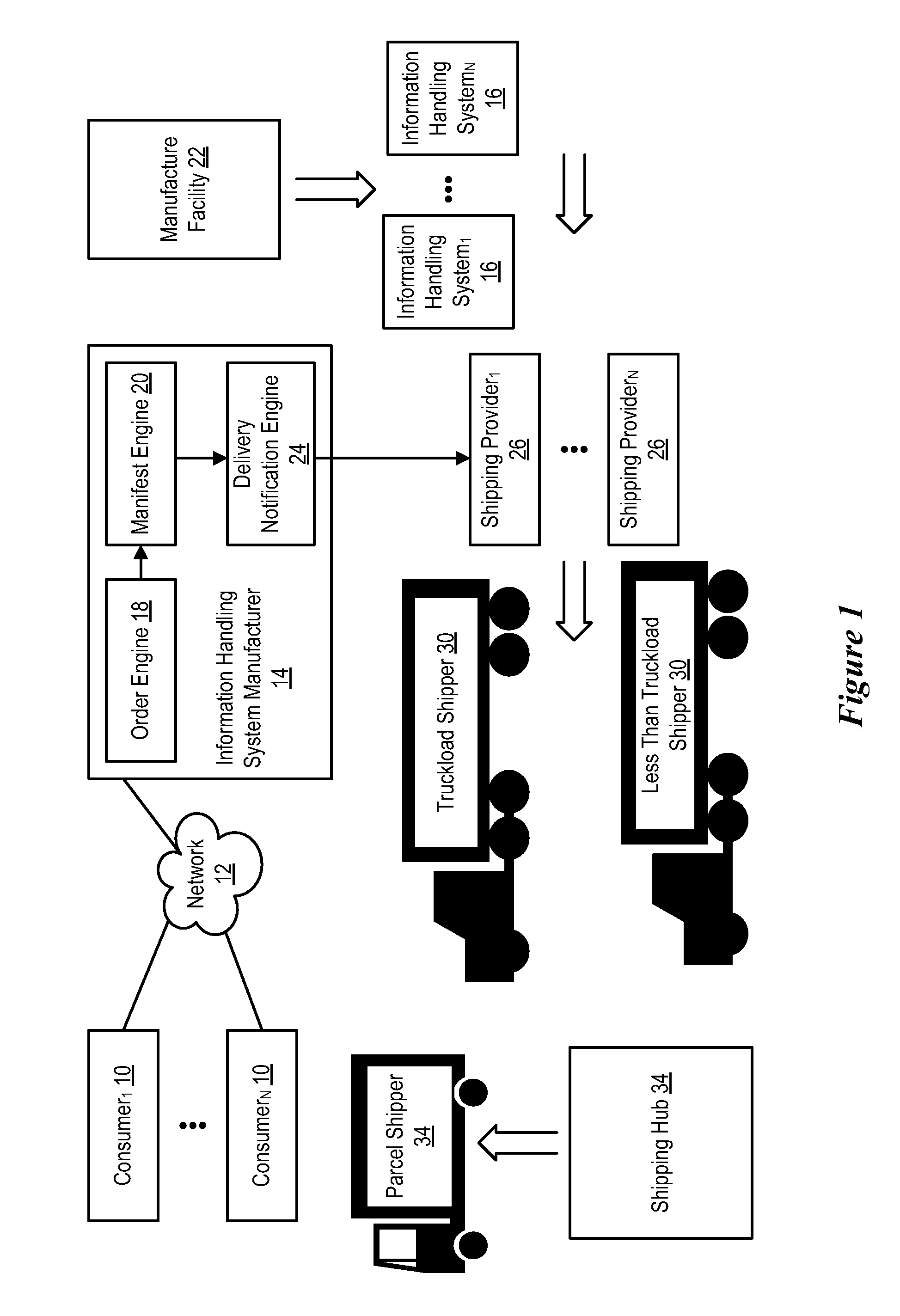

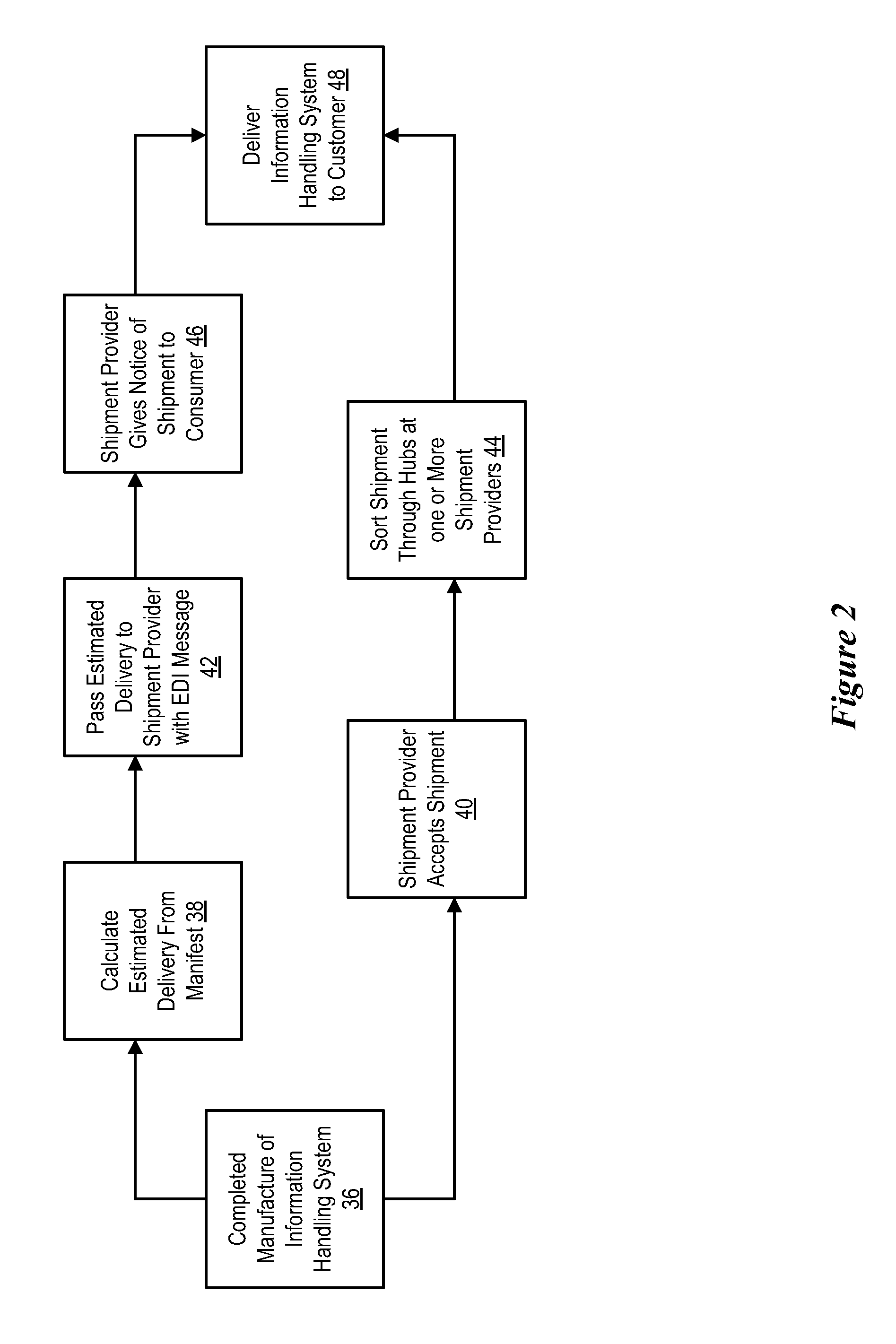

System and Method for Estimating a Shipment Delivery Date

InactiveUS20090106033A1Reduce disadvantagesReduce problemsResourcesData acquisition and loggingTransport timeEngineering

An estimated delivery date model determines an estimated delivery date for a shipment of a product to a consumer. For example, a built-to-order information handling system shipped through plural shipping providers has an estimated delivery date determined to provide early notice of the shipment to the consumer. The delivery date is estimated from a manifest for the product based on time in transit adjusted for predicted delays, such as in hubs or due to non-shipping days.

