Low-cost alternating pole permanent magnet hub motor for electric vehicle drive

A wheel hub motor and alternating pole technology, which is applied in electric vehicles, motors, electric components, etc., can solve the problems of high cost and large amount of rare earth permanent magnet materials, and achieve the effects of reducing usage, simplifying production process, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. In order to more clearly and perfectly illustrate the structural features and beneficial effects of the motor of the present invention, a detailed layered description will be made in conjunction with a three-phase alternating pole permanent magnet hub motor.

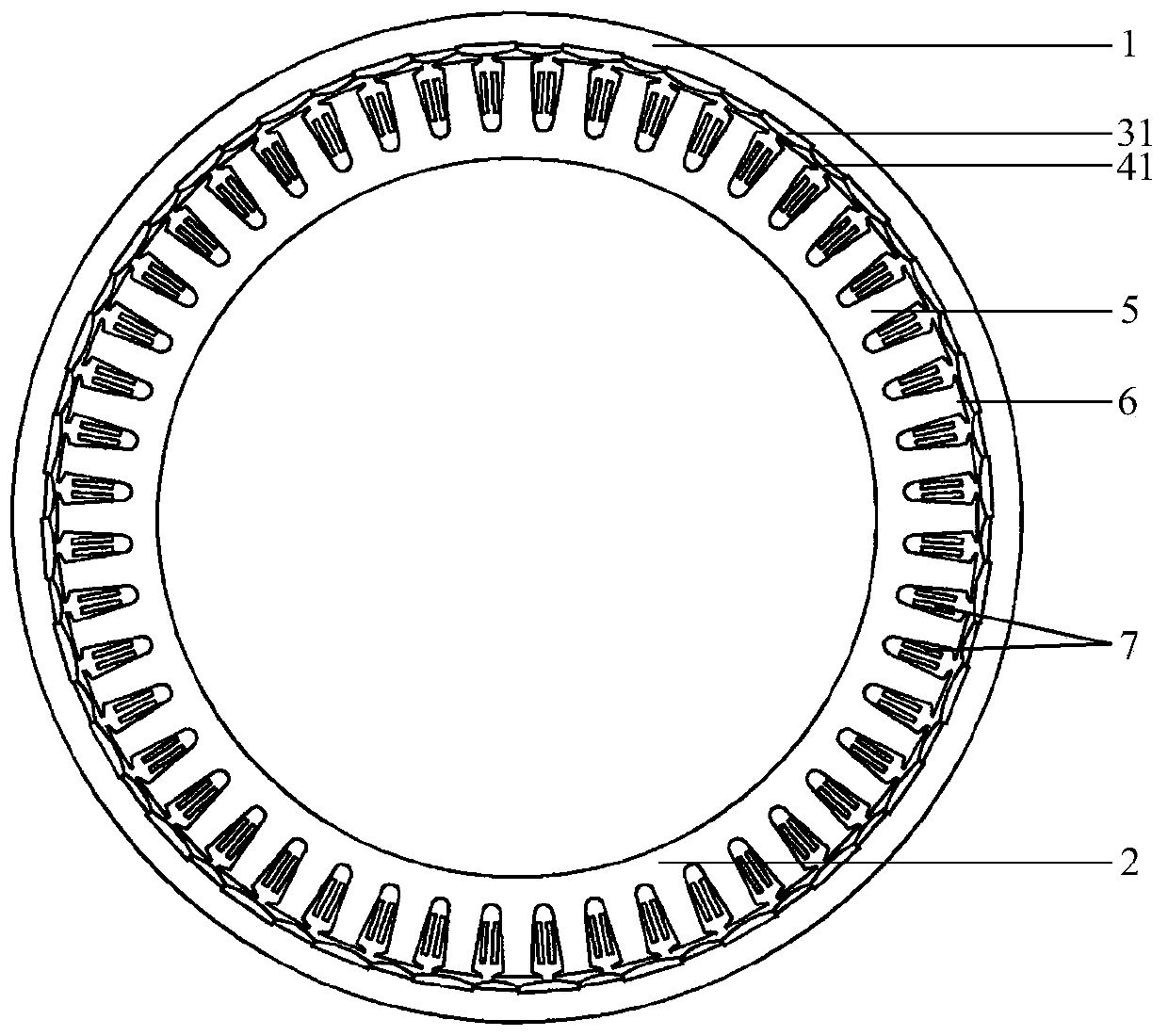

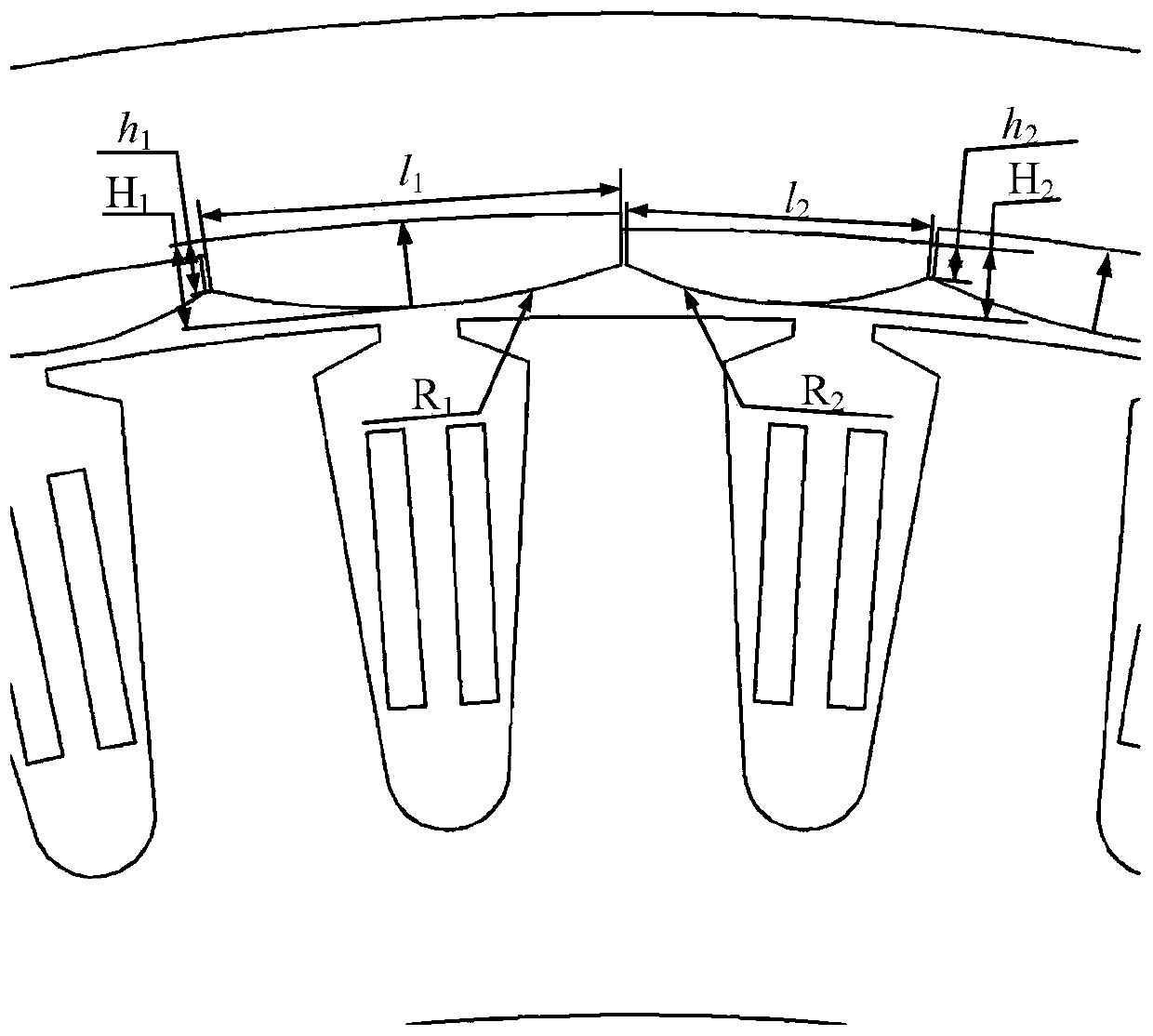

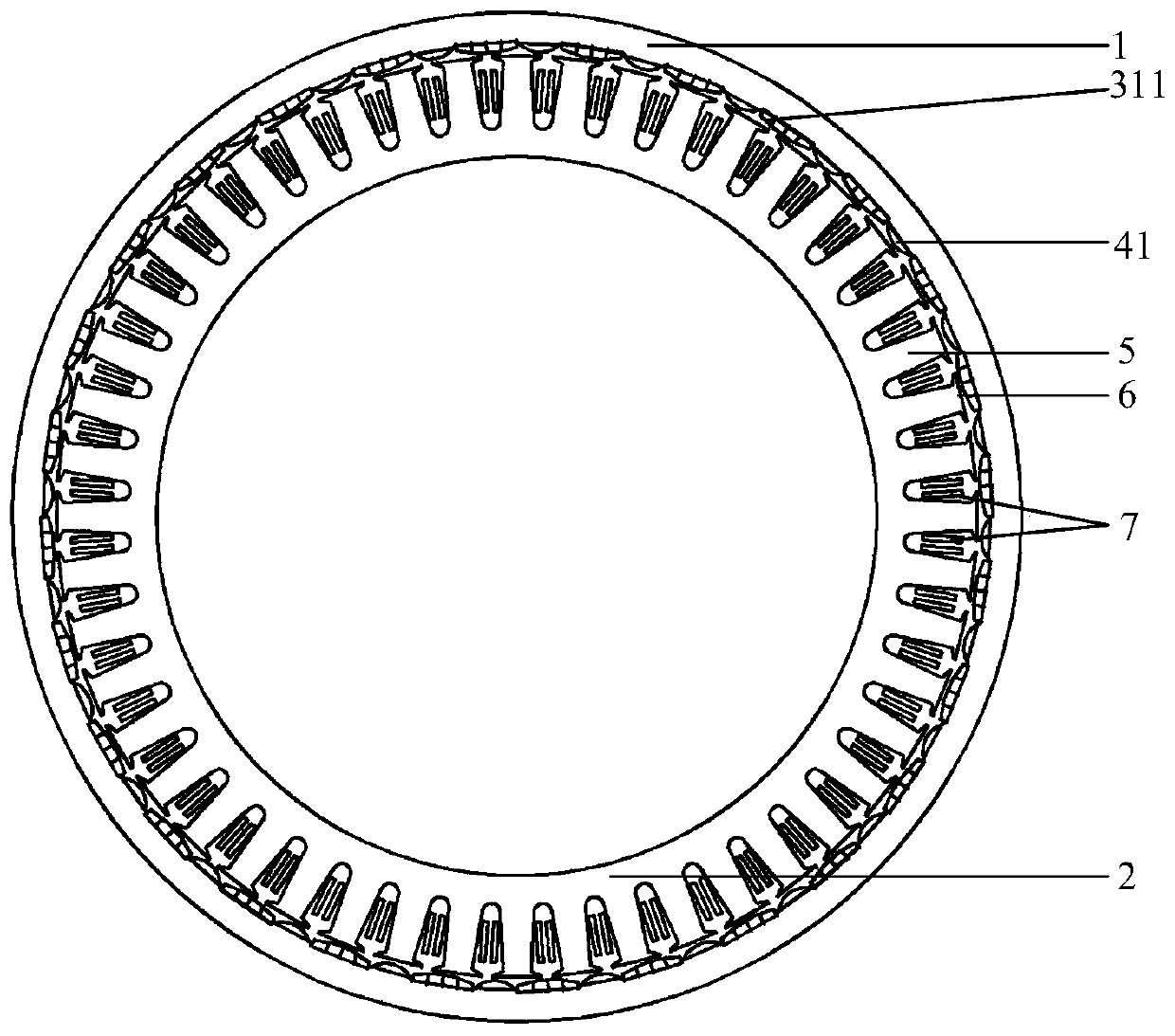

[0042] figure 1 It is the structural diagram of the example motor I of the present invention, figure 2 It is a partially enlarged view of the motor I of the example of the present invention, including an outer rotor 1 and an inner stator 2 . The outer rotor 1 adopts bread-shaped permanent magnets 31 and bread-shaped dummy poles 41 . The magnetization directions of all bread-shaped permanent magnets 31 are the same along the radial direction, that is, they all point to the center of the circle or deviate from the center of the circle. In Example I of the present invention, the mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com