Magnet unit, magnet array, magnetic levitation planar motor and lithographic device using magnetic levitation planar motor

A technology of magnet unit and plane motor, which is applied in electromechanical devices, photolithography process exposure devices, microlithography exposure equipment, etc., to achieve the effects of small magnetic leakage, light weight and strong magnetic density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

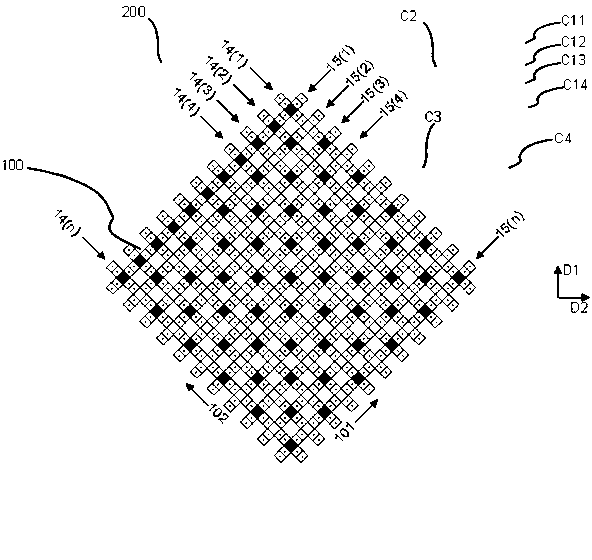

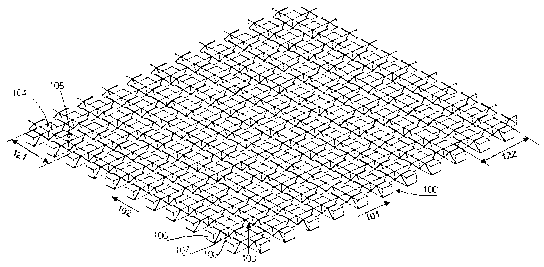

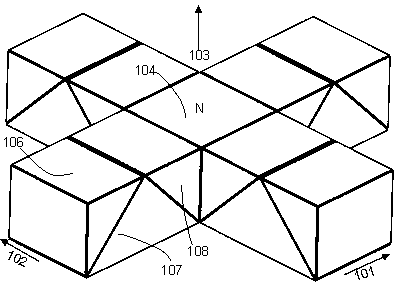

[0091] like figure 1 as shown, figure 1 It is a structural schematic diagram of a method for arranging a permanent magnet array of a planar motor provided by the present invention. The planar motor includes a permanent magnet array (or magnet array) 100 and a coil array 200 , and the coil array 200 is above or below the magnet array 100 and has a certain gap with the magnet array 100 . The magnetic levitation planar motor includes: a magnet array 100 and a coil array 200 . The magnet array 100 can move relative to the coil array 200 in a large range along the first direction 101 and the second direction 102 . Wherein, the magnet array 100 has a periodic sequence of rows 14 (n) and a periodic sequence of columns 15 (n), wherein n is a natural number. The row sequence 14(n) and the column sequence 15(n) of the magnet array 100 are arranged in the first direction 101 and the second direction 102 respectively. The distribution of magnet arrays in two directions is detailed as ...

Embodiment 2

[0101] Figure 10 gives figure 1 The second embodiment of the magnet array. like Figure 10 As shown, the second embodiment is a cross-sectional view of the periodic magnet array of the Halbach magnet group along the first axis direction 101 or the second direction 102 . This array comprises three types of magnets, wherein, the first prism magnet 136 of the third type magnet is vertically directed to the second prism magnet 137 of the third type magnet along the inclined plane magnetization direction, and the magnetic poles of the second prism magnet 137 of the third type magnet are The direction is parallel to the first axial direction 101 and points to the first type of N-pole square magnet 134, the third prismatic magnet 138 of the third type of magnet is vertically away from the second prismatic magnet 107 of the third type of magnet along the direction of magnetization on the slope, and the second prismatic magnet 107 of the third type of magnet. The magnetization dire...

Embodiment 3

[0104] Figure 13 gives figure 1 In the third embodiment of the magnet array, such as Figure 13As shown, the third embodiment is a cross-sectional view of the periodic magnet array of the Halbach magnet group along the first direction 101 or the second direction 102 . The array includes three types of magnets, wherein the first magnet 335 of the third type of magnet is parallel to the first axis direction 101 and points to the first type of N-pole trapezoidal prism magnet 337, and the magnetic pole direction of the second magnet 336 of the third type of magnet is It is parallel to the first axis direction 101 and points to the first type N-pole trapezoidal prism magnet 337 . The first type of trapezoidal prism magnets 337 a , 337 b have magnetization directions parallel to the axis 103 upward, and the second type of trapezoidal prism magnets 338 a , 338 b have magnetization directions parallel to the axis 103 downward. like Figure 13 As shown, the first type magnet, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com