Owner:DELL PROD LP

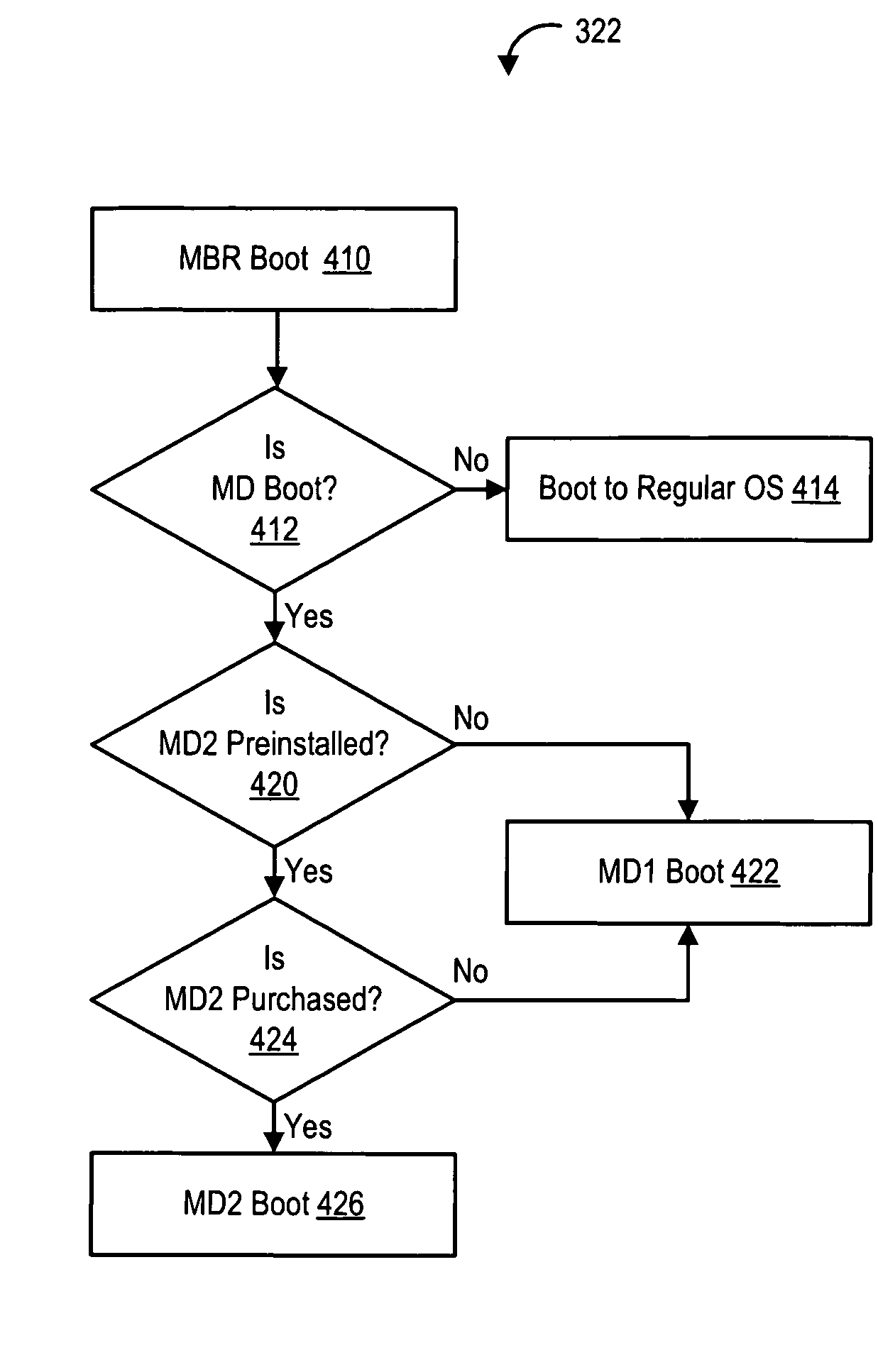

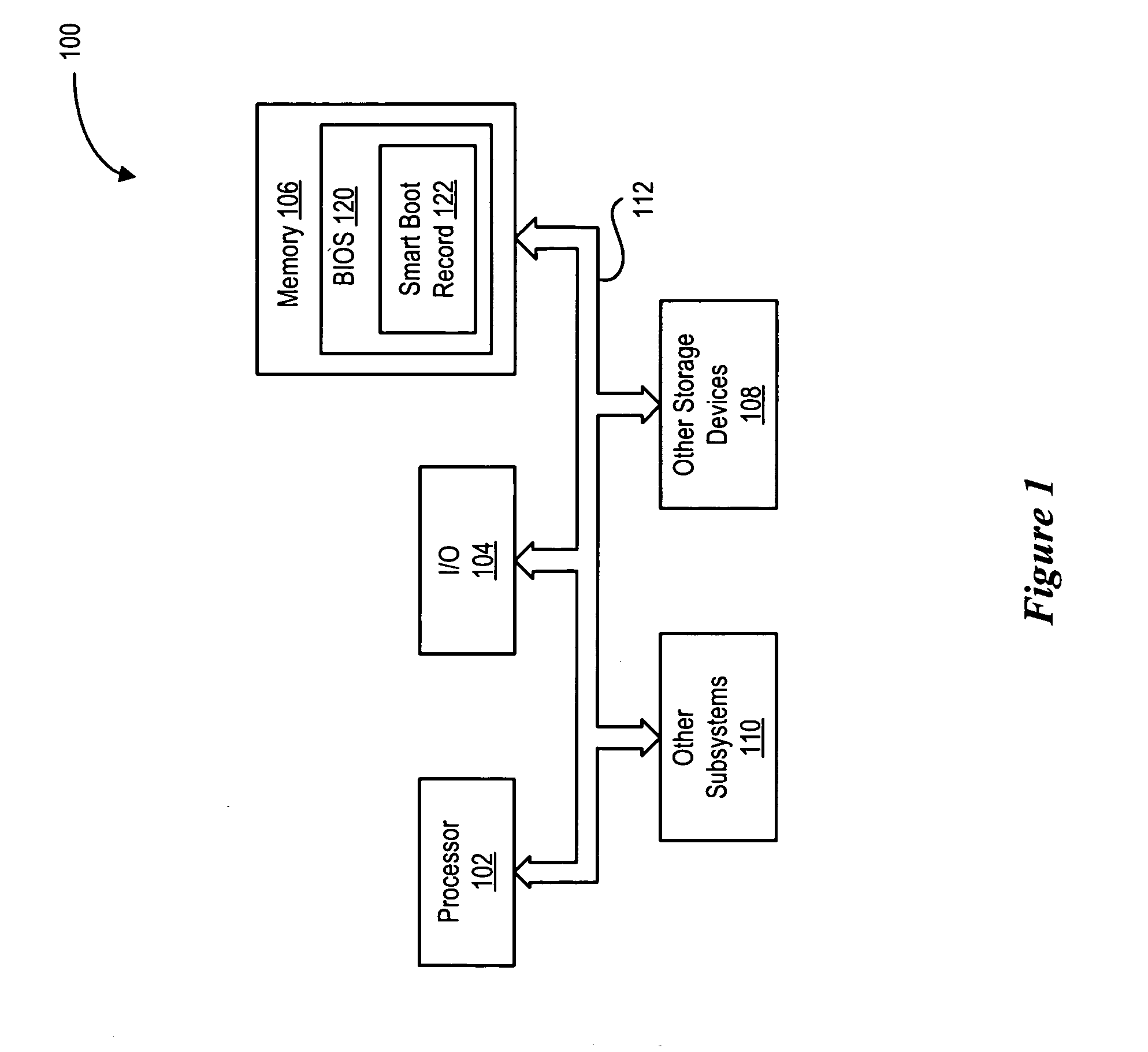

Build-to-order embedded operating system partition

ActiveUS20070186091A1Easy to upgradeImproving build to order processDigital computer detailsData resettingInformation processingOperational system

A method of enabling a user to upgrade an information handling system which includes storing an application within an embedded partition during the fabrication of the information handling system and storing a smart master boot record on the information handling system which enables access to the application stored within the embedded partition of the information handling system is disclosed.

Owner:DELL PROD LP

Dynamic Order Swapping in mass customization production environment

ActiveUS20090143887A1Improve throughputImprove the level ofHand manipulated computer devicesDigital data processing detailsMass customizationProduct order

A method for addressing process variability in a build-to-order, mass customization production environment. The method includes receiving an order for a product having a particular configuration defined by the order, initiating a production order specifically assigned to the order, fabricating the product based upon the production order, determining if an unrelated product order contains an identical product item configuration and automatically swapping identical product items contained on unrelated production orders to optimize overall production process objectives.

Owner:DELL PROD LP

System and method for modular display

ActiveUS20060164325A1Improve user experienceReduce manufacturing costsTelevision system detailsData processing applicationsModularityBuild to order

A modular display system and method assembles an external interface module with a display module to support built-to-order display configurations. The display module has display panel, timing controller and speaker components assembled in a display module housing that accepts a single LVDS and a single audio interface. The external interface module couples to the display module housing to form an integral display system. Selective assembly of the display system from plural types of external interface modules allows selective configuration of the display system with various television and information handling system display functionalities, such as to fill a purchaser order in a build-to-order manufacturing process.

