Hinge for installing bridge cable tower and method for installing hinge

An installation method and installation technology, applied to bridges, bridge parts, bridge construction, etc., can solve the problems of difficult control of welding quality, difficult construction, time-consuming and laborious, etc., and achieve high installation accuracy, time-saving and labor-saving installation. Safe and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

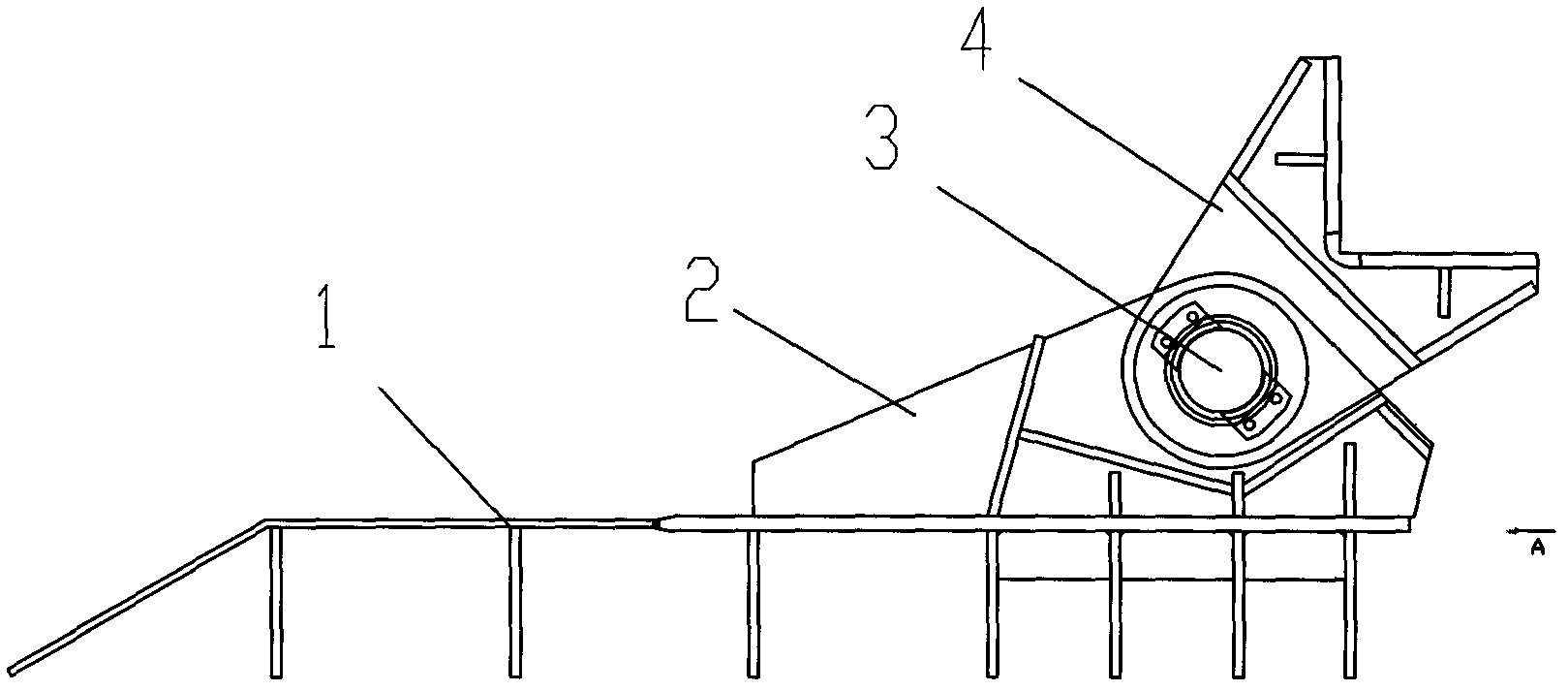

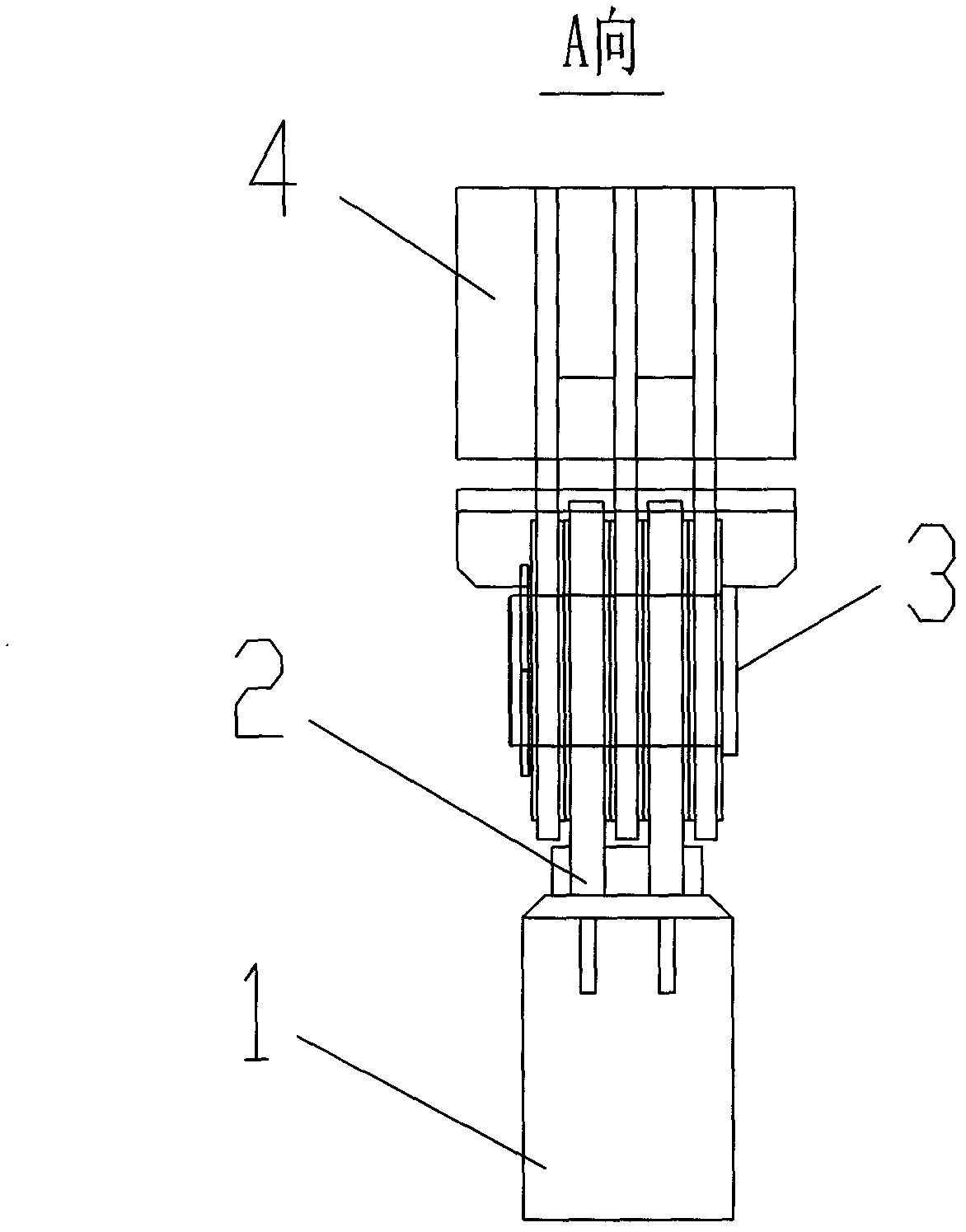

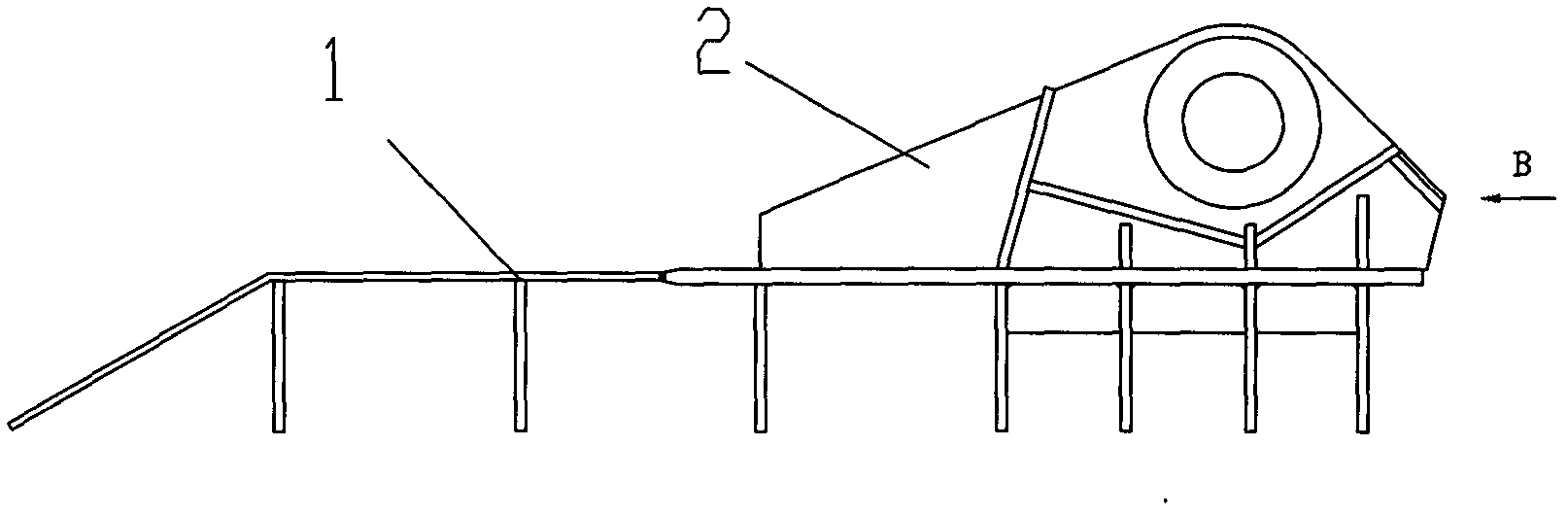

[0028] Below in conjunction with accompanying drawing, the present invention will be described in further detail: as figure 1 and 2 As shown, the heavy-duty hinge for bridge tower installation of the present invention comprises a lower hinge base 2, a hinge shaft 3, an upper hinge base 4 and a lower hinge base anchor plate 1, the lower hinge base is fixed on the lower hinge base anchor plate, and the upper hinge base and the lower hinge base are fixed on the lower hinge base anchor plate. The lower hinge seat is connected by a hinge shaft, the upper hinge seat can rotate freely relative to the lower hinge seat, and the upper hinge seat is connected to the first section of the cable tower. Among them, the diameter of the pin shaft is Φ400mm, and it is made of 40Cr steel after quenching and tempering treatment. The material of ear plate 5 and 6 is made of Q345B steel plate with a thickness of 90mm. The upper hinge seat structure reference Figure 5 and Image 6 , the structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com