Stator of generator

A generator and stator technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as stator processing difficulties, achieve the effect of simple manufacturing and processing, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

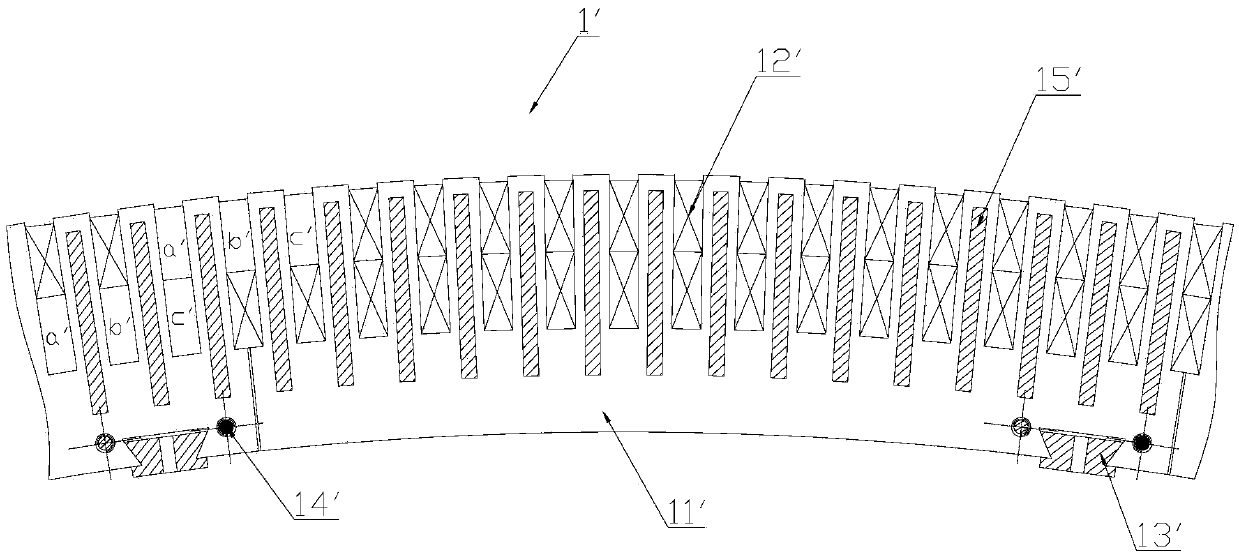

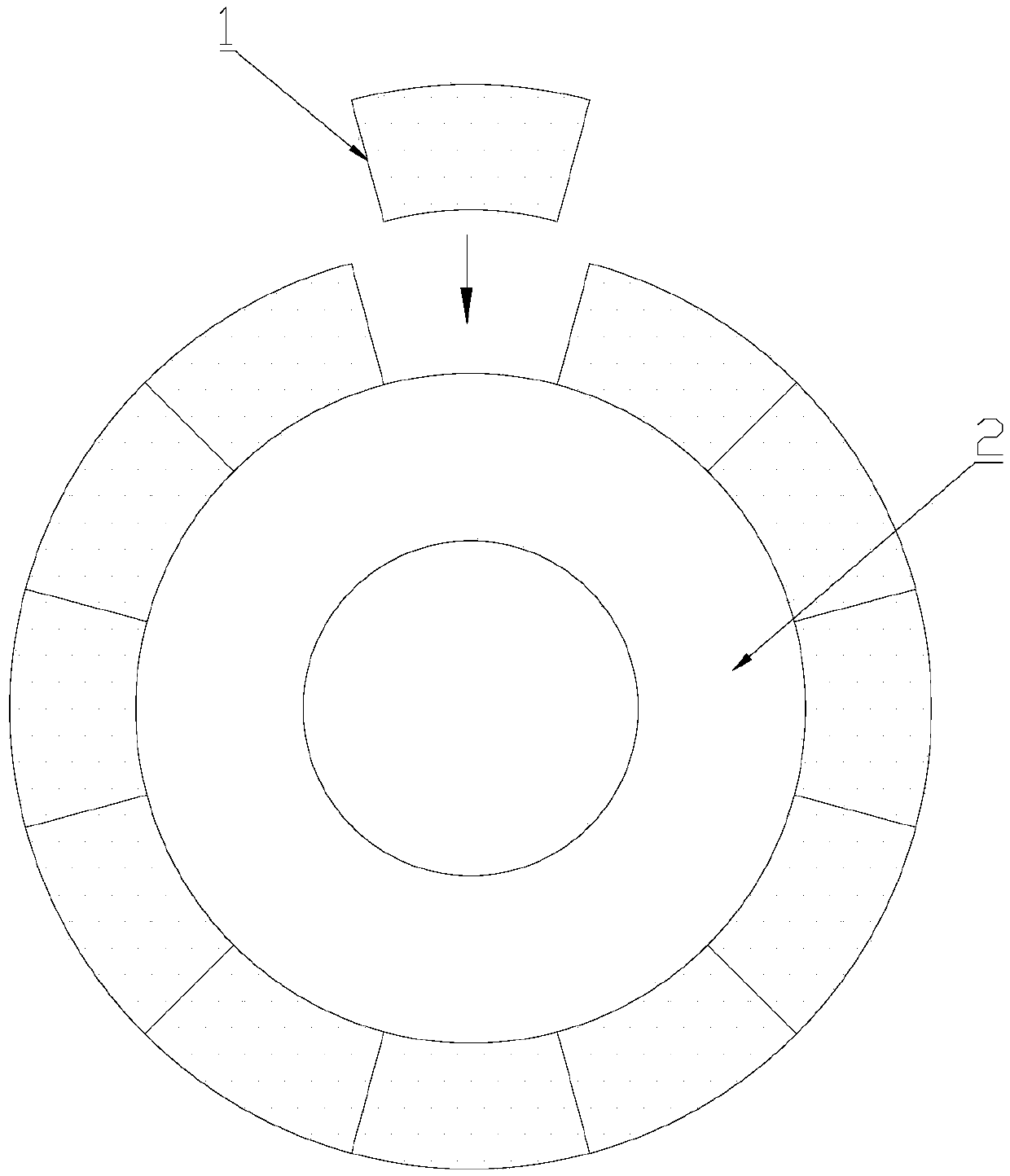

[0034] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

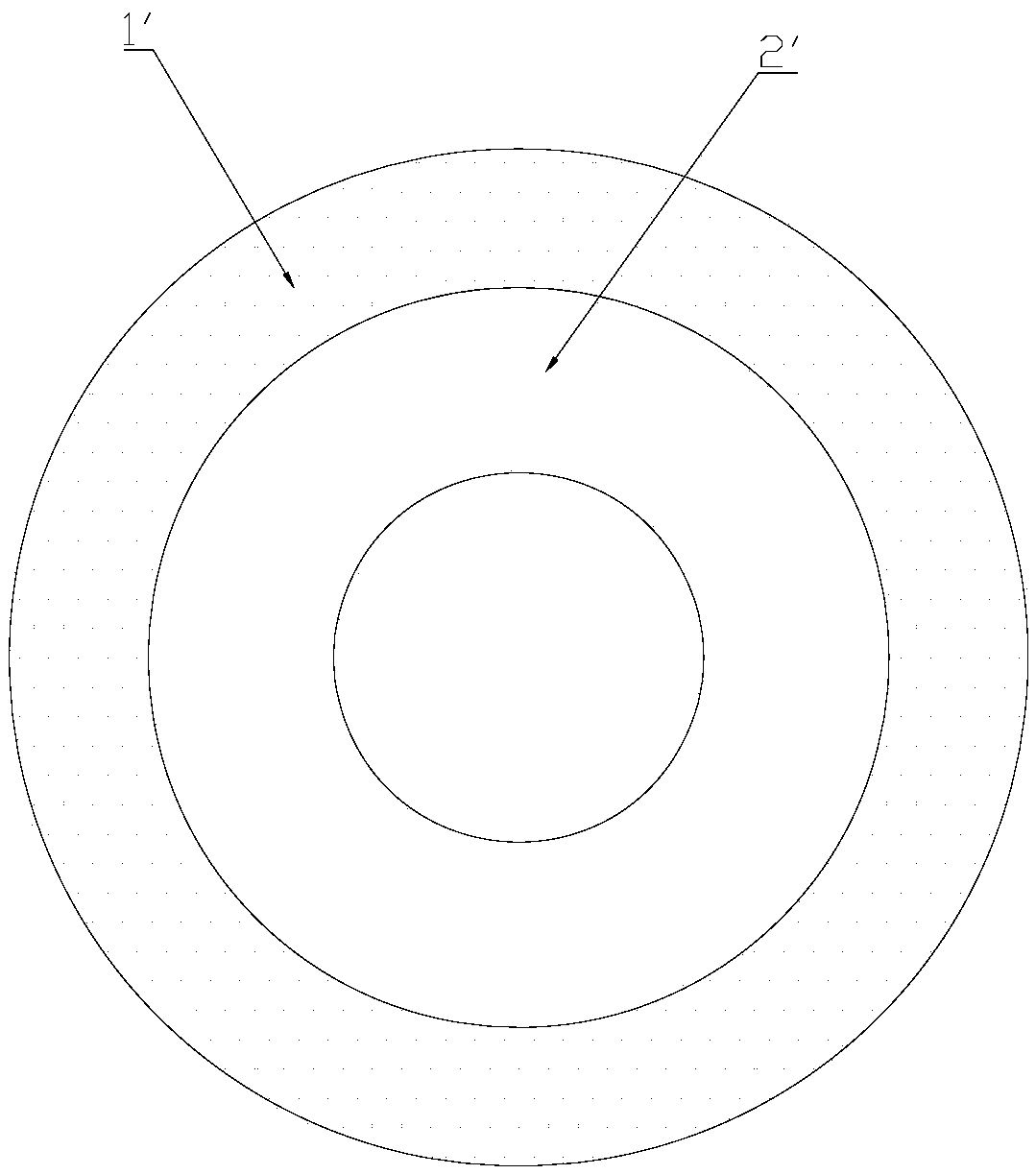

[0035] Such as Figure 3 to Figure 5 As shown, according to the embodiment of the present invention, the stator of the generator includes a plurality of stator units 1, the stator unit 1 includes a core module 11 and a winding 10 arranged on the core module 11, the iron core module 11 includes a stator core 111, and the stator core 111 It has a yoke portion 111a and at least one tooth portion 111b fixedly arranged on the yoke portion 111a, each tooth portion 111b is provided with a winding 10 correspondingly, the yoke portion 111a is provided with a groove 112 along the axial direction of the stator, and the groove 112 is provided with a fixed key 113, and the fixed key 113 is provided with a mounting hole 113a.

[0036] The stator is divided into a plurality of independent stator units 1, each stator unit 1 is processed independently, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com