Owner:DELL PROD LP

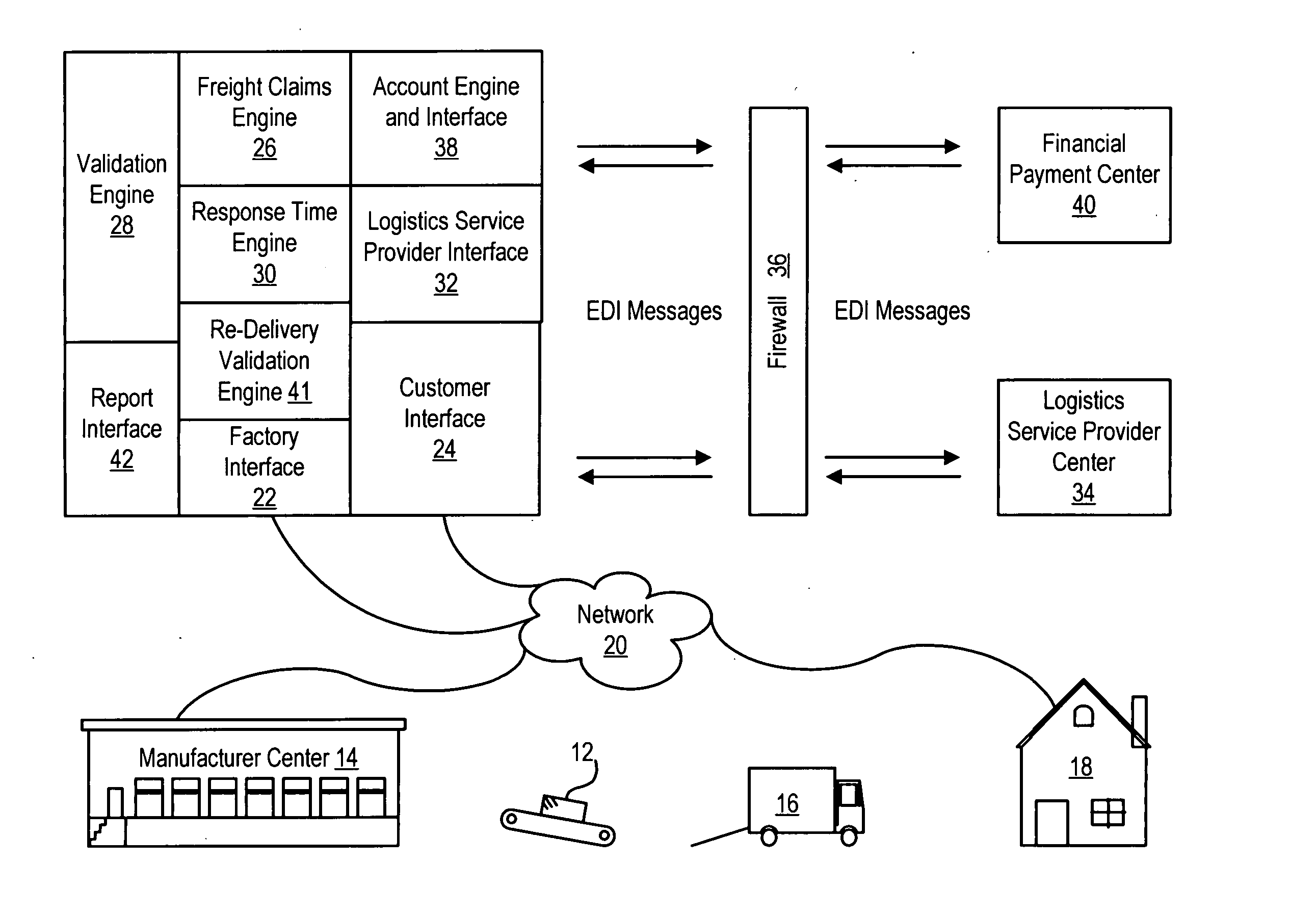

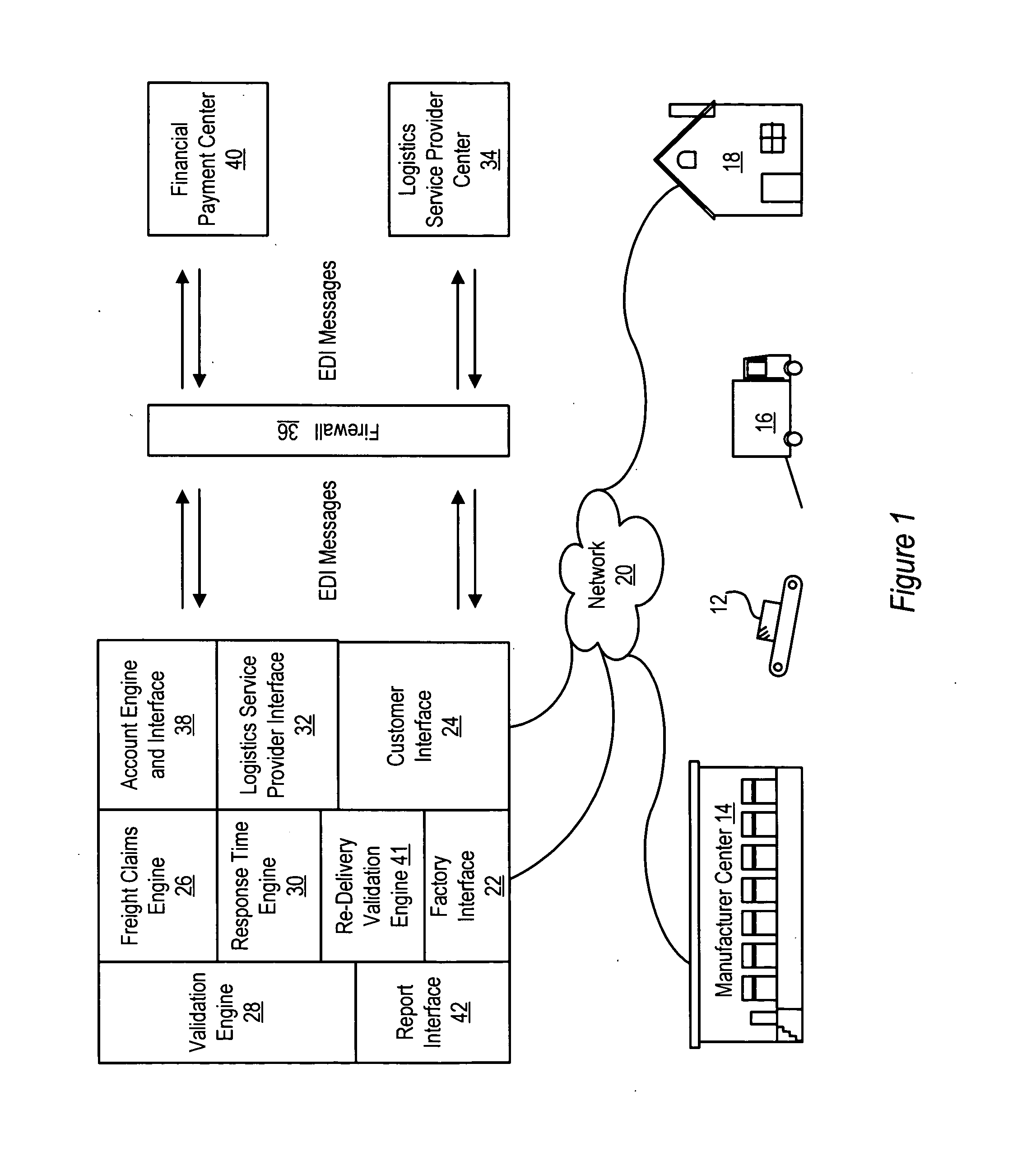

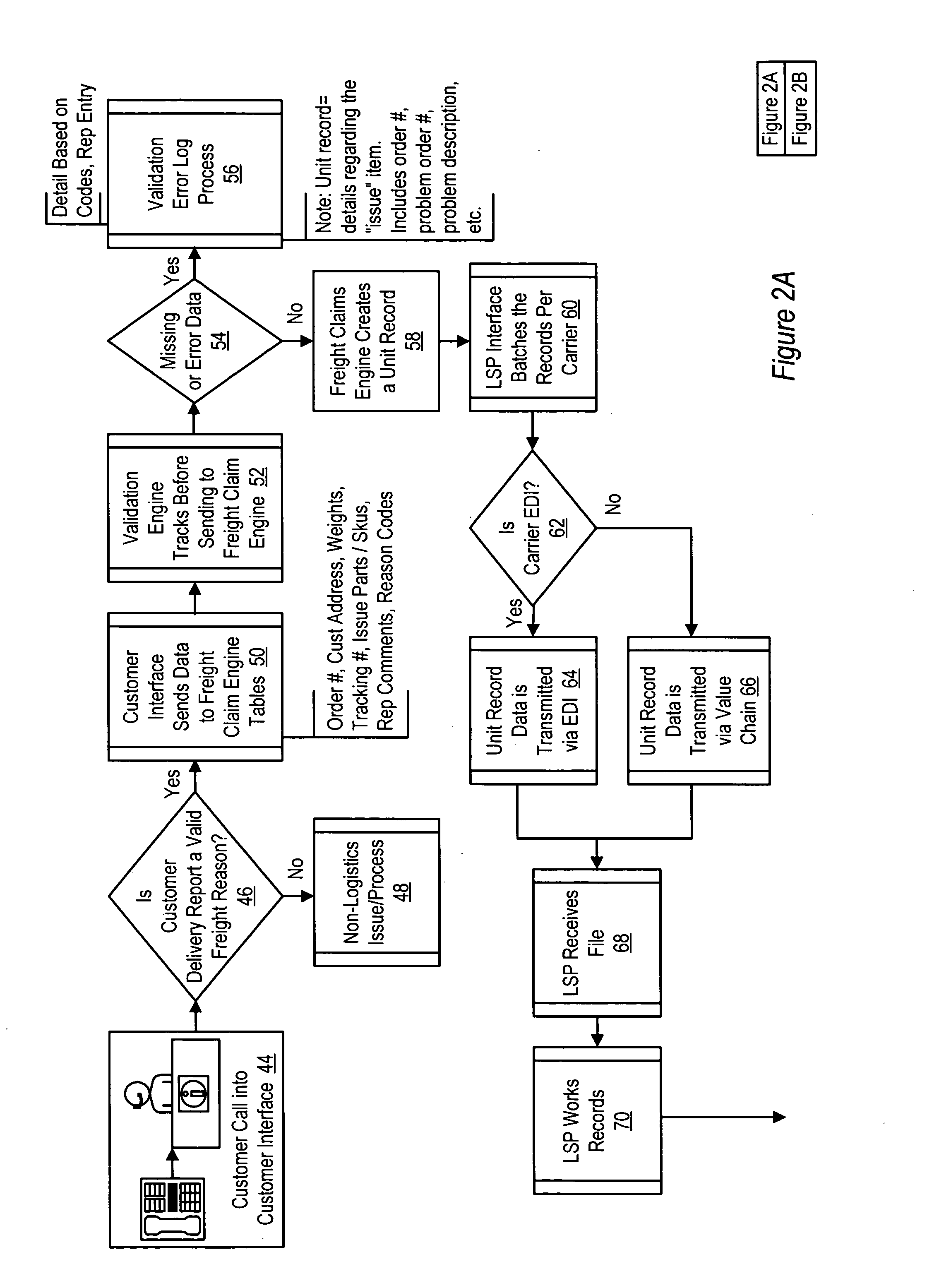

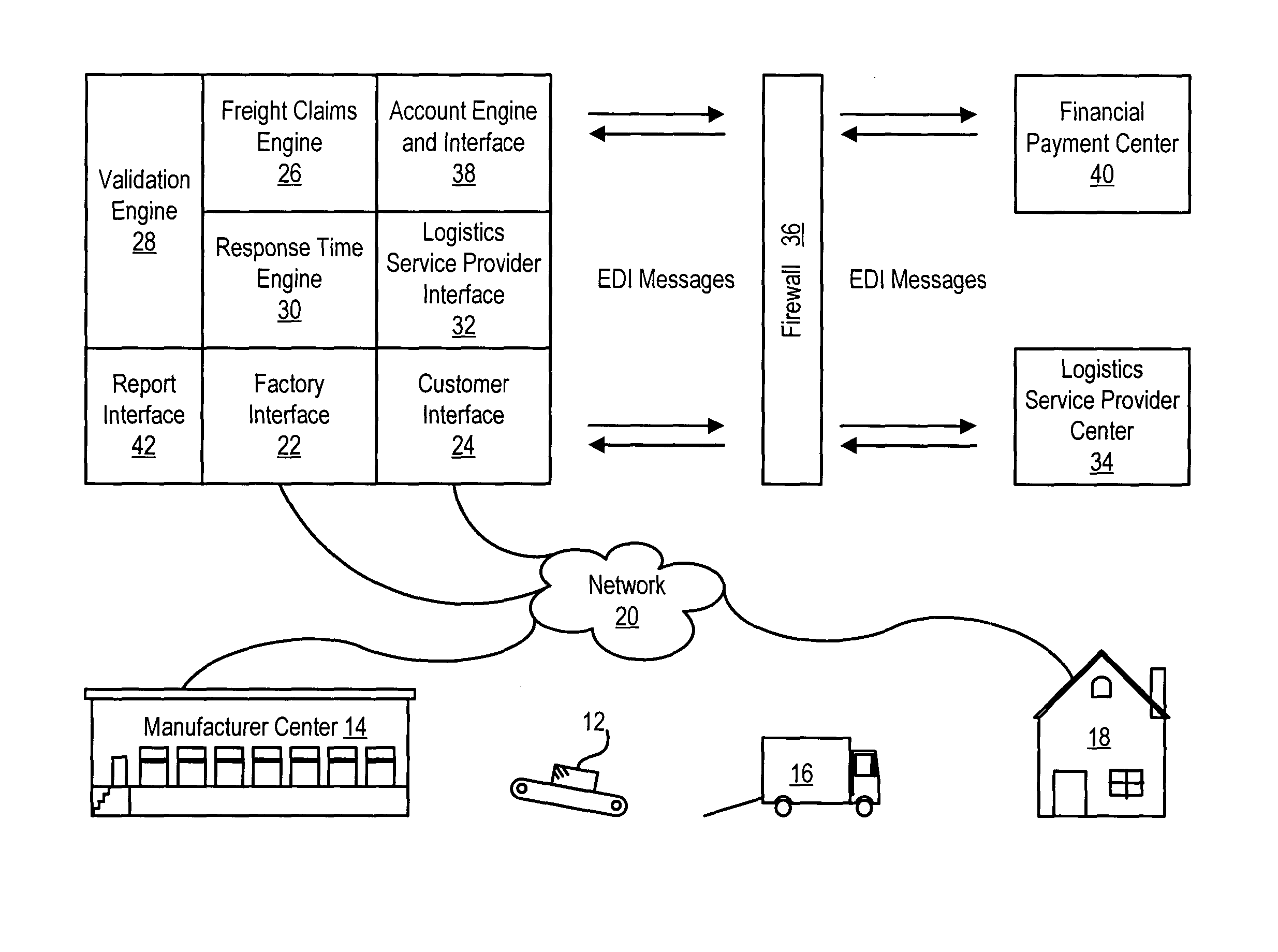

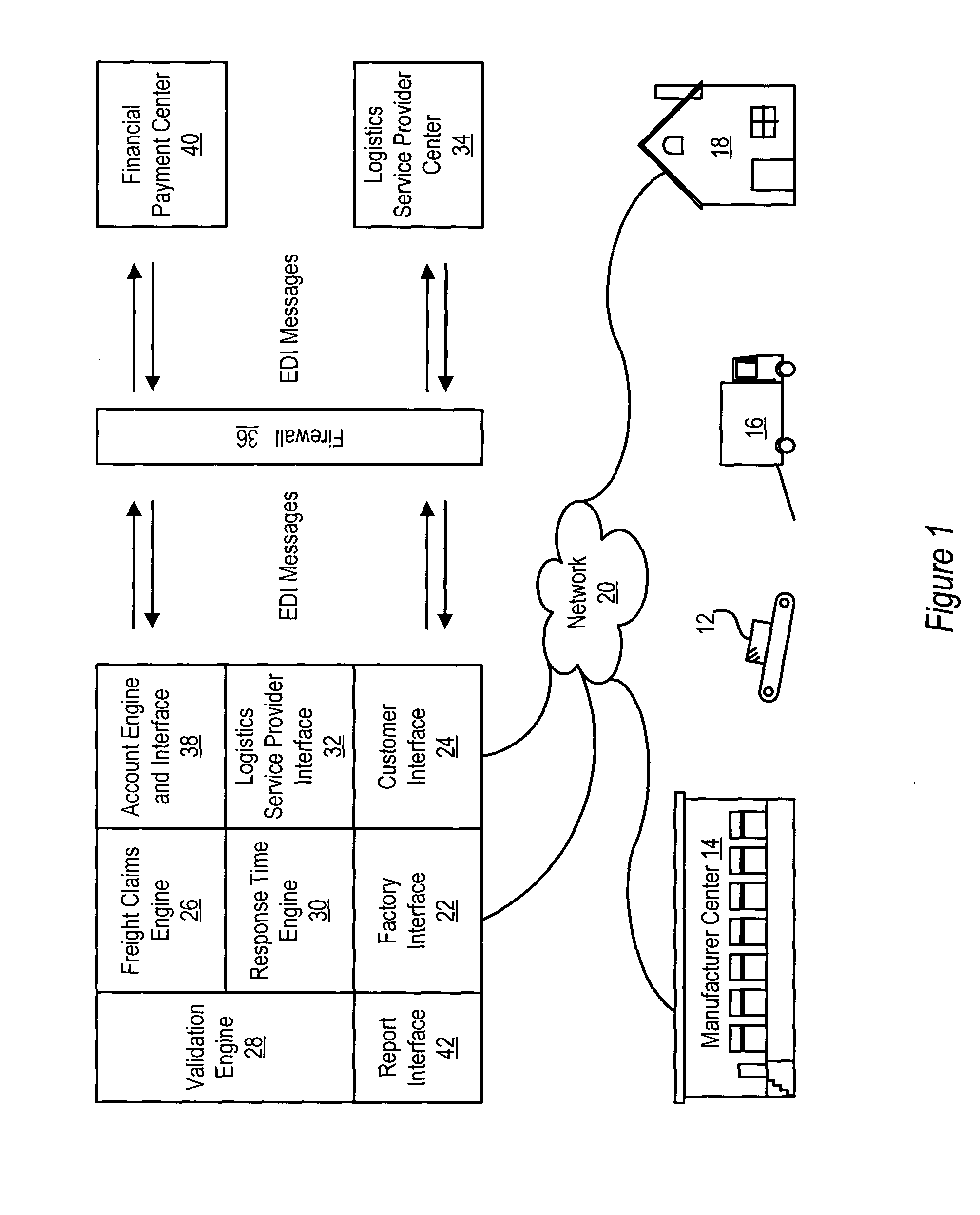

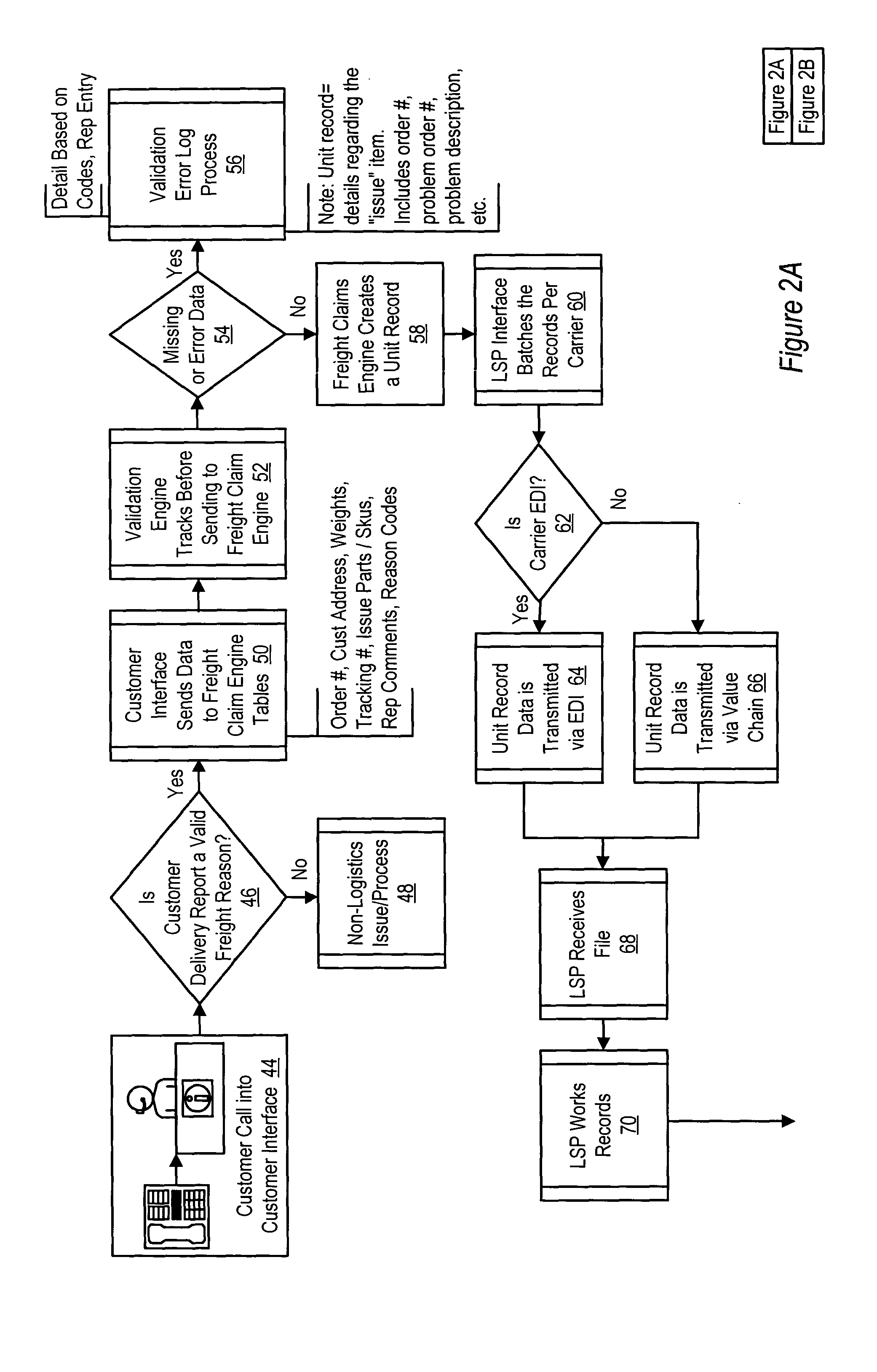

Method and system for managing exchanges related to freight claims

InactiveUS20050055285A1Improve delivery serviceImproves logistics service provider response timeOffice automationLogisticsInformation processingLogistics management

Freight claims of a manufacturer to a logistics service provider are automated to manage re-orders of built to order products, such as information handling systems, in response to delivery reports from customers for lost or damaged freight. Upon receipt of a delivery report, a customer interface allows manual initiation of a re-delivery order for another delivery of the product from the manufacturer center to the customer. A freight