Heat treatment method for medium-modulus and large-modulus gears

A heat treatment method and a large modulus technology, applied in the field of heat treatment, can solve the problems of accumulative error of helical tooth pitch in the inner hole, etc., and achieve the effects of shortening production time, ensuring carburizing quality, and optimizing process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

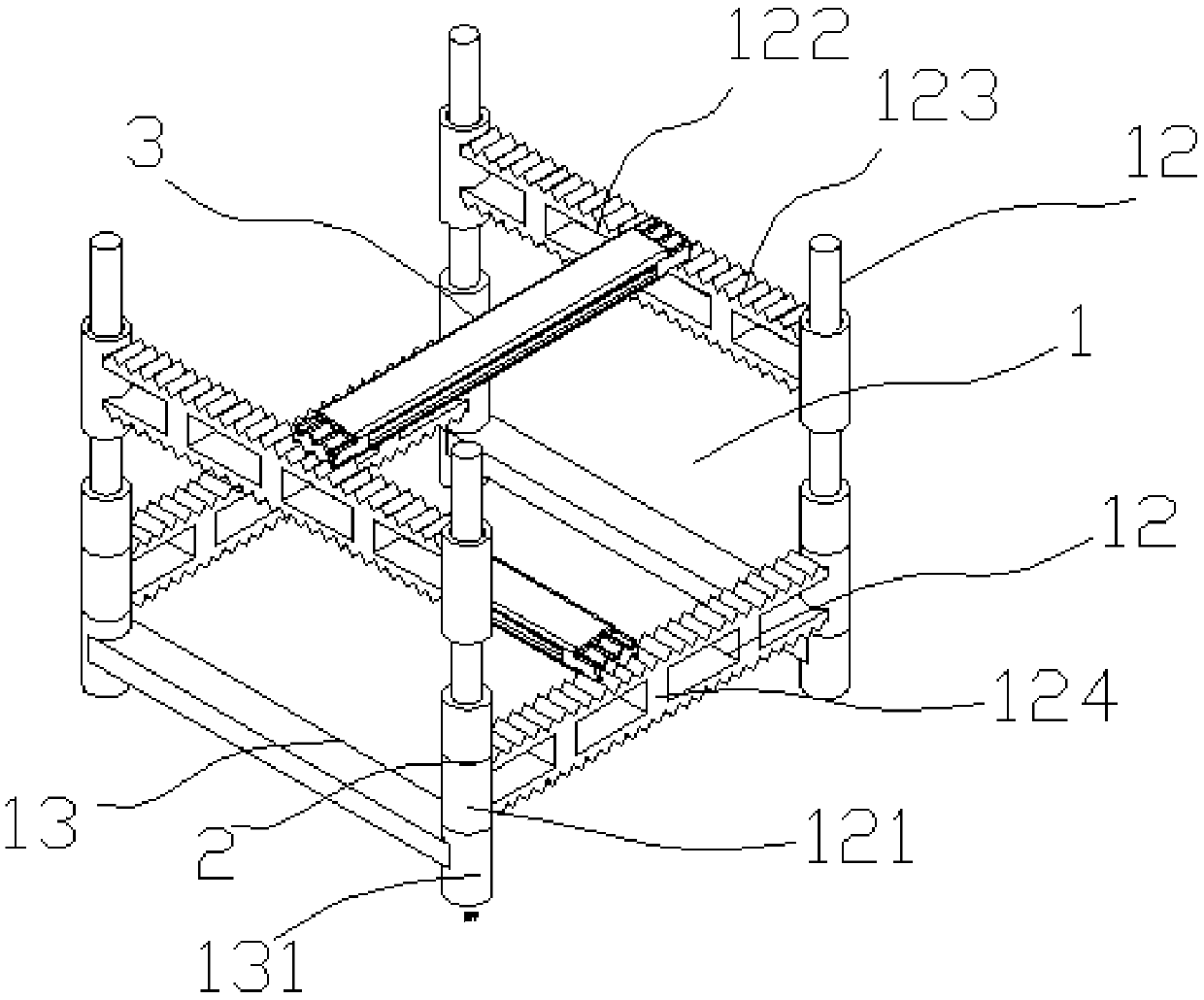

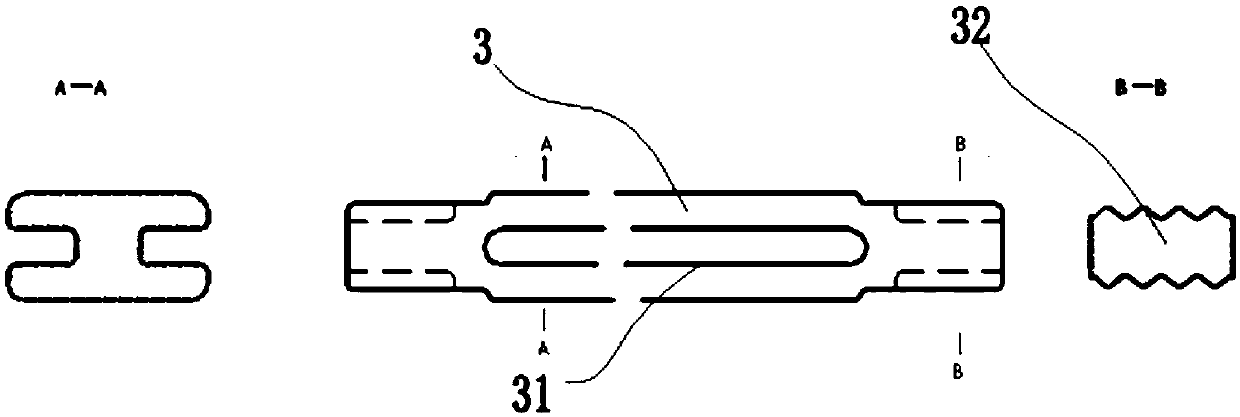

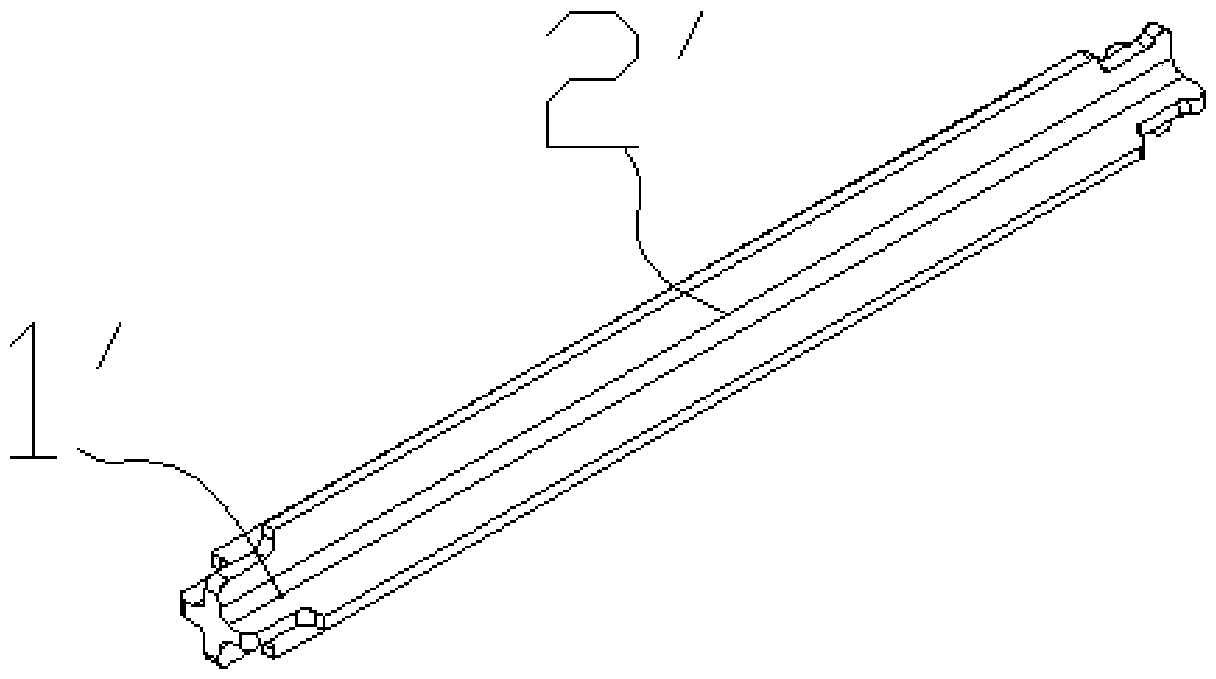

Image

Examples

Embodiment 1

[0047] The heat treatment method for medium and large modulus gears disclosed in this implementation includes the following steps:

[0048] S1. Preheating: heat the semi-finished gear into the furnace to 460±10°C and keep it warm for 30-50 minutes;

[0049] S2. Heating: the heating rate is 8-10°C / min, the flow rate of methanol is 20-25ml / min, and the maximum flow rate of natural gas is 0.25±0.05m 3 / h, heat up to 870~900℃, keep warm for 220~240min;

