Stator permanent magnet type cursor motor structure for reducing positioning force

A vernier motor, permanent magnet technology, applied in the magnetic circuit shape/style/structure, magnetic circuit static parts and other directions, can solve the problems of reduced positioning force, large positioning force, etc., to achieve high power density and increase manufacturing costs , the effect of improving power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

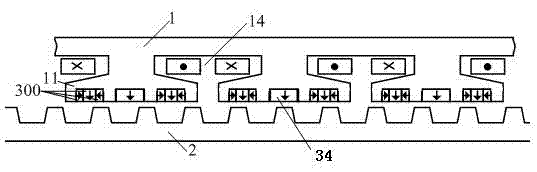

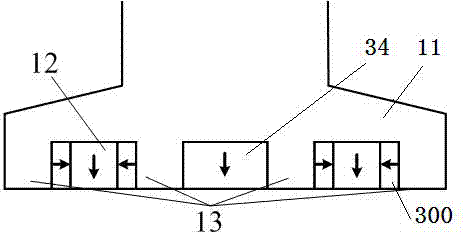

[0019] see figure 1 The structure of the stator permanent magnet vernier motor with reduced positioning force in the present invention includes two parts, the primary 1 and the secondary 2. There is an air gap between the primary 1 and the secondary 2, and the thickness of the air gap is selected according to the size and requirements of the motor. . The secondary 2 is formed by slotting the iron core to form a trapezoidal slot, the slotting on the primary 1 forms a slotted structure, and there is a slot 14 between two adjacent teeth on the primary 1, and the slot 14 is used to place the winding, and the winding is centralized or distributed Winding, groove 14 can adopt various groove types, select according to specific needs.

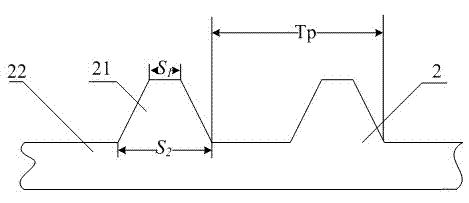

[0020] see figure 1 and figure 2 , a tooth of the secondary 1 includes a tooth 21 and a yoke 22, and the tooth 21 is trapezoidal in shape on the side opposite to the air gap. Width of tooth 21 near the air gap side S 1 and pitch T p Ratio K ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com