Technique for processing welded structure cement carbon quenching gear

A technology of carburizing, quenching and welding structures, which is applied in the coating process of metal materials, manufacturing tools, coatings, etc., which can solve problems such as weld cracking and deformation, achieve the elimination of welding stress, reduce energy consumption, and solve the deformation of welding parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

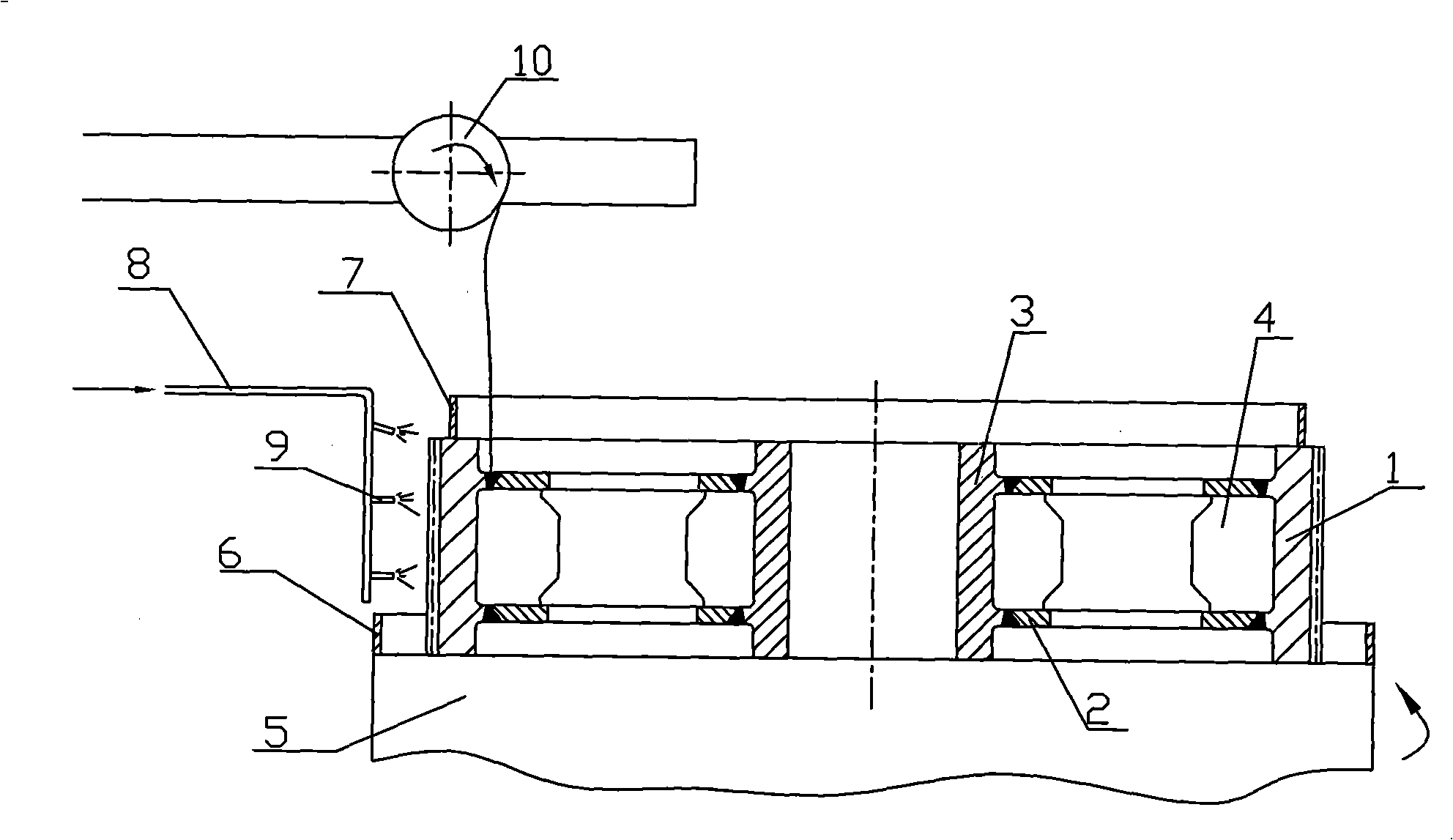

Image

Examples

Embodiment 1

[0026] A process for carburizing and quenching gears with a welded structure. The modulus of the gears is 8 and the diameter is 1200mm. 20CrMnMo is selected as the ring gear material (the weight of the ring gear is about 1000Kg), 20MnMo is selected as the hub material, and 16Mn is selected as the spoke plate, Rib material, make the forging blanks of ring gear and wheel hub, and Line, blanking web, ribs, and then proceed as follows:

[0027] (1) Process the inner and outer circles and both ends of the ring gear, process the hub, web and ribs, and leave allowances on the inner hole and both ends of the hub;

[0028] (2) Hobbing the ring gear and leaving an appropriate finishing allowance;

[0029] (3) Carburizing and quenching of the ring gear, using the gas carburizing method, using isopropanol as a carburizing agent, the carburizing temperature is 930°C, carburizing for 25 hours, and the depth of the carburizing layer is 0.8-1.2mm. After the ring gear is released from the fu...

Embodiment 2

[0036] A process for carburizing and quenching gears with a welded structure. The modulus of the gears is 20 and the diameter is 2000mm. 17CrNiMo6 is selected as the ring gear material (the weight of the ring gear is about 2500Kg), 20MnMo is selected as the hub material, and Q235 is selected as the spoke plate. Rib material, make the forging blanks of ring gear and wheel hub, and Line, blanking web, ribs, and then proceed as follows:

[0037] (1) Process the inner and outer circles and both ends of the ring gear, process the hub, web and ribs, and leave allowances on the inner hole and both ends of the hub;

[0038] (2) Hobbing the ring gear and leaving an appropriate finishing allowance;

[0039] (3) Carburizing and quenching of the ring gear, using gas carburizing method, isopropanol as carburizing agent, carburizing temperature is 910°C, carburizing 80h, carburizing layer depth is 2.5-2.8mm, after the ring gear is out of the furnace Air cooling to 810°C for quenching, oil ...

Embodiment 3

[0045] The gears to be processed in this embodiment are the same as those in Embodiment 1, the materials and equipment used are the same, and the processing steps are basically the same. The depth of the layer is 0.8-1mm. After the ring gear is out of the furnace, it is air-cooled to 830°C for quenching, oil-cooled, and then tempered at a low temperature. The tempering temperature is 210°C and the holding time is 8h. The tooth surface hardness of the obtained ring gear is HRC62.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tooth surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com