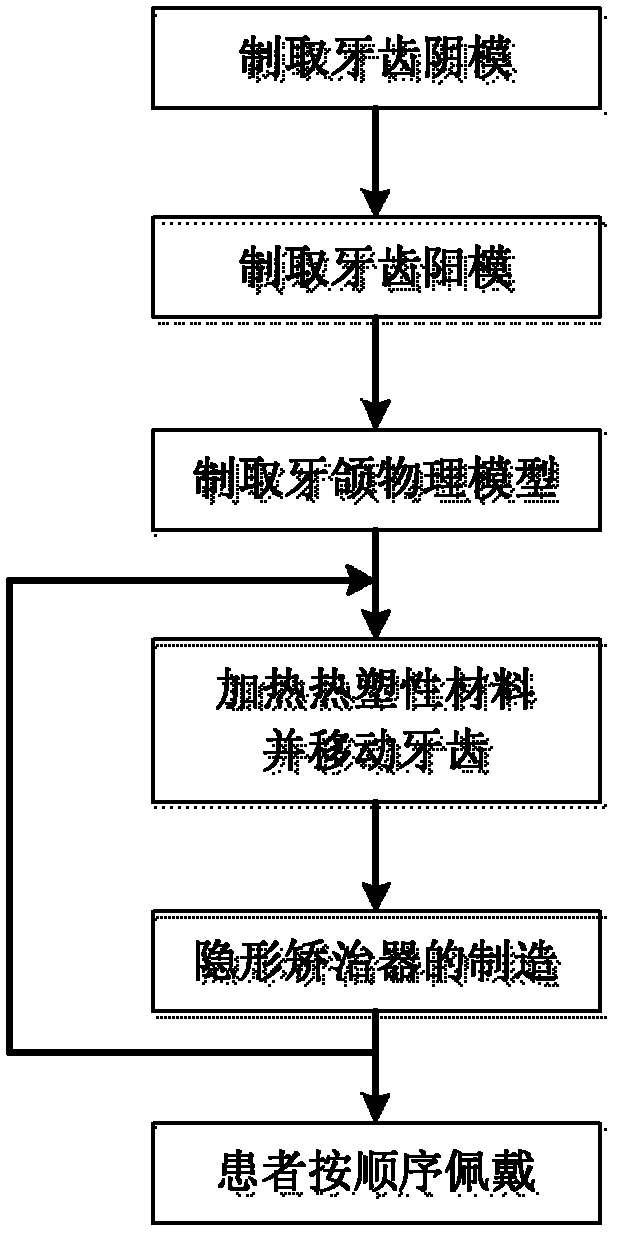

Manufacturing method for invisible orthotic device and product thereof

A technology of invisible aligners and manufacturing methods, which is applied in medical science, dental prosthetics, orthodontics, etc., can solve the problems of inconvenient direct operation by orthodontists, long manufacturing cycle, and limited application, so as to reduce the cost of orthodontics, Low cost and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

