Tangential-set magnet permanent synchronization motor

A technology of permanent magnet synchronous motor and magnetic steel, which is applied to synchronous motors with stationary armatures and rotating magnets, etc., which can solve the problems of low power-to-weight ratio, large magnetic flux leakage coefficient, and difficulty in weakening magnetic field during electric operation, and achieve improved Effects of output power and increased air gap flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

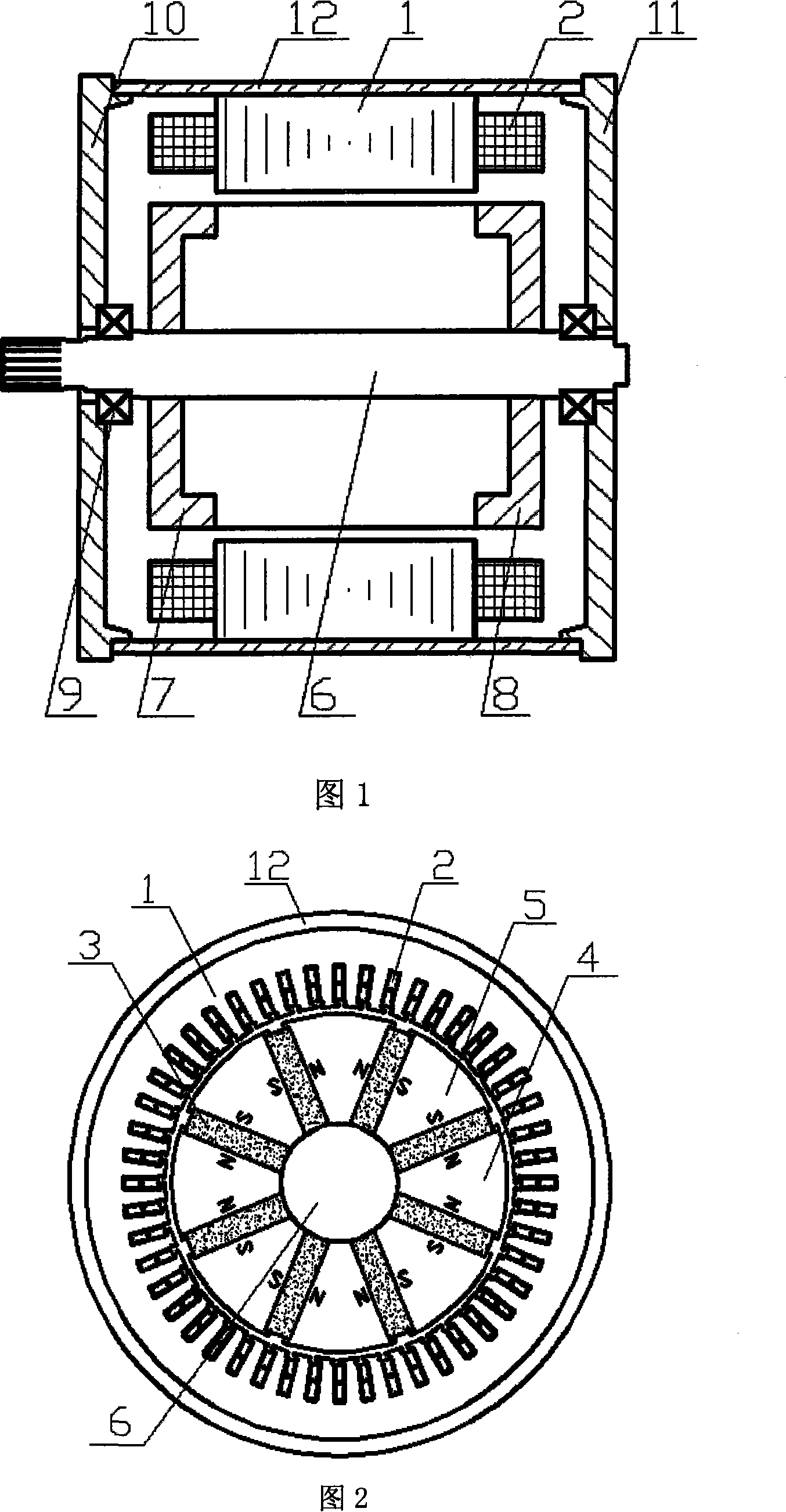

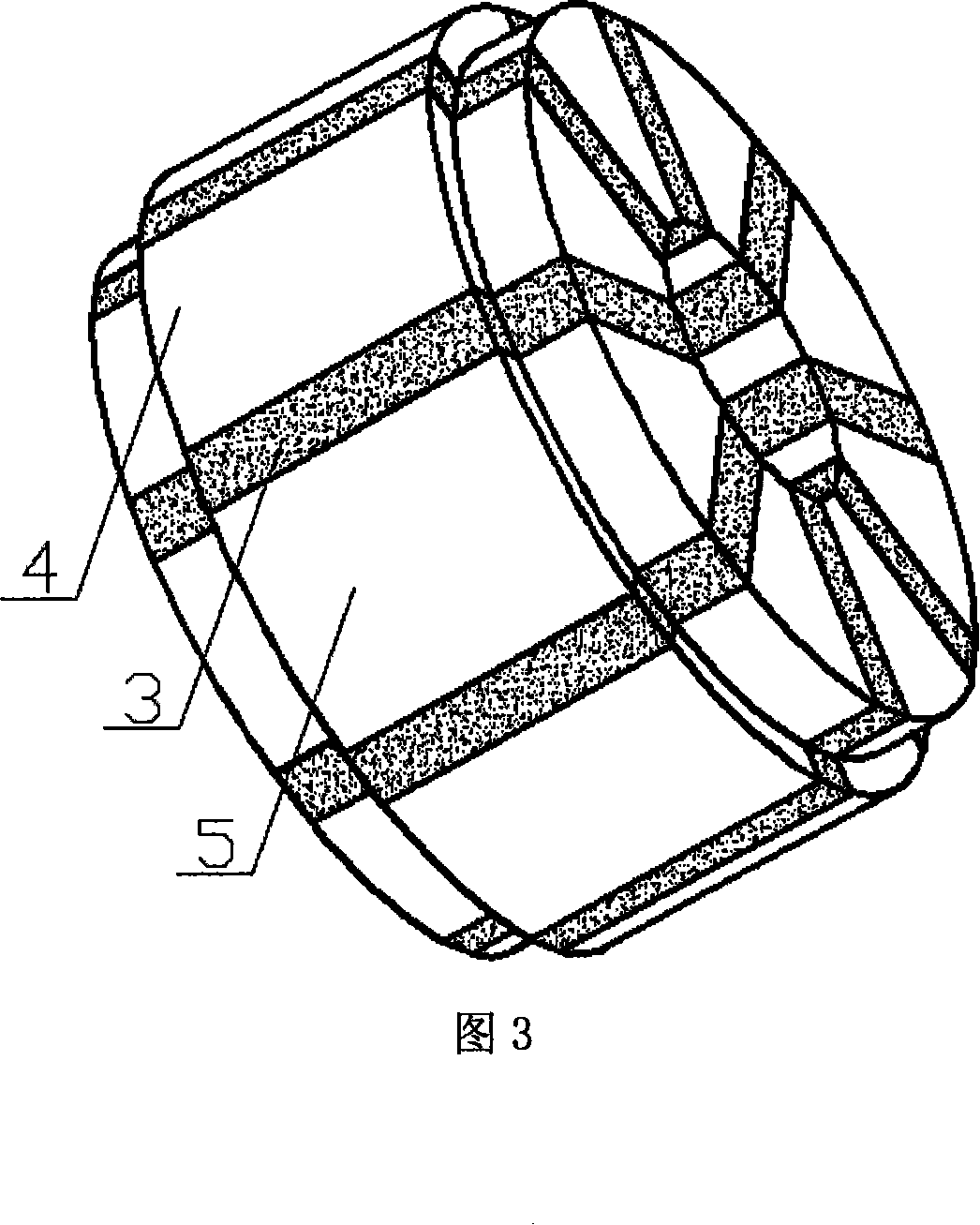

[0020] The structure of the tangential magnet steel permanent magnet synchronous motor of the present invention is shown in Figure 1. The stator is composed of a stator core 1 and an armature winding 2 embedded in its slot, and a tangentially magnetized permanent magnet 3 and a rotor magnetizer are arranged on the rotor. , the material of the rotor magnetizer is a whole piece of steel, and the tangentially magnetized permanent magnets 3 and the rotor magnetizers are arranged alternately. Figure 2 shows a four-pair pole structure. Of course, the number of tangentially magnetized permanent magnets 3 and the number of pole pairs of the motor can be more , the adjacent permanent magnets have the same polarity on the rotor magnetizer between them, which are N poles or S poles, the N pole magnetizer is the rotor N pole magnetizer 4, and the S pole magnetizer is the rotor S pole magnetizer 5. The axial length of the tangentially magnetized permanent magnet 3 and the rotor magnetizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com