Ring spinning frame comprising drawing systems

A ring spinning machine and drafting technology, which is applied in the direction of continuous winding spinning machine, spinning machine, textile and paper making, can solve problems such as troubles, and achieve the effect of simplifying the implementation mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

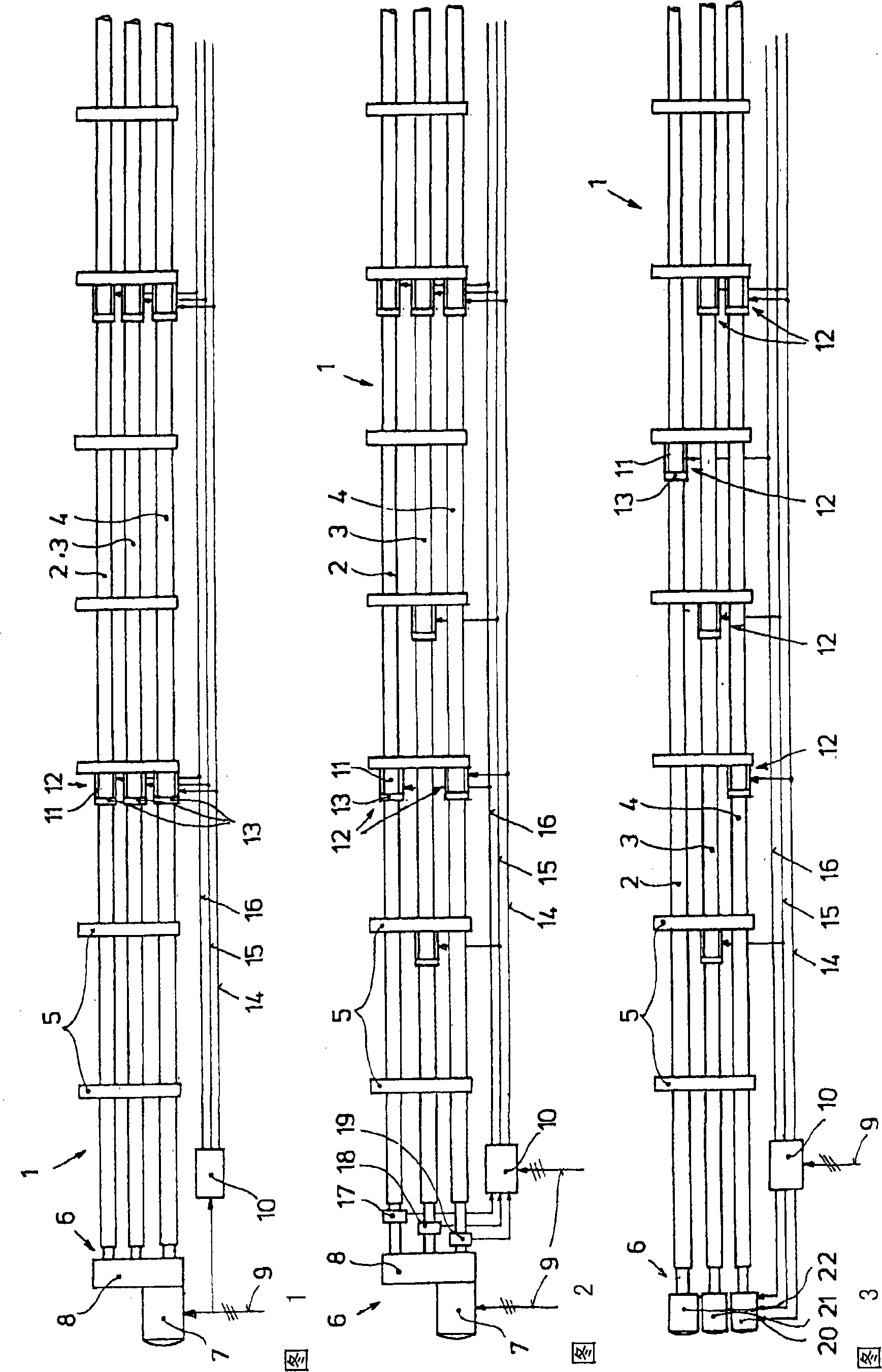

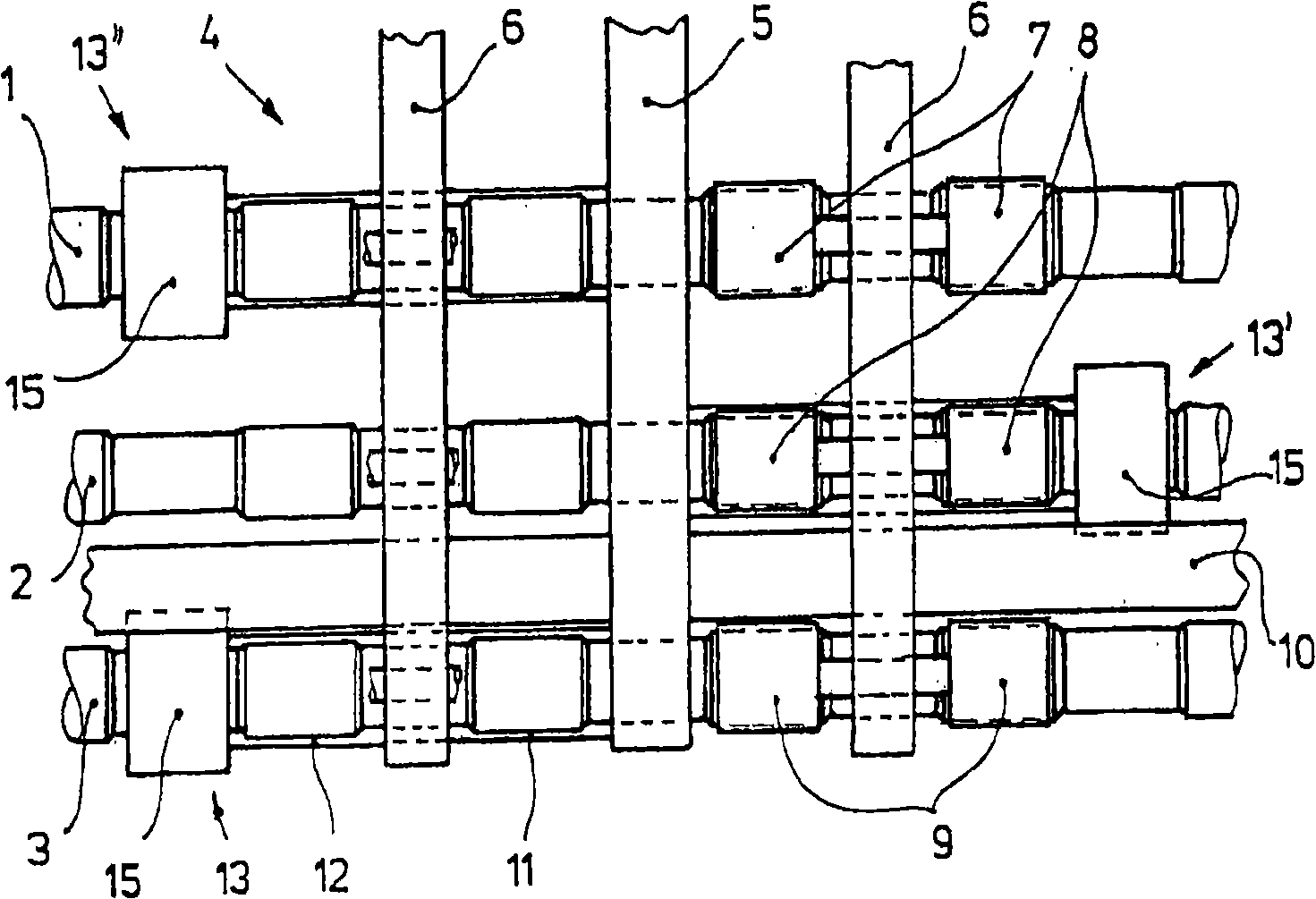

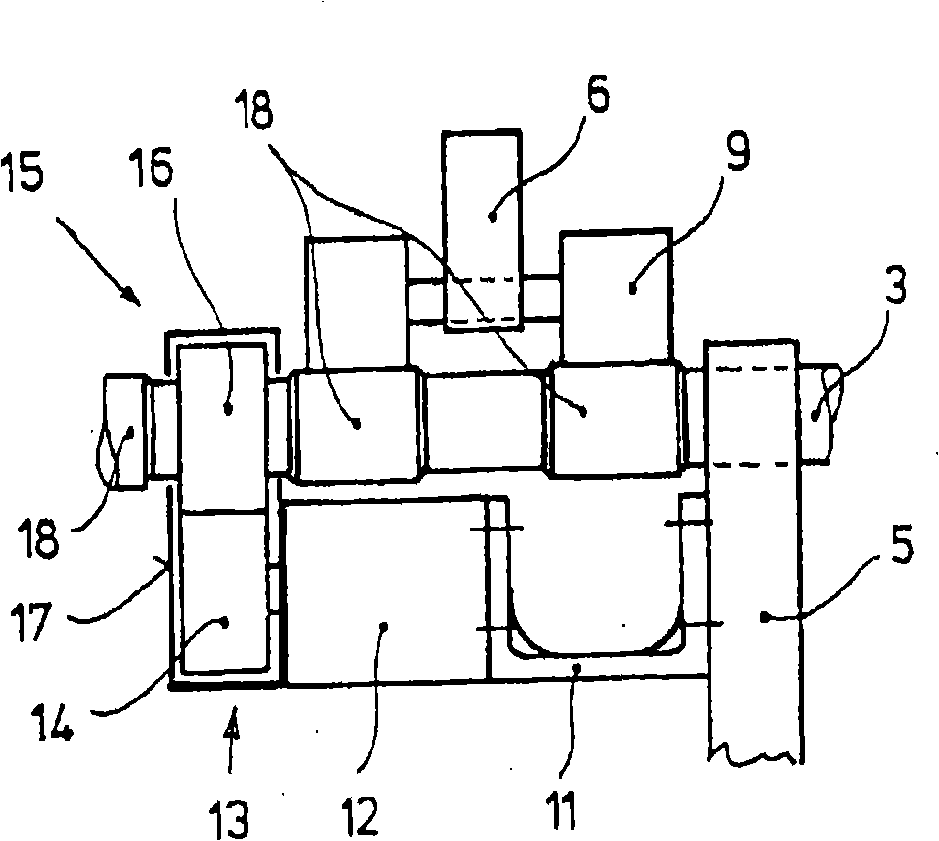

[0051] Exemplary embodiments of the invention are shown purely schematically in the drawings. in:

[0052] 1 is a plan view of the starting area of a drafting mechanism with a drafting mechanism-main drive and a drafting roller-auxiliary drive;

[0053] FIG. 2 is a view of the rotational speed control mechanism of the drive with the drafting roller-auxiliary drive as in FIG. 1;

[0054] FIG. 3 is a view of the same main drive as in FIG. 1 with drafting rollers realized by means of synchronous motors.

[0055] 1 to 3 of the accompanying drawings show the starting area of the three drafting rollers 2, 3 and 4 of the drafting mechanism 1; these three drafting rollers also continue to the right. They are supported at regular intervals in the drafting roller feet 5 . In the embodiment of FIGS. 1 and 2 , the drafting rollers are drive-connected to one another at their left-hand end via a drafting mechanism-main drive 6 in a form-fitting manner, wherein the drafting mechanism-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com