claim engine automatically initiates communication to the logistics service provider and determines the response of the logistics service provider to the delivery report. A re-delivery validation engine overrides manually initiated re-delivery orders in the event of a first set of predetermined logistics service provider responses, such as acceptance by the customer of the product, and allows re-delivery orders to continue to the manufacturer center in the event of a second set of predetermined logistics service provider responses, such as acceptance of financial responsibility by the logistics service provider for the product due to a failed delivery or damage inflicted during shipment.

Owner:DELL PROD LP

Method and system for automated freight claims

InactiveUS20050055258A1Improve delivery serviceShort response timeOffice automationLogisticsInformation processingLogistics management

Freight claims of a manufacturer to a logistics service provider are automated to manage re-orders of built to order products, such as information handling systems, in response to delivery reports from customers for lost or damaged freight. A freight claim engine automatically initiates communication to the logistics service provider for customer delivery reports of freight claims and determines whether to re-order the delivery of the product based on the response of the logistics service provider. Responses to a freight claim by the logistics service provider that indicate delivery of the product in a desired time precludes a re-build of the product to improve customer satisfaction and reduce manufacturer costs.

Owner:DELL PROD LP

Method for dynamically managing multicast sessions for software downloads and related systems

ActiveUS7899877B2High high environmentMultiple digital computer combinationsProgram loading/initiatingStart timeHigh volume manufacturing

