High-precision rolling displacement detecting device

A rolling displacement and detection device technology, applied in the direction of measuring devices, instruments, etc., to achieve the effects of simplified design and implementation, high detection accuracy and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

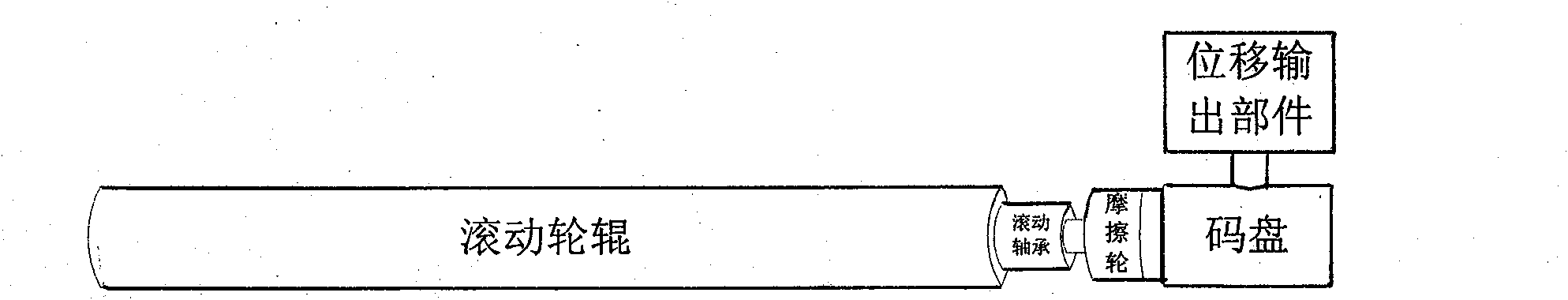

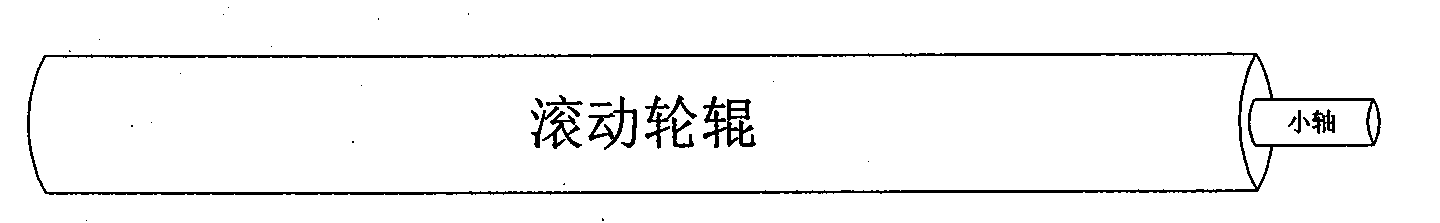

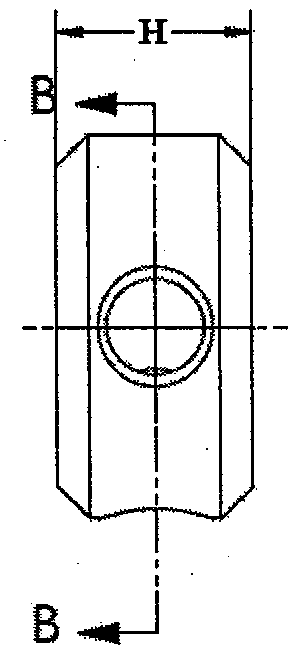

[0028] A high-precision rolling displacement detection device of the present invention, its overall structure schematic diagram is as follows figure 1 shown. The device mainly includes the following parts: rolling wheel rollers, rolling bearings, friction wheels, code discs and displacement output components. The position connection relationship between them is: the rolling wheel is connected with the rolling bearing and the friction wheel, and the friction wheel is driven to rotate under the support of the rolling bearing; the front of the friction wheel is connected with the small shaft part of the rolling wheel through the rolling bearing, and the rear is connected with the code disc. Connect and transmit the output rolling displacement to the code disc in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com