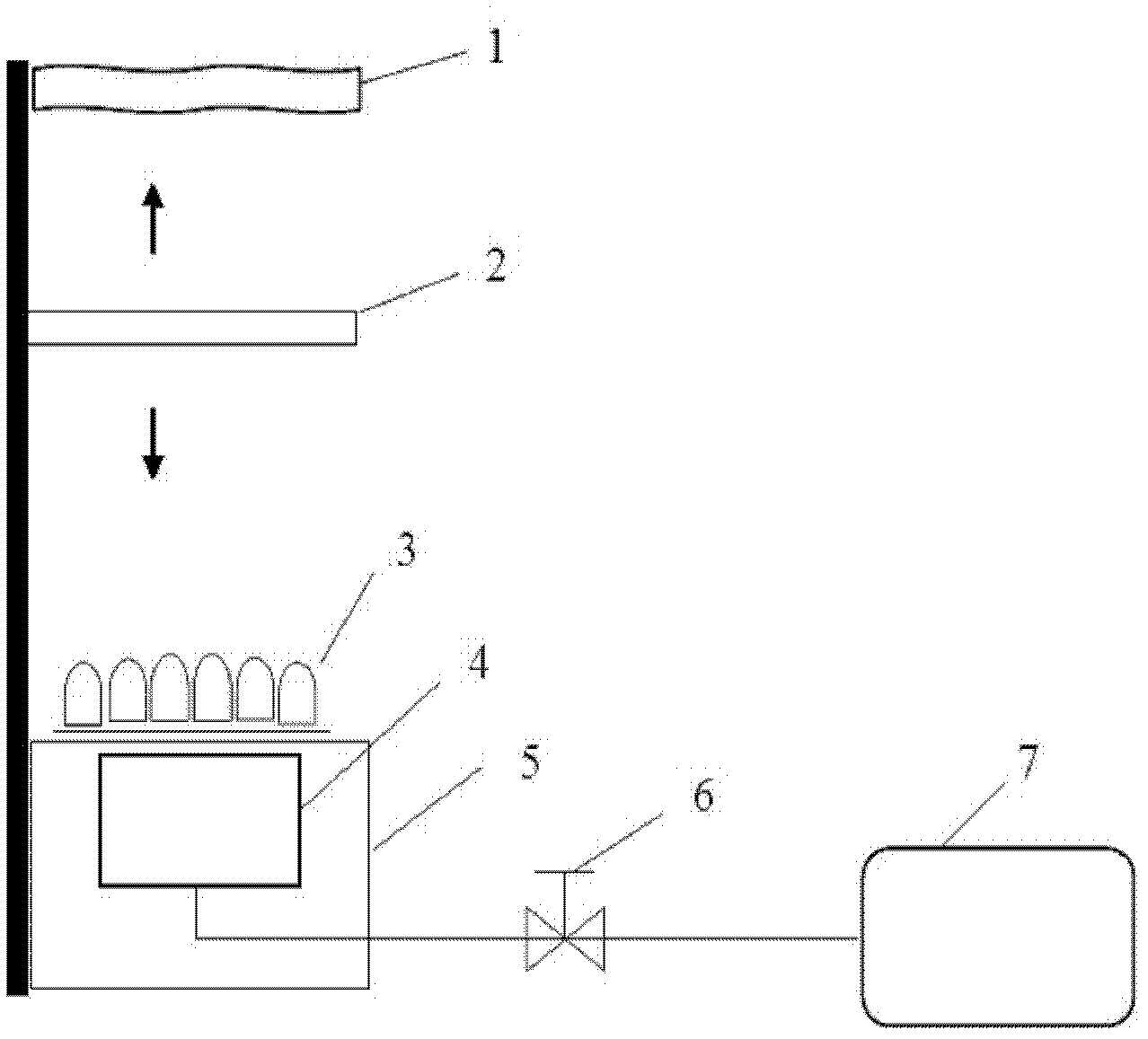

Method used

Image

Examples

Embodiment 1

[0027] The binder can be prepared by melting paraffin wax and ethylene-vinyl acetate copolymer or polyethylene by appropriate weight percentage, such as 50-90%: 10-50%, and then ZrO 2 or Al 2 o 3 The powder is added to the binder in the molten state to make a thermoplastic material, and the binder and ZrO 2 or Al 2 o 3 The weight ratio of the powder is 1:4-9:16. In this example, 100g of binder was obtained by melting paraffin wax and ethylene-vinyl acetate copolymer at a weight ratio of 70:30 at 120°C; 400g of ZrO 2 The powder was slowly added to 100 g of molten (120° C.) binder to obtain 500 g of thermoplastic material; it was placed in an extruder at 120° C. and extruded and sheared until a thermoplastic material with uniform composition was obtained.

