Compound ceramic material

A technology of composite ceramics and ceramic materials, applied in the field of ceramics, can solve the problems of not being able to meet market demand, low molding pressure, uneven particle size, etc., and achieve the effects of good thermal shock resistance, uniform porosity, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

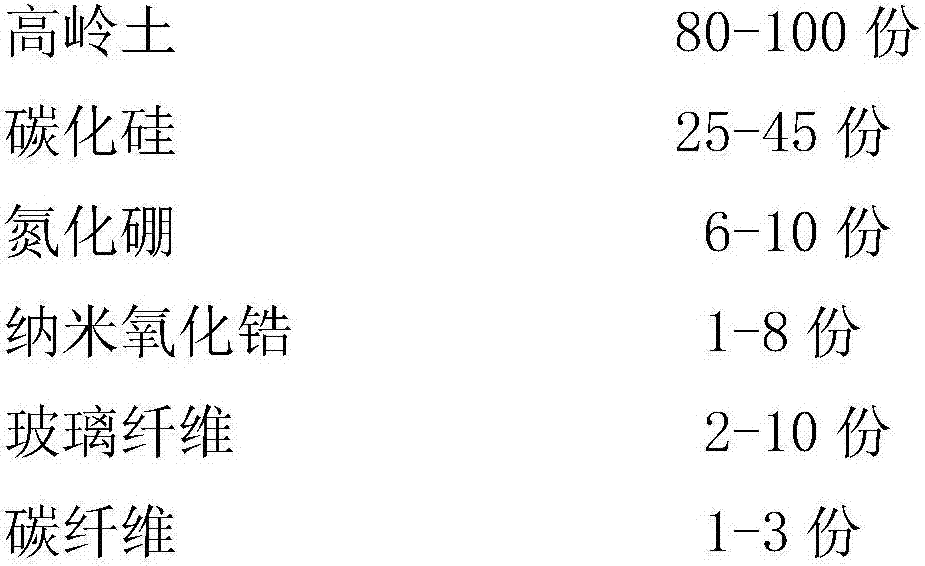

[0024] This embodiment discloses a composite ceramic material. In parts by weight, the ceramic material includes:

[0025]

[0026]

Embodiment 2

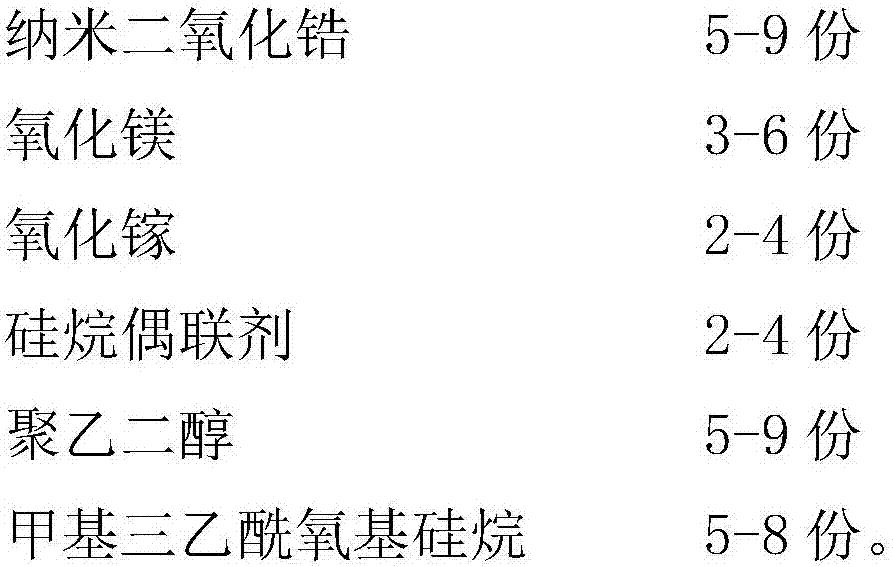

[0028] A composite ceramic material is disclosed in this embodiment, and the components of the ceramic material include:

[0029]

Embodiment 3

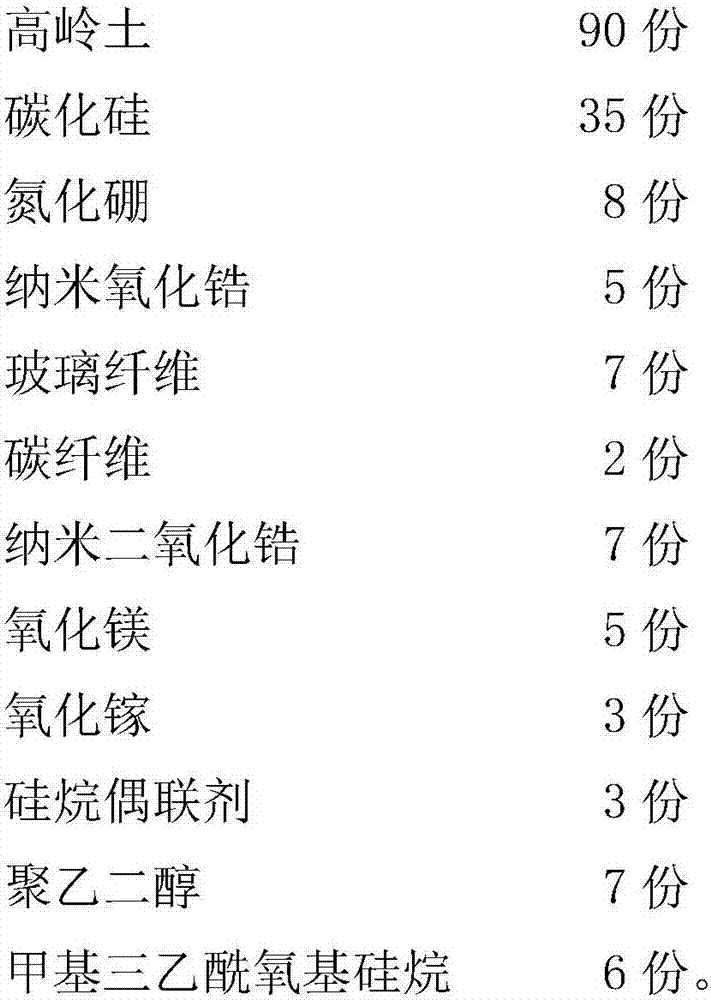

[0031] This embodiment discloses a composite ceramic material. In parts by weight, the ceramic material includes:

[0032]

[0033]

[0034] Further, the particle size of the nano-zirconia is 50-100nm.

[0035] Further, the particle size of the nano zirconium dioxide is 10-50nm.

[0036] The composite material in the above examples has the characteristics of corrosion resistance, heat change resistance, high hardness, good thermal shock resistance and impact resistance after high temperature sintering, and the ceramic material also has certain adsorption performance, which is an environmentally friendly type ceramic material.

[0037] The ceramic material in the above embodiments has good high temperature resistance and corrosion resistance, and its mechanical strength is relatively high, and the interior of the ceramic has a uniform porosity, which improves the comprehensive performance of the ceramic material.

[0038] The ceramic materials in the above examples are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com