Adjustable bending rubber joint

A technology of flexible rubber joints and rubber joints, which is applied in the direction of pipes/pipe joints/fittings, expansion compensation devices for pipelines, mechanical equipment, etc., can solve the problem of costing a lot of manpower, material resources and time, increasing engineering installation personnel, The flexible rubber joint is not easy to put in, so as to save manpower and material resources, save time and effort for disassembly, and improve the ability to withstand negative pressure (vacuum degree)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

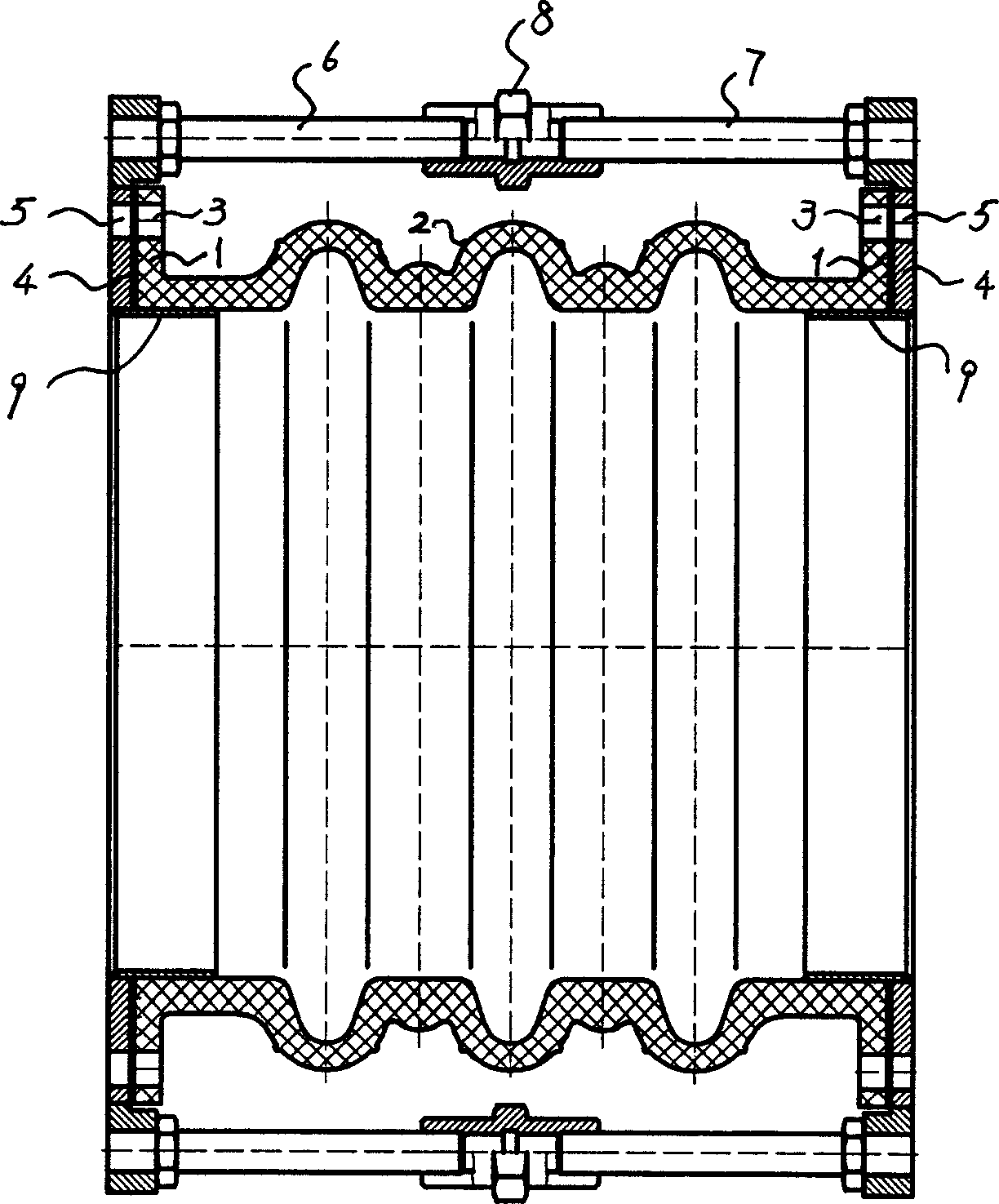

[0011] As shown in the figure, the adjustable flexible rubber joint of the present invention includes a corrugated rubber pipe joint body 2 with two connecting end faces 1, and connecting holes 3 uniformly arranged on the connecting end faces 1, Positioning flanges 4 are respectively arranged on the two connecting end faces 1, and the connecting holes 5 on the positioning flanges 4 correspond to the connecting holes 3 on the connecting end faces 1; the two positioning flanges 4 They are connected by length-adjustable telescopic rods. The telescopic rod is composed of two lead screws 6, 7 with opposite helical directions and a screw nut 8 connecting the two lead screws 6, 7. Positioning tubes 9 extending toward the inner diameter of the corrugated rubber pipe joint body 2 are respectively arranged on the inner diameter peripheral surfaces of the two positioning flanges 4 . A rubber liner is arranged on the outer end surface of the positioning flange 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com