Wind generating set

A technology for wind turbines and components, applied in the direction of wind turbines, engines, engine components, etc., can solve the time-consuming problem of main bearing installation, and achieve the effect of saving time and labor for installation and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

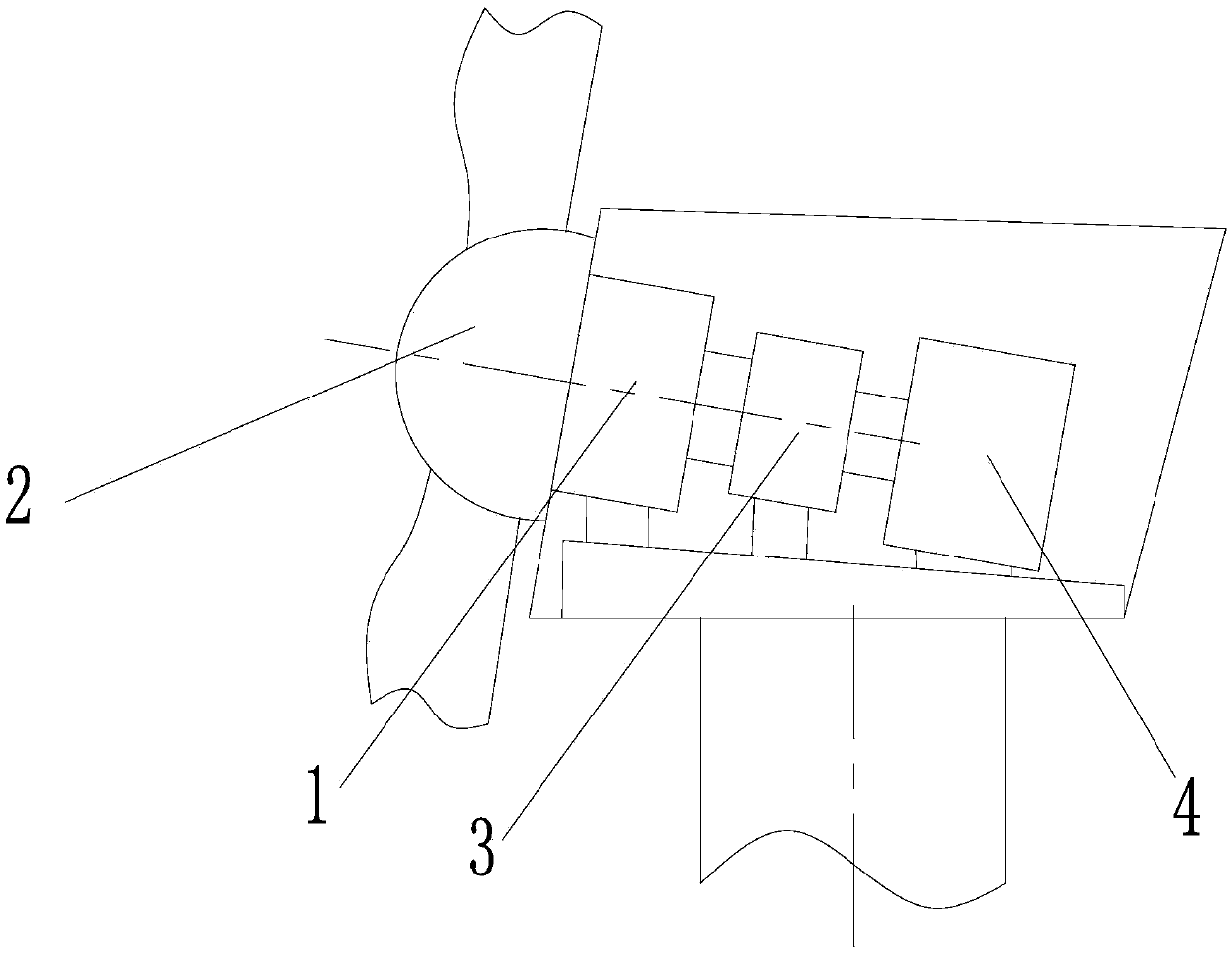

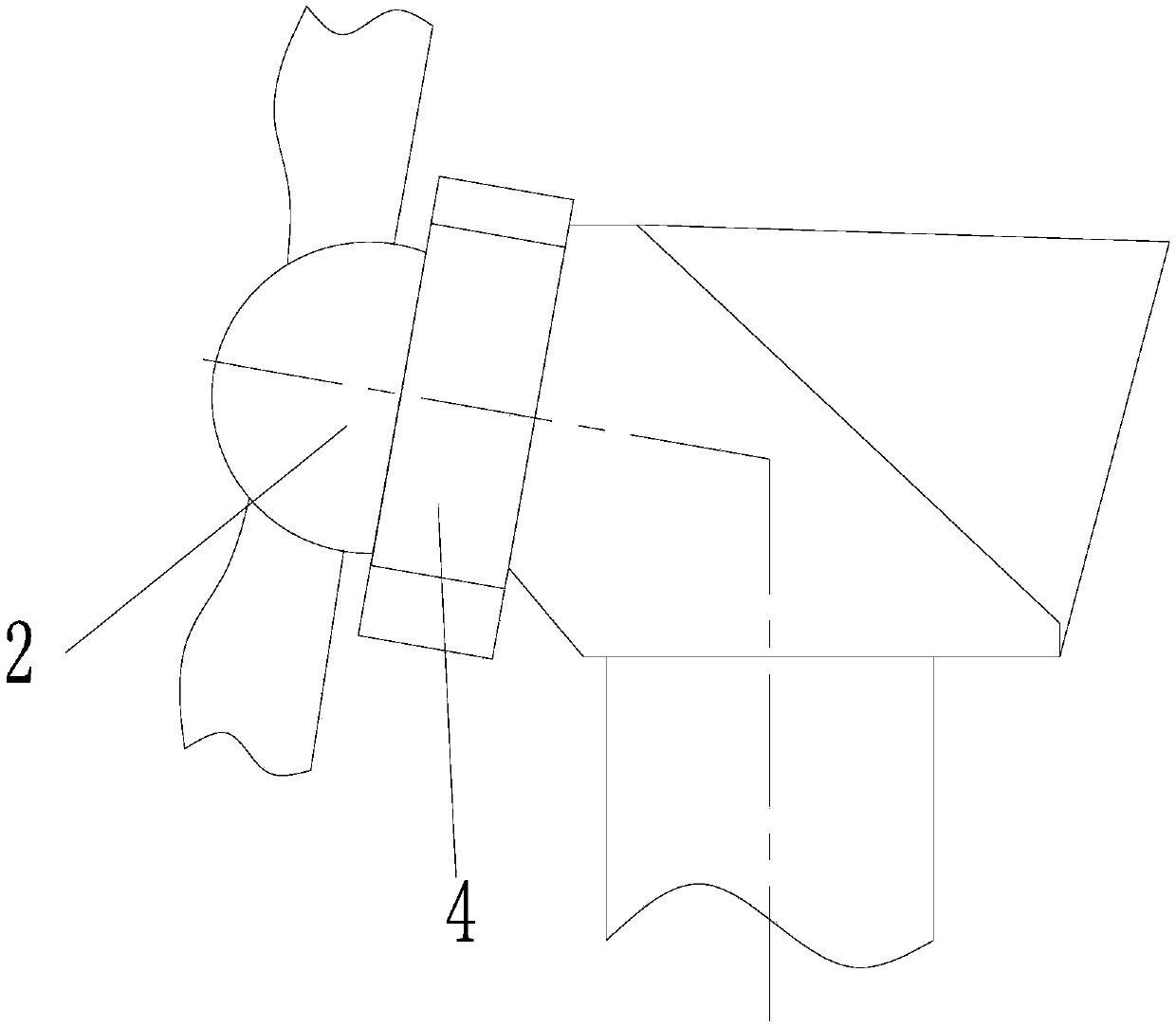

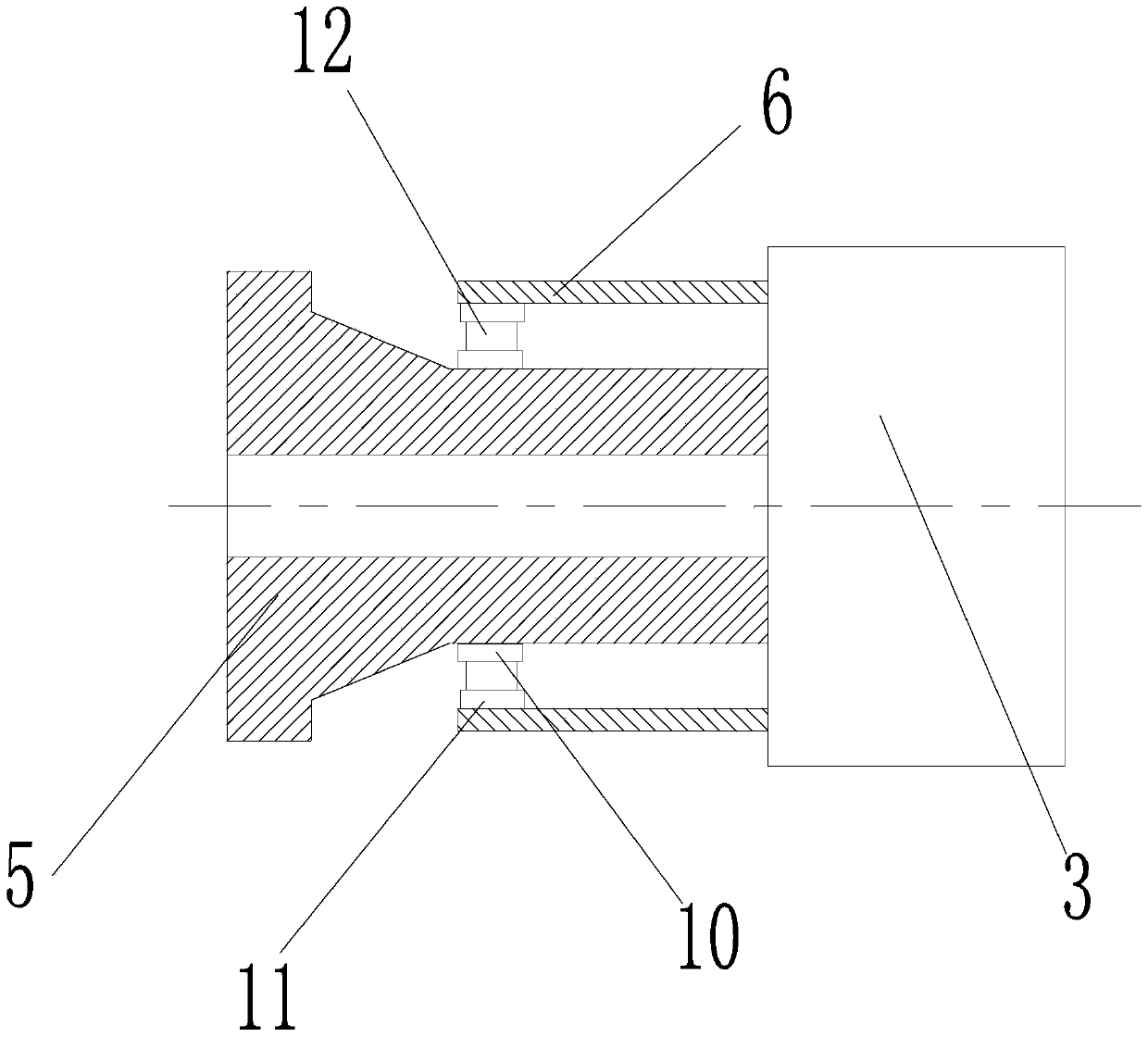

[0031] Such as Figure 5 As shown in the embodiment of the fundamental invention, the wind power generator includes an inner shaft 5 and an outer shaft 6 sleeved outside the inner shaft 5, and a bearing assembly is arranged between the inner shaft 5 and the outer shaft 6 to The inner shaft 5 and the outer shaft 6 can rotate relatively, and at the same time, they can transmit the gravity and wind load of the impeller 2. The bearing assembly includes an inner ring, an outer ring, and a rolling assembly 12 arranged between the inner ring and the outer ring. The inner ring is integrally formed on the inner shaft 5 and / or the outer ring is integrally formed It is formed on the outer shaft 6. This arrangement can solve the problem of easy axial movement of the inner ring and / or outer ring of the bearing during use, and ensure the reliability of the bearing during use. In addition, since the inner ring is integrally formed on the inner shaft 5 and the outer ring is integrally formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com