Stator modular hybrid excitation consequent pole flux reverse motor

A technology of mixed excitation and magnetic flux reversal, applied in the direction of magnetic circuits, electric components, electrical components, etc., can solve the problems of high risk of permanent magnet demagnetization, high cost of permanent magnet use, difficulty in high-speed and weak magnetic operation, etc., to reduce demagnetization Risk, convenient modular processing, and the effect of improving mass production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

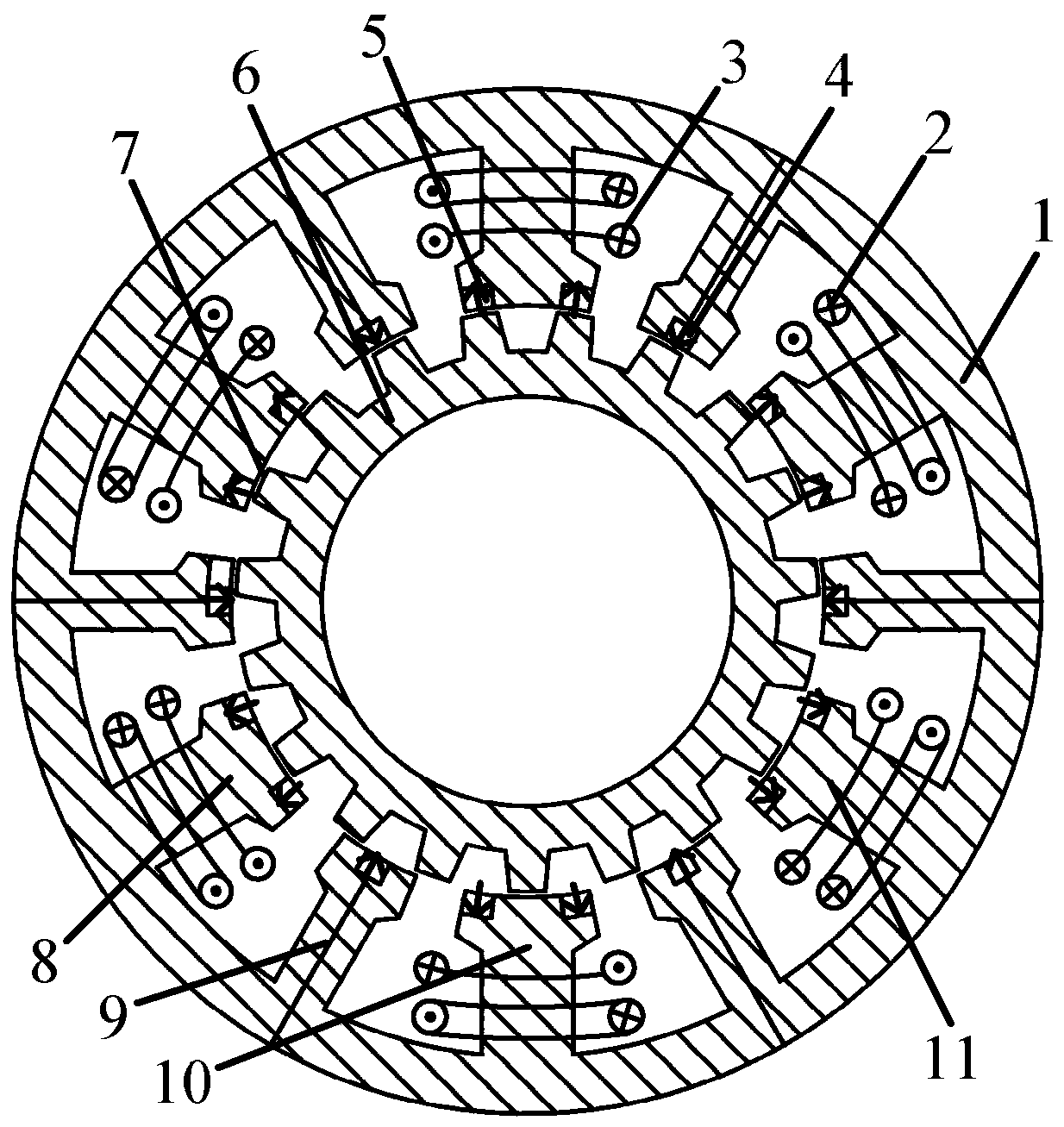

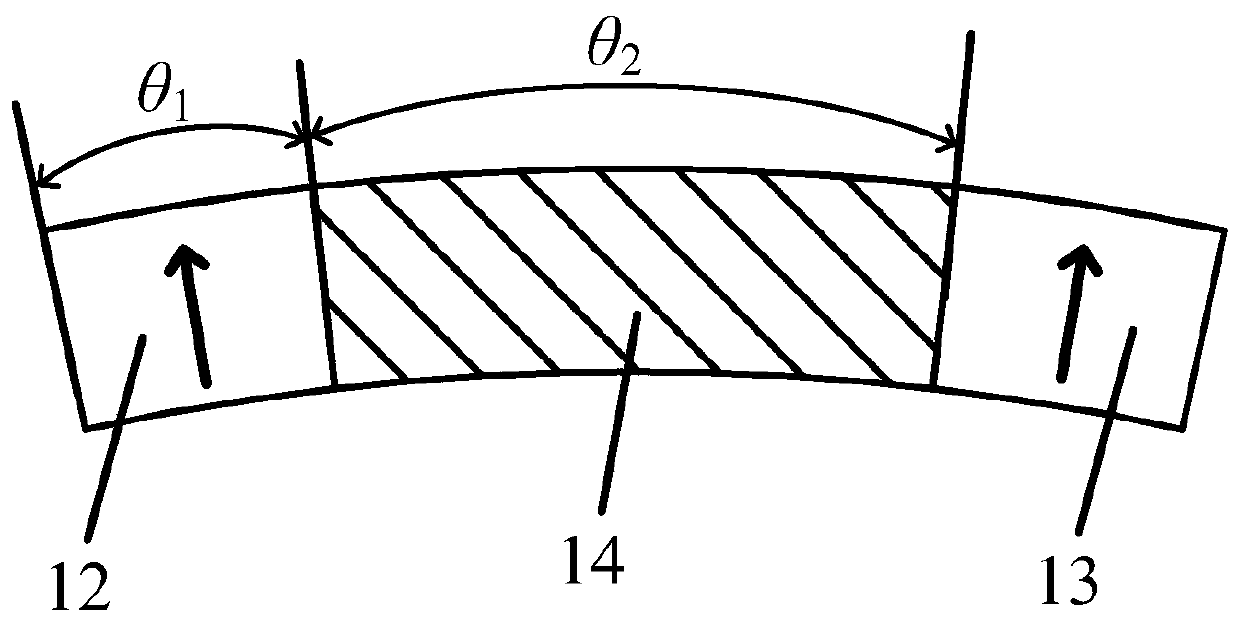

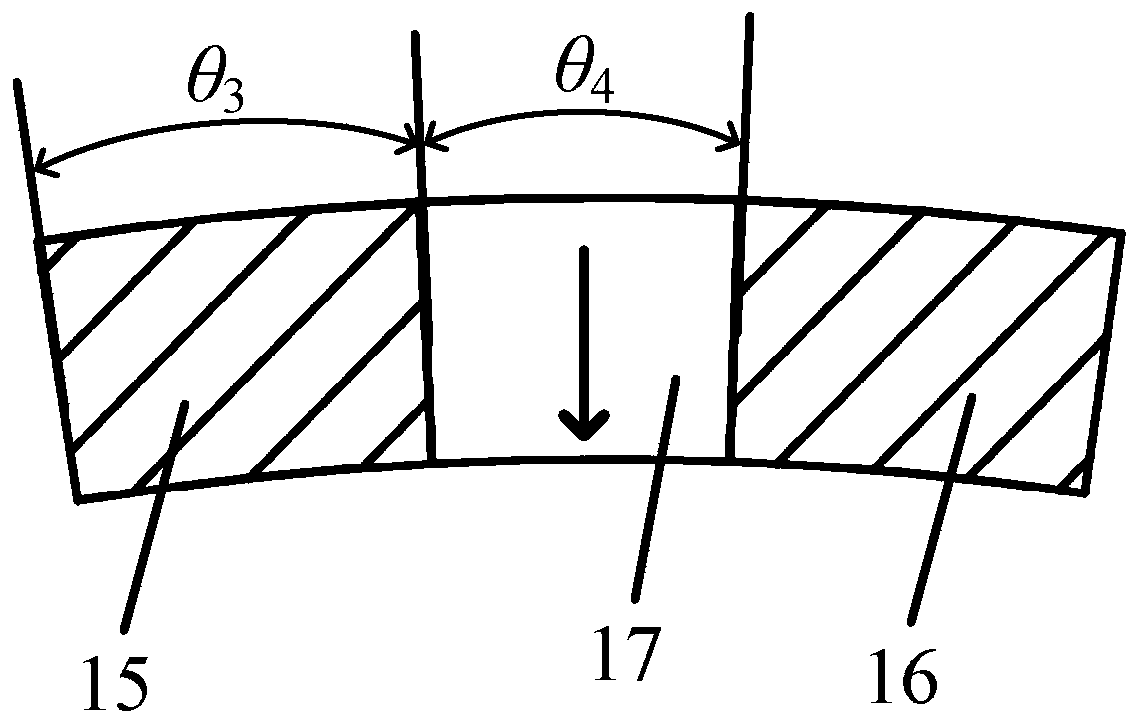

[0028] Such as figure 1 As shown, two permanent magnets with the same polarity are pasted on the two side edges of the surface of the large stator teeth, and a salient pole stator core is formed between the two permanent magnets. The cores form an alternating pole stator structure. A permanent magnet is pasted in the middle of the surface of the small stator teeth. Two salient pole stator cores are formed on both sides of the permanent magnet. The two salient pole stator cores and the permanent magnets between them form an alternating pole stator structure. . Such as figure 2 As shown, the pole arcs (θ 1 )same. Such as image 3 As shown, the pole arcs (θ 3 )same. By adjusting the pole arc θ of the permanent magnet 12 1 , pole arc θ of salient pole core 14 2 , Pole arc θ of permanent magnet 17 4 and the pole arc θ of the salient pole core 15 3 , can adjust the output electromagnetic performance and magnetic modulation performance of the permanent magnet of the motor...

Embodiment 2

[0031] Such as Figure 4 As shown, a permanent magnet is pasted in the middle of the surface of the large stator teeth. Two salient pole stator cores are formed on both sides of the permanent magnet. The two salient pole stator cores and the permanent magnets in between form an alternating Pole stator structure; two permanent magnets with the same polarity are pasted on the two side edges of the surface of the small stator teeth, and a salient pole stator core is formed between the two permanent magnets, and the salient pole stator core between the two permanent magnets and the The iron core forms an alternating pole stator structure. Similarly, the pole arcs of the two salient pole stator cores on the large stator teeth are the same, and the pole arcs of the two permanent magnets on the small stator teeth are the same.

[0032] combine figure 1 Describe how the windings of this motor are connected. Taking the three-phase armature winding as an example, in order to eliminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com