Compound amorphous alloy axial flux motor

A technology of amorphous alloy and axial flux, applied in the manufacture of motor generators, synchronous motors with stationary armatures and rotating magnets, magnetic circuits, etc., can solve the limited range of field weakening and speed expansion, and the amount of permanent magnets Large, difficult to adjust the magnetic field and other problems, to achieve the effect of reducing dosage, reducing manufacturing costs, and weakening the magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention will be further described:

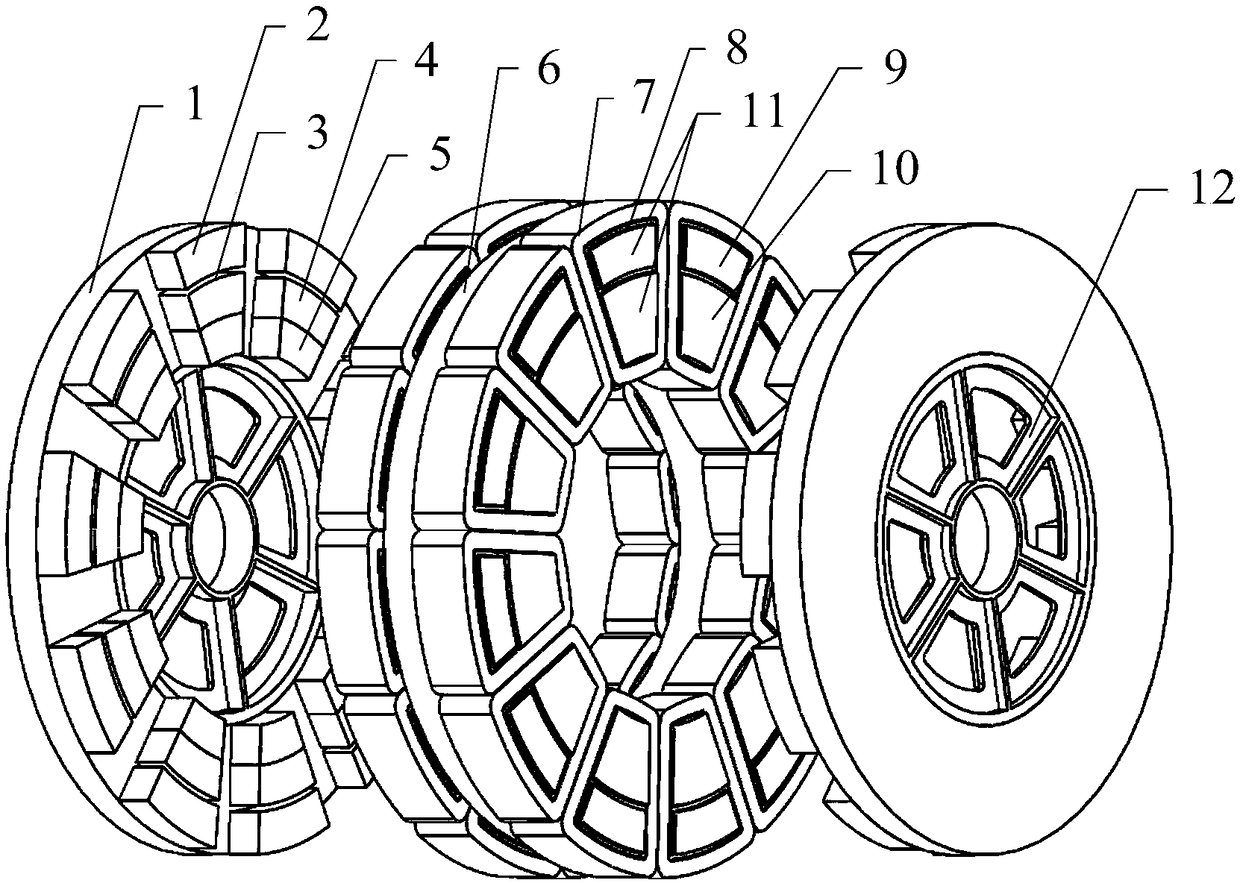

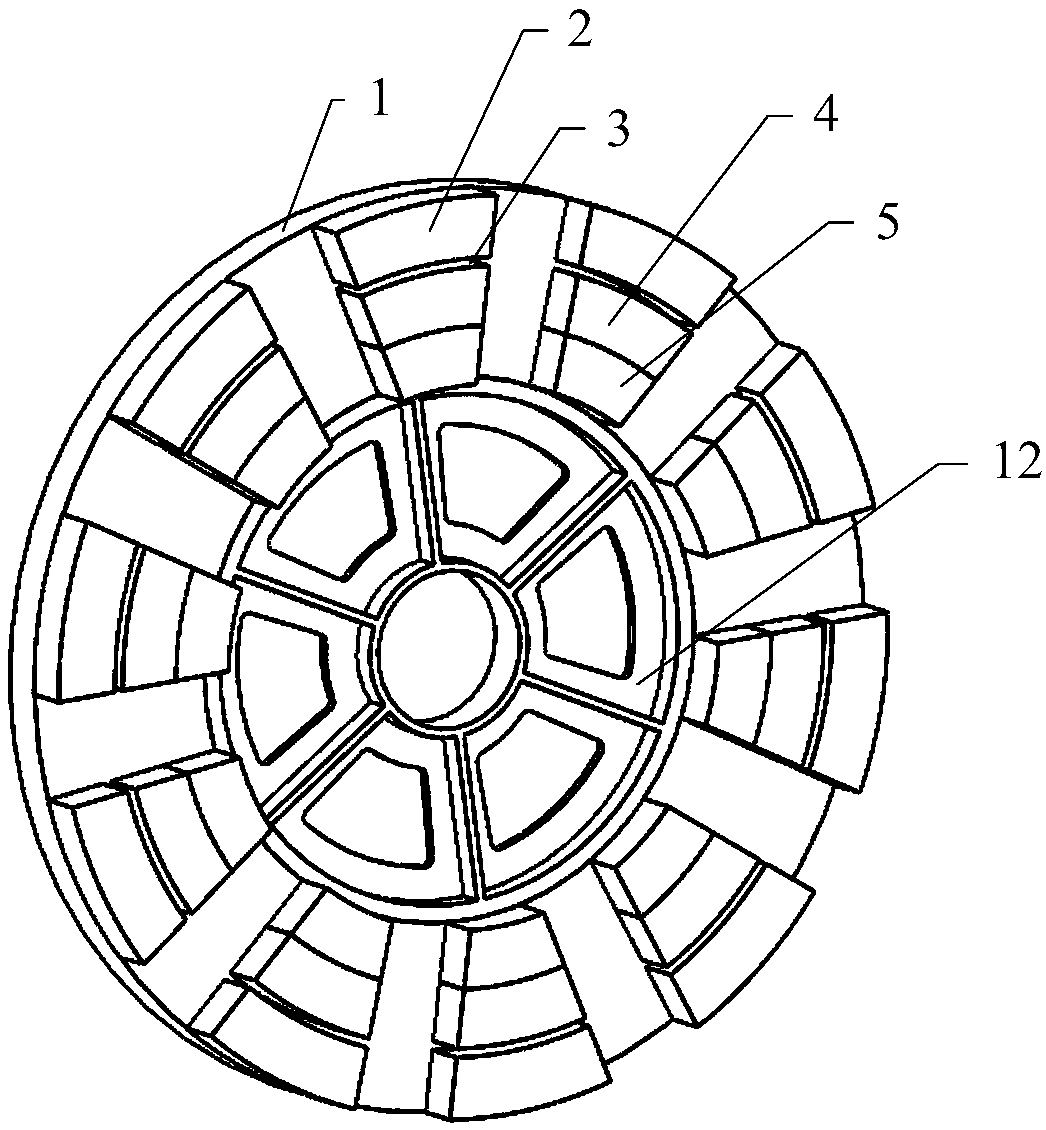

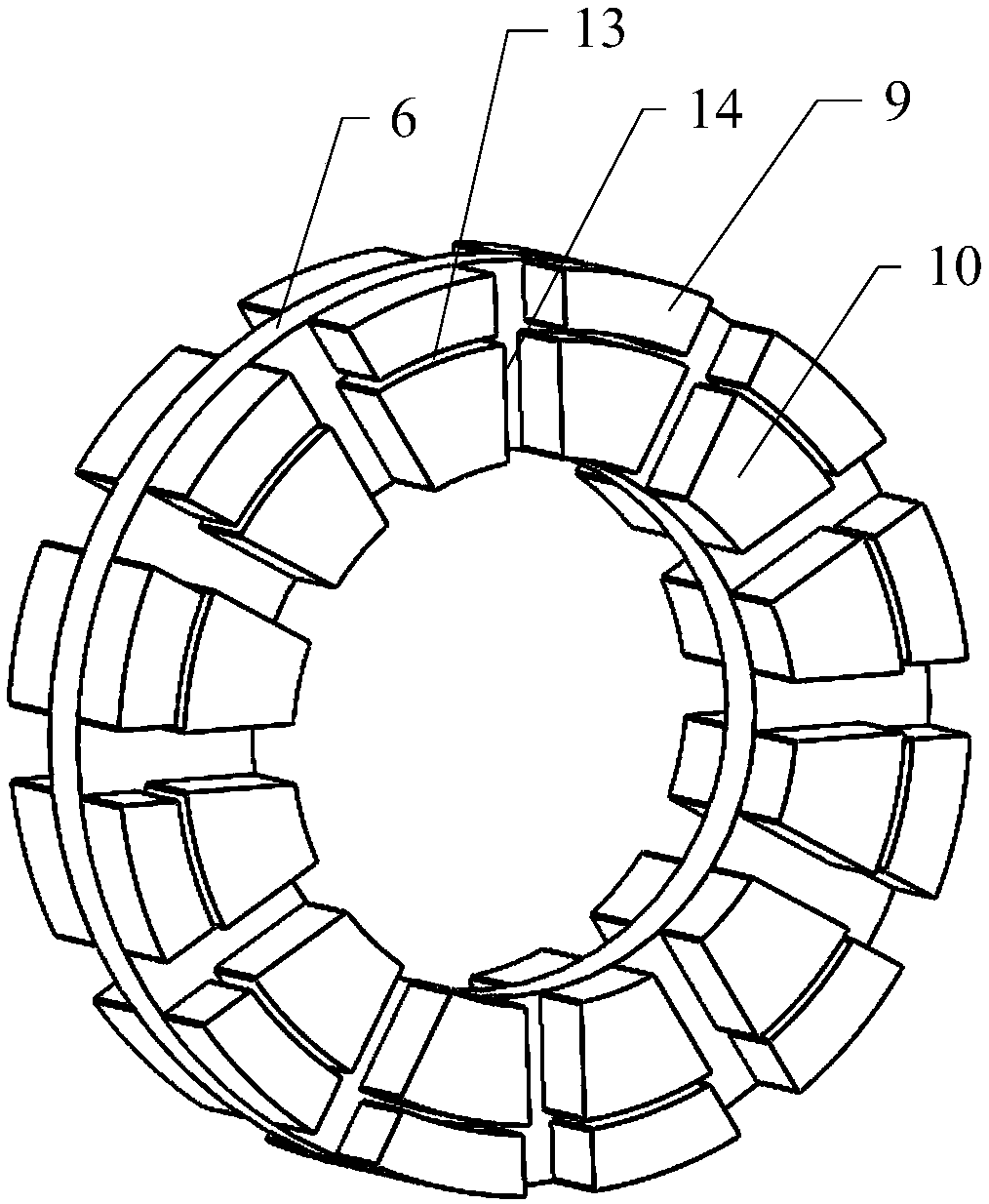

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a composite amorphous alloy axial flux motor includes a stator, a casing, an end cover, a rotating shaft, a bearing and a rotor, and is characterized in that: the stator core is an amorphous alloy stator core, and the stator core includes a stator yoke part 6 and stator tooth part 11. The stator tooth part 11 is composed of an inner tooth part 10 and an outer tooth part 9. A plurality of inner tooth parts 10 and outer tooth parts 9 are evenly distributed on the stator yoke part 6 in the circumferential direction. There is an inner tooth 10 on the inner side of each outer tooth 9, the stator core is embedded in the casing, the DC field winding 8 is wound on the outer tooth 9, and the DC field winding 8 and the outer tooth 9 are provided with The first insulator 15, each external tooth p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com