Large power wind-gathering current-guiding wind power machine

A wind motor and high-power technology, which is applied to wind power generators, wind power generators at right angles to the wind direction, control of wind power generators, etc., can solve the problems of high power, high efficiency, and low efficiency of wind power generation devices, and achieve low cost, Easy implementation, high output power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

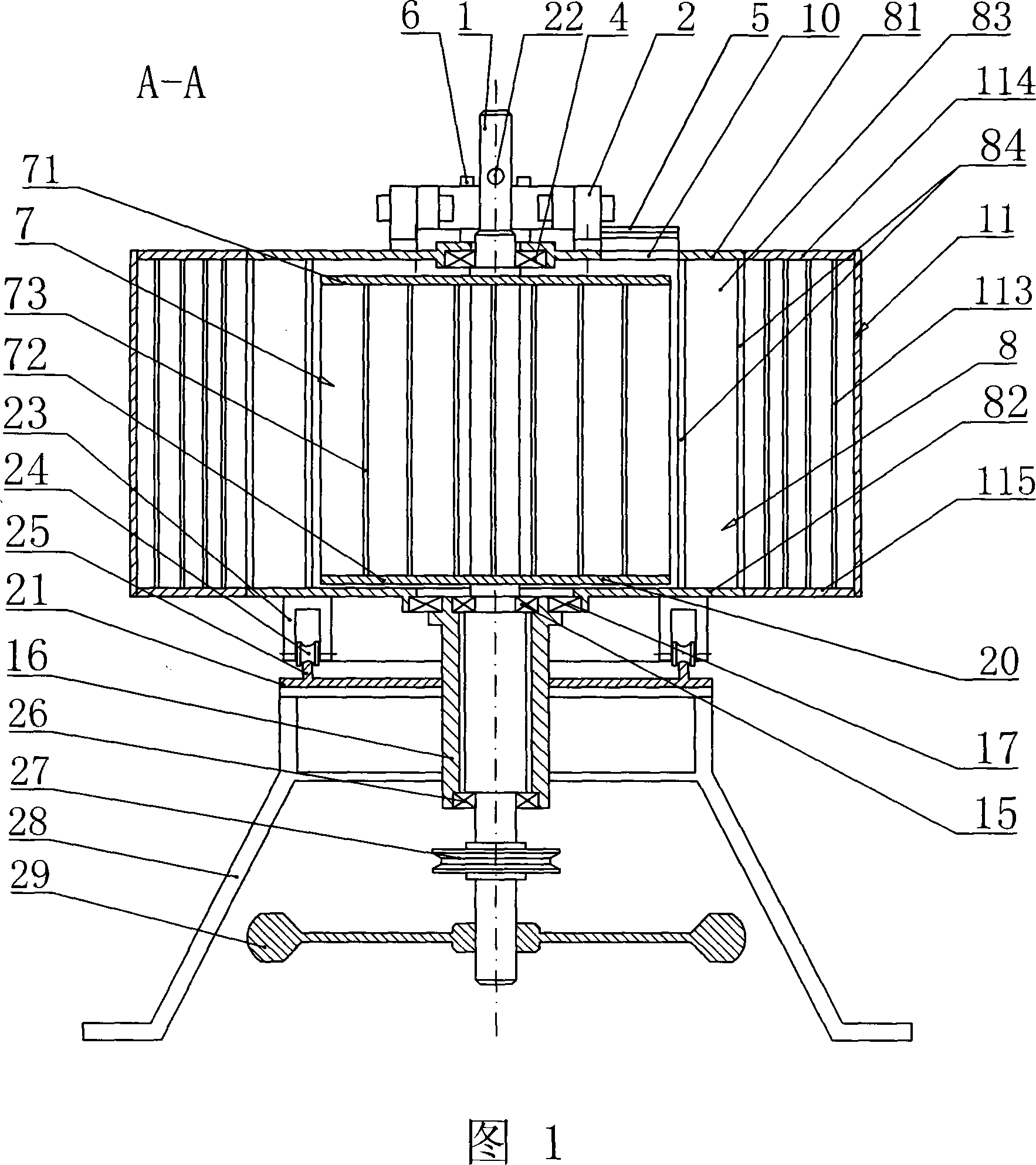

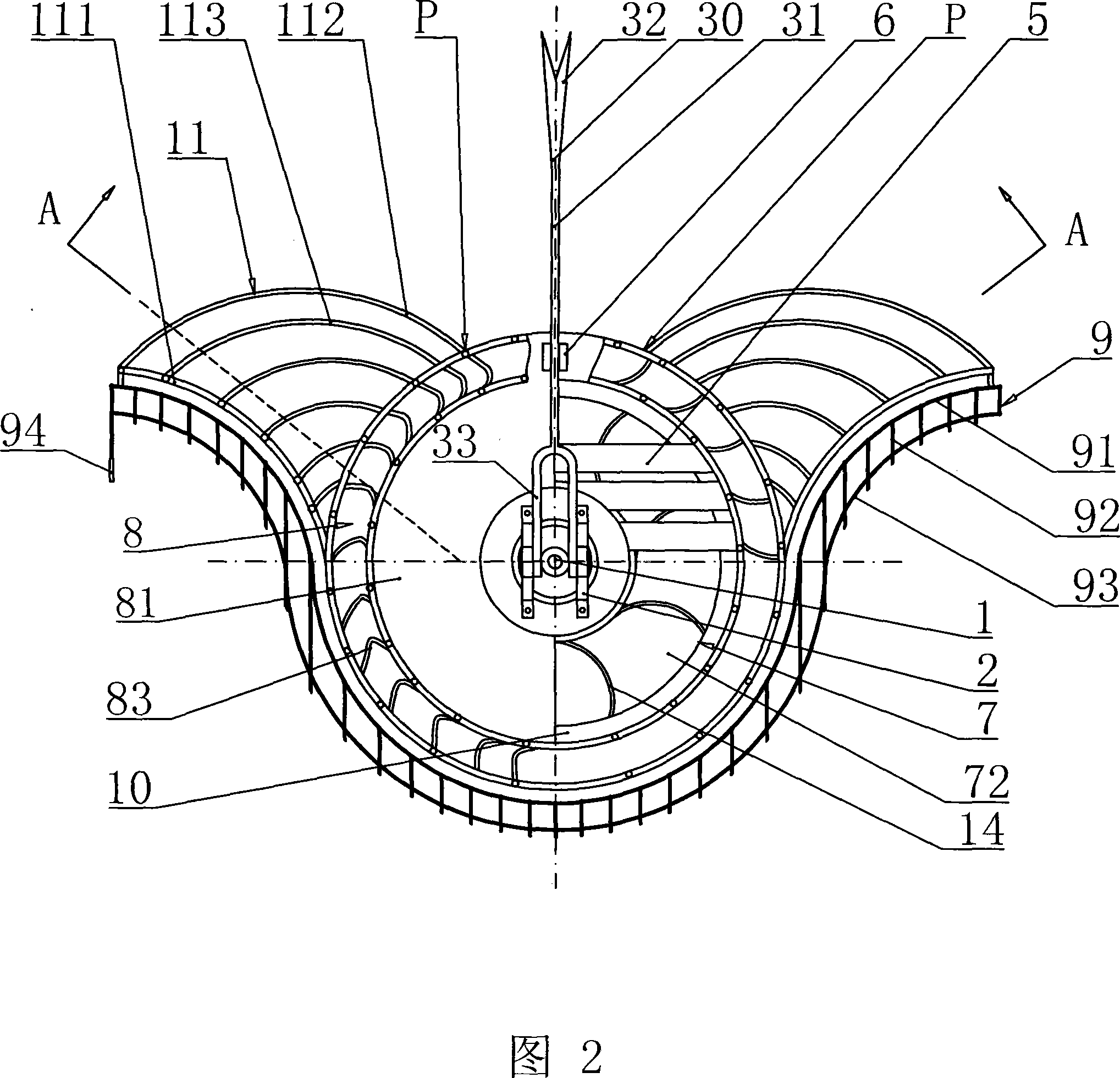

