Full-automatic saw grinding and tooth pressing machine

A fully automatic, saw grinding technology, applied in metal sawing equipment, tool dressing of sawing machine devices, metal processing equipment, etc., can solve the problems of limited grinding ability, large size, and unfavorable service life of band saws, and achieve high speed. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described now in conjunction with accompanying drawing:

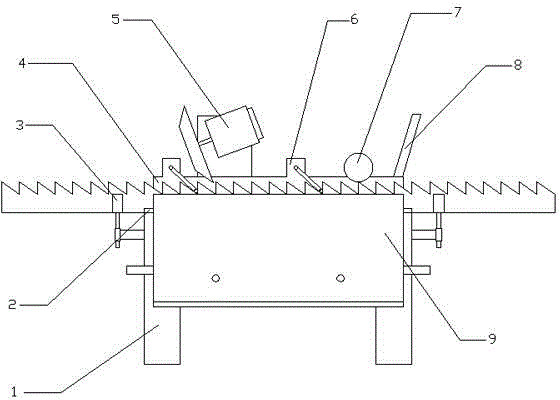

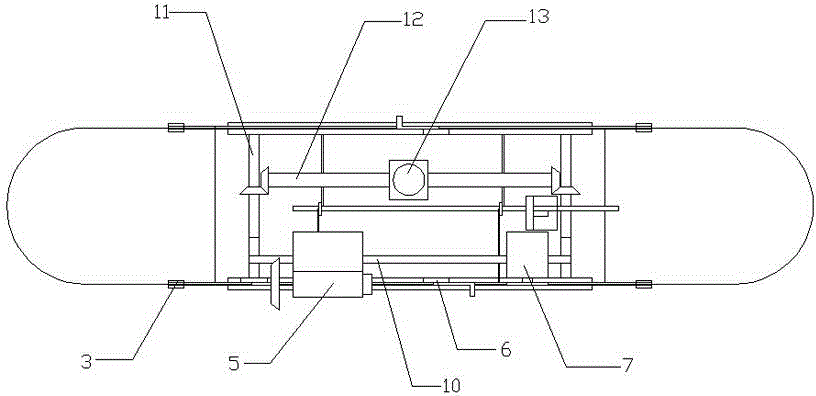

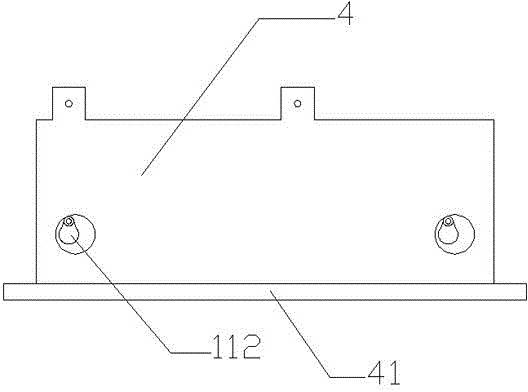

[0028] Such as Figure 1-8 A full-automatic saw grinding and pressing machine shown includes a machine frame body 1, a workbench 2 for placing a band saw is provided on the upper end of the machine frame 1, and a tooth grinding part is provided above the workbench 2 on one side. 5 and the pressing tooth part 7, the two ends of the working platform 2 are provided with limit claws 3; the middle of the machine frame 1 is provided with a driving motor 13, a horizontally arranged transmission rod 12 and a vertically arranged manual clamping rod 8 , the two ends of the transmission rod 12 are provided with two transmission cross bars 11 arranged perpendicularly thereto, and the two ends of the transmission rod 12 are provided with conical gears at positions corresponding to the transmission cross rods 11 . The inner side of the workbench 2 is provided with a movable plate 4, and the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com