Ultrahigh-speed permanent magnet disk motor and installation method thereof

A permanent disk, ultra-high-speed technology, applied in the direction of electromechanical devices, magnetic circuit shape/style/structure, electrical components, etc., can solve the problems of long effective air gap and low reliability of the rotor, and achieve enhanced rotor strength and stable properties , the effect of uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

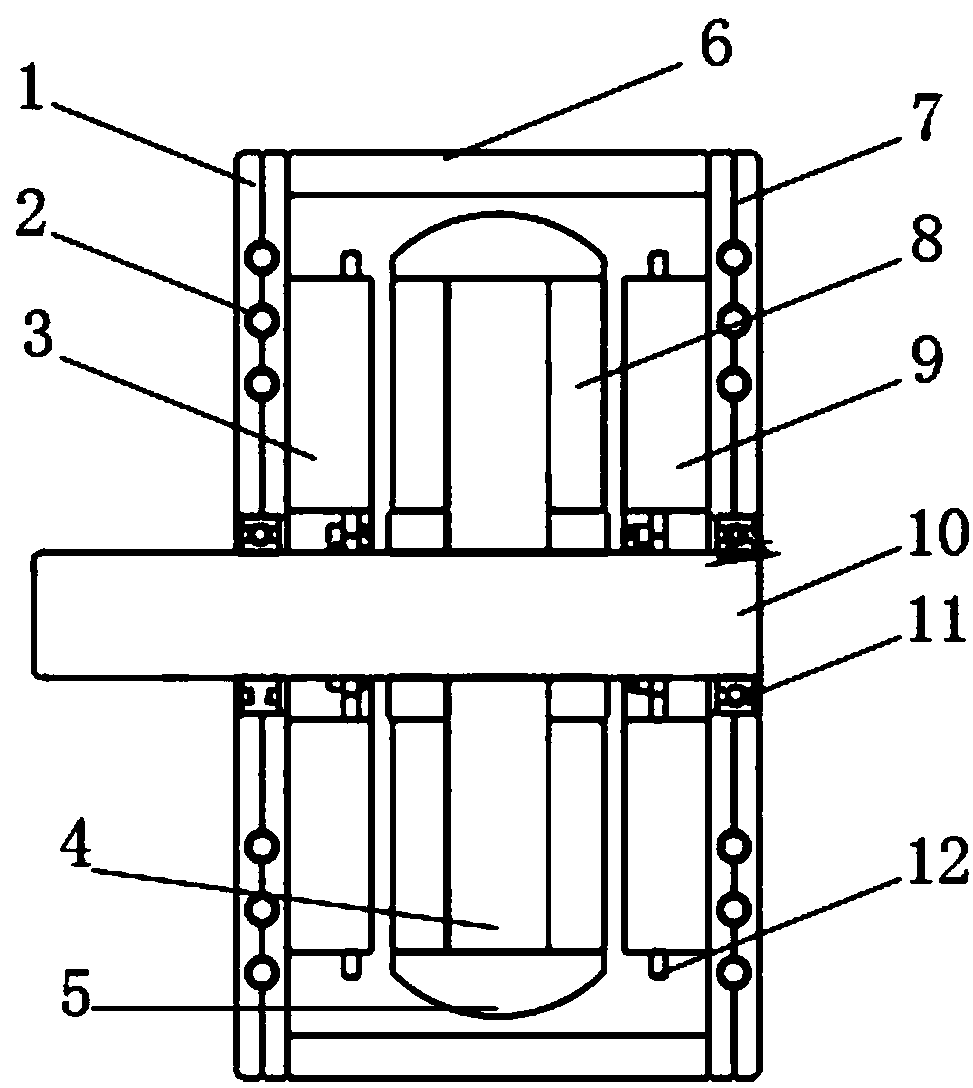

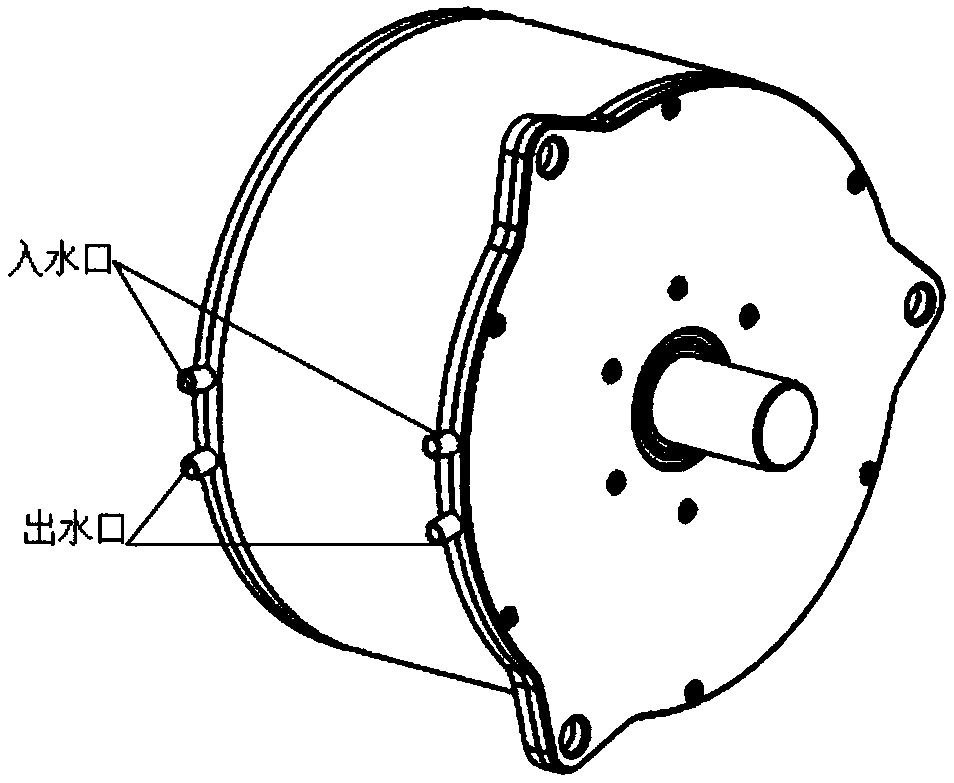

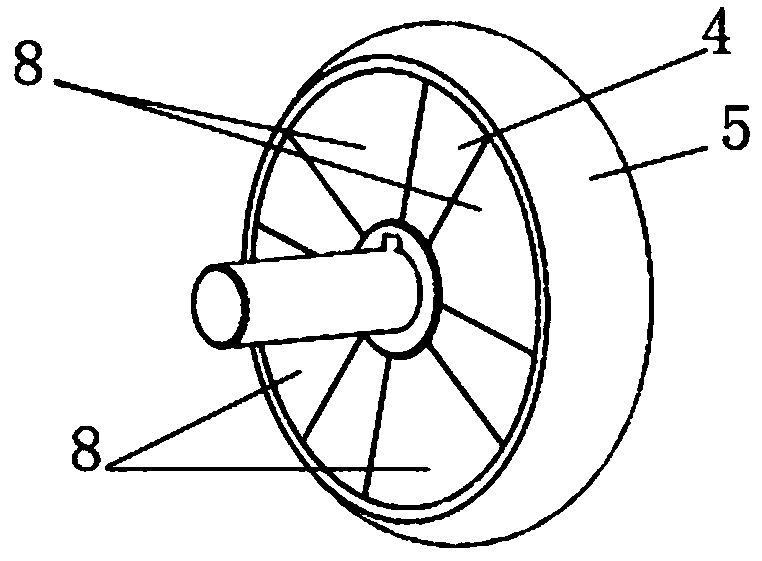

[0038] See attached Figure 1-11 , an ultra-high-speed permanent disk motor, which includes: a front end cover 1, a heat dissipation pipeline 2, a first stator core 3, a casing 6, a rear end cover 7, a second stator core 9, a ceramic bearing 11, Stator winding 12, screw 14, key 18, rotor fixing sleeve 19, stator wedge 20, high-speed rotor 16. The high-speed rotor includes a high-speed rotor core 4 (see Figure 8 ), permanent magnet 8 (see Figure 4 ), rotor jacket 5 (see Figure 6 ), rotor shaft 10.

[0039] The motor adopts a double stator structure. When used as a motor, the electromagnetic torque generated by the active current on the two stators acts together on the rotor to do mechanical work, with large output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com