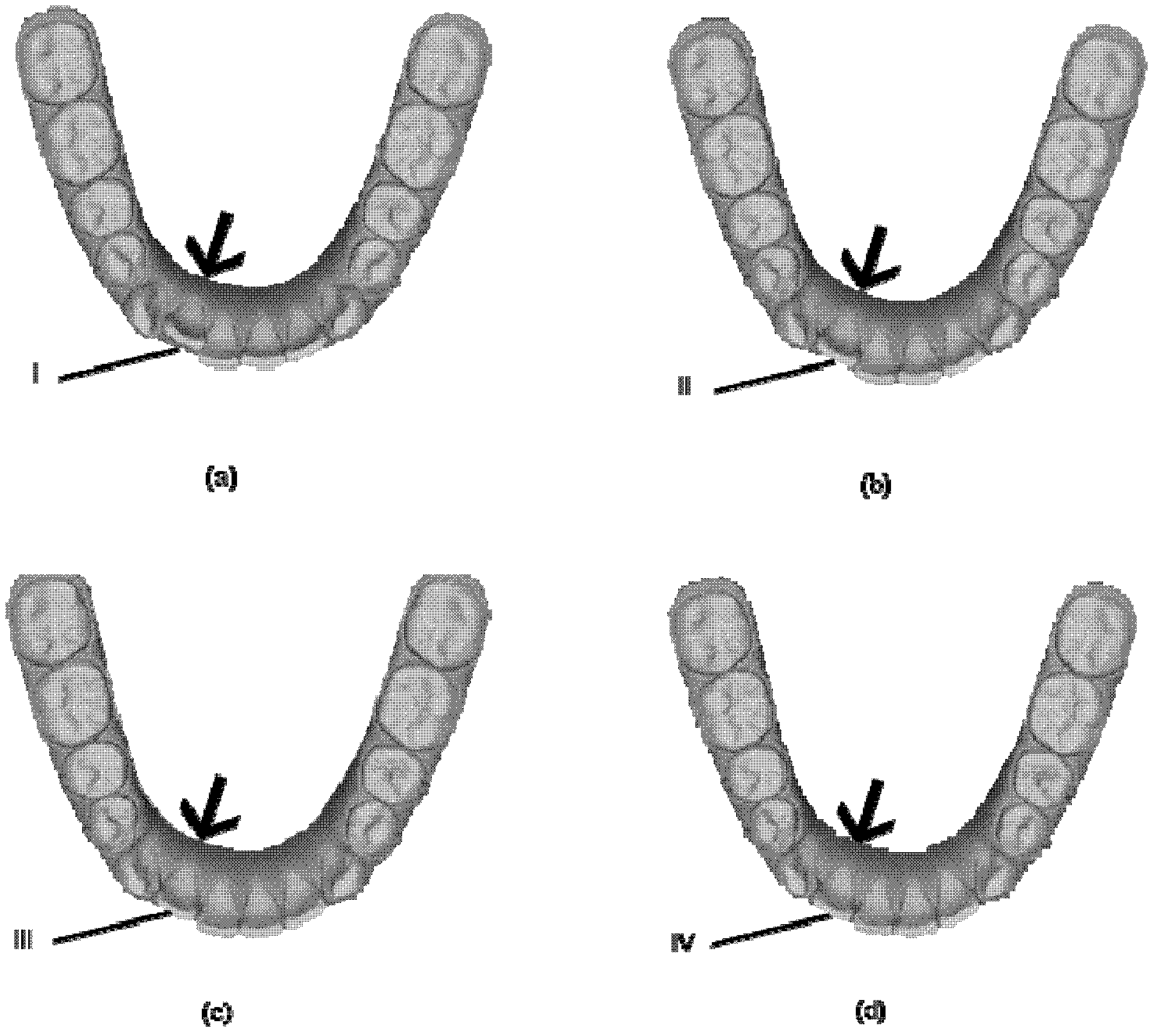

[0028] Use silicone rubber to obtain the tooth model of the patient with tooth deformity; use gypsum to make the tooth model model on the tooth model model, trim the tooth model, cut off the plaster part corresponding to...

Embodiment 2

[0037] In this example, 180g of binder was obtained by melting paraffin wax and polyethylene with a weight ratio of 50:50 at 135°C; 320g of Al 2 o 3 The powder was slowly added to 180 g of molten (135° C.) binder to obtain 500 g of thermoplastic material; it was placed in an extruder at 135° C. and extruded and sheared until a thermoplastic material of uniform composition was obtained.

[0038] Use silicone rubber to obtain the tooth model of the patient with tooth deformity; use gypsum to make the tooth model model on the tooth model model, trim the tooth model, cut off the plaster part corresponding to the gingival part, and remove the gingival part The gypsum tooth male mold is placed on the tooth part of the silicone rubber female mold again, and then the thermoplastic material is filled in the silicone rubber female mold at this time to obtain a physical model of the patient's teeth and jaws composed of thermoplastic materials and plaster (see figure 2 ), figure 2 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com