Owner:DELL PROD LP

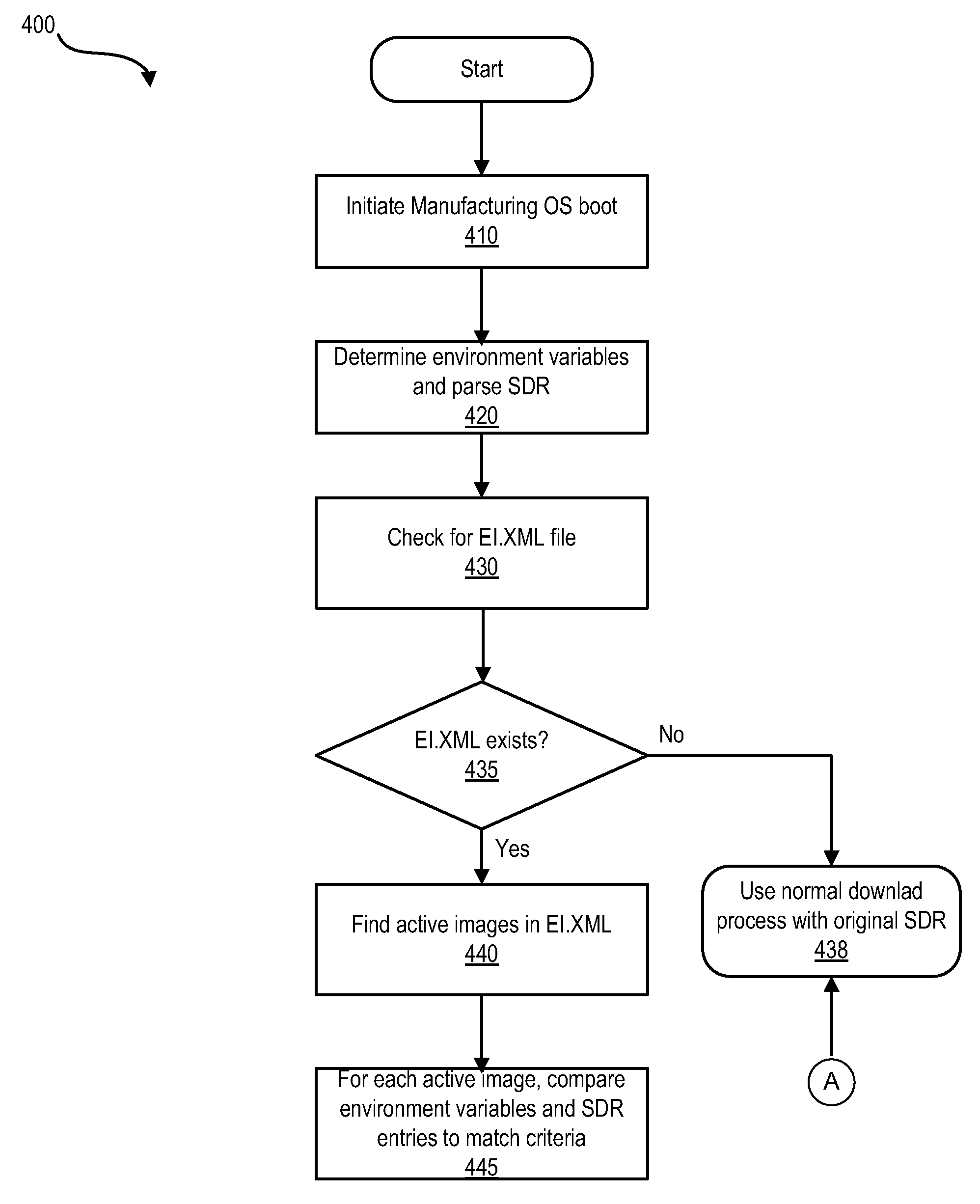

Replacement of Build to Order Parts with Post Configured Images in any Manufacturing Environment

ActiveUS20110150315A1Minimization requirementsShorten the timeImage analysisCharacter and pattern recognitionBuild to orderEmbedded system

