Suspended magnetic iron structure of magnetic suspension vehicle and its production mehtod

A technology for levitation magnets and maglev trains, which is applied in vehicle parts, electromagnets, electric vehicles, etc., can solve the problem that the complexity of the cost process cannot meet the requirements of mass production, economic benefits, and can not well meet the requirements of urban traffic passenger flow and vehicle load. Insufficient passenger capacity and other problems, to achieve the effect of being beneficial to protection, ensuring insulation performance and quality, and improving electromagnetic attraction and suspension force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

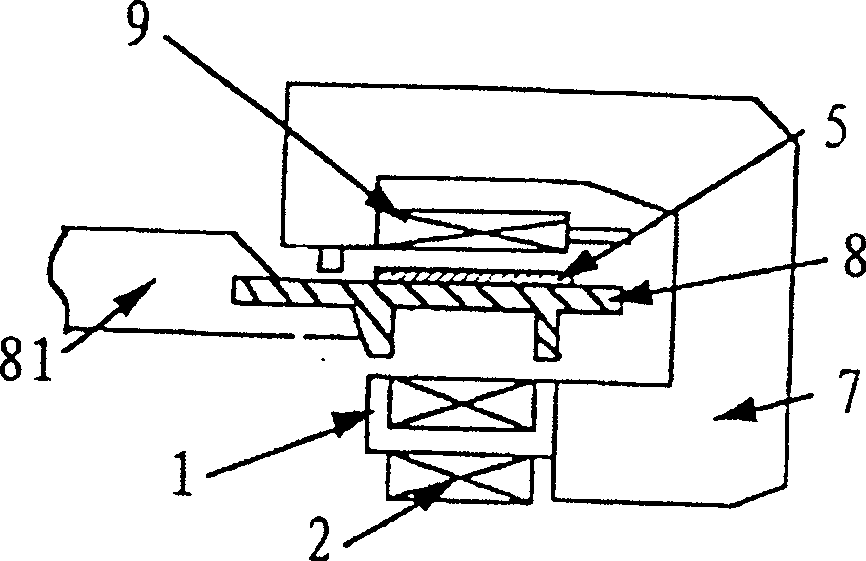

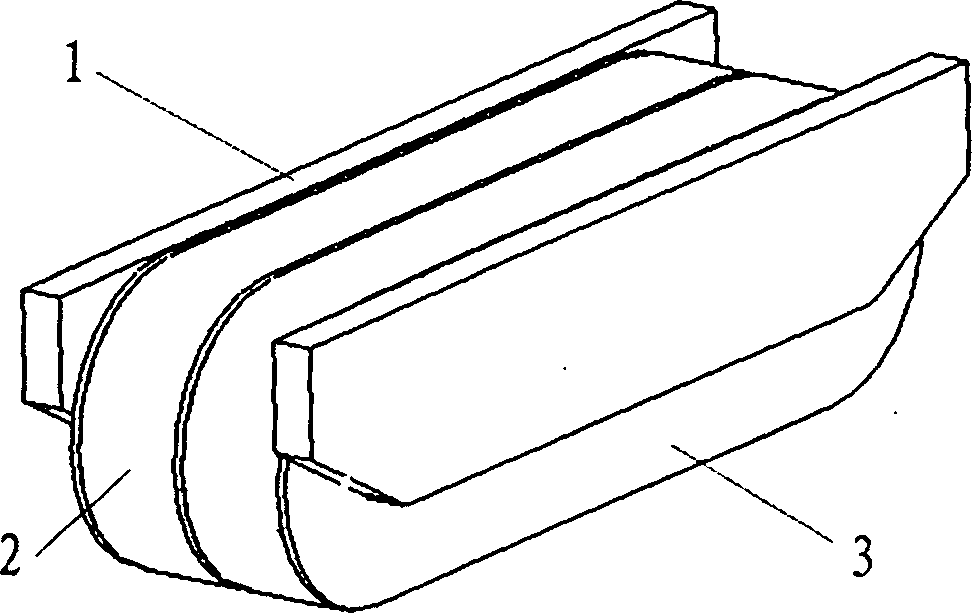

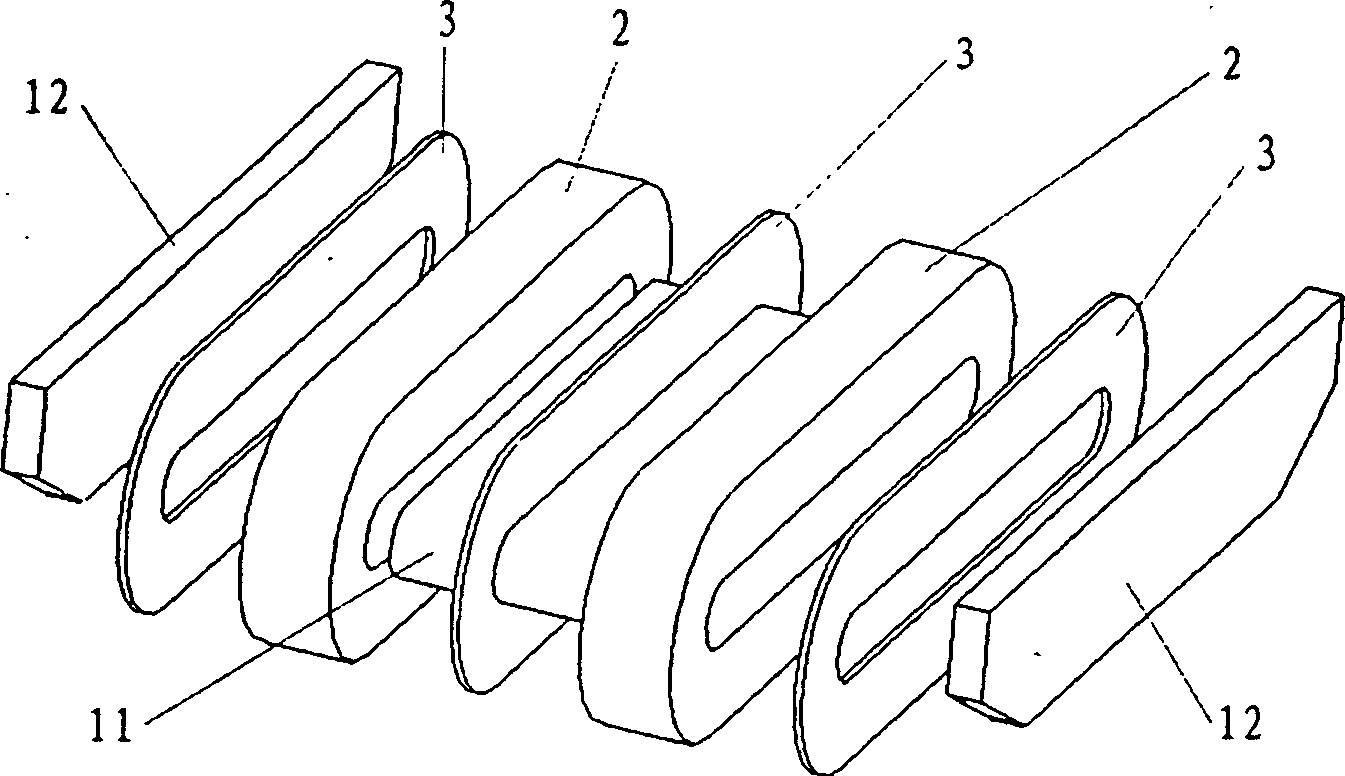

[0036] see figure 2 and image 3 As shown, the suspension magnet of the present invention is composed of an iron core 1 , a coil 2 and a cooling jacket 3 . The iron core 1 is a split combined structure, which is composed of two magnetic poles 12 located on both sides and a magnetic pole 11 located in the middle of the two magnetic poles 12 and connected to one end of the two magnetic poles 12 respectively, and is fixed on the Together, they form an iron core with a circular cross-section. The coil 2 is wound from a 0.15-0.30mm thick aluminum foil 22 and a 0.01-0.03mm thick insulating film 21 (such as a polyurethane film). The present invention replaces the general enameled wire with aluminum foil, so that the coil can withstand a larger excitation current . The coil 2 is set on the magnet 11, and the number of the coil 2 can be one, but in order to increase the number of turns of the coil 2 and the effect of cooling in a limited space, it is preferable to divide it into tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com