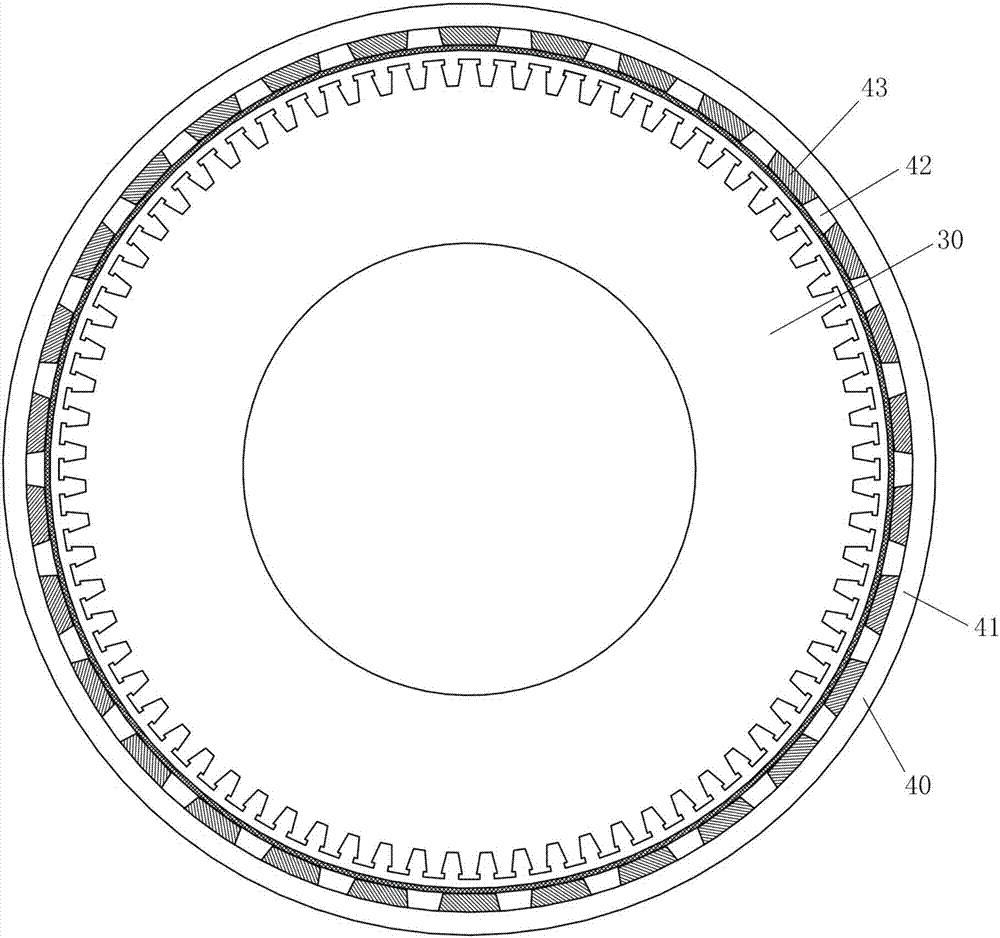

Process equipment and method for curing and formation of magnetic pole protection coating layer

A process equipment, curing and molding technology, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve problems such as uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

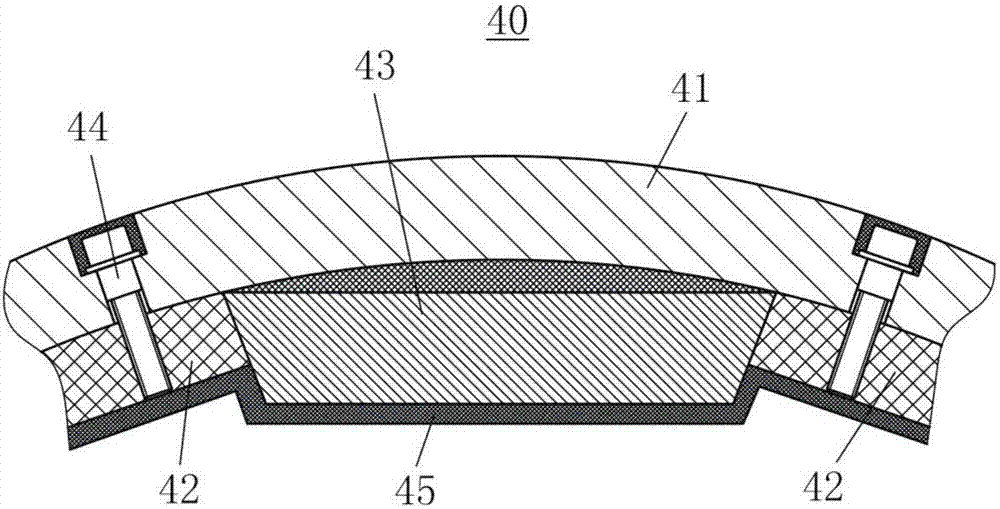

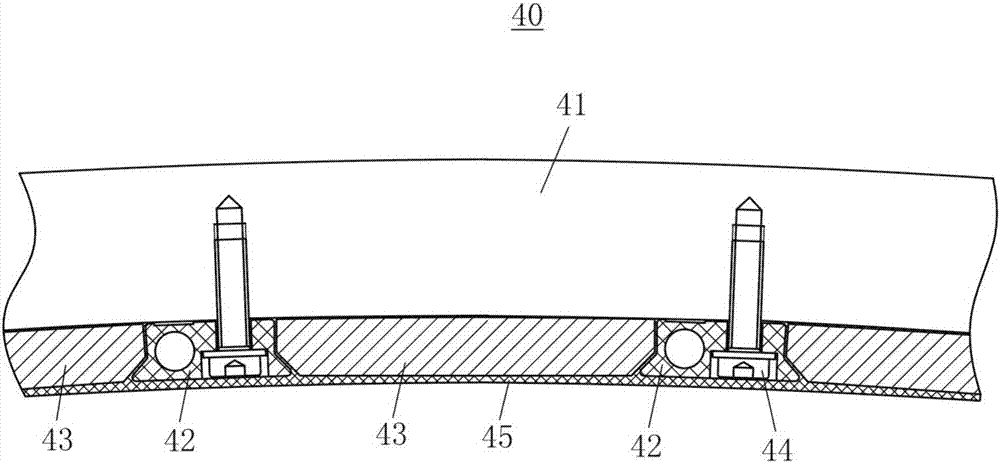

Embodiment Construction

[0073] For the outer rotor, the process equipment for curing and molding of the magnetic pole protective coating may include a first energy transfer system for heating the adhesive mixing space from the inner side of the rotor (magnetic pole side) and from the outer side of the rotor (yoke side). ) a second energy transfer system for heating the adhesive mixing space. According to the embodiment of the present invention, the process equipment for curing and molding the protective cladding may only include the first energy transfer system for pressurizing the adhesive mixing space from one side, or may include the first energy transfer system for pressurizing the adhesive mixing space from both sides respectively. The first energy transfer system and the second energy transfer system are pressurized and heated in the adhesive mixing space. According to the embodiment of the present invention, the second energy transfer system can use the same or similar method as the first ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com