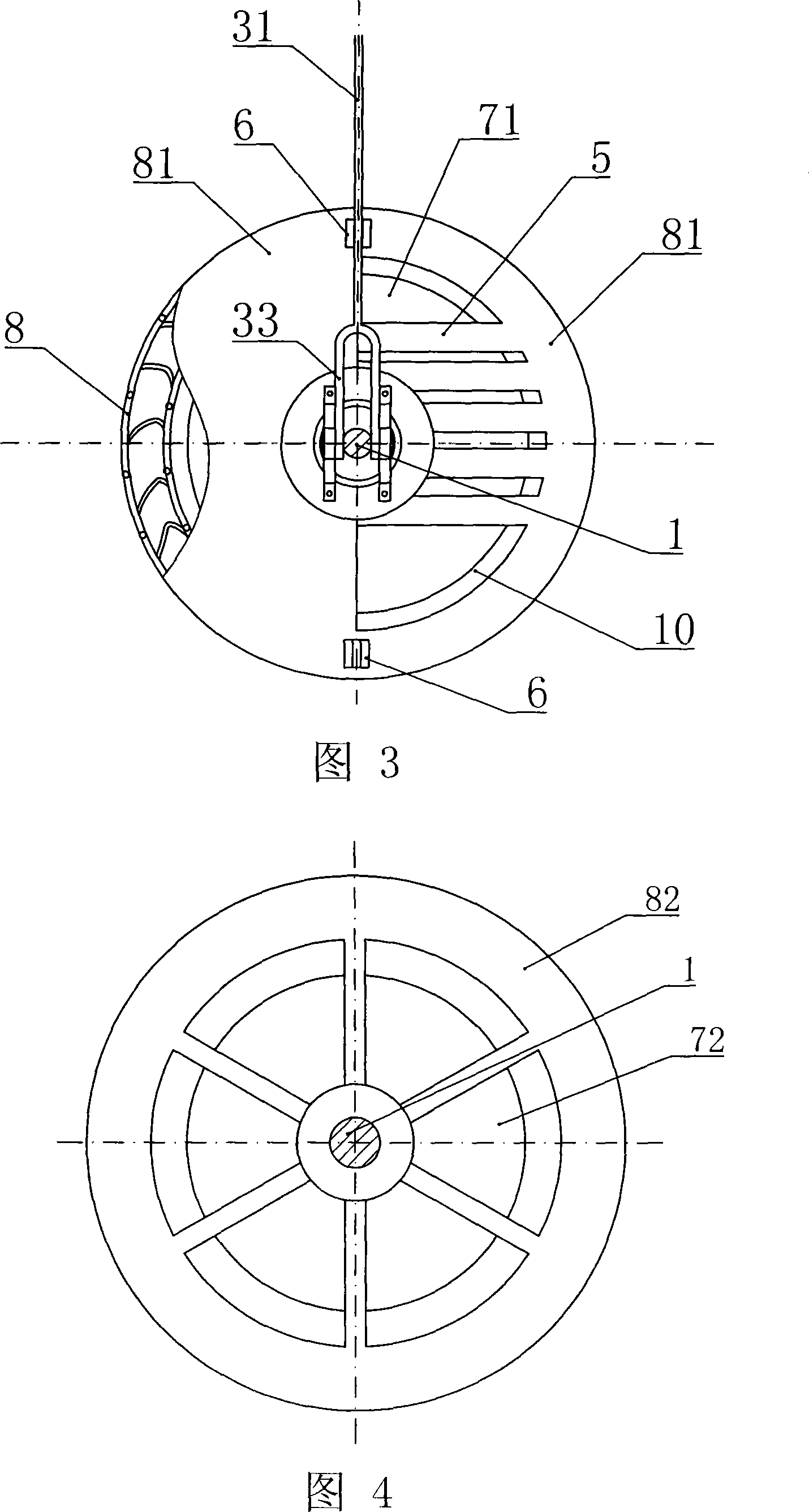

[0016] 1 to 4, the embodiment of the present invention includes a machine base 28, a main shaft 1, an impeller 7, a flow guide frame 8, a wind control louver 9, a wind gathering cover 11, a tail rudder 30, a power output wheel 27 and an inertia wheel 29 . The bottom of the main shaft 1 is vertically rotatably connected in the main shaft sleeve 16 on the machine base 28 through two upper and lower bearings 4 and 15 . An impeller 7 is fixedly mounted on the top of the main shaft 1 . A power take-off wheel 27 and an inertia wheel 29 are installed near the lower end of the main shaft 1 . An annular guide frame 8 surrounding the contour of the impeller 7 is installed outside the impeller 7, and the center of the upper cover 81 of the guide frame is rotatably connected with the main shaft 1 through the upper cover bearing 4. The center of the lower cover 82 of the air guide frame is rotatably connected with the upper end of the main shaft sleeve 16 on the base 28 through the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com