Cylindrical-type linear magnetic-gear composite permanent magnet motor

A permanent magnet motor, linear motor technology, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as thrust fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

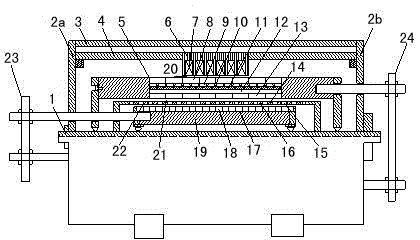

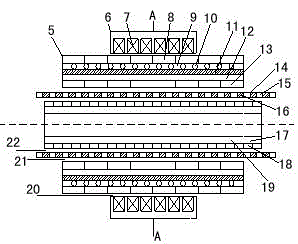

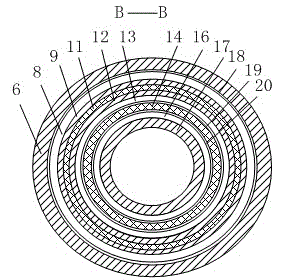

[0007] Such as figure 1 As shown, the cylindrical linear magnetic gear compound permanent magnet motor includes a brushless DC linear motor and a linear magnetic gear. The compound permanent magnet motor has double mechanical ports and a three-layer air gap structure, including the main armature winding and The auxiliary damping winding can realize the bidirectional transmission of electromechanical energy; the brushless DC linear motor and the linear magnetic gear are coaxially integrated in a cylindrical structure, that is, the low-speed mover 17 and the inner stator 14 that constitute the magnetic gear and the The high-speed mover 5 and the outer stator 6 of the brushless DC linear motor form a double-stator double-move structure.

[0008] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the low-speed mover 17 leads to the low-speed mover connecting rod 23; the high-speed mover 5 leads to the high-speed mover link 24; the inner stator 14 is made of high mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com