Wind generating set

A technology for wind turbines and magnets, applied in wind turbines, wind power generation, wind turbine control, etc., can solve the problems of increased use of magnets, rising costs, high costs, etc., and achieve the effect of reducing the risk of loss of magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

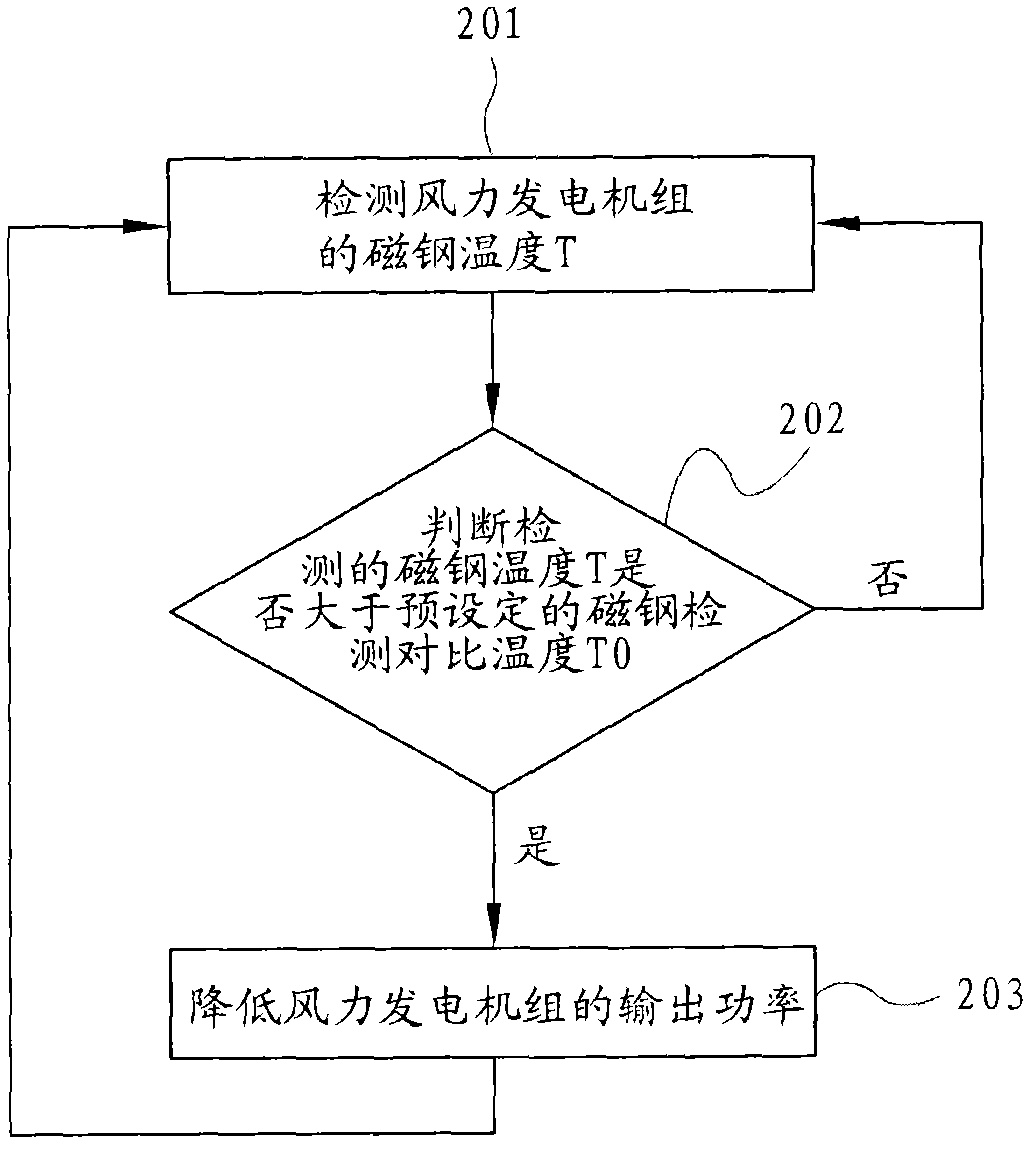

[0025] The invention provides a control method for a wind power generating set, the basic concept of which is to control the output power of the generating set according to the temperature of the magnetic steel of the wind generating set. In general, the higher the output power of the generator set, the greater the heat generated by the winding part of the generator set, which will make the temperature of the magnetic steel higher. When it is detected that the temperature of the magnetic steel is rising and approaching a predetermined value (it can be the design limit value or a different gradient value), the generator set is controlled to reduce the output power accordingly, so that the heat generation of the winding part is reduced, thereby Keep the temperature of the magnetic steel at a safe working temperature to protect the performance of the magnetic steel and prolong the service life of the magnetic steel.

[0026] Hereinafter, embodiments of the present invention will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com