Owner:DELL PROD LP

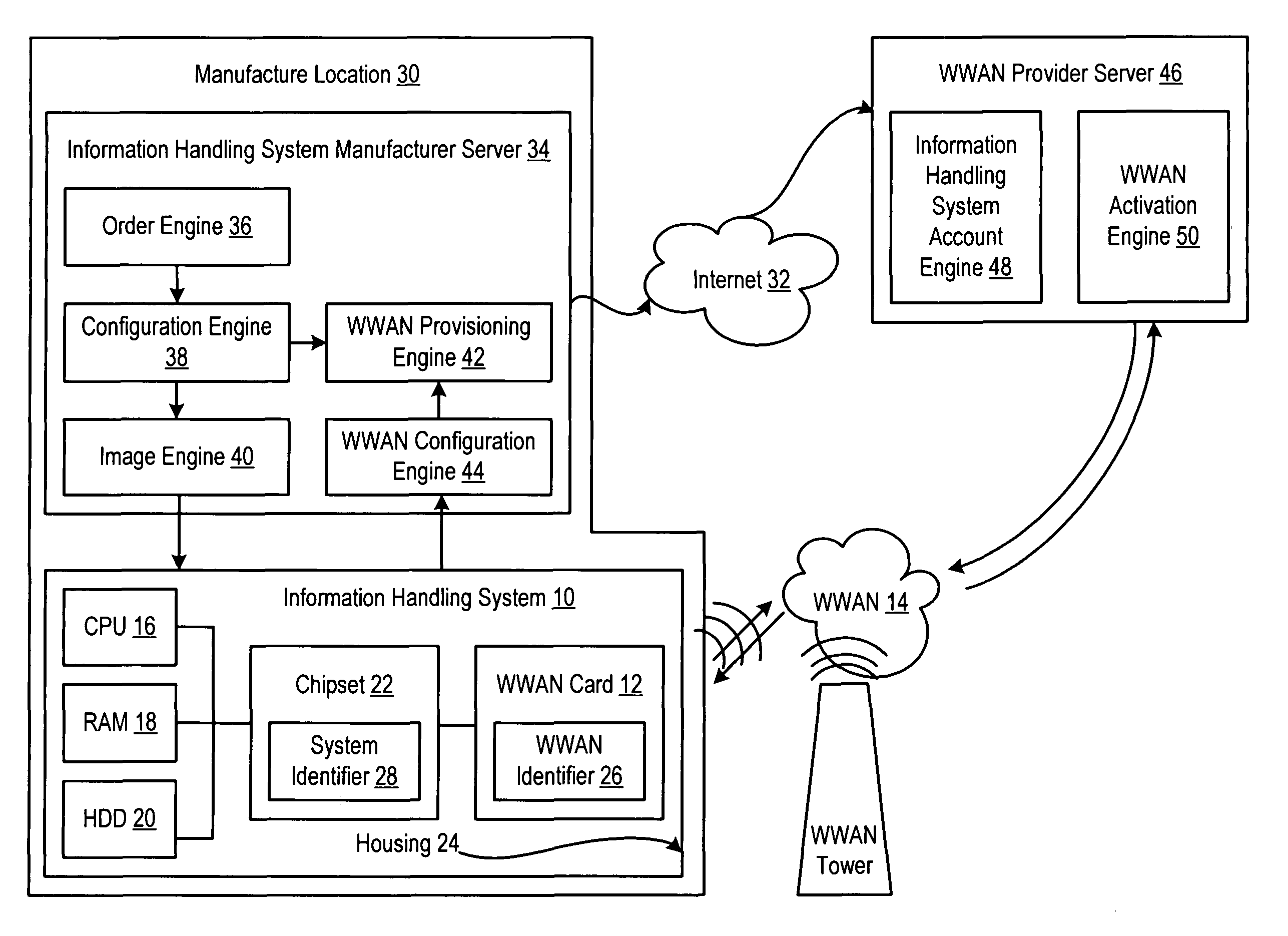

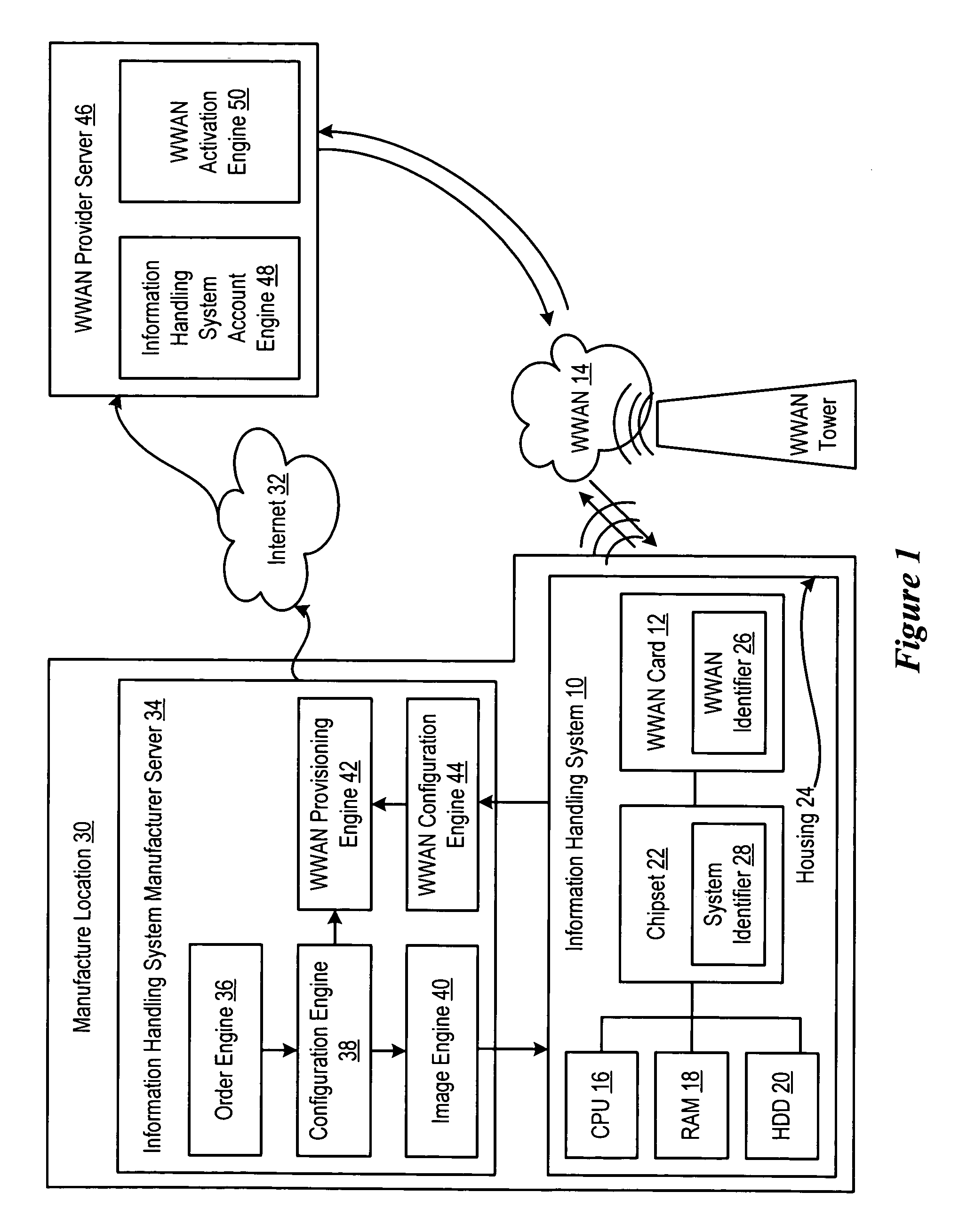

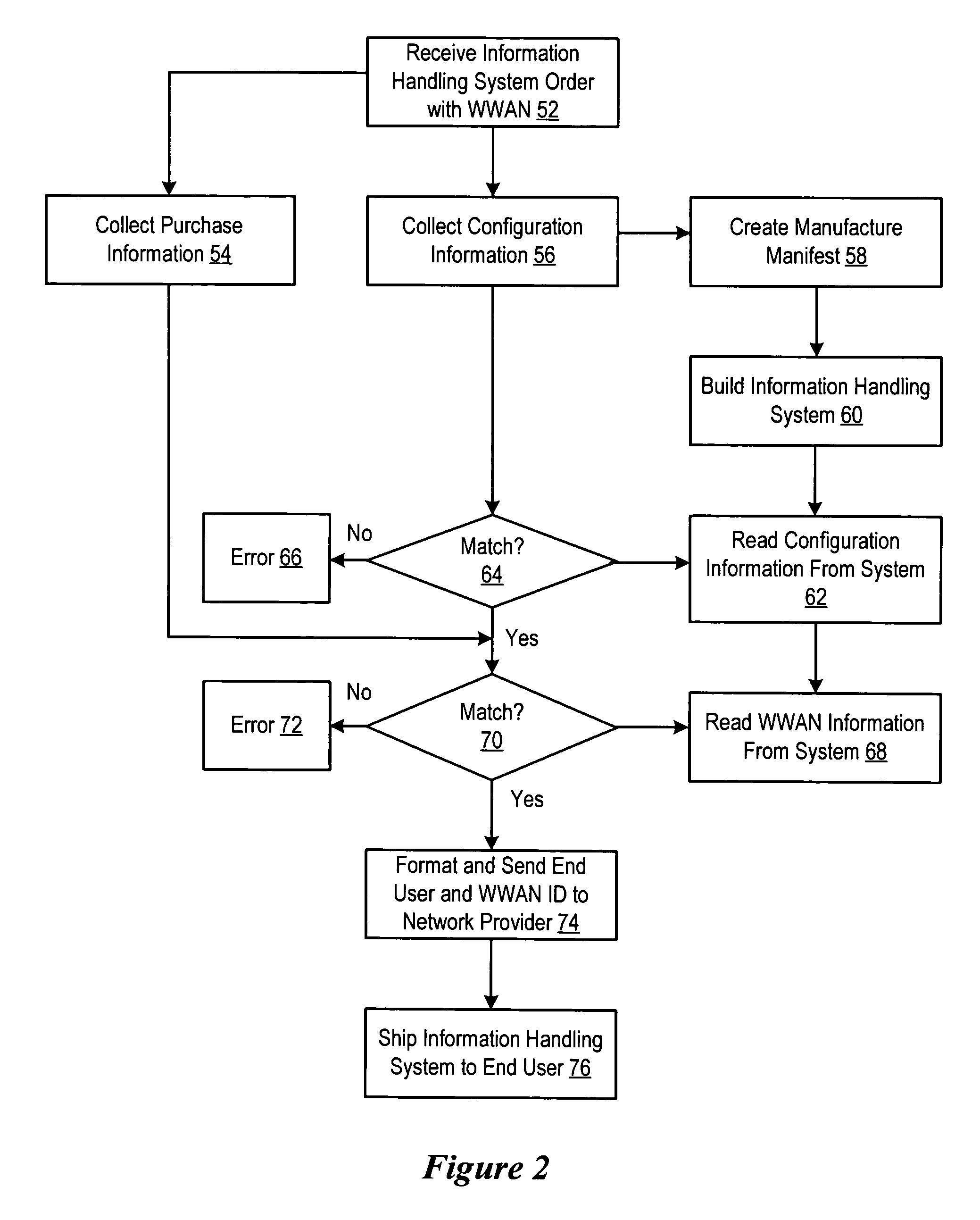

System and method for managing information handling system wireless network provisioning

ActiveUS7885858B2Reduce disadvantagesReduce problemsCash registersBuying/selling/leasing transactionsHandling systemBuild to order

Information handling systems are built to order with provisioned wireless wide area network (WWAN) service coordinated through a WWAN network provider as part of the manufacture of the information handling system. A WWAN component is built into the information handling system and then queried to retrieve a WWAN identifier, such as ESM or SIM information. The identifier is associated with end user information of the information handling system and formatted as a request for WWAN provisioning sent to a network service provider. The network service provider applies the WWAN identifier and end user information to contact the end user for setting up a WWAN account or, alternatively, to automatically set up a WWAN account for the end user.

Owner:DELL PROD LP

System and method for customer delivery notification

Build-to-order products are shipped to consumers through plural shipping providers by giving the consumer an estimated delivery date for the arrival of the product at the consumer delivery address. Using an estimated delivery date makes the notice agnostic of the shipping provider so that multiple transport means may be used to ship the product.

Owner:DELL PROD LP

System and method for configuring information handling system integrated circuits

ActiveUS7693596B2Integration of featureReduce disadvantagesDigital computer detailsCAD circuit designFeature setOrder form

Processing components to manufacture information handling systems have build-to-order integrated circuits with plural selectively-enabled features set at the information handling system manufacture location. For instance, fuses integrated in the integrated circuits are selectively blown at the information handling system manufacture location to permanently disable features so that the processing components have a desired configuration. As another example, feature enable or disable states are programmed in flash incorporated in the integrated circuit, with the flash programmability subsequently disabled to permanently set the features so that the processing components have a desired configuration. Features are set with keys provided by the processing component manufacturer to track the information handling system manufacturer's use of the features.

