Electromagnetic oscillation energy collection device

A technology of oscillating energy and collecting device, applied in electromechanical devices, electrical components, etc., can solve the problems of large magnetic circuit reluctance, small air gap magnetic density, large magnetic leakage, etc., to increase output voltage and output electric power, reduce Small reluctance, reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

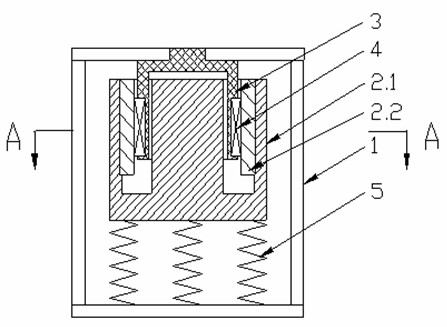

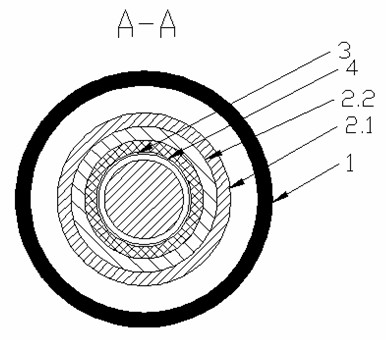

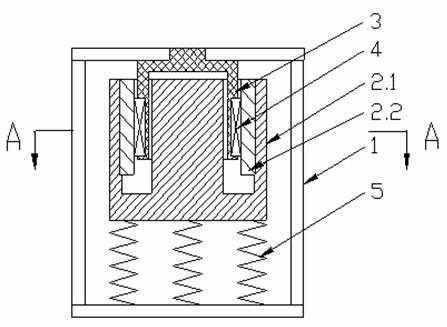

[0013] With reference to the accompanying drawings, the electromagnetic oscillation energy harvesting device includes a housing 1, a mover composed of a magnetically permeable core 2.1 and a permanent magnet 2.2 placed in the housing, an insulated cup-shaped stator 3, a coil winding 4 and a spring 5, and a permeable magnet The core 2.1 is a whole formed by connecting the concentric cylindrical inner core and the bottom of the circular outer core, and has an E-shaped longitudinal section. The permanent magnet 2.2 is located between the inner core and the outer core of the magnetic permeable core 2.1, and is fixed on the outer core. The inner surface of the inner surface, the bottom of the magnetic conductor core 2.1 is connected with one end of the spring 5, the other end of the spring 5 is against the bottom of the housing, the cup-shaped stator 3 is fixed to the inner top surface of the housing 1, and its circular cup is placed In the annular air gap formed by the inner core a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com