[0050] S3. Carburizing: raise the temperature to 895±5°C, the flow rate of methanol is 35~40ml / min, and the maximum flow rate of natural gas is 1.5±0.20m 3 / h, carbon potential is 1.0±0.05% CP, heat preservation 360~400min;

[0051] S4. Diffusion: reduce the temperature to 875±5°C, the flow rate of methanol is 20~25ml / min, and the maximum flow rate of natural gas is 0.2±0.05m 3 / h, the carbon potential is 0.65±0.05%CP, keep warm for 220~240min;

[0052] S5. Cool down: keep the flow rate and carbon potential of the penetrating ...

Embodiment 2

[0066] The heat treatment method for medium and large modulus gears disclosed in this implementation includes the following steps:

[0067] S1. Preheating: heat the semi-finished gear into the furnace to 470±10°C, and keep it warm for 40-50 minutes;

[0068] S2. Heating: the heating rate is 10-12°C / min, the flow rate of methanol is 26-32ml / min, and the maximum flow rate of natural gas is 0.25±0.05m 3 / h, heat up to 870~880℃, keep warm for 300~350min;

[0069] S3. Carburizing: raise the temperature to 895±5°C, the flow rate of methanol is 40~45ml / min, and the maximum flow rate of natural gas is 1.05±0.20m 3 / h, carbon potential is 1.05±0.05% CP, heat preservation 460~560min;

[0070] S4. Diffusion: reduce the temperature to 890±5°C, the flow rate of methanol is 28~32ml / min, and the maximum flow rate of natural gas is 0.2±0.05m 3 / h, the carbon potential is 0.75±0.05%CP, keep warm for 300~350min;

[0071] S5. Cool down: Keep the flow rate and carbon potential of the penetrat...

Embodiment 3

[0076] This embodiment is basically the same as Embodiment 2, the difference is that

[0077] Step S2. Heating: the heating rate is 10-12°C / min, the flow rate of methanol is 26-32ml / min, the temperature is raised to 870-900°C, and the temperature is kept for 300-350min;

[0078] Step S3. Carburizing: raise the temperature to 900±5°C, the flow rate of methanol is 36-38ml / min, the carbon potential is 1.10±0.05%CP, and keep warm for 480-500min;

[0079] Step S4. Diffusion: lower the temperature to 890±5° C., the flow rate of methanol is 24-26 ml / min, the carbon potential is 0.75±0.05% CP, and keep warm for 260-280 min; the rest is the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Bore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com