Owner:DELL PROD LP

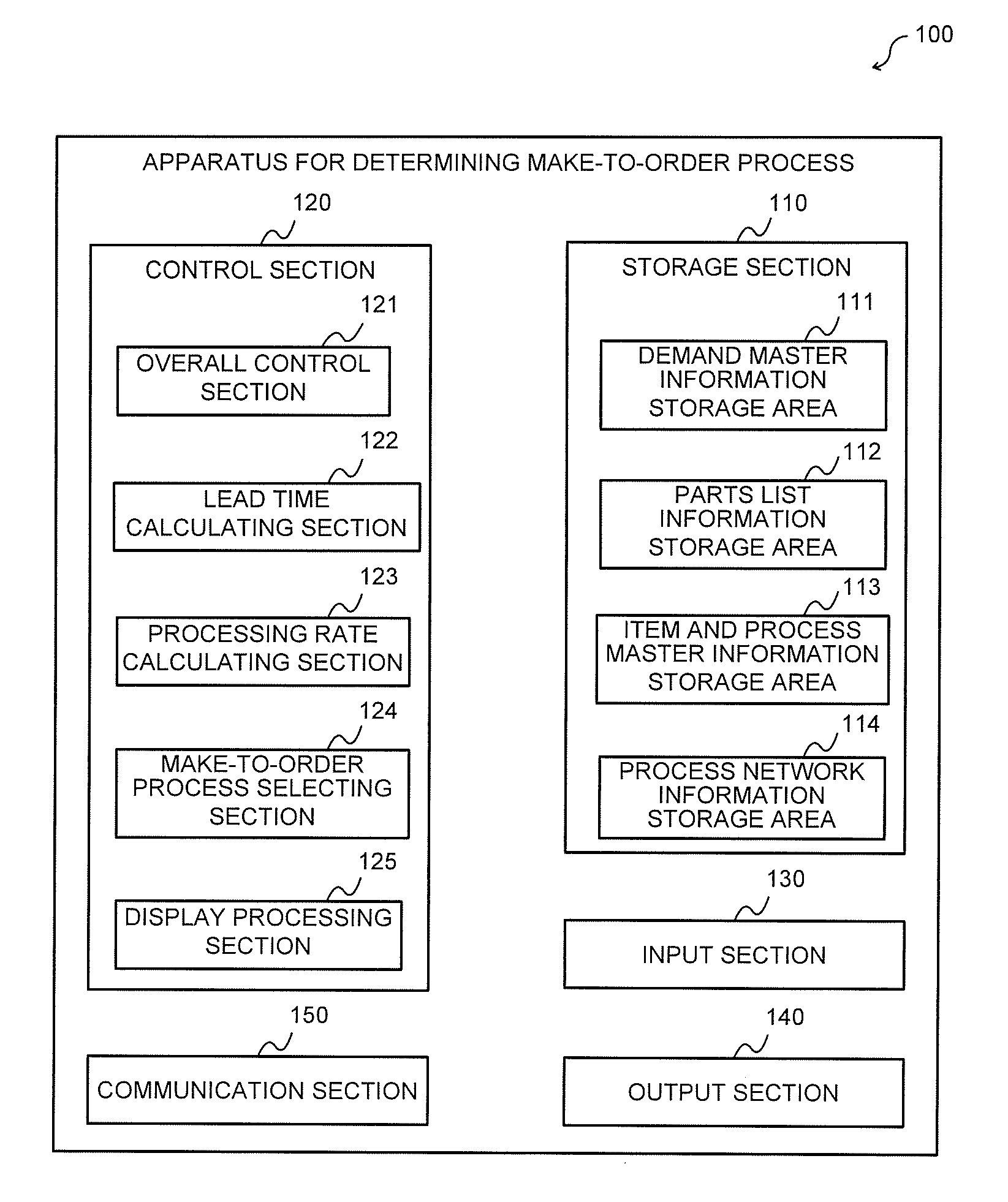

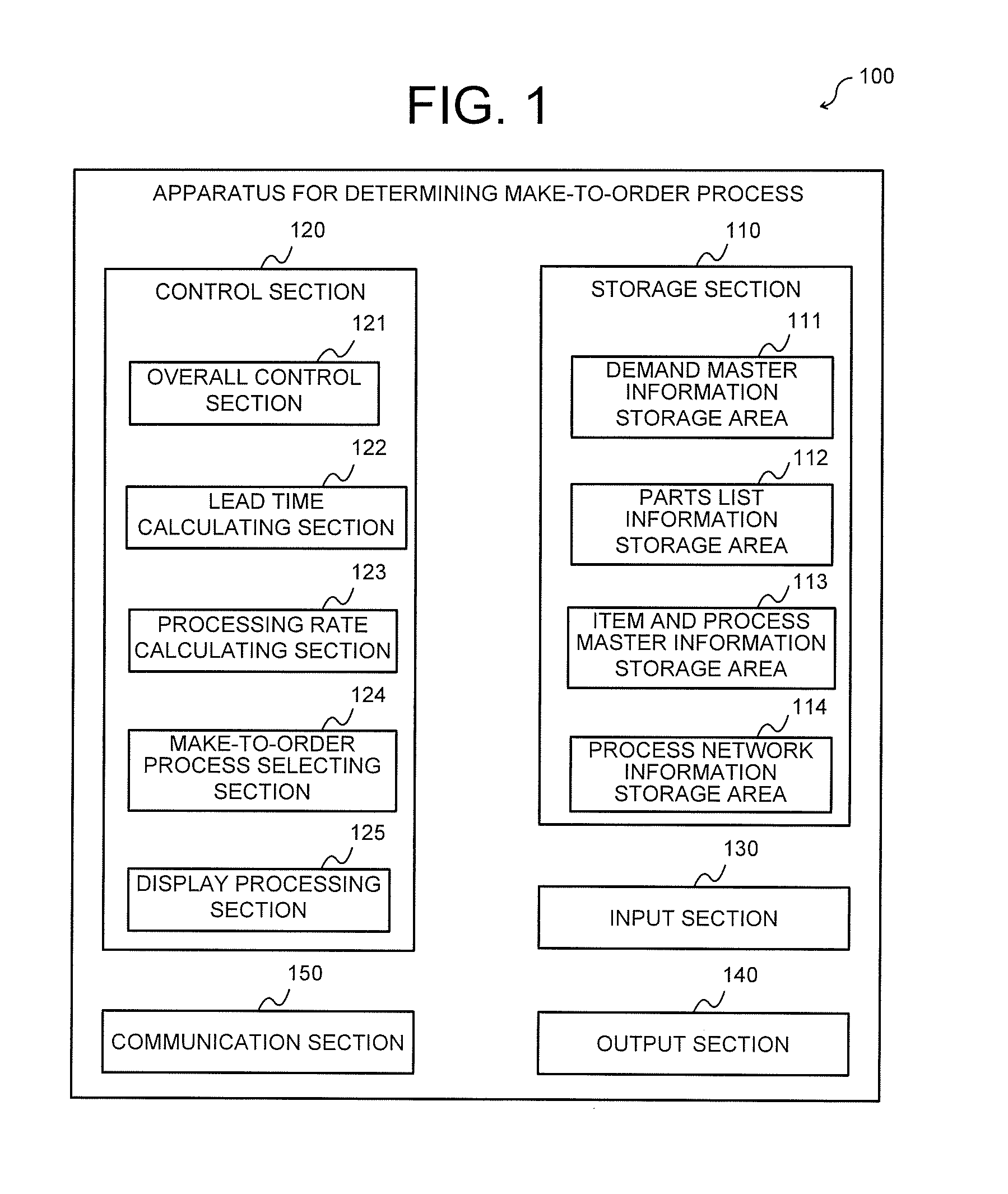

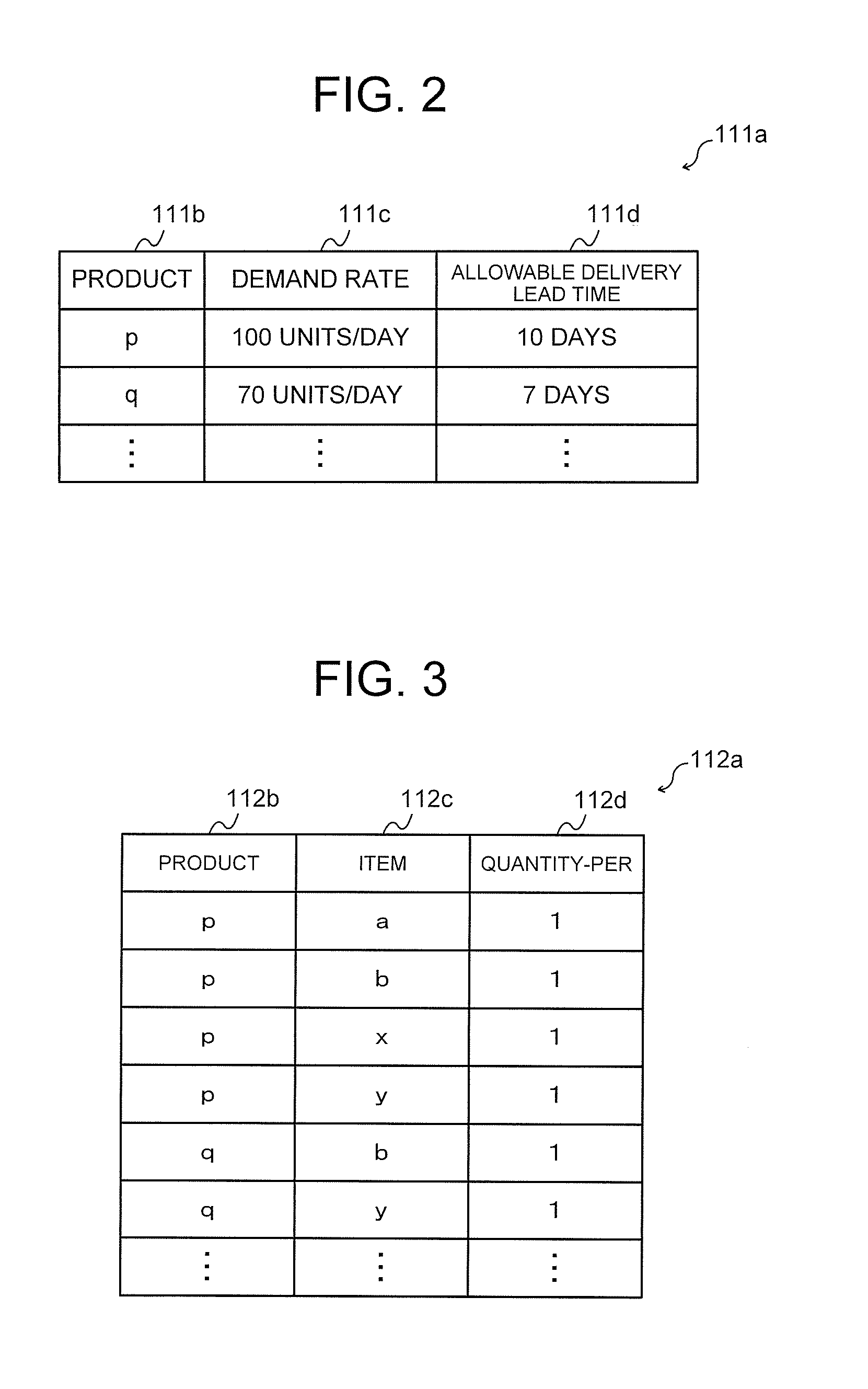

Device for determining build-to-order production process, program, system for determining build-to-order production process, and method for determining build-to-order production process

A build-to-order production process is determined in consideration of magnitude of demand. A lead time calculating section (122) calculates process-specific lead time proportional to the time at which the number of items required to produce the amount of demand for products which are periodically ordered is processed for each process of manufacturing a product and selects a process in the range in which the sum value after the calculated process-specific lead time is added to the travel time between the processes does not exceed the lead time permissible by the client as a build-to-order selection process.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com